吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2466-2473.doi: 10.13229/j.cnki.jdxbgxb20210317

• 农业工程·仿生工程 • 上一篇

冻结过程冰黏附界面应力特性规律与分析

陈奕颖1,2( ),金敬福1,2,王家旭1,2,齐迎春1,2,王琳3,陈廷坤1,2(

),金敬福1,2,王家旭1,2,齐迎春1,2,王琳3,陈廷坤1,2( )

)

- 1.吉林大学 生物与农业工程学院,长春 130022

2.吉林大学 工程仿生教育部重点实验室,长春 130022

3.拖拉机动力系统国家重点实验室,河南 洛阳 471039

Stress characteristic of ice adhesion interface during freezing process

Yi-ying CHEN1,2( ),Jing-fu JIN1,2,Jia-xu WANG1,2,Ying-chun QI1,2,Lin WANG3,Ting-kun CHEN1,2(

),Jing-fu JIN1,2,Jia-xu WANG1,2,Ying-chun QI1,2,Lin WANG3,Ting-kun CHEN1,2( )

)

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.State Key Laboratory of Power System of Tractor,Luoyang 471039,China

摘要:

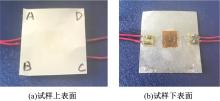

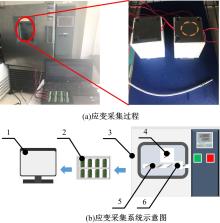

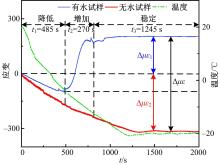

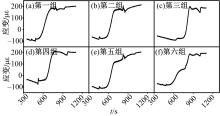

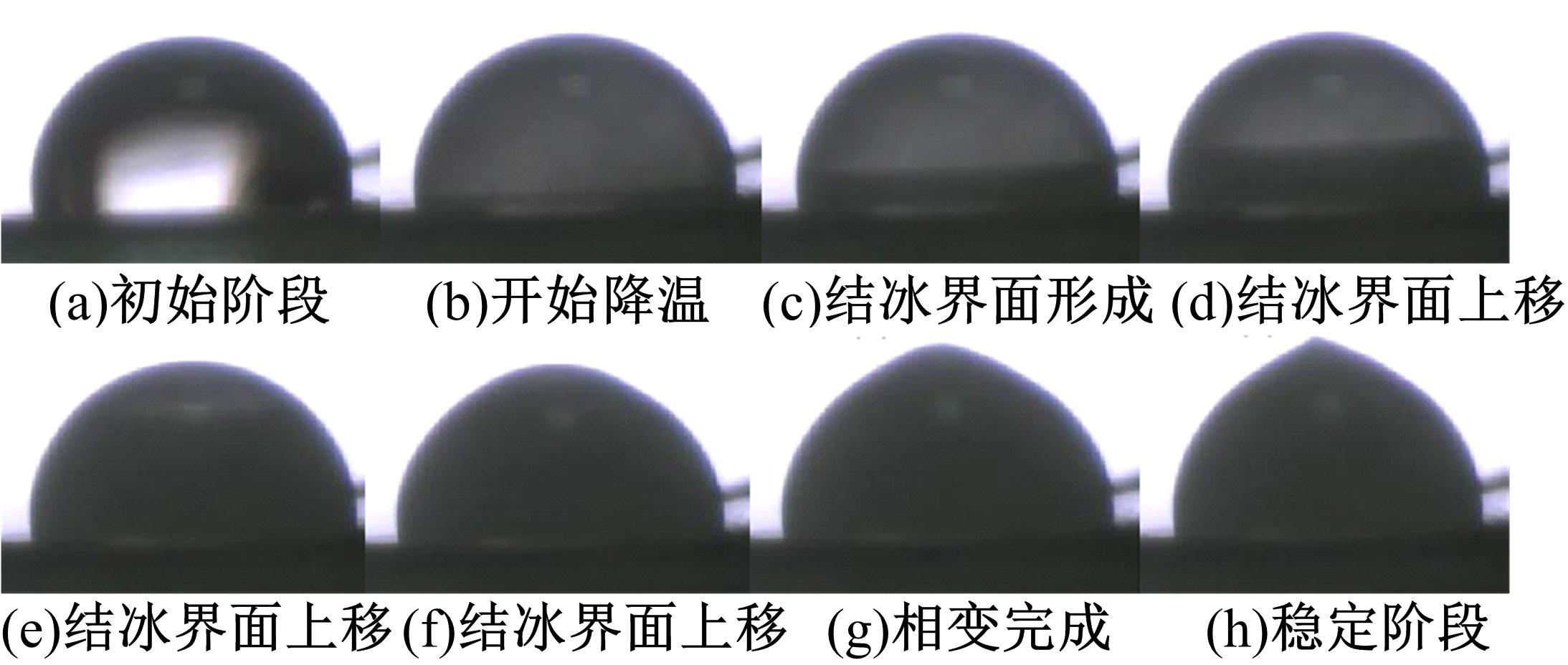

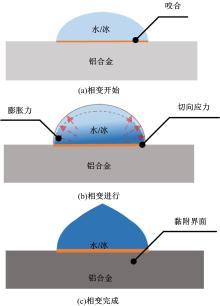

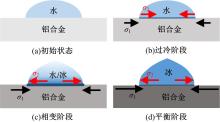

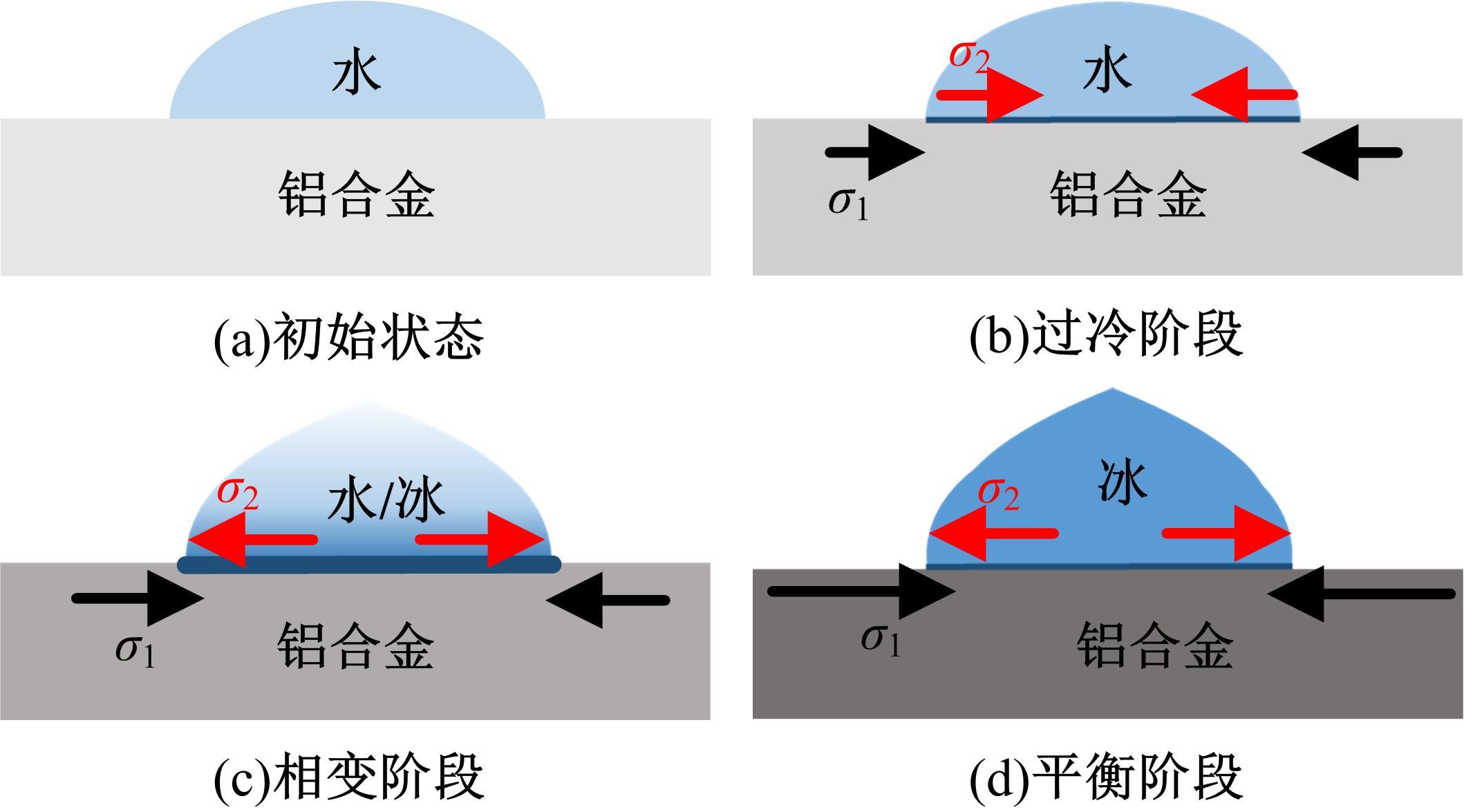

