吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (2): 394-399.doi: 10.13229/j.cnki.jdxbgxb.20220338

• 材料科学与工程 • 上一篇

碳纳米管掺杂3YSZ陶瓷的低温闪烧

- 长春工业大学 材料科学与工程学院,长春 130012

Flash sintering of 3YSZ doping with CNT at low temperature

Yue YANG( ),Pei-lei ZHAO,Tian-hui MA,Jian-ming JIA

),Pei-lei ZHAO,Tian-hui MA,Jian-ming JIA

- School of Materials Science and Engineering,Changchun University of Technology,Changchun 130012,China

摘要:

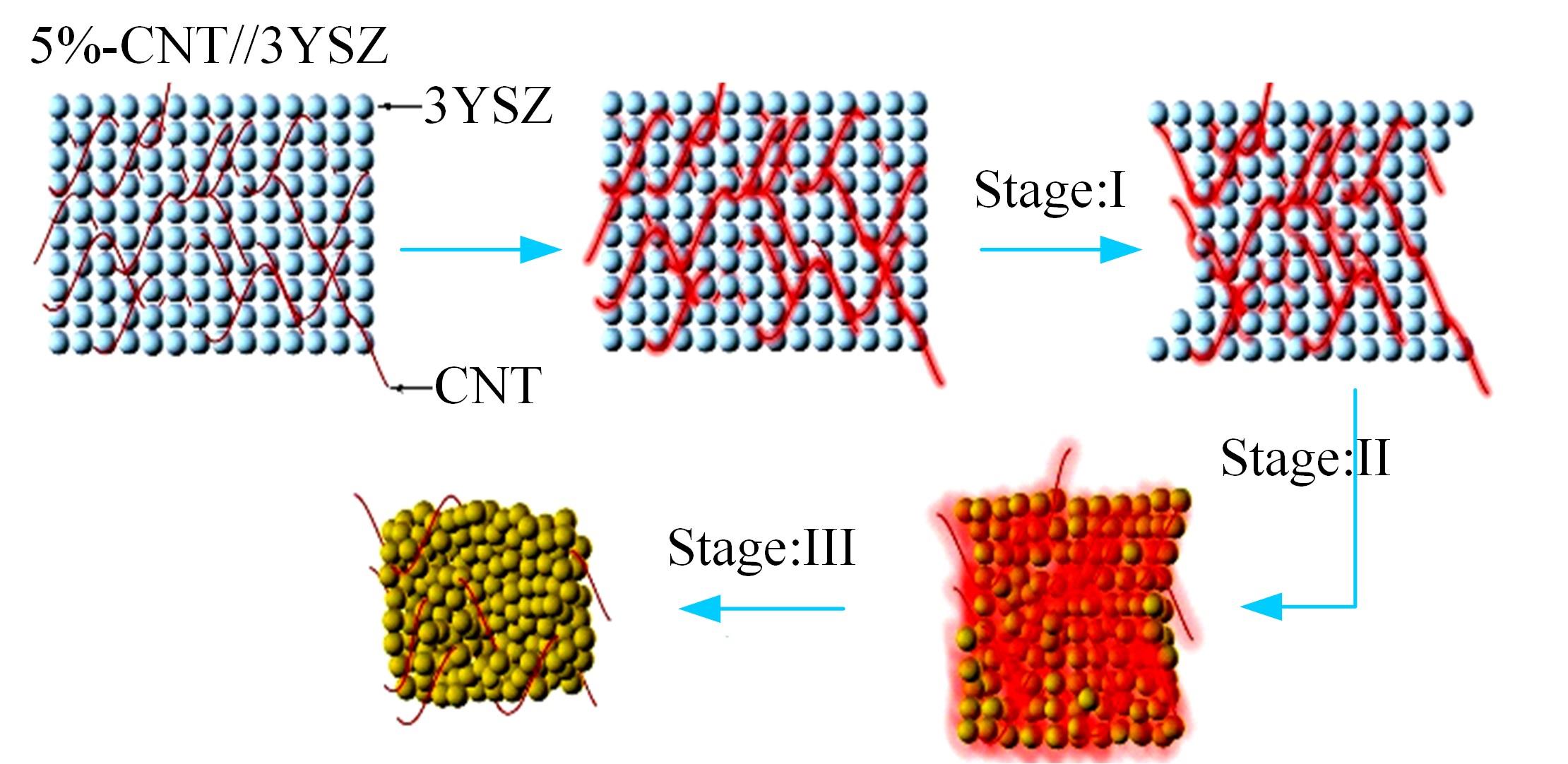

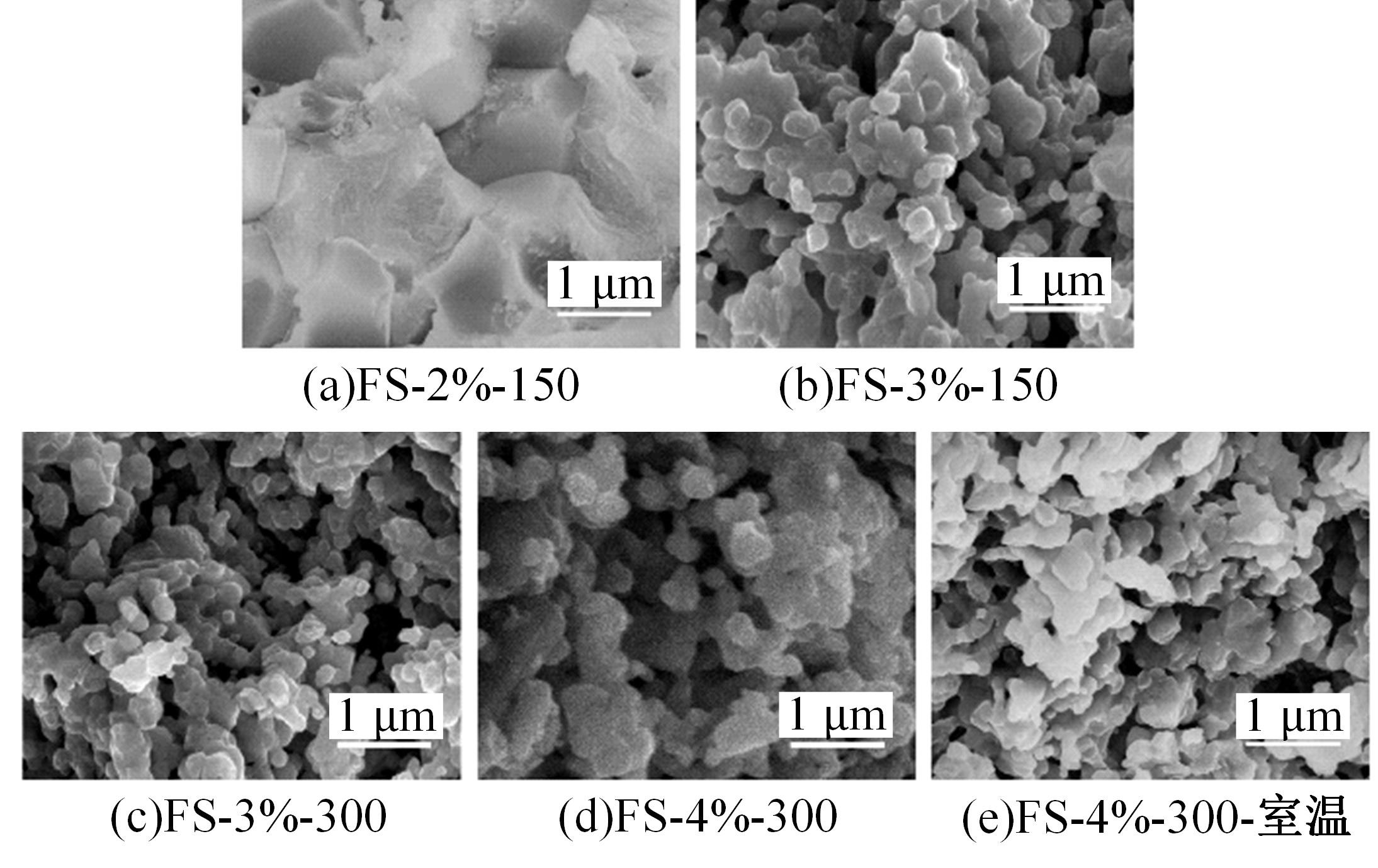

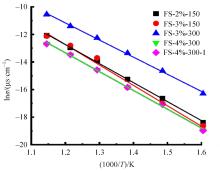

以3 mol%氧化钇稳定氧化锆(3YSZ)粉末为基材通过添加导电相-碳纳米管(CNT),同时辅助交流电场和压力,在200 ℃进行复合材料的低温烧结。主要探讨了CNT含量对烧结材料的物相组成、微观组织形貌以及离子电导率的影响规律。结果表明:在此温度下材料烧结致密,相组成均为稳定相t-ZrO2;CNT含量为2%时,离子电导率为0.20 μs/cm;当CNT含量为3%时,离子电导率达到0.83 μs/cm,当CNT含量增加到4%时,材料导电性能增强,闪烧起始电压降低,但由于局部过度烧结导致离子电导率下降为0.6 μs/cm。同时,3YSZ-4%CNT复合材料可实现室温烧结。

中图分类号:

- TB34

| 1 | Guan S H, Liu Z P. Theoretical aspects on doped-zirconia for solid oxide fuel cells: from structure to conductivity[J]. Chinese Journal of Chemical Physics, 2021, 34 (2): 125-136. |

| 2 | Lv Y M, Xie J T, Wang D B, et al. Review of cell performance in solid oxide fuel cells[J]. Journal of Materials Science, 2021, 55(17): 7184-7207. |

