吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 2013-2020.doi: 10.13229/j.cnki.jdxbgxb20200633

• 材料科学与工程 • 上一篇

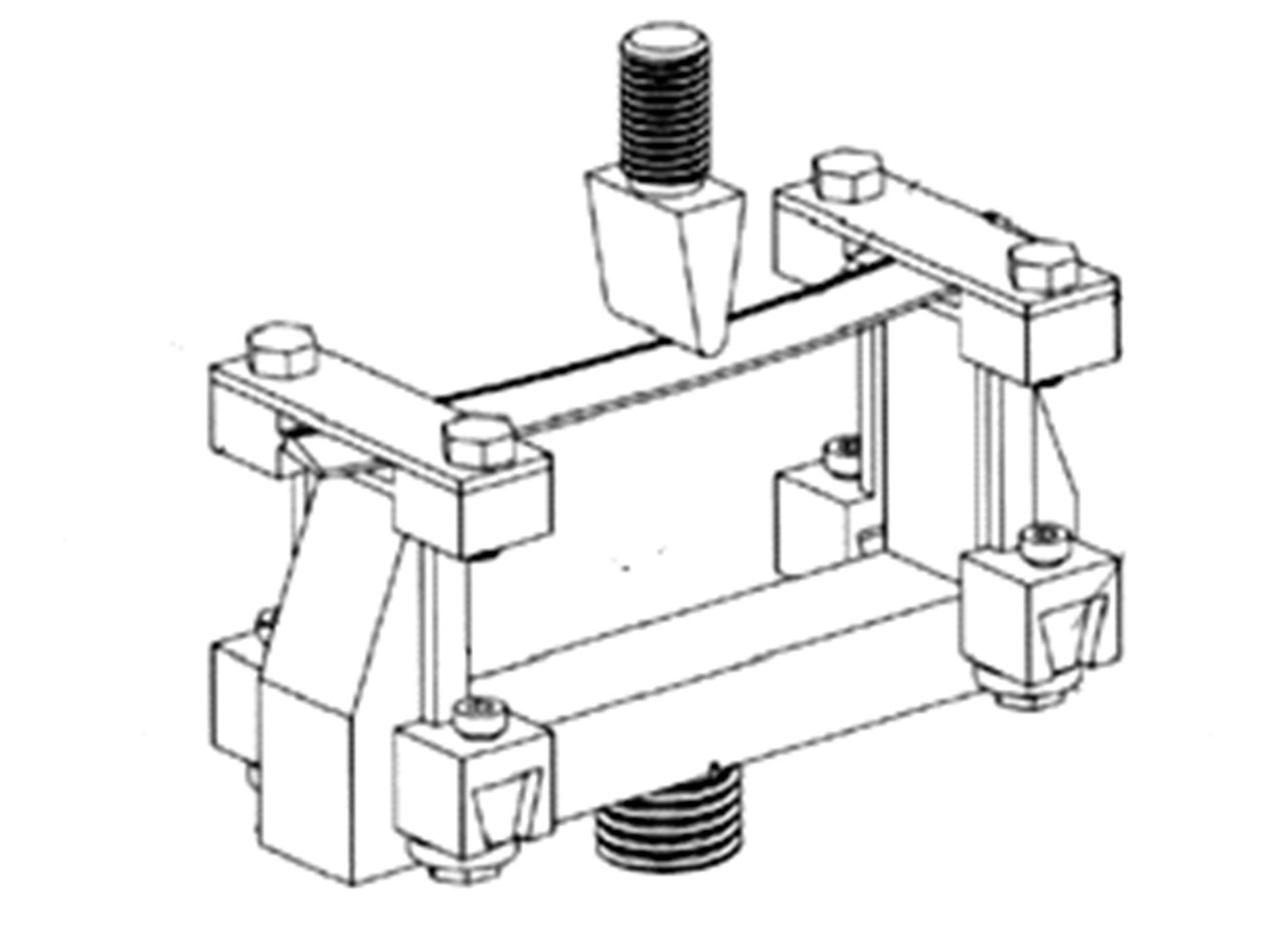

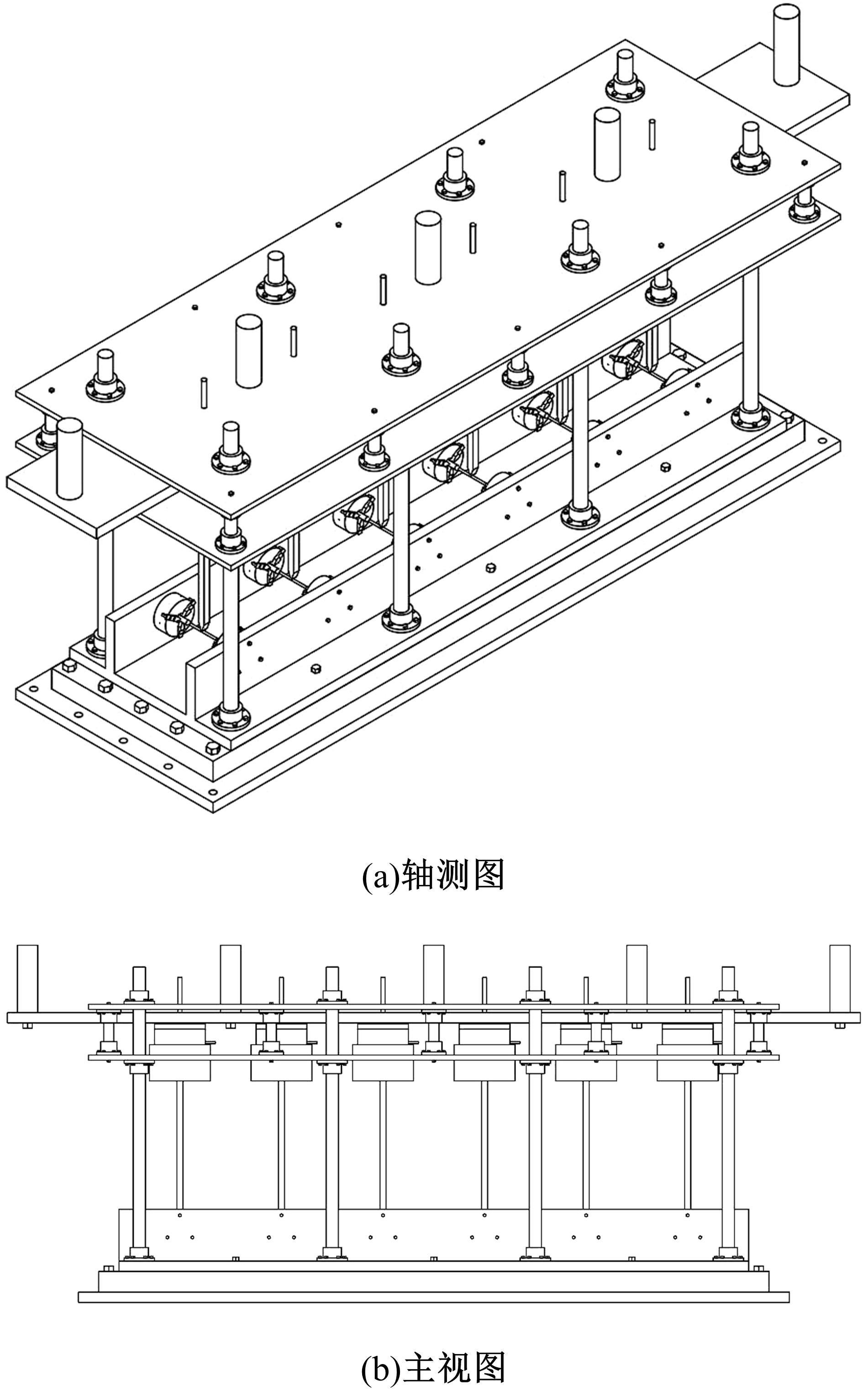

一机六件等应力三点弯曲疲劳试验机的研制

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 辊锻工艺研究所,长春 130022

Development about three⁃point bending fatigue experiment machine that can test six specimens at same time

Qing-guang YAN1( ),Zi-xuan FENG1,Xiang-ji LI2,Ying-wei WANG1

),Zi-xuan FENG1,Xiang-ji LI2,Ying-wei WANG1

- 1.College of Material Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute,Jilin University,Changchun 130022,China

摘要:

