吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1926-1932.doi: 10.13229/j.cnki.jdxbgxb20210445

• 农业工程·仿生工程 • 上一篇

不同冰点介质对冰黏附强度的影响

陈奕颖1( ),金敬福1,丛茜2,3,陈廷坤1,2(

),金敬福1,丛茜2,3,陈廷坤1,2( ),任露泉2

),任露泉2

- 1.吉林大学 生物与农业工程学院,长春 130022

2.吉林大学 工程仿生教育部重点实验室,长春 130022

3.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Influence of media with different low freezing points on ice adhesion strength

Yi-ying CHEN1( ),Jing-fu JIN1,Qian CONG2,3,Ting-kun CHEN1,2(

),Jing-fu JIN1,Qian CONG2,3,Ting-kun CHEN1,2( ),Lu-quan REN2

),Lu-quan REN2

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

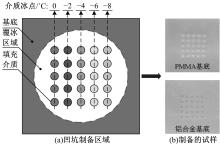

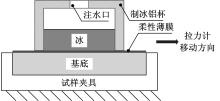

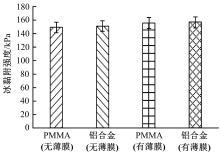

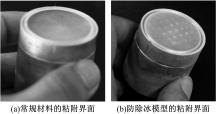

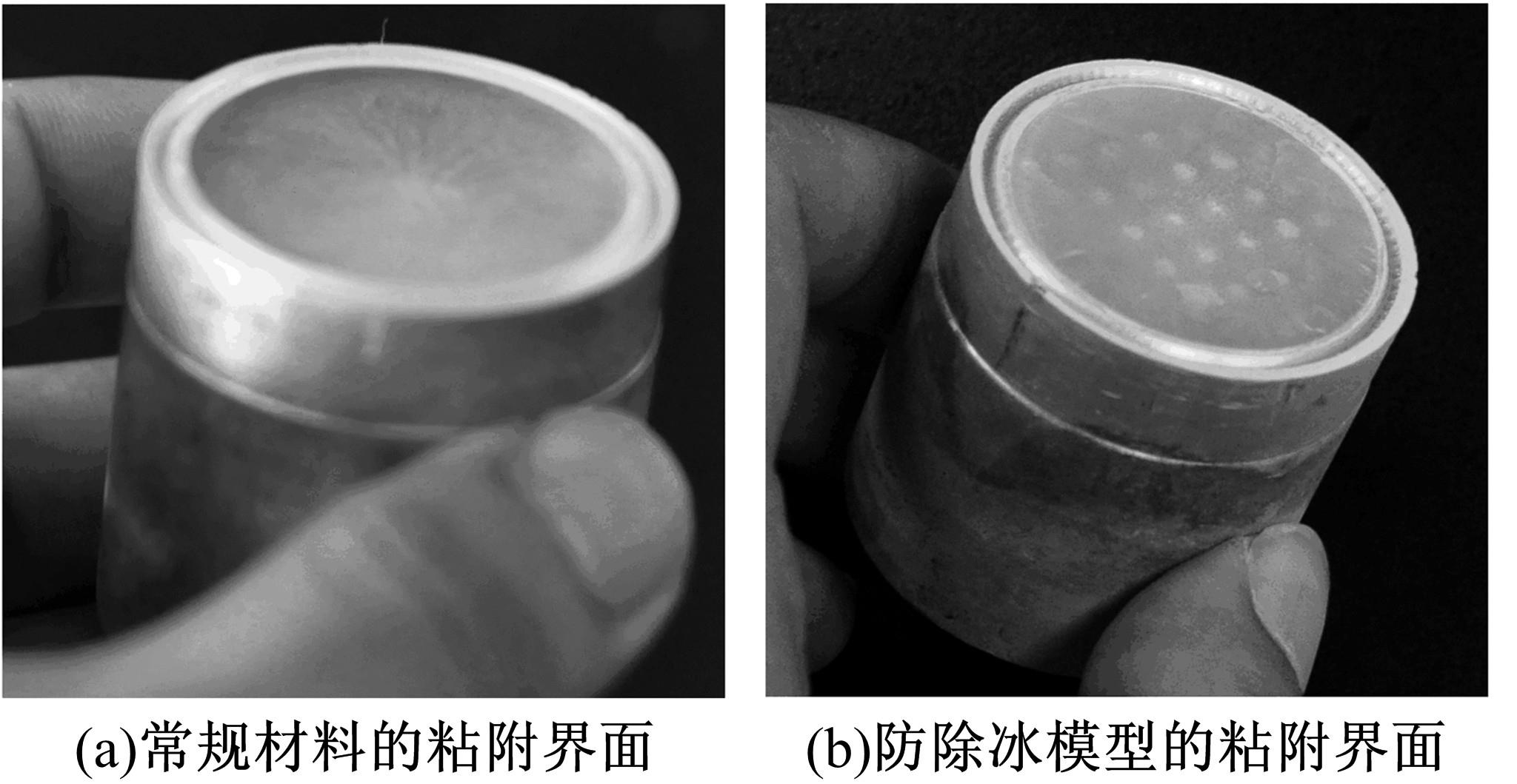

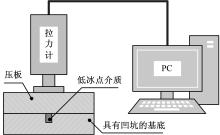

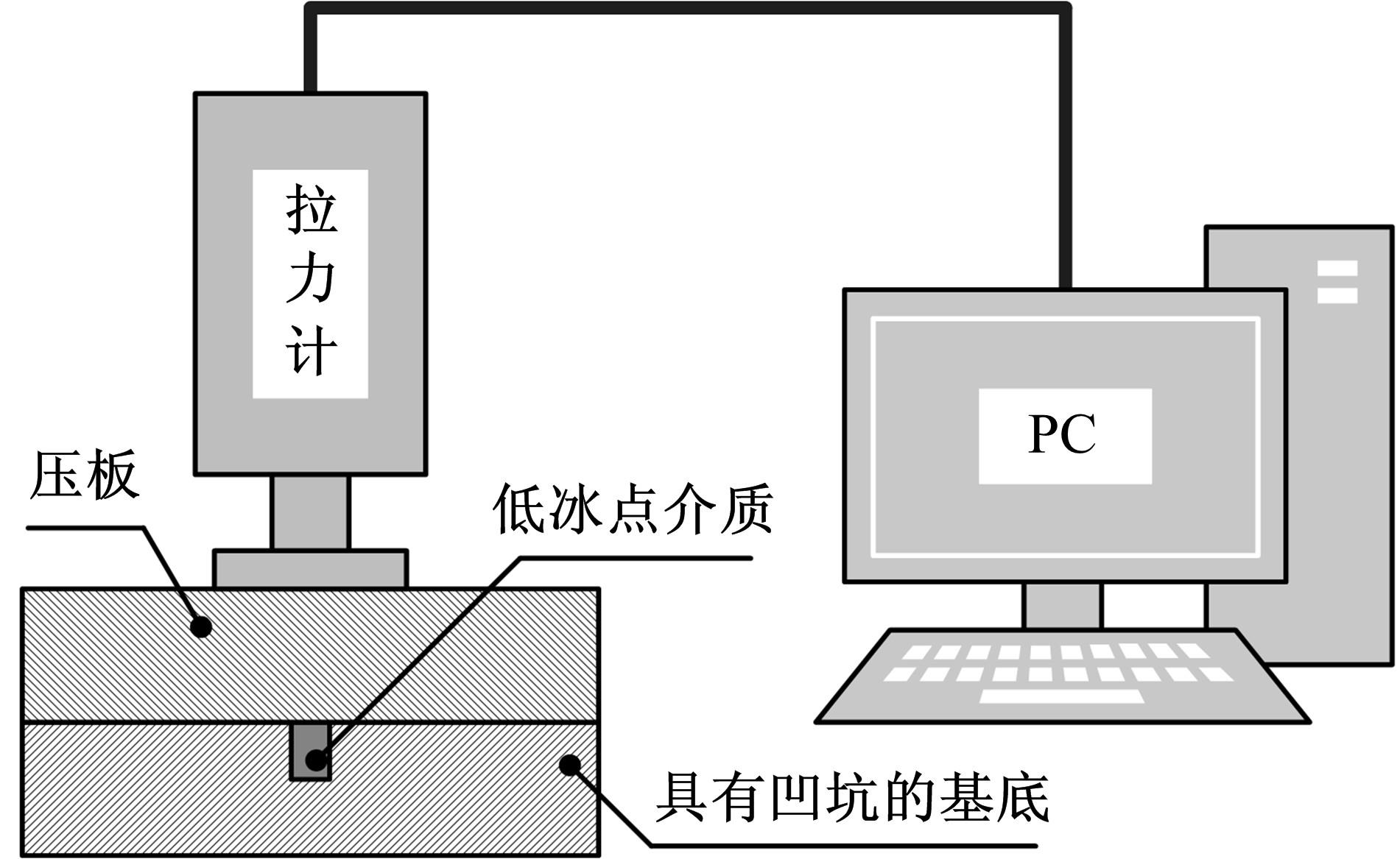

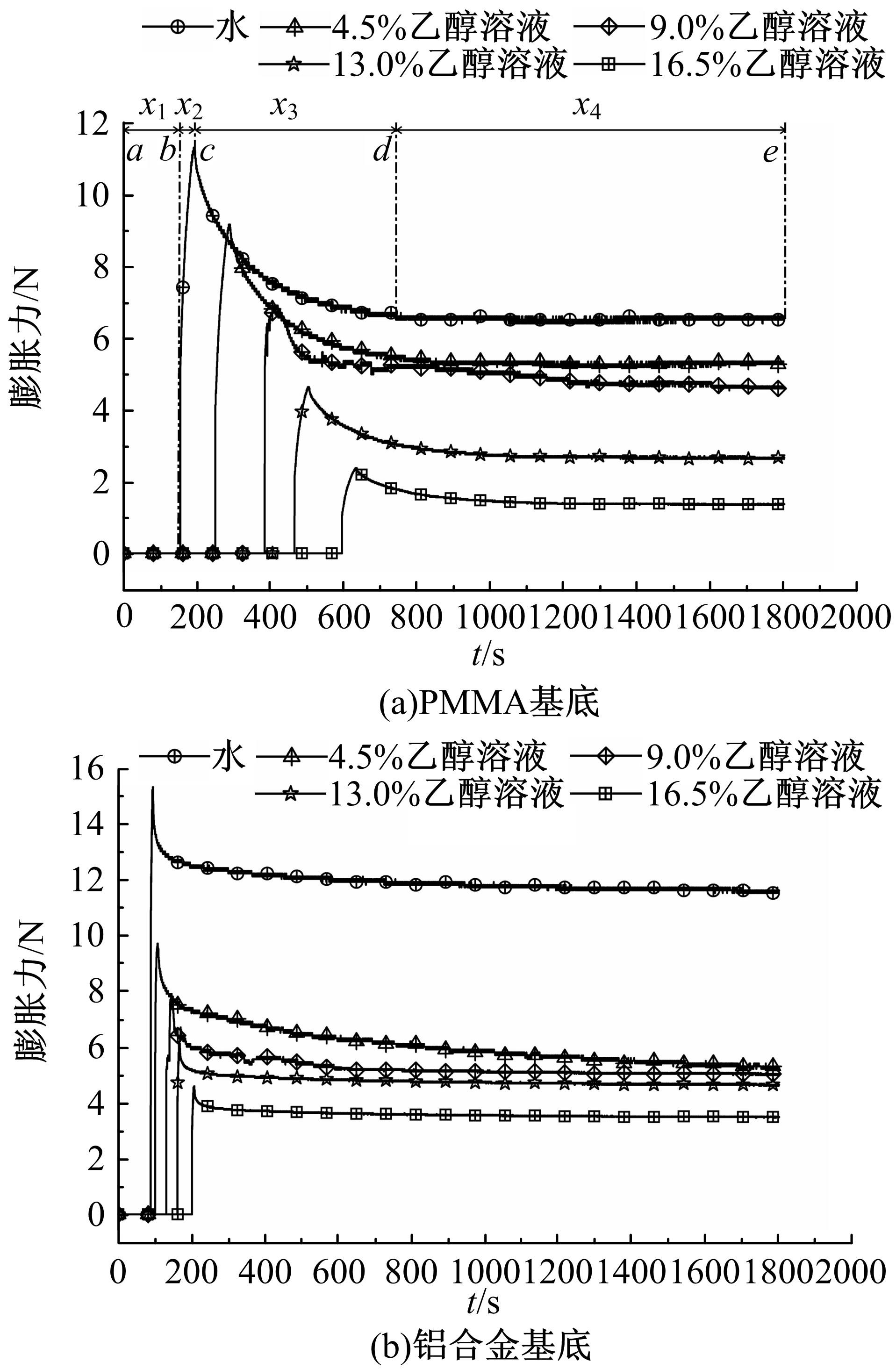

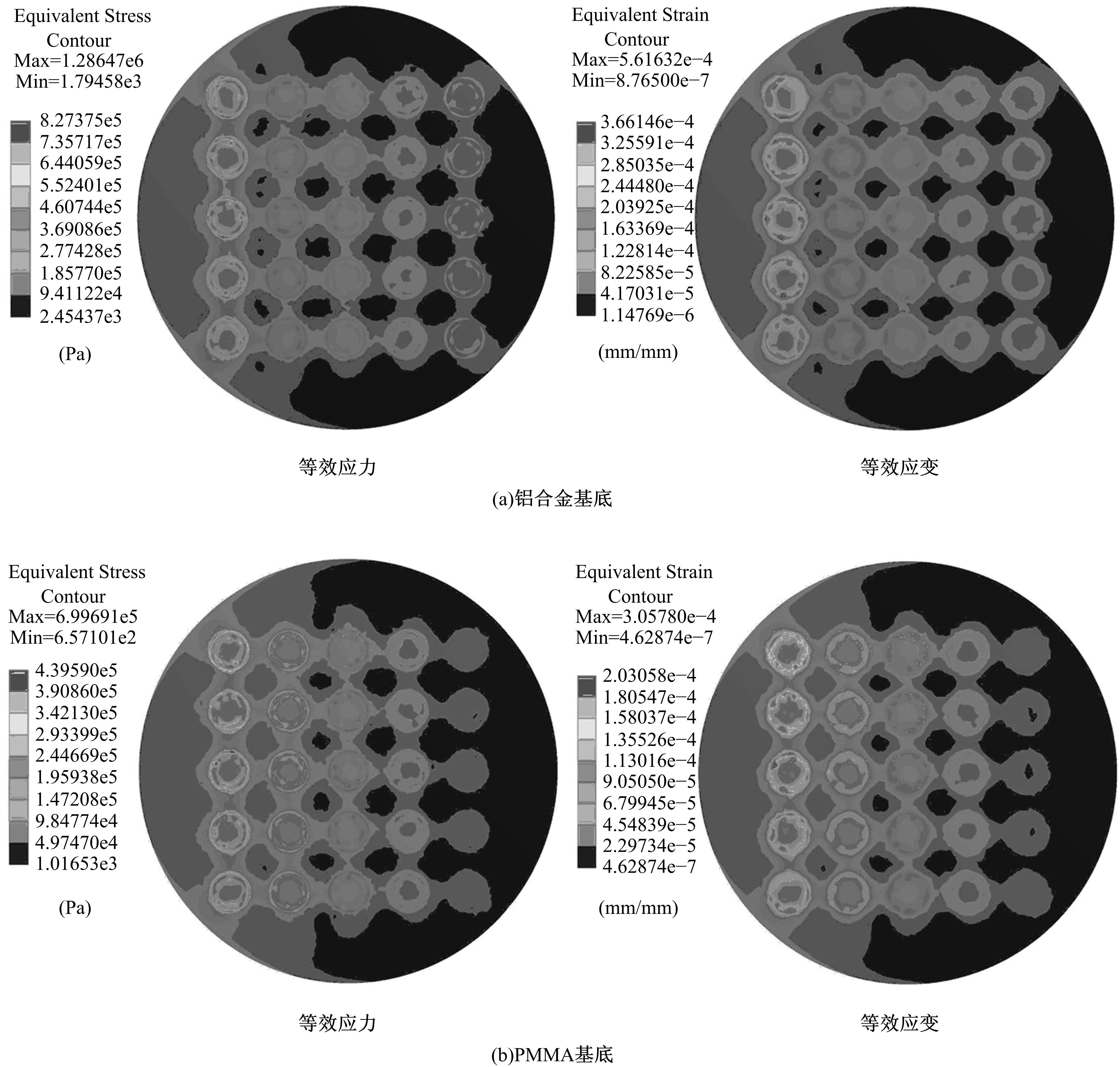

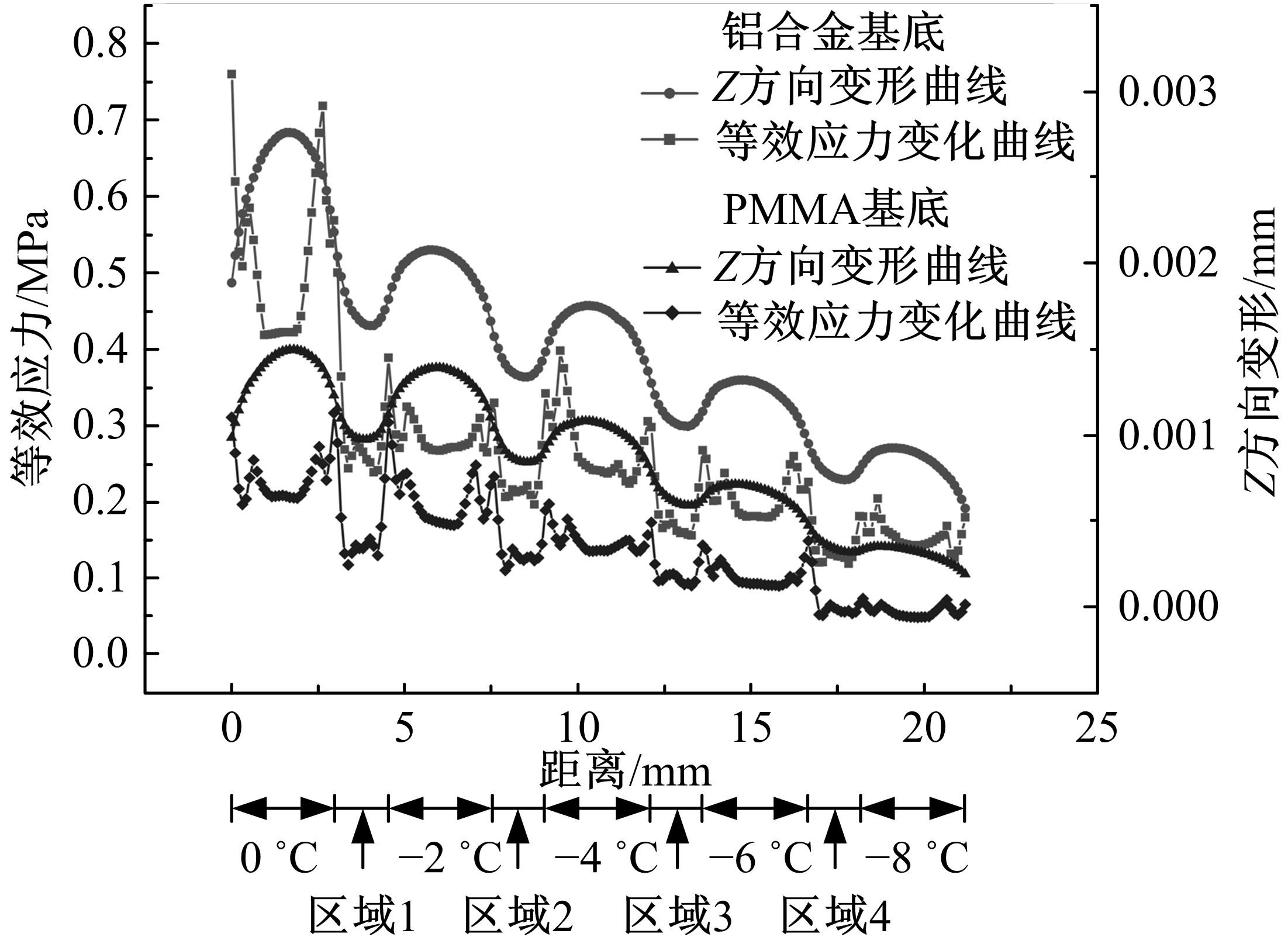