| 3 | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J].吉林大学学报:工学版, 2017, 47(2): 552-556. |

| Yang Yue, Li Xue, Xu Xiao-dan. Microstructure and properties of sintered Ti-B-C-N powder[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(2): 552-556. | |

| 4 | Cologna M, Rashkova B, Raj R. Flash sintering of nanograin zirconia in <5 s at 850 ℃[J]. Journal of the American Ceramic Society, 2010, 93 (11): 3556-3559. |

| 5 | 苏兴华, 吴亚娟, 安盖, 等. 陶瓷材料闪烧机理研究进展[J]. 硅酸盐学报, 2020, 48 (12): 1872-1879. |

| Su Xing-hua, Wu Ya-juan, An Gai, et al. Advances in mechanisms for flash sintering of ceramic materials[J]. Journal of The Chinese Ceramic Society, 2020, 48(12): 1872-1879. | |

| 6 | Liu J M, Li X, Wang X L, et al. Alternating current field flash sintering 99% relative density ZnO ceramics at room temperature[J]. Scripta Materialia, 2020, 176: 28-31. |

| 7 | Xiao W W, Ni N, Fan X H, et al. Ambient flash sintering of reduced graphene oxide/zirconia composites: role of reduced graphene oxide[J]. Journal of Materials Science & Technology, 2021, 60: 70-76. |