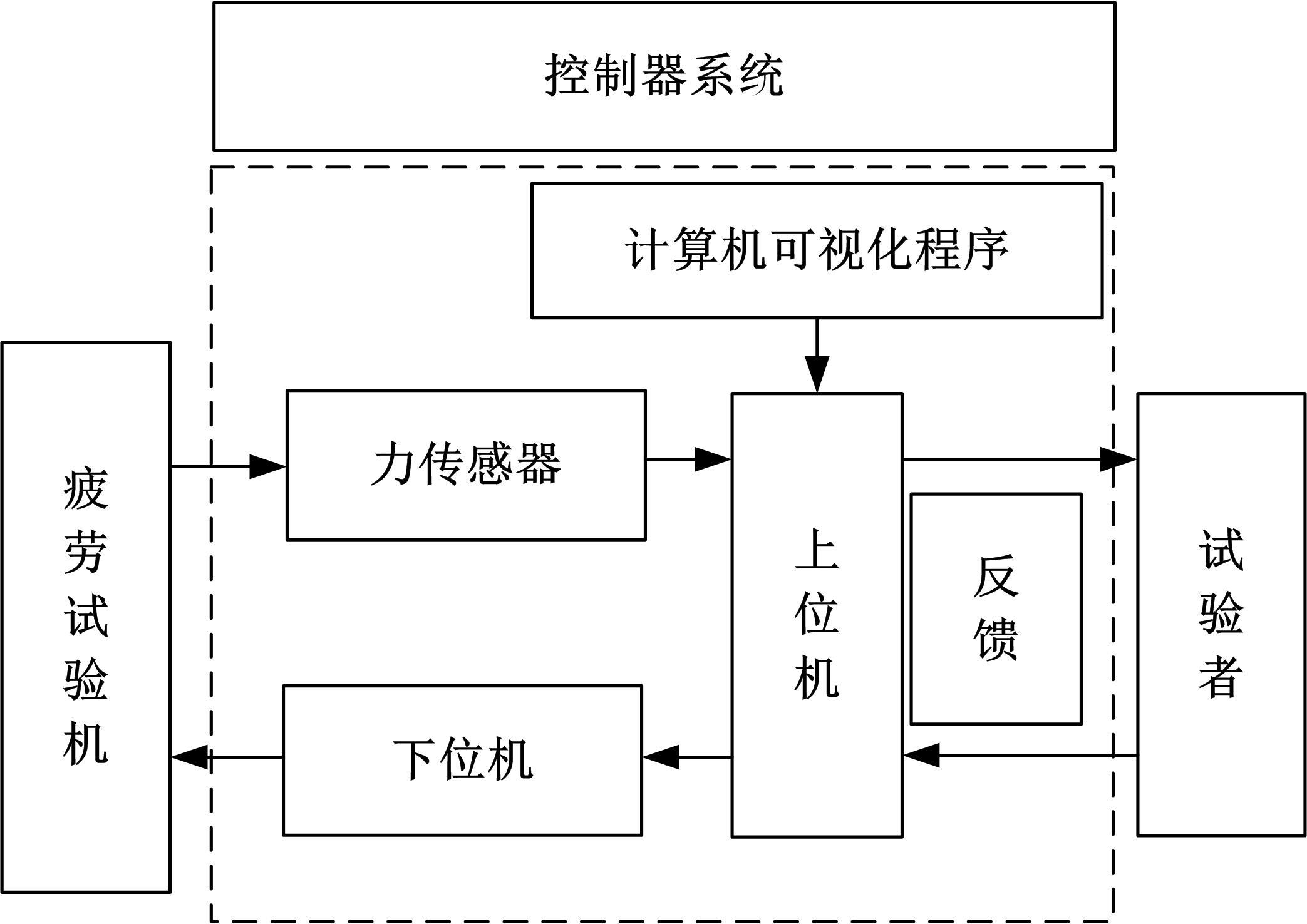

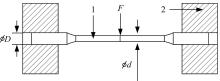

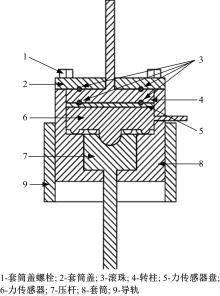

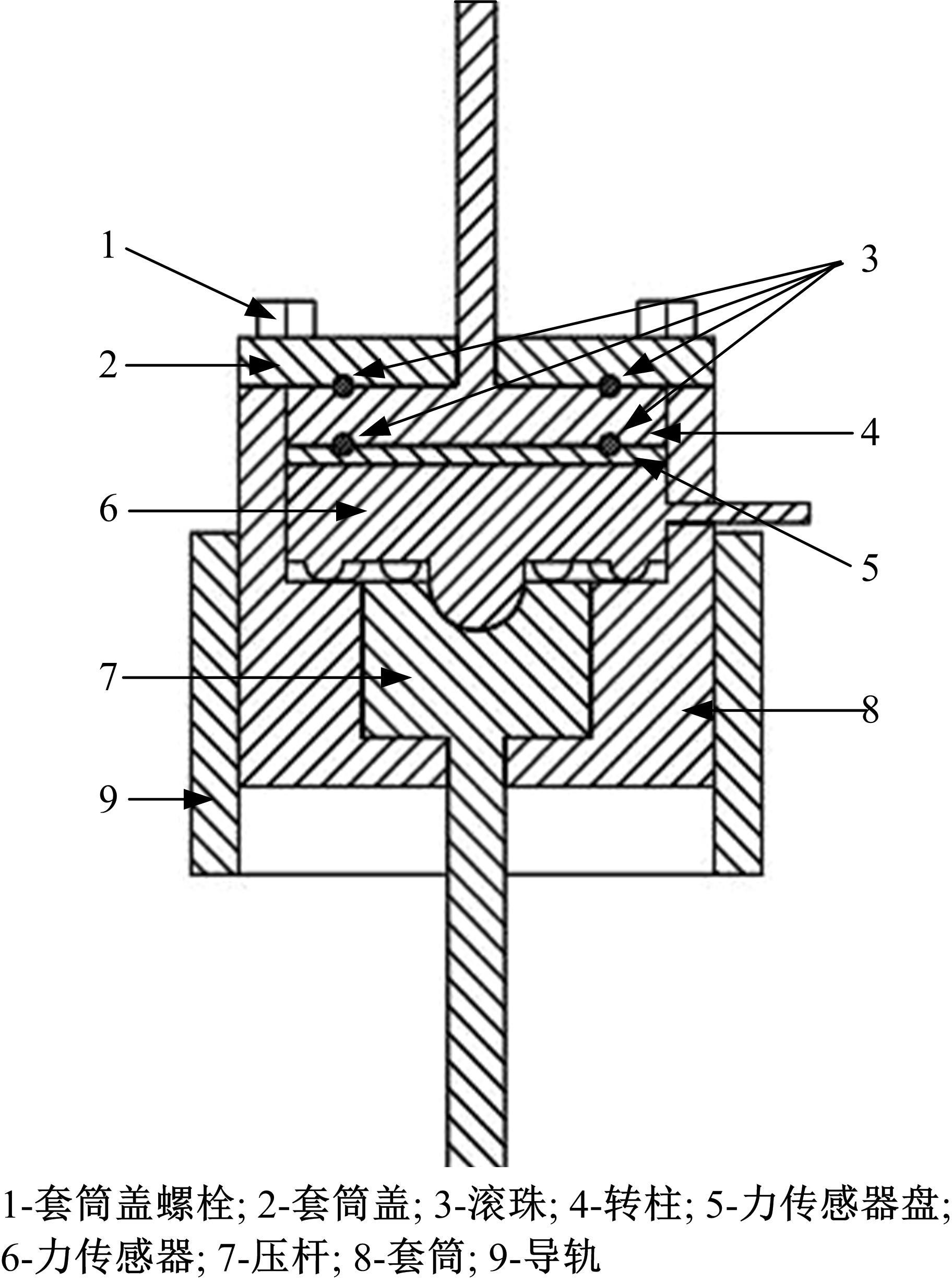

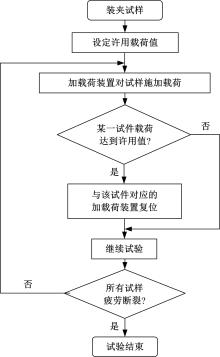

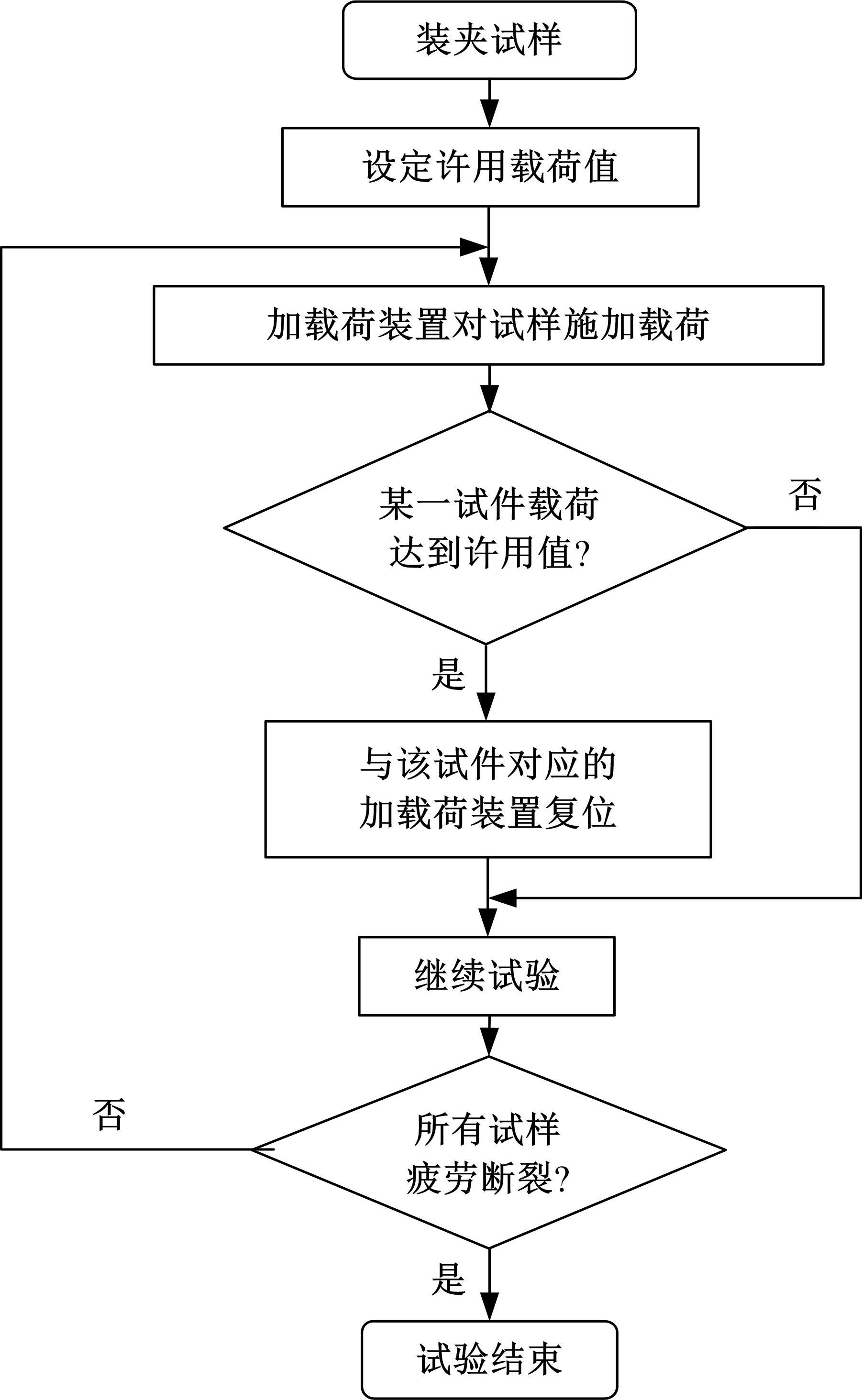

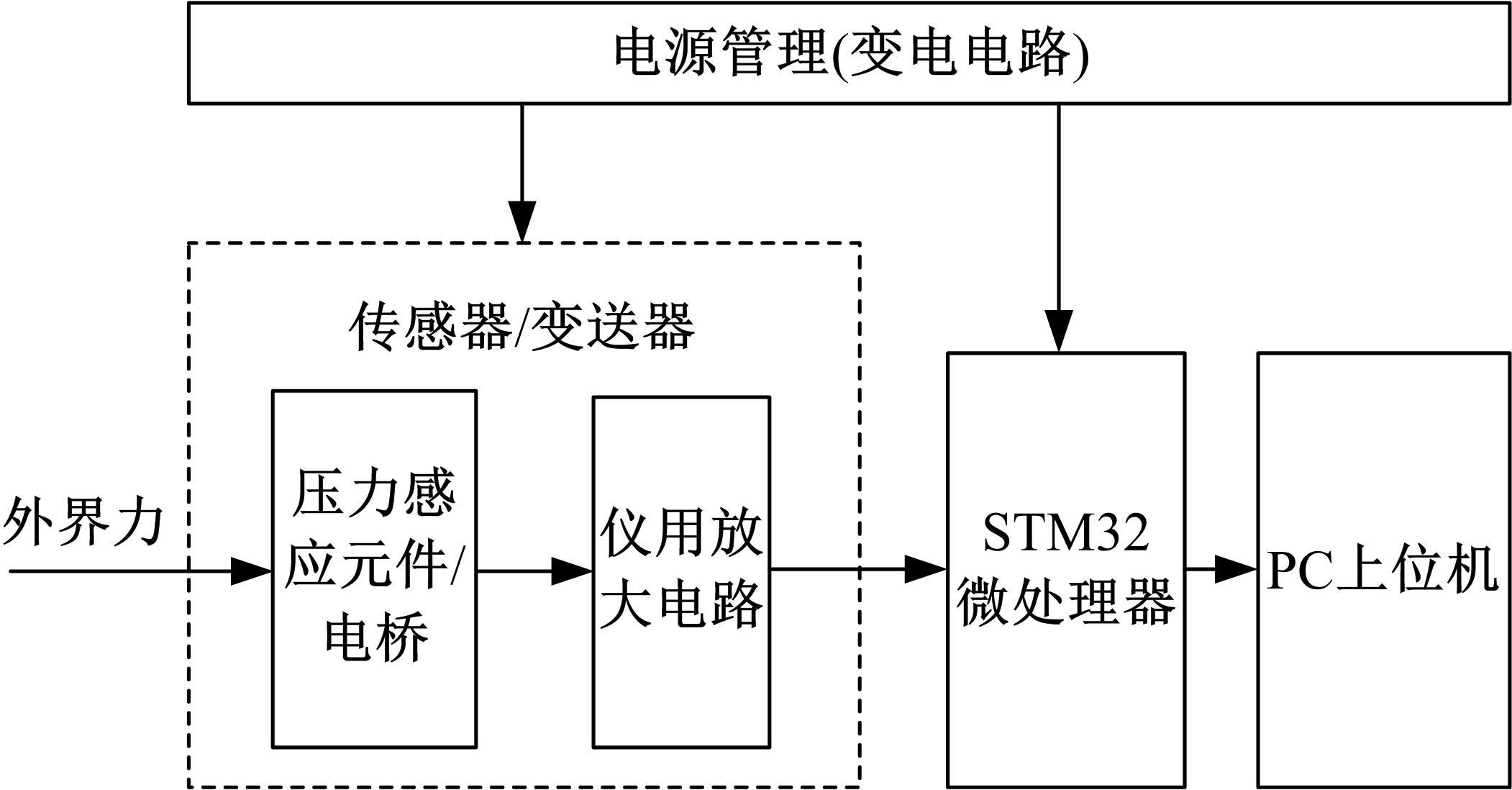

