吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 458-465.doi: 10.13229/j.cnki.jdxbgxb20211106

• 车辆工程·机械工程 • 上一篇

基于竞争失效模型的滚珠丝杠副可靠性设计建模

刘璐1,2( ),周华西1,2,陈传海3,4,龚梦辉1,2,冯虎田1,2,周长光1,2(

),周华西1,2,陈传海3,4,龚梦辉1,2,冯虎田1,2,周长光1,2( )

)

- 1.南京理工大学 机械工程学院,南京 210094

2.数控机床功能部件性能测试评价与可靠性技术重点实验室,江苏 苏州 215600

3.吉林大学 数控装备可靠性教育部重点实验室,长春 130022

4.吉林大学 机械与航空航天工程学院,长春 130022

Reliability design model of ball screws based on competition failure

Lu LIU1,2( ),Hua-xi ZHOU1,2,Chuan-hai CHEN3,4,Meng-hui GONG1,2,Hu-tian FENG1,2,Chang-guang ZHOU1,2(

),Hua-xi ZHOU1,2,Chuan-hai CHEN3,4,Meng-hui GONG1,2,Hu-tian FENG1,2,Chang-guang ZHOU1,2( )

)

- 1.Department of Mechanical Engineering,Nanjing University of Science and Technology,Nanjing 210094,China

2.Key Laboratory of Performance Test Evaluation and Reliability Technology for Functional Components of CNC Machine Tools,Suzhou 215600,China