根据水/冰和铝合金的热膨胀系数差异及水结冰相变膨胀特性,观察水在铝合金表面的冻结过程,并利用应变测试方法间接获取结冰界面应力变化规律。结合水滴在铝合金表面冻结过程中的形态特征,分析了结冰过程冻结界面切向黏附力的形成规律及产生特点。试验发现,在冻结过程中,随着环境温度的降低,水与铝合金间的界面应变先逐渐降低;当铝合金表面附着水发生相变时,结冰黏附界面应变迅速增加;待铝合金表面附着水完全冻结后,黏附界面应变趋于稳定。分析表明,低温环境里铝合金表面附着水进入过冷状态,水及铝合金基底收缩,界面应变降低;当水开始相变,与基底表面接触区域附着水相变冻结,伴随冰黏附现象的产生,咬合并黏附于界面,相变膨胀力克服铝合金基底的收缩应力,界面应变迅速增加;待附着水完全冻结结冰及环境温度稳定时,冰与铝合金间形成稳定的黏附界面,结冰黏附界面应力趋于稳定。研究结冰黏附界面应力特性有助于阐释结冰黏附及其强度的形成规律,为工程领域开发或优化过程干预式防除冰技术提供理论支撑。

中图分类号:

- TB131

| 1 | Liu Y, Ma L Q, Wang W, et al. An experimental study on soft PDMS materials for aircraft icing mitigation[J]. Applied Surface Science, 2018, 447(1): 599-609. |

| 2 | Filomena P, Antonio C, Dariusz D, et al. Superhydrophobic coatings as anti-icing systems for small aircraft[J]. Aerospace, 2020, 7(1): No2. |

| 3 | Rustem M, Zhandos B, Saltanat B, et al. Numerical simulations on static vertical axis wind turbine blade icing[J]. Renewable Energy, 2021, 170: 997-1007. |

| 4 | Rossi A, Jubayer C, Koss H, et al. Combined effects of wind and atmospheric icing on overhead transmission lines[J]. Journal of Wind Engineering & Industrial Aerodynamics, 2020, 204: 104271. |

| 5 | 沈杰,白旭.风速对寒区船舶杆件结构霜冰结冰的影响分析[J].舰船科学技术,2020,42(5):56-60. |

| Shen Jie, Bai Xu. Analysis of the influence of wind speed on rime and ice formation of ship's pole structure in cold region[J]. Ship Science and Technology, 2020, 42(5): 56-60. | |