在铝合金和聚甲基丙烯酸甲酯表面加工用于填充不同低冰点水溶液的凹坑,并测试冰在其表面的黏附强度。试验表明:界面具有相变温度梯度的试样使表面覆冰主动剥离脱落。测量凹坑内低冰点水溶液在冻结过程中产生的相变膨胀力变化曲线,对其进行函数拟合,结合有限元模拟分析基底表面具有相变温度梯度对冰黏附界面稳定性的影响。分析表明:低温环境下界面具有的相变温度梯度使冰黏附界面形成应力集中,破坏冰黏附界面的稳定性,并且相邻凹坑内低冰点水溶液相变产生的膨胀力改变冰黏附界面无凹坑区域的应力、应变,干扰无凹坑区域冰黏附界面的稳定性,进一步影响冰在材料表面的黏附稳定性。

中图分类号:

- TB131

| 1 | Lv J Y, Song Y L, Jiang L, et al. Bio-inspired strategies for anti-icing[J]. ACS Nano, 2014, 8(4): 3152-3169. |

| 2 | Wang J B, Zhang J, Zhang Y, et al. Impact of rotation of wheels and bogie cavity shapes on snow accumulating on the bogies of high-speed trains[J]. Cold Regions Science and Technology, 2019, 159: 58-70. |