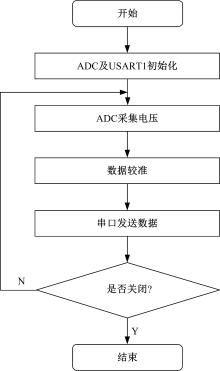

为解决传统一机一件弯曲疲劳试验机效率不高的问题,研制了一种新型一机六件等应力三点弯曲疲劳试验机,用于检测H13钢的疲劳寿命。首先,通过压力机对试样施加载荷,并利用力传感器实时检测载荷是否超过许用值。当载荷超过许用值时,控制器立即撤销该试样上的载荷,而不影响其他试样进行疲劳试验。同时压力机继续加载,直到所有试样断裂,试验结束。该种疲劳试验机能同时对6个试样进行疲劳试验,提高了试验效率。

中图分类号:

- TG76

| 1 | 佟倩,马跃,孙齐松,等. 国内外H13钢组织和性能对比分析[J]. 上海金属, 2020, 42(1): 55-59. |

| Tong Qian, Ma Yue, Sun Qi-song, et al. Comparative analysis on microstructure and properties of H13 steel at home and abroad[J]. Shanghai Metals, 2020, 42(1): 55-59. | |

| 2 | 水春雨,李鹏,刘烁,等. 一种铁路声屏障疲劳试验机[P].中国: CN201920370283.7,2019-10-25. |

| 3 | 王志国. 高频疲劳试验机多头试验系统设计与动态特性研究[D]. 沈阳:东北大学机械工程与自动化学院, 2011. |

| Wang Zhi-guo. Multiple fixture design of HF fatigue testing machine and its dynamic characteristics research[D]. Shenyang: School of Mechanical Engineering and Automation, Northeastern University, 2011. | |