| 6 | 陈奕颖,丛茜,任露泉,等.冷藏设备防除冰表面非连续特征设计与试验[J].农业工程学报,2021,37(7):261-267. |

| Chen Yi-ying, Cong Qian, Ren Lu-quan, et al. Design and experiment of the non-continuous anti-icing surface for refrigeration equipment[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(7): 261-267. | |

| 7 | 陈炳彬,张征,鲁聪达,等.复合材料层合结构在防覆冰/除冰系统中的应用[J].中国机械工程,2019, 30(7): 771-776. |

| Chen Bing-bin, Zhang Zheng, Lu Cong-da, et al. Applications of composite laminated structures in anti-icing and de-icing systems[J]. China Mechanical Engineering, 2019, 30(7): 771-776. | |

| 8 | Fay L, Shi X M. Environmental impacts of chemicals for snow and ice control: state of the knowledge[J]. Water, Air, & Soil Pollution, 2012, 223(5): 2751-2770. |

| 9 | Shi Z H, Zhao Y Q, Ma C K. Parametric study of ultrasonic de-icing method on a plate with coating[J]. Coatings, 2020, 10(7):No.631. |

| 10 | Li W, Zhan Y L, Yu S R. Applications of superhydrophobic coatings in anti-icing: theory, mechanisms, impact factors, challenges and perspectives[J]. Progress in Organic Coatings, 2021, 152: 106117. |