3.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

4.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

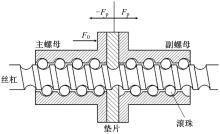

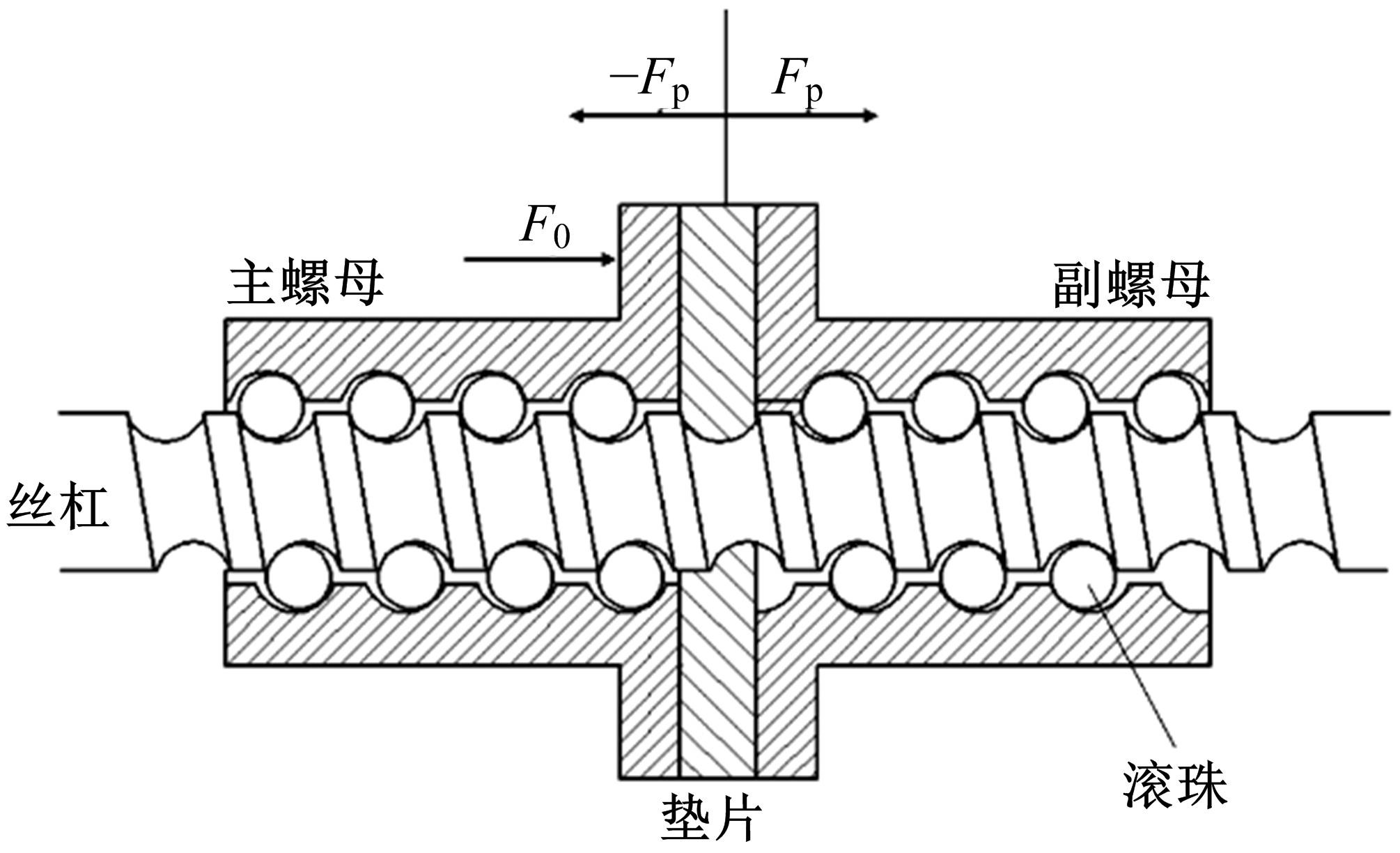

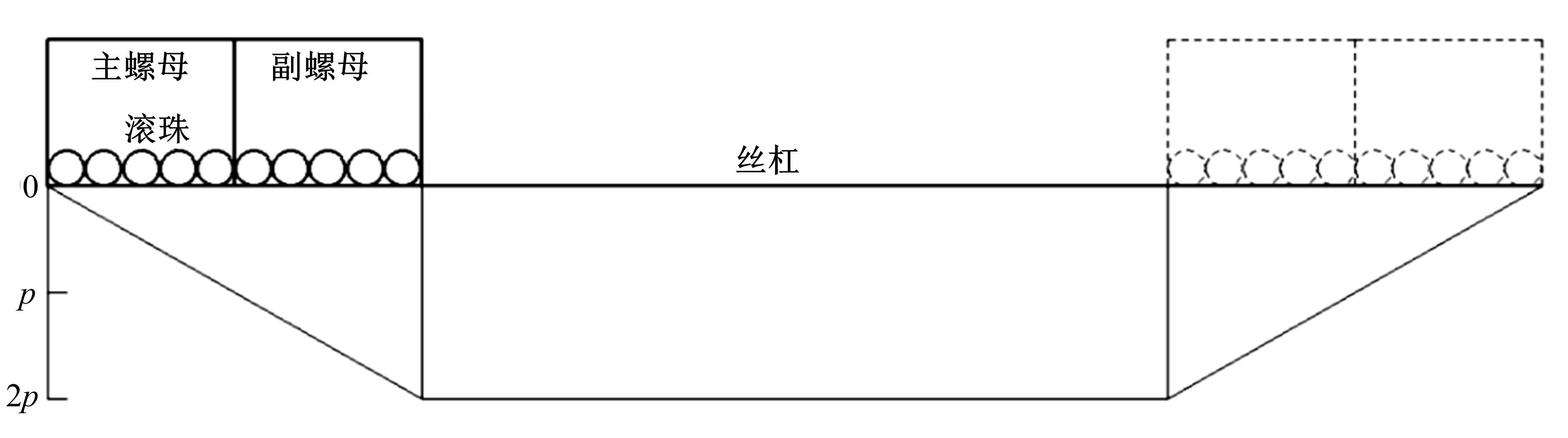

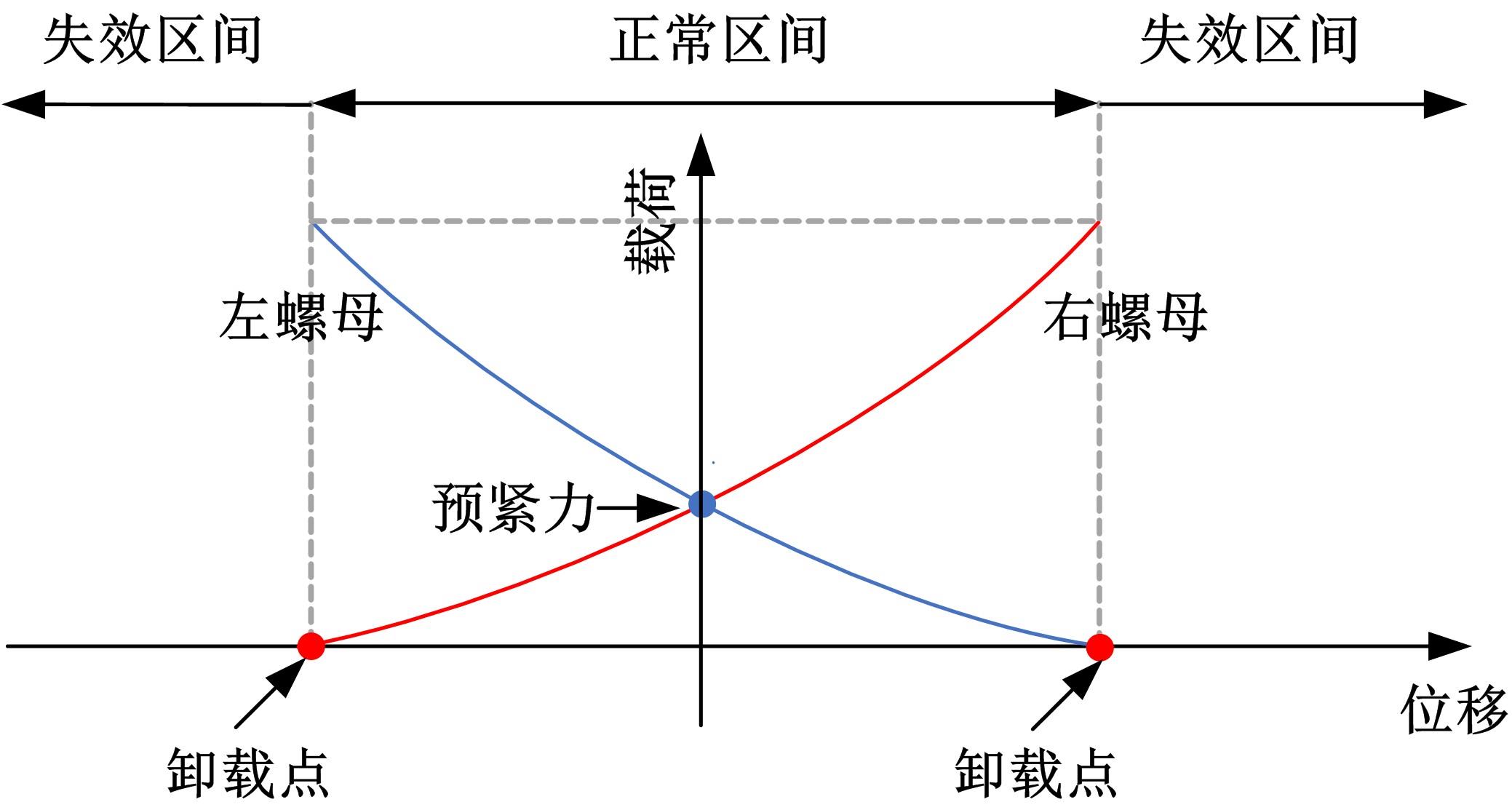