| 3 | Cao Y H, Wu Z L, Su Y, et al. Aircraft flight characteristics in icing conditions[J]. Progress in Aerospace Science, 2015, 74: 62-80. |

| 4 | Fakorede O, Feger Z, Ibrahim H, et al. Ice protection systems for wind turbines in cold climate: characteristics, comparisons and analysis[J]. Renewable & Sustainable Energy Reviews, 2016, 65: 662-675. |

| 5 | Lan C Y, Li C, Wang S L. Parabolic antenna snow melting and removal using heat from the transmitter room[J]. Energy, 2019, 181: 738-744. |

| 6 | Zhu Y C, Huang X B, Jia J Y, et al. Experimental study on the thermal conductivity for transmission line icing[J]. Cold Regions Science and Technology, 2016, 129: 96-103. |

| 7 | Bao L Y, Huang Z Y, Priezjev N V, et al. A significant reduction of ice adhesion on nanostructured surfaces that consist of an array of single-walled carbon nanotubes: a molecular dynamics simulation study[J]. Applied Surface Science, 2018, 437: 202-208. |

| 8 | Borrebaek P O A, Jelle B P, Zhang Z L. Avoiding snow and ice accretion on building integrated photovoltaics-challenges, strategies, and opportunities[J]. Solar Energy Materials and Solar Cells, 2020, 206: 110306. |

| 9 | Wang Z J. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft[J]. Energy and Buildings, 2017, 140: 42-49. |

| 10 | Fakorede O, Feger Z, Ibrahim H, et al. Ice protection systems for wind turbines in cold climate characteristics, comparisons and analysis[J]. Renewable & Sustainable Energy Reviews, 2016, 65: 662-675. |

| 11 | 金敬福, 李杨, 陈廷坤, 等. 涂层弹性模量对结冰附着强度的影响[J]. 吉林大学学报: 工学版, 2017, 47(5): 1548-1553. |

