吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 353-360.doi: 10.13229/j.cnki.jdxbgxb20211084

• 车辆工程·机械工程 • 上一篇

虑及结构参数误差的滚珠丝杠接触载荷建模与分析

程强1,2( ),王畅1,2,齐宝宝3,张彩霞1,2(

),王畅1,2,齐宝宝3,张彩霞1,2( ),杨聪彬1,2,刘志峰1,3

),杨聪彬1,2,刘志峰1,3

- 1.北京工业大学 先进制造与智能技术研究所,北京 100124

2.北京工业大学 先进制造技术北京市重点实验室,北京 100124

3.吉林大学 机械与航空航天工程学院,长春 130022

Modeling and analysis of contact load of ball screw with error of structural parameters

Qiang CHENG1,2( ),Chang WANG1,2,Bao-bao QI3,Cai-xia ZHANG1,2(

),Chang WANG1,2,Bao-bao QI3,Cai-xia ZHANG1,2( ),Cong-bin YANG1,2,Zhi-feng LIU1,3

),Cong-bin YANG1,2,Zhi-feng LIU1,3

- 1.Institute of Advanced Manufacturing and Intelligent Technology,Beijing University of Technology,Beijing 100124,China

2.Beijing Key Laboratory of Advanced Manufacturing Technology,Beijing University of Technology,Beijing 100124,China