| 11 | Maghsoudi K, Vazirinasab E, Momen G, et al. Icephobicity and durability assessment of superhydrophobic surfaces: the role of surface roughness and the ice adhesion measurement technique[J]. Journal of Materials Processing Technology, 2021, 288: 116883. |

| 12 | Maghsoudi K, Momen G, Jafari R, et al. Rigorous testing to assess the self-cleaning properties of an ultra-water repellent silicone rubber surface[J]. Surface & Coatings Technology, 2019, 374: 557-568. |

| 13 | Jiang G, Chen L, Zhang S D, et al. Superhydrophobic SiC/CNTs coatings with photothermal deicing and passive anti-icing properties[J]. ACS Applied Materials and Interfaces, 2018, 10(42): 36505-36511. |

| 14 | Zhao Z H, Chen H W, Liu X L, et al. Development of high-efficient synthetic electric heating coating for anti-icing/de-icing[J]. Surface and Coatings Technology, 2018, 349: 340-346. |

| 15 | Zeng X C, Yan Z X, Lu Y C, et al. Reduction of ice adhesion using surface acoustic waves: nanoscale vibration and interface heating effects[J]. Langmuir, 2021, 37(40): 11851-11858. |

| 16 | Koji M, Tomoastu K. Fundamental study on adhesion of ice to cooling solid surface[J]. International Journal of Refrigeration, 2007, 30(5): 851-860. |

| 17 | Kirill A E, Alexandre M E, Ludmila B B. Water and ice adhesion to solid surfaces: Common and specific, the Impact of temperature and surface wettability[J]. Coatings, 2020, 10(7): No.648. |

| 18 | Chen T K, Cong Q, Sun C B, et al. Influence of substrate initial temperature on adhesion strength of ice on aluminum alloy[J]. Cold Regions Science and Technology, 2018, 148: 142-147. |

| 19 | Vercillo V, Tonnicchia S, Romano J, et al. Design rules for laser-treated icephobic metallic surfaces for aeronautic applications[J]. Advanced Functional Materials, 2020, 30(16): 1-12. |

| 20 | Beemer D L, Wang W, Kota A K. Durable gels with ultra-low adhesion to ice[J]. Journal of Materials Chemistry A, 2016, 4(47): 18253-18258. |

| 21 | 金敬福,韩丽曼,曹敏,等.水滴结冰相变体积膨胀规律[J].吉林大学学报:工学版,2016,46(5):1546-1551. |

| Jin Jing-fu, Han Li-man, Cao Min, et al. Volume expansion rule of water drops during the freezing process[J]. Journal of Jilin University(Engineering and Technology Edition),2016, 46(5): 1546-1551. | |

| 22 | 张受谦.化工手册[M].济南:山东科学技术出版社,1986. |

| 23 | Zhang X, Liu X, Min J C, et al. Shape variation and unique tip formation of a sessile water droplet during freezing[J]. Applied Thermal Engineering, 2019, 147: 927-934. |

| 24 | Song M J, Dang C B, Higashi T, et al. Review of experimental data associated with the solidification characteristics of water droplets on a cold plate surface at the early frosting stage[J]. Energy & Buildings, 2020, 223: 110113. |

| 25 | 曹敏,陈廷坤,丛茜,等.表面形态对结冰附着强度的影响[J].吉林大学学报:工学版,2013,43(5):1314-1319. |

| Cao Min, Chen Ting-kun, Cong Qian, et al. Influence of PMMA surface morphology on ice adhesion strength[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(5): 1314-1319. | |

| 26 | Cong Q, Xu J, Ren L Q, et al. Changes of water/ice morphological, thermodynamic, and mechanical parameters during the freezing process[J]. Arabian Journal for Science and Engineering, 2021, 46(11): 10631-10639. |

| 27 | 秦大同,谢里阳.现代机械设计手册(第一卷)[M].北京:化学工业出版社,2011. |

| 28 | 陈廷坤.基于干扰冰-固界面粘附稳定性的主动防/除冰方法研究[D].长春:吉林大学生物与农业工程学院,2019. |

| Chen Ting-kun. Research on active anti/de-icing method based on disturbing the adhesion stability of ice-solid interface[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2019. |

| [1] | 陈奕颖,金敬福,丛茜,陈廷坤,任露泉. 不同冰点介质对冰黏附强度的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1926-1932. |

|

||