吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3397-3403.doi: 10.13229/j.cnki.jdxbgxb.20220054

• 材料科学与工程 • 上一篇

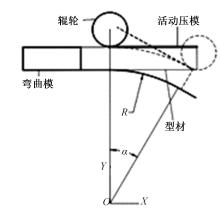

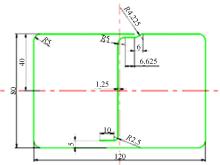

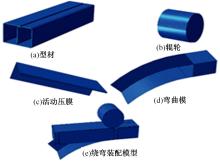

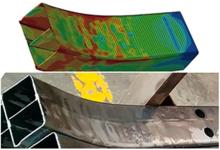

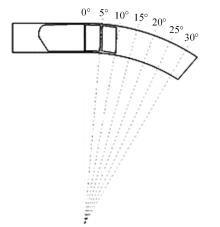

日字形防护梁绕弯成形形变数值模拟

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 重庆研究院,重庆 401123

Numerical simulation on deformation of protective beam with “日”-shaped section during rotary draw bending

Ce LIANG1( ),Fu-lei HUANG1,Ji-cai LIANG1,2,Yi LI1(

),Fu-lei HUANG1,Ji-cai LIANG1,2,Yi LI1( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Chongqing Research Institute,Jilin University,Chongqing 401123,China

摘要:

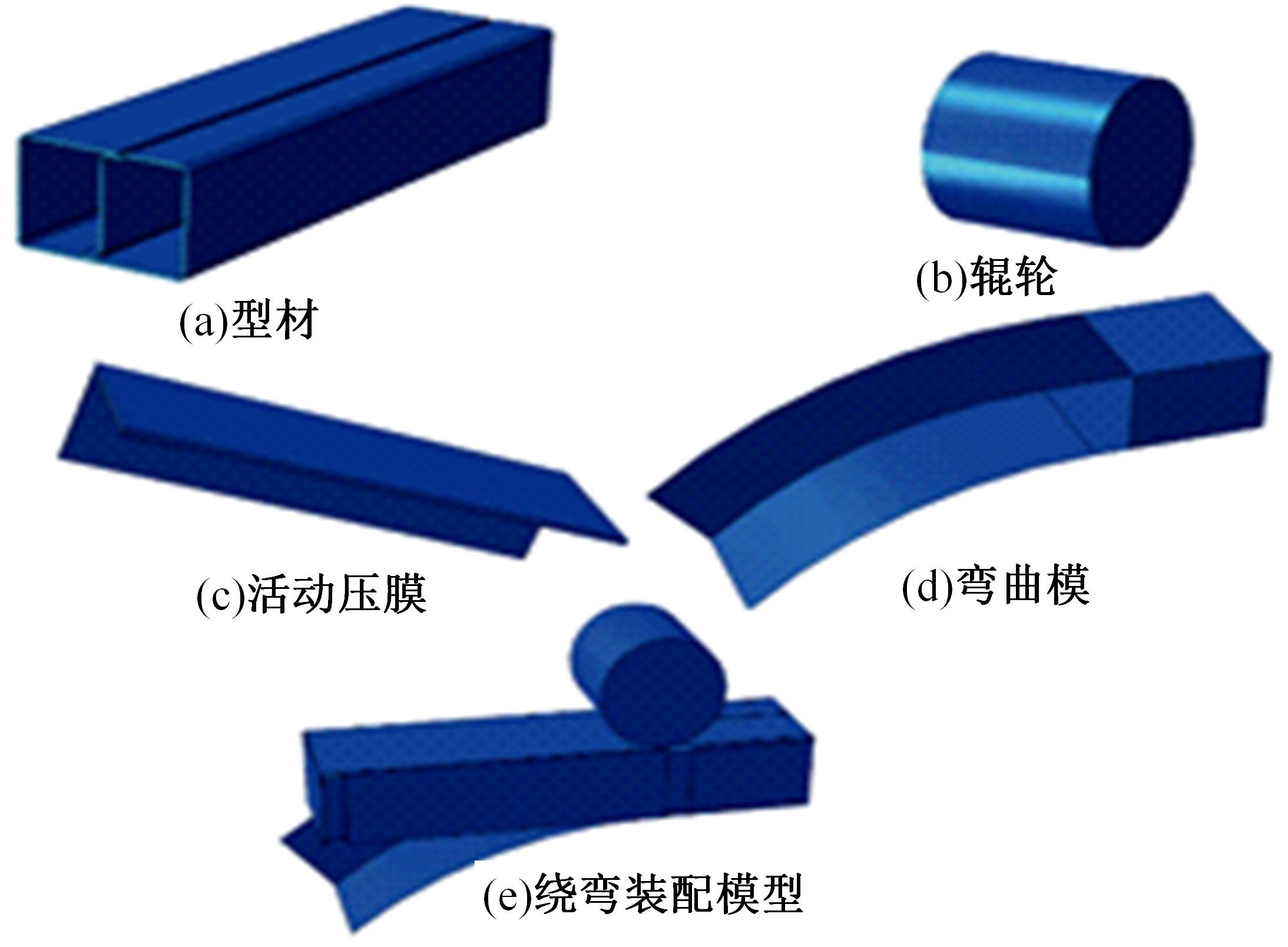

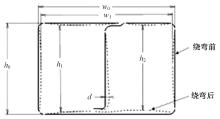

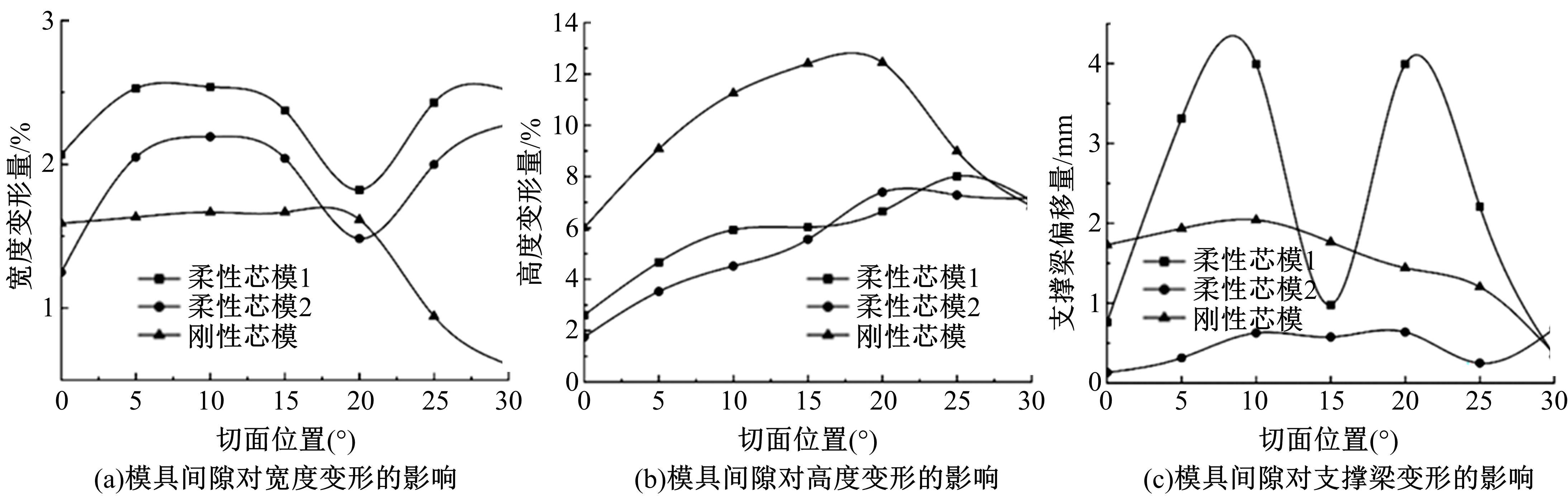

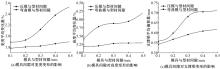

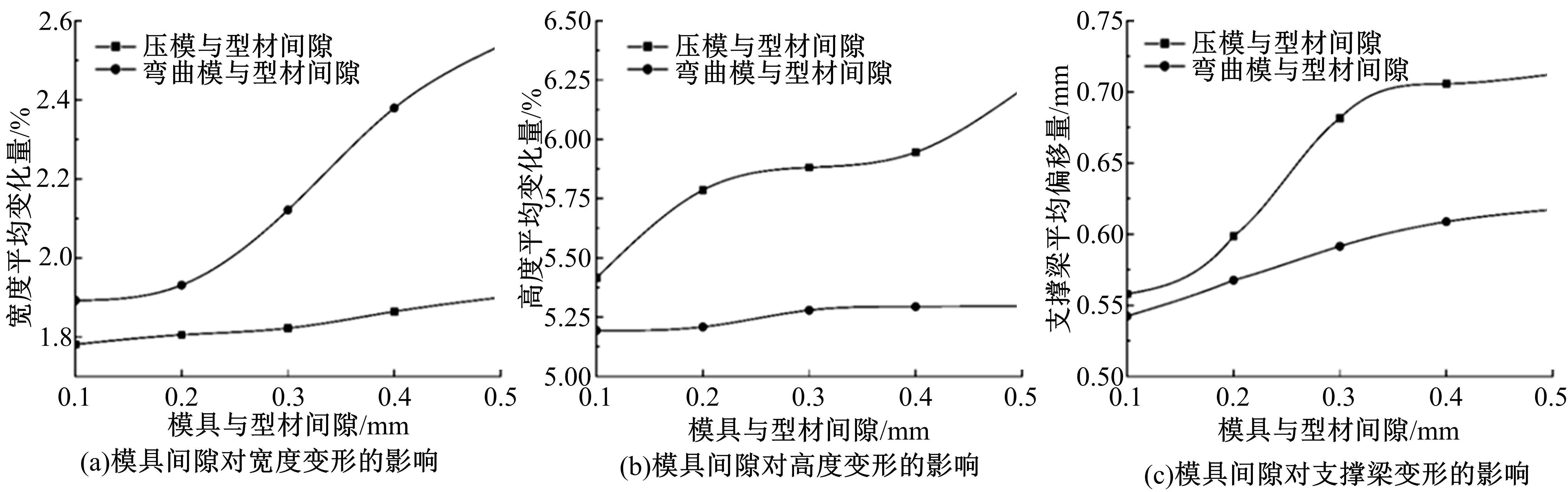

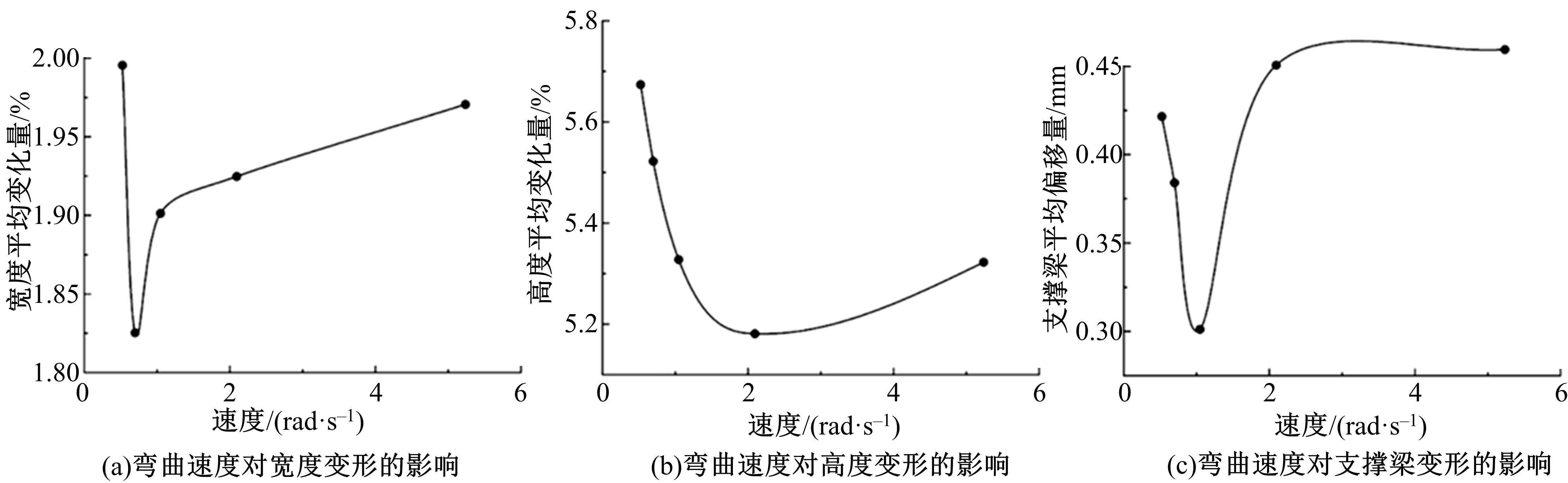

使用有限元模拟方法,建立了“日”字形截面防护梁绕弯成形过程的有限元模型,并对其可靠性进行验证。解决了高强钢防护梁产品质量预测问题,得到了芯模种类、型材厚度和绕弯成形速度对截面变形的影响规律。结果表明,带有自锁装置的柔性芯模对截面变形的抵制效果最好。随着型材厚度的增加,截面变形减小;随着弯曲速度的增大,截面变形先减小后增大。该方法为防护梁产品成形质量预测提供了理论依据。

中图分类号:

- TG356

| 1 | 王爱成. 商用车防护梁辊弯与绕弯成形技术研究[D]. 长春: 吉林大学材料科学与工程学院, 2019. |

| Wang Ai-cheng. Research on roll forming and pure rolling rotary draw bending technologies of commercial vehicle bumper beam[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2019. | |