3.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

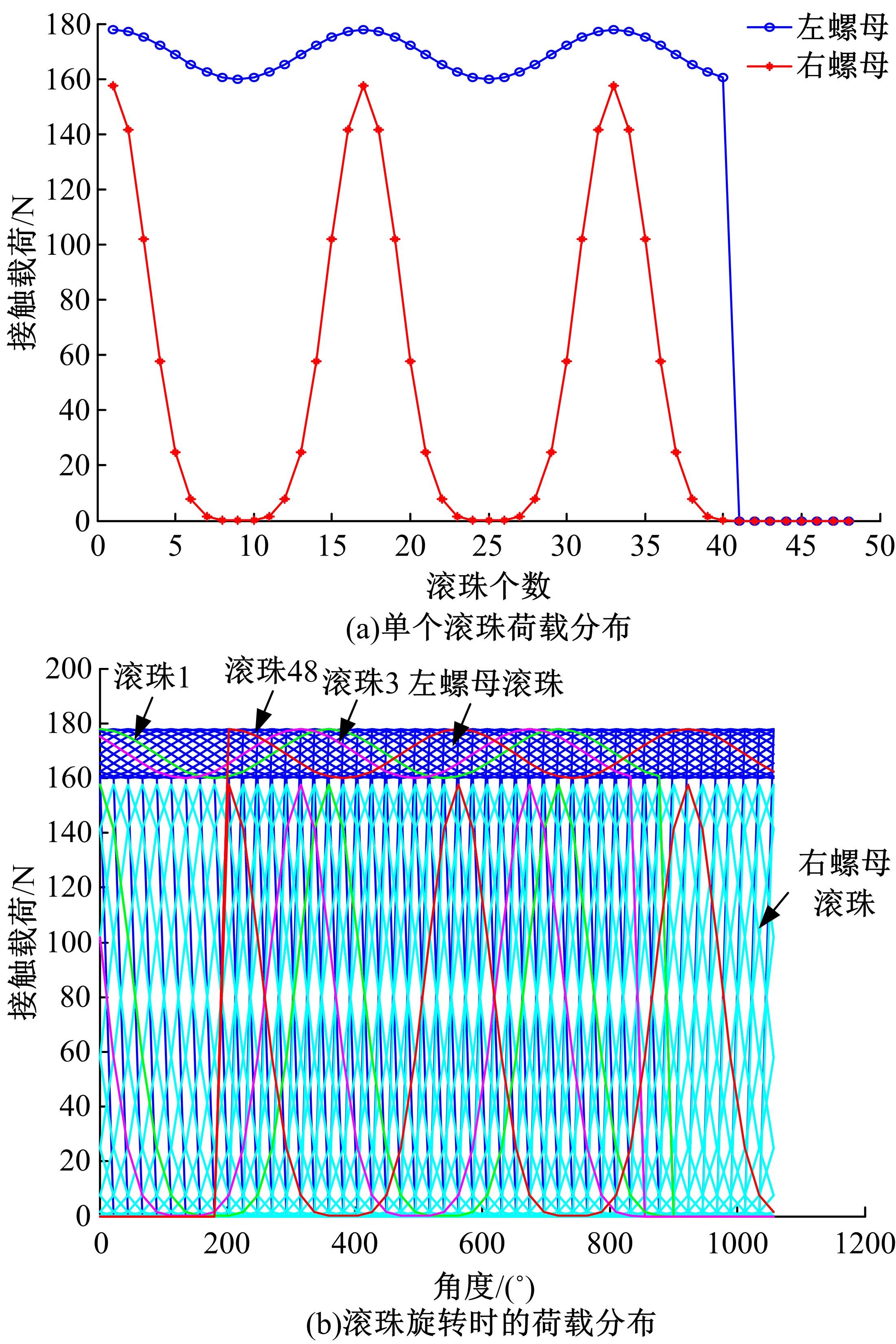

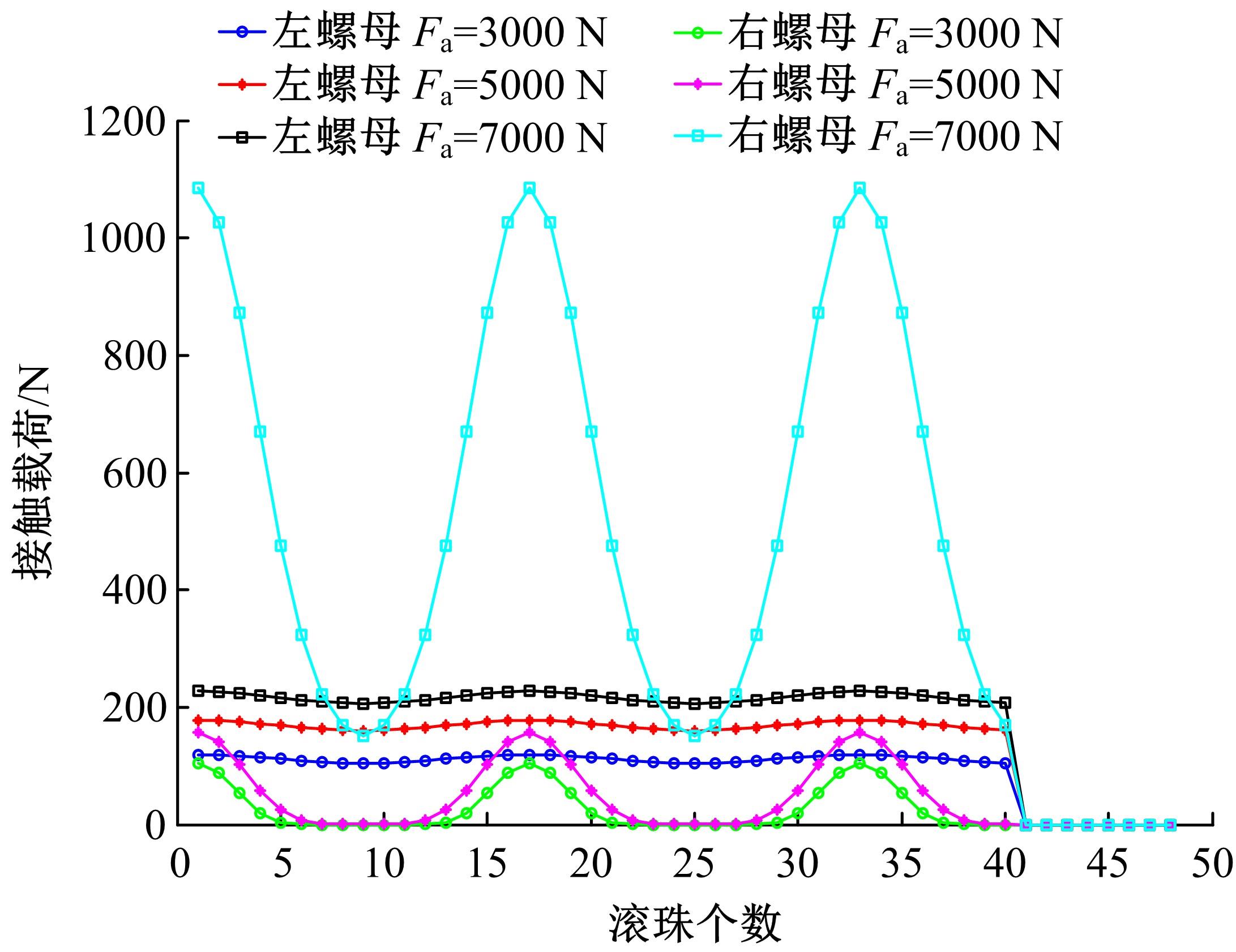

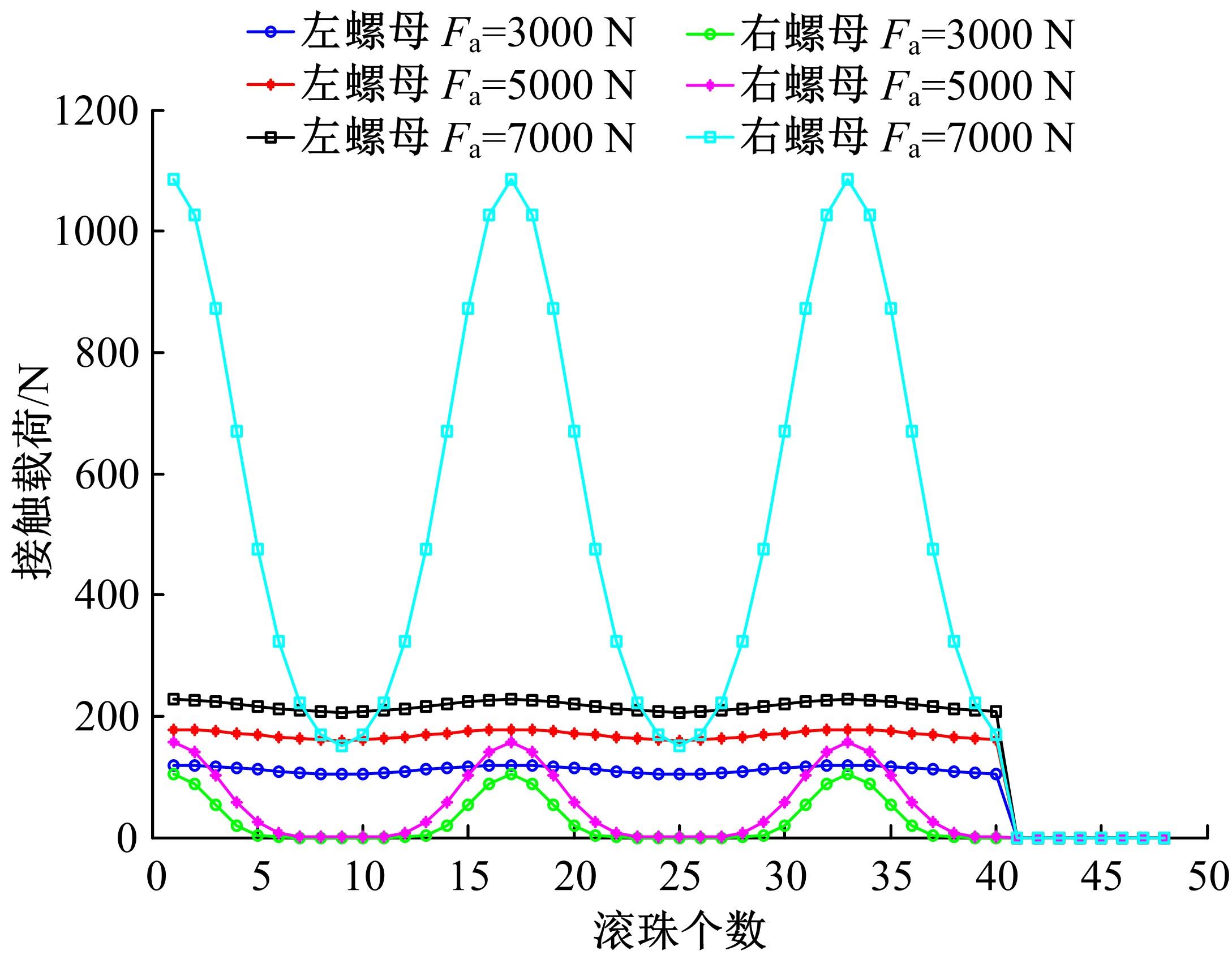

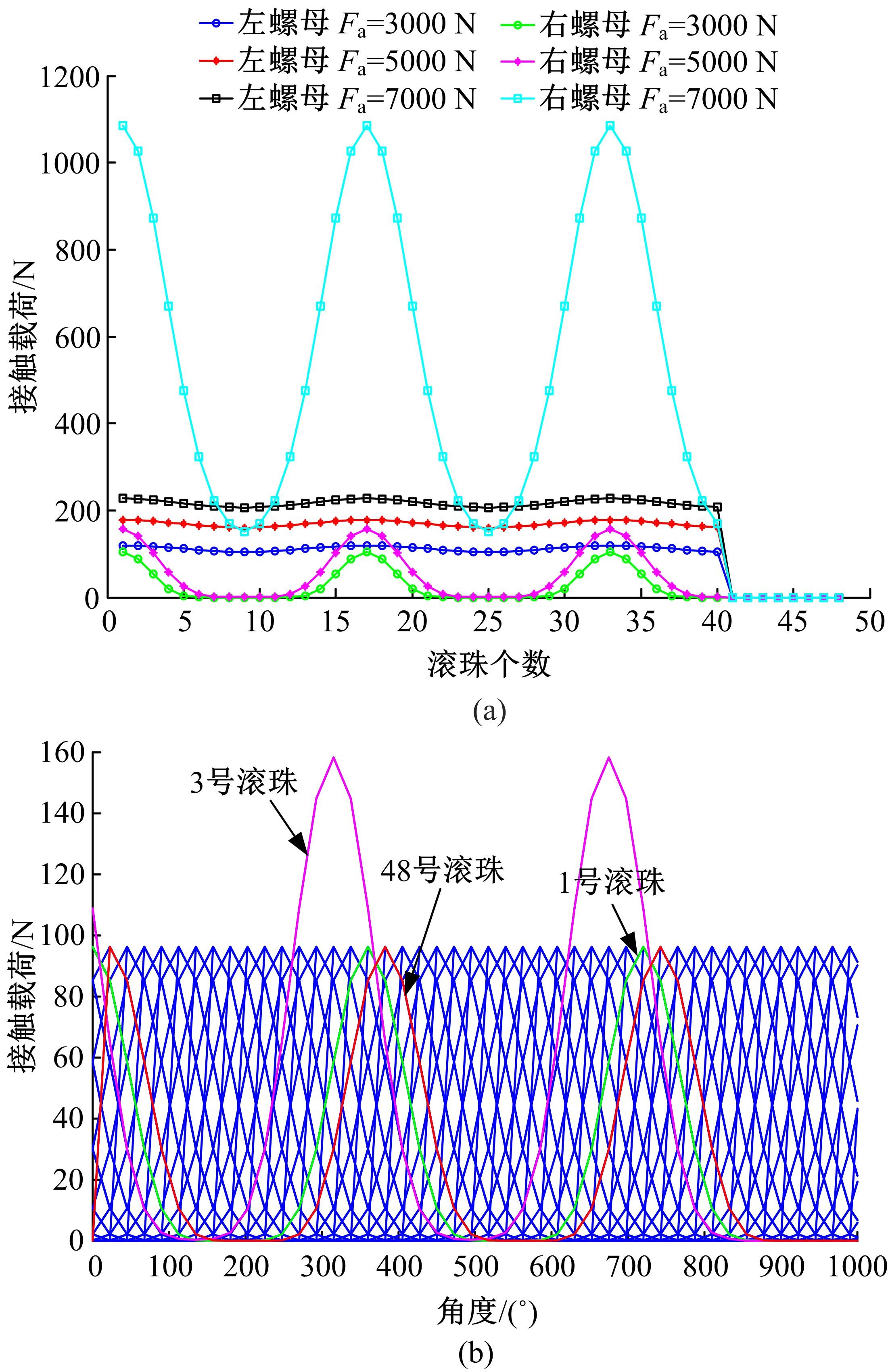

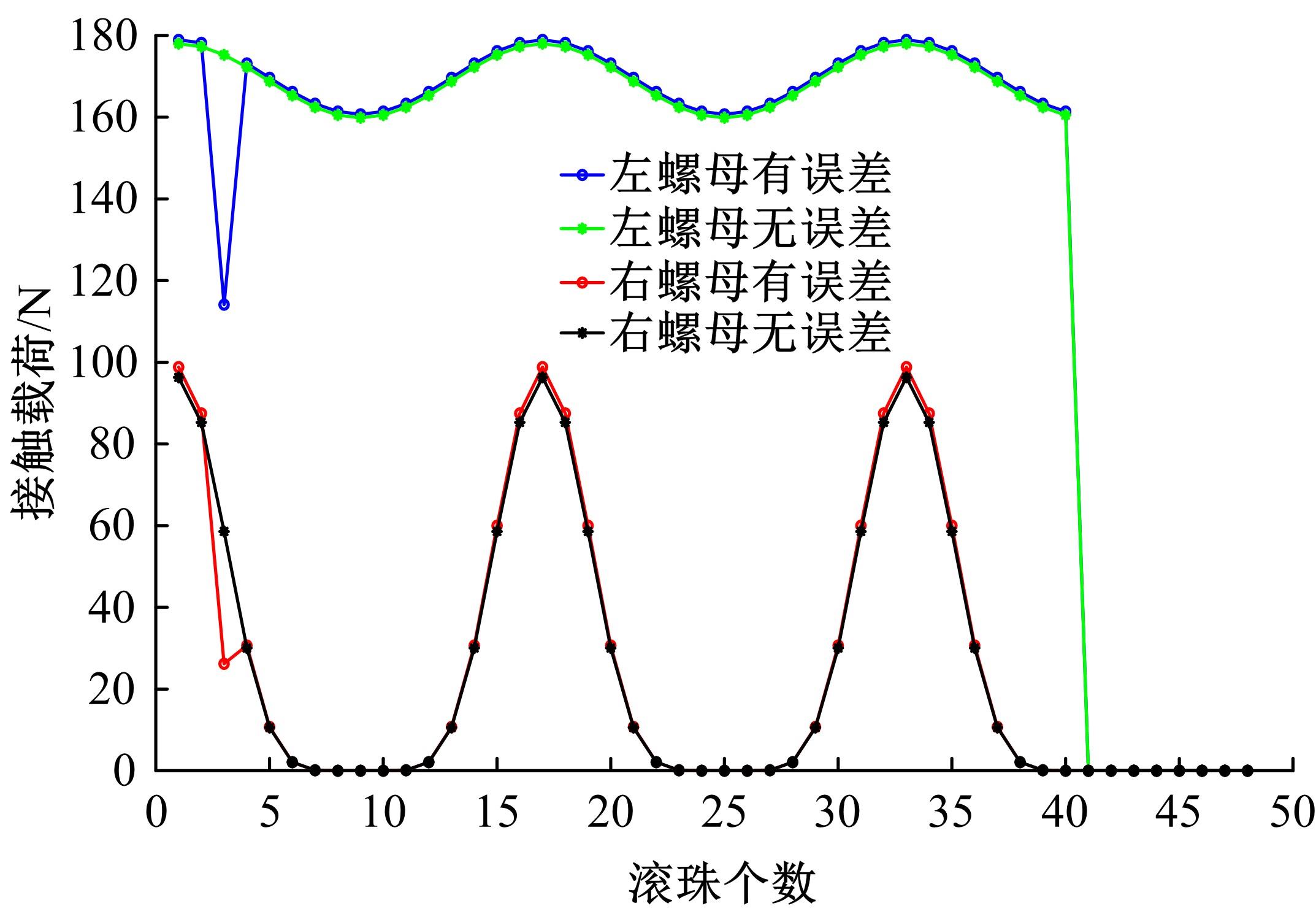

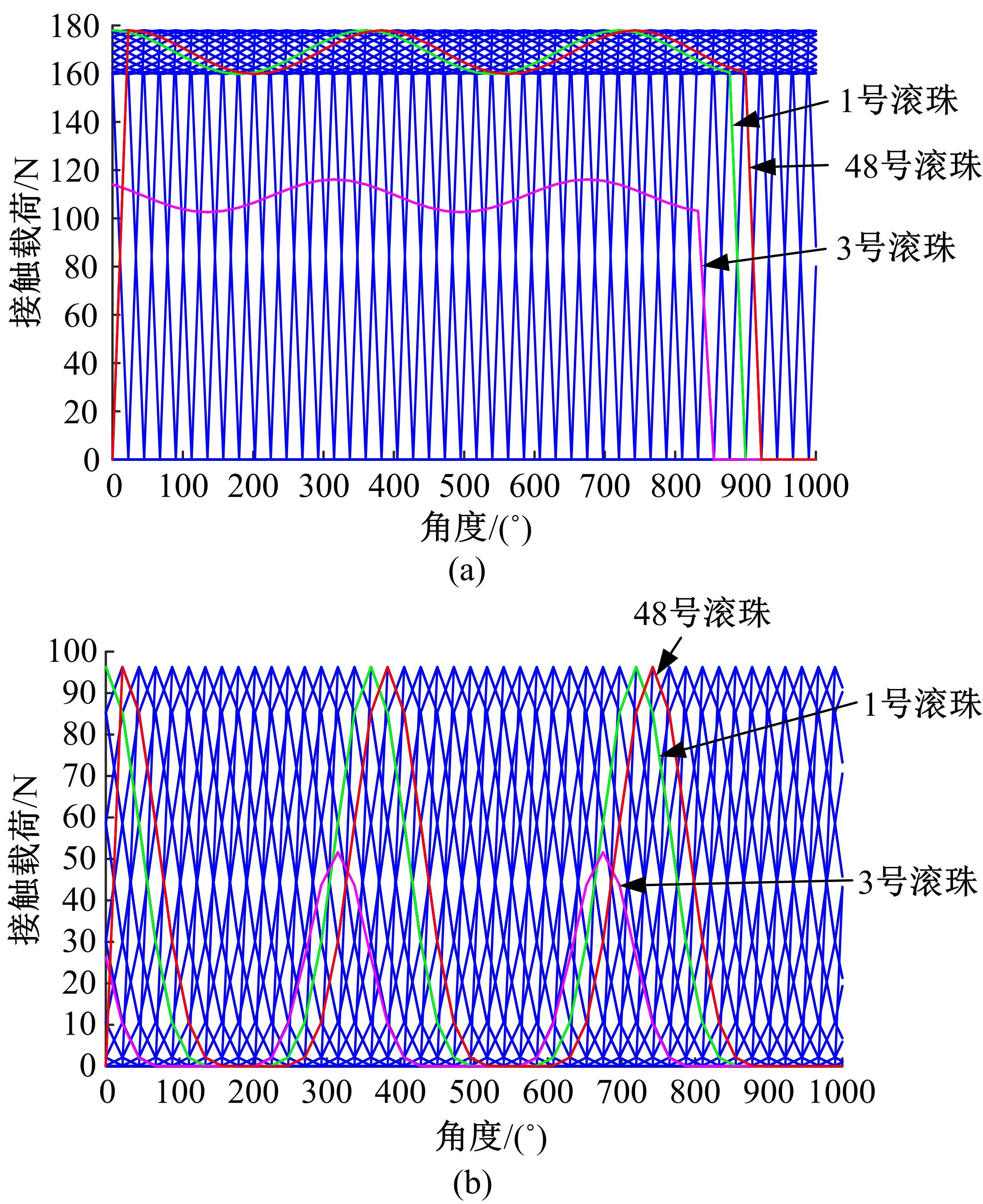

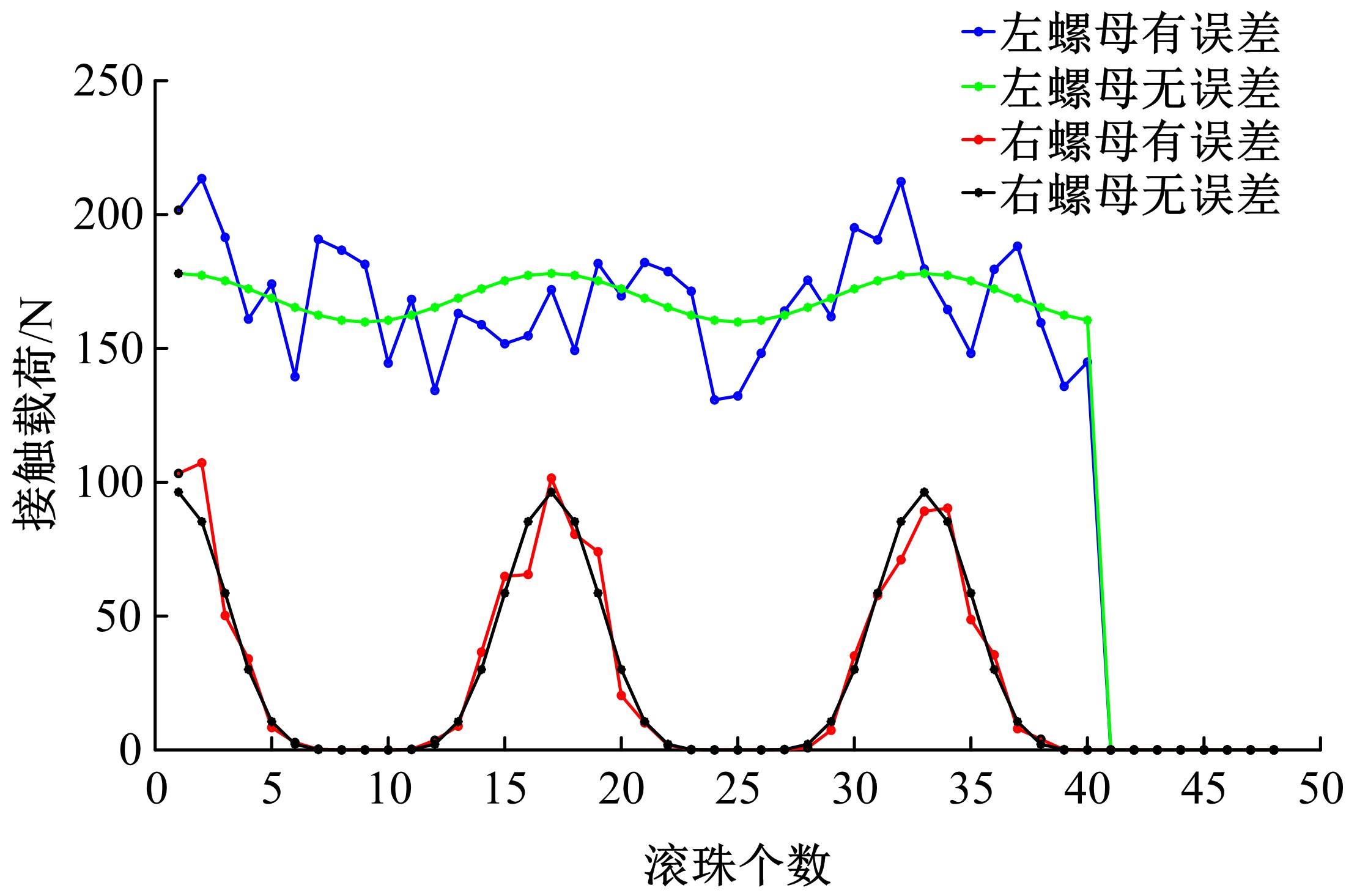

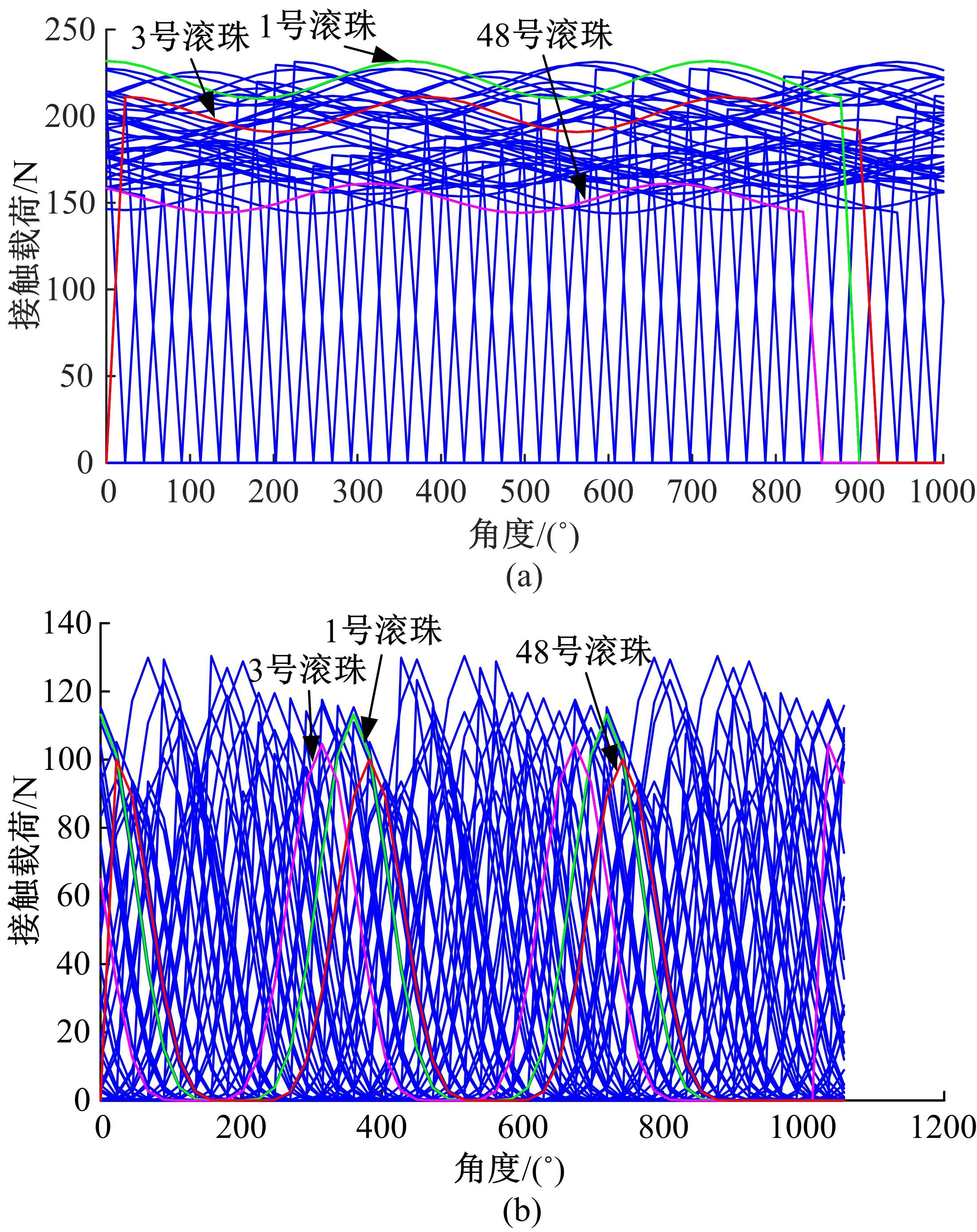

为提高滚珠丝杠副的定位精度,提出了一种复合载荷作用下考虑滚珠几何误差的双螺母滚珠丝杠副载荷分布模型,分析了在不同轴向载荷和径向载荷复合作用下所有滚珠接触载荷分布状况,在此基础上分析了滚珠几何误差对滚珠动静态接触载荷分布的影响。仿真分析结果表明:本文提出的载荷分布模型对提高滚珠丝杠副的位置精度预测及其定位误差补偿有较好的参考意义。

中图分类号:

- TH132

| 1 | 刘品, 刘岚岚. 可靠性工程基础[M].北京: 中国计量出版社, 2009. |