| 4 | Nozaki M, Sakane M, Fujiwara M. Low cycle fatigue testing using miniature specimens[J]. International Journal of Fatigue, 2019, 137(10):No.105636. |

| 5 | 林星豪,陈卫华,吴世勇,等. H13钢压铸模具开裂分析[J].失效分析与预防, 2019, 14(4): 265-268. |

| Lin Xing-hao, Chen Wei-hua, Wu Shi-yong, et al. Cracking analysis of H13 steel die casting mould[J]. Failure Analysis and Prevention, 2019, 14(4): 265-268. | |

| 6 | 余世杰,陈猛,欧阳志英. H13热作模具钢冲头的早期断裂原因[J]. 机械工程材料, 2020, 44(3): 78-82, 86. |

| Yu Shi-jie, Chen Meng, Ouyang Zhi-ying. Early fracture cause of H13 hot die steel punch[J]. Materials for Mechanical Engineering, 2020, 44(3): 78-82, 86. | |

| 7 | Shu-Hung Yeh, Chiu Liu-Ho. AISI H13 hot-work steel with hard chromium plating thermal fatigue behavior evaluation[J]. Advanced Materials Research, 2014, 2831: 8-13. |

| 8 | 迟庆新,刘芳. 一种非标件弯曲疲劳试验装置[P]. 中国:CN201910661925.3, 2019-10-22. |

| 9 | . 金属材料疲劳试验旋转弯曲方法[S]. |

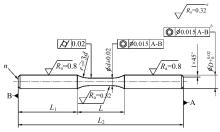

| 10 | 洪友士,吕永华,郑哲敏. 一种等应力试样中的疲劳短裂纹行为[J]. 金属学报, 1990, 26(1): 46-52. |

| Hong You-shi, Lv Yong-hua, Zheng Zhe-min. Short fatigue crack behaviour in ISO-stress specimens[J]. Acta Metallurgica Sinica, 1990, 26(1): 46-52. | |

| 11 | 赵朴. 板材弯曲疲劳试样应力分析和等应力试样设计[J].钢铁研究总院学报, 1986, 6(1): 65-70. |

| Zhao Pu. Stress analysis and ISO-stress sample design for bending fatigue of sheet materials[J]. Journal of Iron and Steel Research, 1986, 6(1): 65-70. | |

| 12 | Li X H, Zheng X Y, Yuan W J, et al. Instability of cracks initiation from a mixed-mode crack tip with ISO-stress intensity factors KI and KII[J]. Theoretical and Applied Fracture Mechanics, 2018, 96: 262-271. |

| 13 | Kanemaru O,Shimizu M,Ohba T, et al. Remaining life prediction by the ISO-stress method of boiler tubes after prolonged service[J]. Journal of the Society of Materials Science, 1997, 46(3): 31-36. |

| 14 | 张华伟,吴佳璐. 三点弯曲工况下复合材料层合板的应力变化[J]. 纺织高校基础科学学报, 2020, 33(1): 32-37. |

| Zhang Wei-hua, Wu Jia-lu. Stress change of composite laminates in three point bending[J]. Basic Sciences Journal of Textile University, 2020, 33(1): 32-37. | |

| 15 | 陶红. 三爪卡盘在测试仪器组装定位中的应用[J]. 中国设备工程, 2018, 33(17): 157-158. |

| Tao Hong. Application of three-jaw chuck in assembly and positioning of test instrument[J]. China Plant Engineerin, 2018, 33(17): 157-158. | |

| 16 | 小威廉·卡丽斯特,大卫·来斯威什. 材料科学与工程基础[M].北京:化学工业出版社, 2004. |

| 17 | 鲁建飞. 热锻模的循环应力分析与疲劳寿命预测[D]. 武汉:武汉理工大学材料科学与工程学院, 2014. |

| Lu Jian-fei. Cycle stress analysis and fatigue life prediction of hot[D]. Wuhan:School of Material Science and Engineering,Wuhan University of Technology, 2014. |