| Jin Jing-fu, Li Yang, Chen Ting-kun, et al. Effect of elastic modulus of coating on ice-adhesion strength on substrate[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(5): 1548-1553. | |

| 12 | 金敬福, 韩丽曼, 曹敏, 等. 水滴结冰相变体积膨胀规律[J]. 吉林大学学报: 工学版, 2016, 46(5): 1546-1551. |

| Jin Jing-fu, Han Li-man, Cao Min, et al. Volume expansion rule of water droplets during freezing process[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(5): 1546-1551. | |

| 13 | Parent O, Ilinca A. Anti-icing and de-icing techniques for wind turbines: critical review[J]. Cold Regions Science and Technology, 2011, 65: 88-96. |

| 14 | Rashid T, Khawaja H A, Edvardsen K. Review of marine icing and anti-/de-icing systems[J]. Journal of Marine Engineering and Technology, 2016, 15(2): 79-87. |

| 15 | Kulinich S A, Farhadi S, Nose K, et al. Superhydrophobic surfaces are they really ice-repellent?[J]. Langmuir, 2011, 27: 25-29. |

| 16 | Nosonovsky M, Hejazi V. Why superhydrophobic surfaces are not always icephobic[J]. ACS Nano, 2012, 6(10): 8488-8491. |

| 17 | Zheng S L, Li C, Fu Q T, et al. Development of stable superhydrophobic coatings on aluminum surface for corrosion-resistant, self-cleaning, and anti-icing applications[J]. Materials & Design, 2016, 93: 261-270. |

| 18 | 郭永刚, 张鑫, 耿铁, 等. 超疏水表面耐久性能的研究进展[J]. 中国表面工程, 2018, 31(5): 63-72. |

| Guo Yong-gang, Zhang Xin, Geng Tie, et al. Research progress on durability of superhydrophobic surfaces[J]. China Surface Engineering, 2018, 31(5): 63-72. | |

| 19 | 佟威, 熊党生. 仿生超疏水表面的发展及其应用研究进展[J]. 无机材料学报, 2019, 34(11):1133-1144. |

| Tong Wei, Xiong Dang-sheng. Bioinspired superhydrophobic materials: progress and functional application[J]. Journal of Inorganic Materials, 2019, 34(11): 1133-1144. | |

| 20 | 李国滨, 刘海峰, 李金辉, 等. 超疏水材料的研究进展[J]. 高分子材料科学与工程, 2020, 36(12): 142-150. |

| Li Guo-bin, Liu Hai-feng, Li Jin-hui, et al. Research progress of preparation of superhydrophobic[J]. Polymer Materials Science and Engineering, 2020, 36(12): 142-150. | |

| 21 | 丁金波, 董威. 表面粗糙度对冰冻黏强度影响试验研究[J]. 航空发动机, 2012, 38(4): 42-46. |

| Ding Jin-bo, Dong Wei. Experimental study of influence of surface roughness on ice adhesion[J]. Aeroengine, 2012, 38(4): 42-46. | |

| 22 | Hassan M F, Lee H P, Lim S P. The variation of ice adhesion strength with substrate surface roughness[J]. Measurement Science and Technology, 2010, 21: 075701. |

| 23 | Tarquini S, Antonini C, Amirfazli A, et al. Investigation of ice shedding properties of superhydrophobic coatings on helicopter blades[J]. Cold Regions Science and Technology, 2014, 100: 50-58. |

| 24 | 丁云飞, 唐珊, 吴会军. 表面微结构对冰粘附强度的影响[J]. 表面技术, 2015, 44(4): 74-78. |

| Ding Yun-fei, Tang Shan, Wu Hui-jun. Study on influence of surface microstructure on ice adhesion strength[J].Surface Technology, 2015, 44(4): 74-78. | |

| 25 | 翟广坤, 李曙林, 陈素素, 等. 氟化改性硅树脂制备的超疏水涂层防覆冰性能[J]. 工程科学学报, 2018, 40(7): 864-870. |