| 2 | 王庆年, 刘松山, 王伟华, 等. 滚珠丝杠式馈能型减振器的结构设计及参数匹配[J]. 吉林大学学报: 工学版, 2012, 42(5): 1100-1106. |

| Wang Qing-nian, Liu Song-shan, Wang Wei-hua, et al. Structural design and parameter matching of ball screw energy regenerative shock absorber[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(5): 1100-1106. | |

| 3 | Niu P, Cheng Q, Liu Z F, et al. A machining accuracy improvement approach for a horizontal machining center based on analysis of geometric error characteristics[J]. International Journal of Advanced Manufacturing Technology, 2021, 112(9/10): 2873-2887. |

| 4 | Qi B B, Cheng Q, Liu Z F, et al. Optimization analysis of structural parameters for ball screw precision retention based on advanced neural fuzzy network[J]. IEEE Access, 2020, 8: 199289-199307. |

| 5 | 潘凯, 梁医, 冯虎田, 等. 基于疲劳加速寿命试验的滚动直线导轨副寿命评价[J]. 组合机床与自动化加工技术, 2021(5): 38-42, 46. |

| Pan Kai, Liang Yi, Feng Hu-tian, et al. Life evaluation of rolling linear guide pair based on fatigue accelerated life test[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2021(5): 38-42, 46. | |

| 6 | 周长光, 冯虎田, 陈增涛. 滚珠丝杠副预紧力衰退预测及试验研究[J]. 机械工程学报, 2020, 56(12): 123. |

| Zhou Chang-guang, Feng Hu-tian, Chen Zeng-tao. Prediction and experimental study on preload decline of ball screw[J]. Chinese Journal of Mechanical Engineering, 2020, 56(12): 123. | |