| 2 | Liang Ji-cai, Chen Chuan-dong, Liang Ce, et al. One-time roll-forming technology for high-strength steel profiles with "日" section[J]. Advances in Materials Science and Engineering, 2019(5): No. 6505914. |

| 3 | Liang Ji-cai, Li Jian-dong, Wang Ai-cheng, et al. Study on the influence of different cores on section quality in the process of pure rolling rotary draw bending wrinkling of profiles with "日"-shape section[J]. The International Journal of Advanced Manufacturing Technology, 2020, 110(1/2): 471-479. |

| 4 | Liu Hai-long, Liu Yu-li. Cross section deformation of heterogeneous rectangular welded tube in rotary draw bending considering different yield criteria[J]. Journal of Manufacturing Processes, 2021, 61: 303-310. |

| 5 | 张洪烈. 考虑各向异性本构的H96双脊矩形管E弯截面变形研究[D]. 西安: 西北工业大学材料学院, 2018. |

| Zhang Hong-lie. Study on the cross sectional deformation of double-ridged rectangular H96 tube in E-type bending considering anisotropic constitutive[D]. Xi'an: School of Materials Science and Engineering, Northwestern Polytechnical University, 2018. | |

| 6 | Zhang Hong-lie, Liu Yu-li. An innovative PVC mandrel for controlling the cross-sectional deformation of double-ridged rectangular tube in rotary draw bending[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95(1): 1303-1313. |

| 7 | Liu Chun-mei, Liu Yu-li, Sun Hong. A novel method to reduce the distortion of ridged rectangular tube in H-typed rotary draw bending[J]. International Journal of Advanced Manufacturing Technology, 2019, 104(5-8): 2149-2161. |