| Zhai Guang-kun, Li Shu-lin, Chen Su-su, et al. Anti-icing performance of superhydrophobic coating prepared by modified fluorinated silicone[J]. Chinese Journal of Engineering, 2018, 40(7): 864-870. | |

| 26 | Shen Y Z, Wu Y, Tao J, et al. Spraying fabrication of durable and transparent coatings for anti-icing application: dynamic water repellency, icing delay, and ice adhesion[J]. ACS Applied Materials & Interfaces, 2019, 11: 3590-3598. |

| 27 | Ghalmi Z, Farzaneh M. Durability of nanostructured coatings based on PTFE nanoparticles deposited on porous aluminum alloy[J]. Applied Surface Science, 2014, 314: 564-569. |

| 28 | Ghalmi Z, Farzaneh M. Experimental investigation to evaluate the effect of PTFE nanostructured roughness on ice adhesion strength[J]. Cold Regions Science and Technology, 2015, 115: 42-47. |

| 29 | 陈绍纲. 轮机工程手册[M]. 1版. 北京: 人民交通出版社, 1992. |

| 30 | 曹敏, 陈廷坤, 丛茜, 等. 表面形态对结冰附着强度的影响[J]. 吉林大学学报: 工学版, 2013, 43(5): 1314-1319. |

| Cao Min, Chen Ting-kun, Cong Qian, et al. Influence of PMMA surface morphology on ice adhesion strength[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(5): 1314-1319. |

| [1] | 于征磊,陈立新,徐泽洲,信仁龙,马龙,金敬福,张志辉,江山. 基于增材制造的仿生防护结构力学及回复特性分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1540-1547. |

| [2] | 于征磊,信仁龙,陈立新,朱奕凝,张志辉,曹青,金敬福,赵杰亮. 仿蜂窝防护结构的承载特性[J]. 吉林大学学报(工学版), 2021, 51(3): 1140-1145. |

| [3] | 刘春宝,陈山石,盛闯,钱志辉,任露泉,任雷. 蜘蛛生物液压驱动原理及其功能仿生探索[J]. 吉林大学学报(工学版), 2020, 50(1): 375-381. |

| [4] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [5] | 吴娜,庄健,张克松,王慧鑫,马云海. 毛蚶贝壳曲面承压力学特性及断裂机理[J]. 吉林大学学报(工学版), 2019, 49(3): 897-902. |

| [6] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [7] | 熙鹏,丛茜,王庆波,郭华曦. 仿生条纹形磨辊磨损试验及耐磨机理分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1787-1792. |

| [8] | 田为军, 王骥月, 李明, 张兴旺, 张勇, 丛茜. 面向水上机器人的水黾运动观测[J]. 吉林大学学报(工学版), 2018, 48(3): 812-820. |

| [9] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [10] | 陈东辉, 刘伟, 吕建华, 常志勇, 吴婷, 慕海锋. 基于虾夷扇贝体表结构的玉米茬根捡拾器仿生设计[J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [11] | 田丽梅, 王养俊, 李子源, 商延赓. 仿生功能表面内流减阻测试系统的研制[J]. 吉林大学学报(工学版), 2017, 47(4): 1179-1184. |

| [12] | 王颖, 李建桥, 张广权, 黄晗, 邹猛. 基于多种介质的仿生步行足力学特性[J]. 吉林大学学报(工学版), 2017, 47(2): 546-551. |

| [13] | 葛长江, 叶辉, 胡兴军, 于征磊. 鸮翼后缘噪声的预测及控制[J]. 吉林大学学报(工学版), 2016, 46(6): 1981-1986. |

| [14] | 李梦, 苏义脑, 孙友宏, 高科. 高胎体仿生异型齿孕镶金刚石钻头[J]. 吉林大学学报(工学版), 2016, 46(5): 1540-1545. |

| [15] | 梁云虹, 任露泉. 自然生境及其仿生学初探[J]. 吉林大学学报(工学版), 2016, 46(5): 1746-1756. |

|

||