| 7 | 束方婷, 冯虎田, 周长光, 等. 双螺母滚珠丝杠副摩擦力矩损失模型及试验研究[J]. 组合机床与自动化加工技术, 2019(4): 37-40. |

| Shu Fang-ting, Feng Hu-tian, Zhou Chang-guang, et al. Drag torque loss model and experimental study of double-nut ball screws[J]. Combined Machine Tool & Automatic Manufacturing Technique, 2019(4): 37-40. | |

| 8 | Kamalzadeh A, Gordon D J, Erkorkmaz K. Robust compensation of elastic deformations in ball screw derives[J]. International Journal of Machine Tools and Manufacture, 2010, 50(6): 559-574. |

| 9 | Feng G H, Pan Y L. Investigation of ball screw preload variation based on dynamic modeling of a preload adjustable feed-drive system and spectrum analysis of ball-nuts sensed vibration signals[J]. International Journal of Machine Tools and Manufacture, 2012, 52: 85-96. |

| 10 | Belayev V G, Turavinov V R. Effect of the lubricant on the performance characteristics of a ball and screw drive[J]. Soviet Engineering Research, 1983, 45(4): 578-586. |

| 11 | 陈勇将, 汤文成, 尹飞鸿, 等. 双螺母垫片预紧式滚珠丝杠副摩擦行为分析[J]. 南京理工大学学报,2016, 40(4): 392-398. |

| Chen Yong-jiang, Tang Wen-cheng, Yin Fei-hong, et al. Friction behavior analysis of ball screw with double nut gaskets[J]. Journal of Nanjing University of Science and Technology, 2016, 40(4): 392-398. | |

| 12 | 陈勇将, 汤文成. 微型滚珠丝杠副摩擦力矩模型的建立与实验验证[J]. 东南大学学报: 自然科学版,2011, 41(5): 982-986. |

| Chen Yong-jiang, Tang Wen-cheng. Establishment and experimental verification of friction torque model of miniature ball screw[J].Journal of Southeast University(Natural Science Edition), 2011, 41(5): 982-986. | |

| 13 | 徐向红, 汤文成, 俞涛, 等. 基于Archard理论的滚珠丝杠磨损预测[J]. 组合机床与自动化加工技术, 2016(2): 54-59. |

| Xu Xiang-hong, Tang Wen-cheng, Yu Tao, et al. Ball screw wear prediction based on archard theory [J]. Modular Machine Tool & Automatic Manufacturing Technique, 2016(2): 54-59. | |