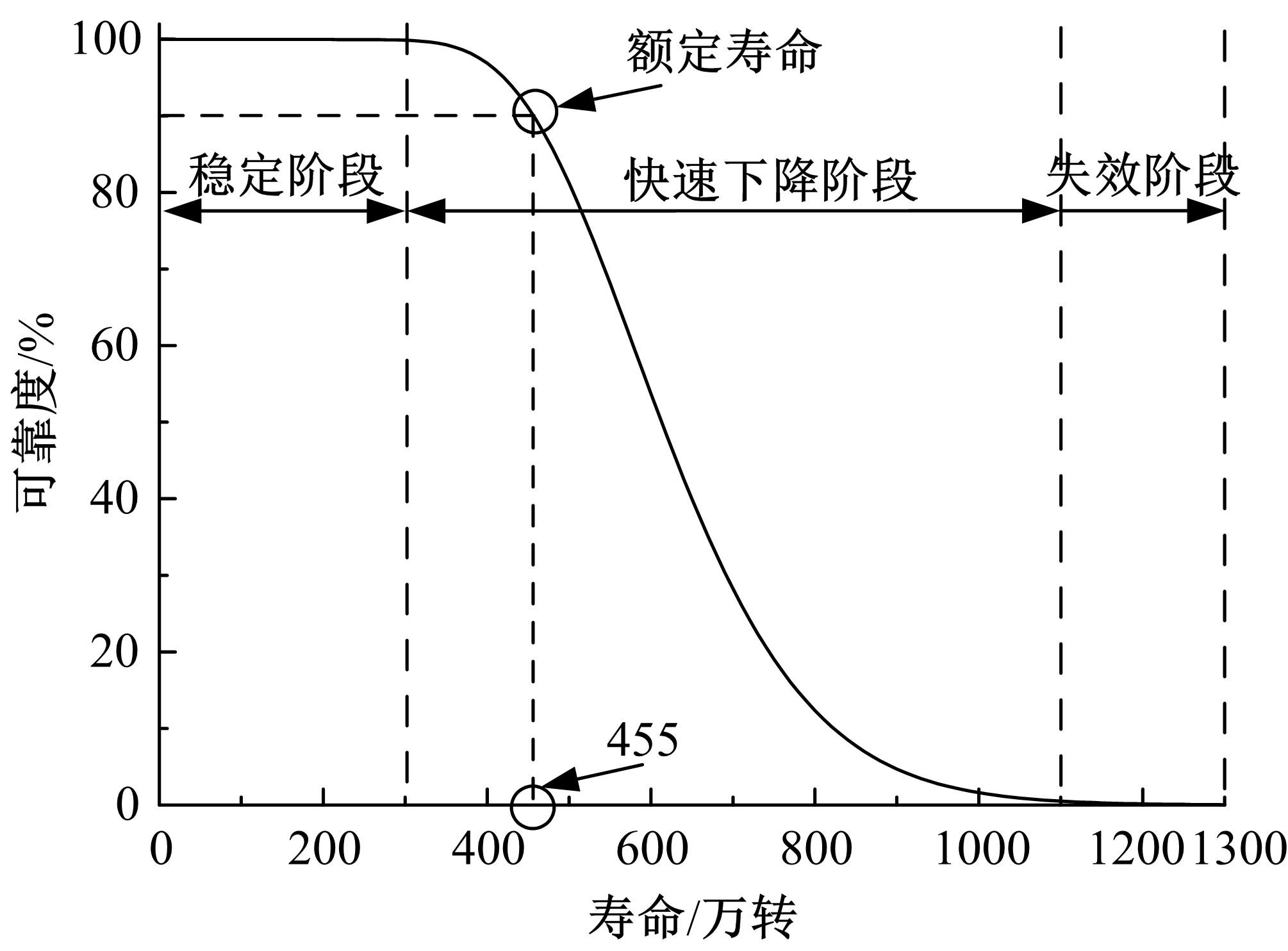

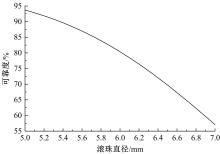

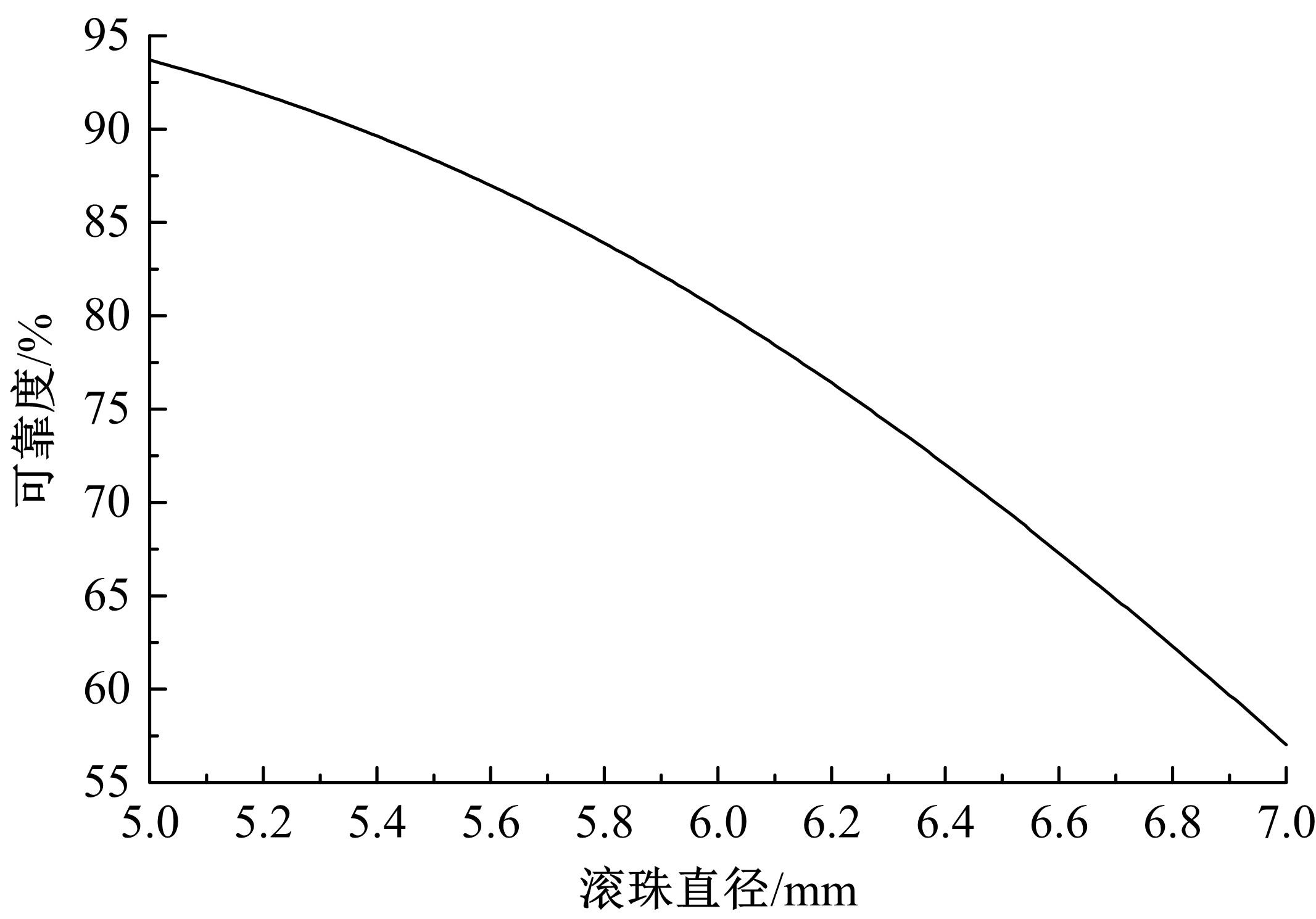

以双螺母预紧滚珠丝杠副为研究对象,分析其失效机理,建立了性能退化失效与疲劳点蚀失效共存状态下的竞争失效模型。综合考虑滚珠直径、滚道半径、接触角、摩擦因数、运行速度等结构参数和使用参数与可靠性指标之间的关系,建立了滚珠丝杠副可靠性设计的数学模型,提出了滚珠丝杠副可靠性定量设计的方法,并通过样本分析验证了该方法的有效性。

中图分类号:

- TH165

| 1 | Feng Hu-tian, Wang Yu-lin, Li Chun-mei, et al. An automatic measuring method and system using a light curtain for the thread profile of a ball screw[J]. Measurement Science & Technology, 2011, 22(8): 085106. |

| 2 | Zhou Chang-guang, Feng Hu-tian, Chen Zeng-tao, et al. Correlation between preload and no-load drag torque of ball screws[J]. International Journal of Machine Tools and Manufacture, 2016, 102: 35-40. |

| 3 | Wang Xiao-yi, Zhou Chang-guang, Ou Yi. Experimental analysis of the wear coefficient for the rolling linear guide[J]. Advances in Mechanical Engineering, 2019, 11(1): 1-7. |