| 8 | Simonetto E, Venturato G, Ghiotti A, et al. Modelling of hot rotary draw bending for thin-walled titanium alloy tubes[J]. International Journal of Mechanical Sciences, 2018, 148: 698-706. |

| 9 | Kajikawa S, Wang G H, Kuboki T, et al. Prevention of defects by optimizing mandrel position and shape in rotary draw bending of copper tube with thin wall[C]∥Proceedings of the 17th International Conference on Metal Forming, Toyohashi, Japan, 2018: 828-835. |

| 10 | Nakajima K, Utsumi N, Saito Y, et al. Deformation property and suppression of ultra-thin-walled rectangular tube in rotary draw bending[J]. Metals, 2020, 10(8): No. 1074. |

| 11 | 王翠竹, 牛卫中. 芯管间隙对JAC590Y高强钢矩形管绕弯成形质量的影响[J]. 锻压技术, 2020, 45: 94-99. |

| Wang Cui-zhu, Niu Wei-zhong. Influences of clearance between mandrel and tube on forming quality for JAC590Y high strength steel rectangular tube in rotary-draw bending[J]. Forging & Stamping Technology, 2020, 45: 94-99. | |

| 12 | 王翠竹, 牛卫中. 弯曲角度与半径对Q345钢矩形管绕弯截面畸变的影响[J]. 塑性工程学报, 2021, 28: 112-118. |

| Wang Cui-zhu, Niu Wei-zhong. Influences of bending angle and radius on section distortion of Q345 steel rectangular tube in rotary-draw bending[J]. Journal of Plasticity Engineering, 2021, 28: 112-118. | |

| 13 | 汪倩. 高强钢矩形管绕弯时宽高比对截面畸变的影响[J]. 机械研究与应用, 2018, 31: 69-70, 80. |

| Wang Qian. Influences of width-depth ratio on cross-sectional distortion of high strength steel rectangular tube in rotary draw bending[J]. Mechanical Research & Application, 2018, 31: 69-70, 80. | |

| 14 | 欧阳芳, 鲁世强, 方军, 等. 几何参数对变弹性模量条件下21-6-9管绕弯成形质量的影响[J]. 塑性工程学报, 2020, 27: 27-37. |

| Ouyang Fang, Lu Shi-qiang, Fang Jun, et al. Effect of geometrical parameters on forming quality of 21-6-9 tube inrotary draw bending under condition of variable elastic modulus[J]. Journal of Plasticity Engineering, 2020, 27: 27-37. | |

| 15 | 付志强, 安子军, 杜凤山,等. 方矩形管连续辊弯成型延伸规律[J]. 吉林大学学报:工学版, 2015, 45(2): 487-493. |

| Fu Zhi-qiang, An Zi-jun, Du Feng-shan, et al. Elongation of rectangular tube in continuous roll forming[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(2): 487-493. | |

| 16 | 仉志强, 付建华, 宋建丽, 等. 厚向强度分布对特厚板三辊预弯成形的影响[J]. 吉林大学学报:工学版, 2015, 45(3): 878-883. |

| Zhang Zhi-qiang, Fu Jian-hua, Song Jian-li. Influence of material strength distribution along thickness on three-roller edge pre-bending of thick plate[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(3): 878-883. |

| [1] | 梁言,王强,宋雨来,刘耀辉. 新型5Cr5MoV模具钢修复性能[J]. 吉林大学学报(工学版), 2022, 52(6): 1301-1307. |

| [2] | 金文明,梁田,梁策,李义,李俊涛,梁继才. 工艺参数对汽车防护梁绕弯成形的截面变形影响[J]. 吉林大学学报(工学版), 2021, 51(4): 1182-1189. |

| [3] | 周杰, 罗艳, 王珣, 王辉, 李洋, 陶亚平. 基于响应面的封头冲压成形工艺多目标优化[J]. 吉林大学学报(工学版), 2016, 46(1): 205-212. |

|

||