| 14 | Cheng Q, Qi B B, Liu Z F, et al. Positioning accuracy degradation and lifetime prediction of the ball screw considering time-varying working conditions and feed modes[J]. Proceedings of the Institution of Mechanical Engineers Part B, Journal of Engineering Manufacture, 2021, 235(6/7): 943-957. |

| 15 | Cheng Q, Qi B B, Liu Z F, et al. An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions[J]. Mechanism & Machine Theory, 2019, 134: 1-23. |

| 16 | Chen Y J, Tang W C. Dynamic contact stiffness analysis of a double-nut ball screw based on a quasistatic method[J]. Mechanism and Machine Theory, 2014, 73: 76-90. |

| 17 | 赵帼娟, 张雷, 卢磊, 等. 四轴抛光平台综合误差建模及分析[J]. 吉林大学学报: 工学版, 2014, 44(6): 1676-1683. |

| Zhao Guo-juan, Zhang Lei, Lu Lei, et al.Modeling and analysis of the volumetric errors of four-axis polishing platform[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(6): 1676-1683. | |

| 18 | 刘庆民, 王龙山, 陈向伟, 等. 滚珠螺母的机器视觉检测[J]. 吉林大学学报: 工学版, 2006, 36(4): 534-538. |

| Liu Qing-min, Wang Long-shan, Chen Xiang-wei, et al. Machine vision inspection of ball nuts[J]. Journal of Jilin University(Engineering and Technology Edition), 2006, 36(4): 534-538. | |

| 19 | 周长光. 滚珠丝杠副预紧力衰退预测及试验研究[D]. 南京: 南京理工大学机械工程学院, 2018. |

| Zhou Chang-guang. Prediction and experimental research on preload decline of ball screw[D]. Nanjing: School of Machanical Engineering, Nanjing University of Science and Technology, 2018. | |

| 20 | Ni Z, Qi A. Analysis of stress and fatigue life of ball screw with considering the dimension errors of balls[J]. International Journal of Mechanical Sciences, 2018, 137: 68-76. |

| 21 | Mei X S, Tsutsumi M, Tao T, et al. Study on the load distribution of ball screws with errors[J]. Mechanism and Machine Theory, 2003, 38(11):1257-1269. |

| [1] | 刘永平,董长斌,魏永峭. 椭圆齿轮传动系统齿面接触与动态磨损分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1620-1627. |

| [2] | 董长斌,刘永平,魏永峭,邓海青,许杰. 椭圆齿轮传动系统非线性动态特性分析[J]. 吉林大学学报(工学版), 2020, 50(2): 483-493. |

| [3] | 王家序,蒋倩倩,李俊阳,韩彦峰,张雷,唐挺. 双圆弧谐波传动柔轮齿形参数多目标优化设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1194-1202. |

| [4] | 陈忠敏, 侯力, 段阳, 张祺, 杨忠学, 蒋易强. 新型摆线针轮行星减速器传动系统的振动特性[J]. 吉林大学学报(工学版), 2018, 48(1): 174-185. |

| [5] | 王家序, 袁攀, 谭春林, 何永强, 李俊阳, 肖科. 基于齿条近似法的谐波传动空间齿廓设计方法[J]. 吉林大学学报(工学版), 2017, 47(4): 1121-1129. |

| [6] | 王海, 姚刚, 邱皖群, 杨春来, 付邦晨. 基于波纹梁的两自由度低频振动能量收集装置[J]. 吉林大学学报(工学版), 2017, 47(4): 1144-1148. |

| [7] | 范成岩, 许树新, 王洪军, 孟繁忠. 三轴正时链系统的磨损及其限定条件[J]. 吉林大学学报(工学版), 2017, 47(1): 122-128. |

| [8] | 林超, 刘毅, 魏艳群, 朱才朝. 端曲面齿轮副复合运动规律及受力分析[J]. 吉林大学学报(工学版), 2017, 47(1): 157-162. |

| [9] | 欧阳天成, 陈南, 牛亚峰. 不同粗糙面渐开线齿轮混合弹流润滑[J]. 吉林大学学报(工学版), 2016, 46(6): 1933-1939. |

| [10] | 林超, 顾思家, 刘毅. 点接触正交变传动比面齿轮副重合度分析[J]. 吉林大学学报(工学版), 2016, 46(2): 471-478. |

| [11] | 李云峰, 王黎钦, 王帅, 安浩俊. 航空发动机中介轴承试验器的研制[J]. 吉林大学学报(工学版), 2016, 46(1): 179-185. |

| [12] | 郭建华, 姜洪源, 胡清明, 李嘉博. 新型人字齿同步带传动干涉与啮合仿真分析[J]. 吉林大学学报(工学版), 2015, 45(4): 1175-1180. |

| [13] | 宋宝玉,解志杰,张锋,王瑞泽,郝明晖,苏代忠. 基于角度域同步平均和阶次分析的低速斜齿轮故障诊断[J]. 吉林大学学报(工学版), 2015, 45(2): 454-459. |

| [14] | 程亚兵,王洋,李磊,安立持,殷帅兵. 汽车V型发动机用正时链传动系统的设计[J]. 吉林大学学报(工学版), 2015, 45(1): 139-144. |

| [15] | 李文良, 王黎钦, 常山, 戴光昊. 齿面摩擦对齿轮系统谐波共振的影响[J]. 吉林大学学报(工学版), 2013, 43(05): 1290-1294. |

|

||