| 4 | 龚梦辉, 周华西, 周长光, 等. 极限载荷工况下滚珠丝杠副疲劳弹性寿命研究[J]. 仪器仪表学报, 2021, 42(6): 37-47. |

| Gong Meng-hui, Zhou Hua-xi, Zhou Chang-guang, et al. Study on fatigue elastic life of ball screw pair under ultimate load condition[J]. Chinese Journal of Scientific Instrument, 2021, 42(6): 37-47. | |

| 5 | Zhou Hua-xi, Zhou Chang-guang, Feng Hu-tian, et al. Theoretical and experimental analysis of the preload degradation of double-nut ball screws[J]. Precision Engineering, 2020, 65: 72-90. |

| 6 | 杜尊令, 张义民. 基于随机流量下柱塞泵的可靠性分析[J]. 吉林大学学报: 工学版, 2021, 51(6): 1967-1974. |

| Du Zun-ling, Zhang Yi-min. Reliability analysis of piston pump under random flow rate[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1967-1974. | |

| 7 | 张英芝, 刘津彤, 申桂香, 等. 基于故障相关性分析的数控机床系统可靠性建模[J]. 吉林大学学报: 工学版, 2017, 47(1): 169-173. |

| Zhang Ying-zhi, Liu Jin-tong, Shen Gui-xiang, et al. Reliability modeling of CNC machine tools system based on failure correlation analysis[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 169-173. | |

| 8 | 赵志欣, 唐慧, 刘仁云. 基于马尔可夫过程的风电系统可靠性分析[J]. 吉林大学学报: 工学版, 2021, 51(2): 697-703. |

| Zhao Zhi-xin, Tang Hui, Liu Ren-yun. Reliability analysis of wind power generation system based on markov process[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 697-703. | |

| 9 | 徐益飞. 精密滚珠丝杠副可靠性试验及评估方法研究[D]. 南京: 南京理工大学机械工程学院, 2015. |

| Xu Yi-fei. Research on reliability test and evaluation method of precision ball screw pair[D]. Nanjing: Department of Mechanical Engineering, Nanjing University of Science and Technology, 2015. | |

| 10 | 薛锋. 滚珠丝杠副精度保持性及加速试验方法研究[D]. 南京: 南京理工大学机械工程学院, 2017. |

| Xue Feng. Research on accuracy maintenance and accelerated test method of ball screw pairs[D]. Nanjing: Department of Mechanical Engineering, Nanjing University of Science and Technology, 2017. | |

| 11 | UNE-. Ball screws, Static and dynamic axial load ratings and operational life[S]. |

| 12 | . 滚珠丝杠副,第5部分: 轴向额定静载荷和额定动载荷及使用寿命[S]. |

| 13 | 龙哲, 申桂香, 王晓峰, 等. 竞争失效的刀具可靠性评估模型[J]. 吉林大学学报: 工学版, 2019, 49(1): 141-148. |

| Long Zhe, Shen Gui-xiang, Wang Xiao-feng, et al. Reliability evaluation model of tool on competitive failure[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(1): 141-148. | |

| 14 | Gustaf Lundberg, Arvid Palmgren. Dynamic Capacity of Rolling Bearings[M]. Sweden: Acta Polytech, 1947. |

| 15 | Arvid Palmgren. Ball and roller bearing engineering[M]. USA: Philadelphia Skf Industries Inc, 1959. |

| 16 | Zhou Chang-guang, Ou Yi, Feng Hu-tian, et al. Investigation of the precision loss for ball screw raceway based on the modified archard theory[J]. Industrial Lubrication and Tribology, 2017, 69(2): 166-173. |

| 17 | Zhou Chang-guang, Xie Jing-lun, Feng Hu-tian. Investigation of the decompression condition of double-nut ball screws considering the influence of the geometry error and additional elastic unit[J]. Mechanism and Machine Theory, 2021, 156: 104164. |

| 18 | Seshadri V. The Inverse Gaussian Distribution[M]. UK: Oxford University Press, 1993. |

| [1] | 程强,王畅,齐宝宝,张彩霞,杨聪彬,刘志峰. 虑及结构参数误差的滚珠丝杠接触载荷建模与分析[J]. 吉林大学学报(工学版), 2022, 52(2): 353-360. |

|

||