| 8 | Muccillo R, Ferlauto A S, Muccillo E N S. Flash sintering samaria-doped ceria–carbon nanotube composites[J]. Ceramics, 2019, 2(1): 64-73. |

| 9 | Du Y, Stevenson A J, Vernat D, et al. Estimating joule heating and ionic conductivity during flash sintering of 8YSZ[J]. Journal of the European Ceramic Society, 2016, 36(3): 749-759. |

| 10 | 刘金铃,刘佃光, 王一光, 等. 氧化物陶瓷闪烧机理及其应用研究进展[J]. 无机材料学报, 2022, 37(5): 473-480. |

| Liu Jin-ling, Liu Dian-guang, Wang Yi-guang, et al. Research progress on the flash sintering mechanism and application of oxide ceramics[J]. Journal of Inorganic Materials, 2022, 37(5): 1-8. | |

| 11 | 杨悦, 马天惠, 赵培雷, 等. 快速热压烧结制备立方相Li7La3Zr2O12固态电解质[J]. 吉林大学学报: 工学版, 2023, 53(8): 2272-2276. |

| Yang Yue, Ma Tian-hui, Zhao Pei-lei,et al. Preparation of cubic Li7La3Zr2O12 solid electrolyte by fast hot-press sintering[J]. Journal of Jilin University (Engineering and Technology Edition),2023,53(8): 2272-2276. |

| [1] | 杨悦,马天惠,赵培雷,贾剑明. 快速热压烧结制备立方相Li7La3Zr2O12固态电解质[J]. 吉林大学学报(工学版), 2023, 53(8): 2272-2276. |

| [2] | 张晓明,王洪艳,李俊锋 . 改性MWNTs/纳米HA/PLA骨修复材料的制备[J]. 吉林大学学报(工学版), 2008, 38(04): 844-847. |

|

||