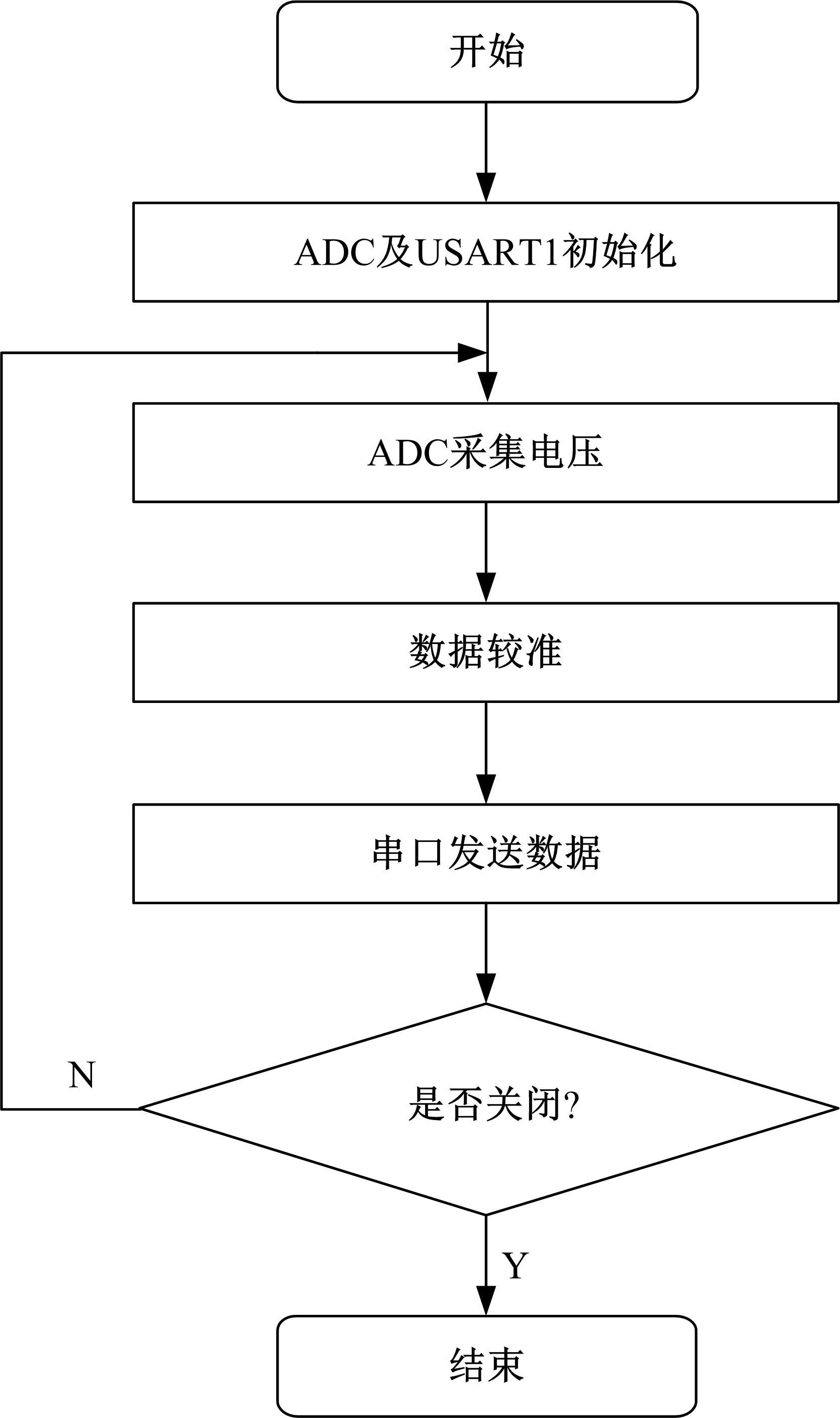

| [1] | 杨诚, 宋萍, 彭文家, 邓高寿, 刘雄军. 装甲车辆综合测试系统上位机平台设计[J]. 吉林大学学报(工学版), 2017, 47(6): 1796-1803. |

| [2] | 杨晓红, 杭文先, 秦绍刚, 刘勇兵, 刘利萍. H13钢激光熔覆钴基复合涂层的组织及耐磨性[J]. 吉林大学学报(工学版), 2017, 47(3): 891-899. |

| [3] | 刘家安, 于思荣, 朱先勇. Zn-22Al泡沫夹芯复合板的三点弯曲性能[J]. 吉林大学学报(工学版), 2012, 42(02): 344-348. |

|

||