吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (4): 1182-1189.doi: 10.13229/j.cnki.jdxbgxb20200807

• 车辆工程·机械工程 • 上一篇

工艺参数对汽车防护梁绕弯成形的截面变形影响

金文明1,2( ),梁田1,2,梁策1(

),梁田1,2,梁策1( ),李义1,李俊涛1,3,梁继才1,2

),李义1,李俊涛1,3,梁继才1,2

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 辊锻工艺研究所,长春 130022

3.长春富维安道拓汽车饰件系统有限公司,长春 130033

Influence of process parameters on cross-sectional deformation of rotary draw bending forming of automobile protective beams

Wen-ming JIN1,2( ),Tian LIANG1,2,Ce LIANG1(

),Tian LIANG1,2,Ce LIANG1( ),Yi LI1,Jun-tao LI1,3,Ji-cai LIANG1,2

),Yi LI1,Jun-tao LI1,3,Ji-cai LIANG1,2

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute,Jilin University,Changchun 130022,China

3.Changchun Faway Adient Automotive System Co. ,Ltd. ,Changchun 130033,China

摘要:

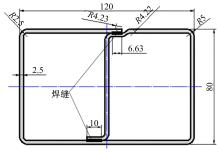

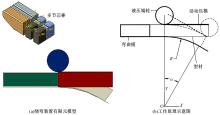

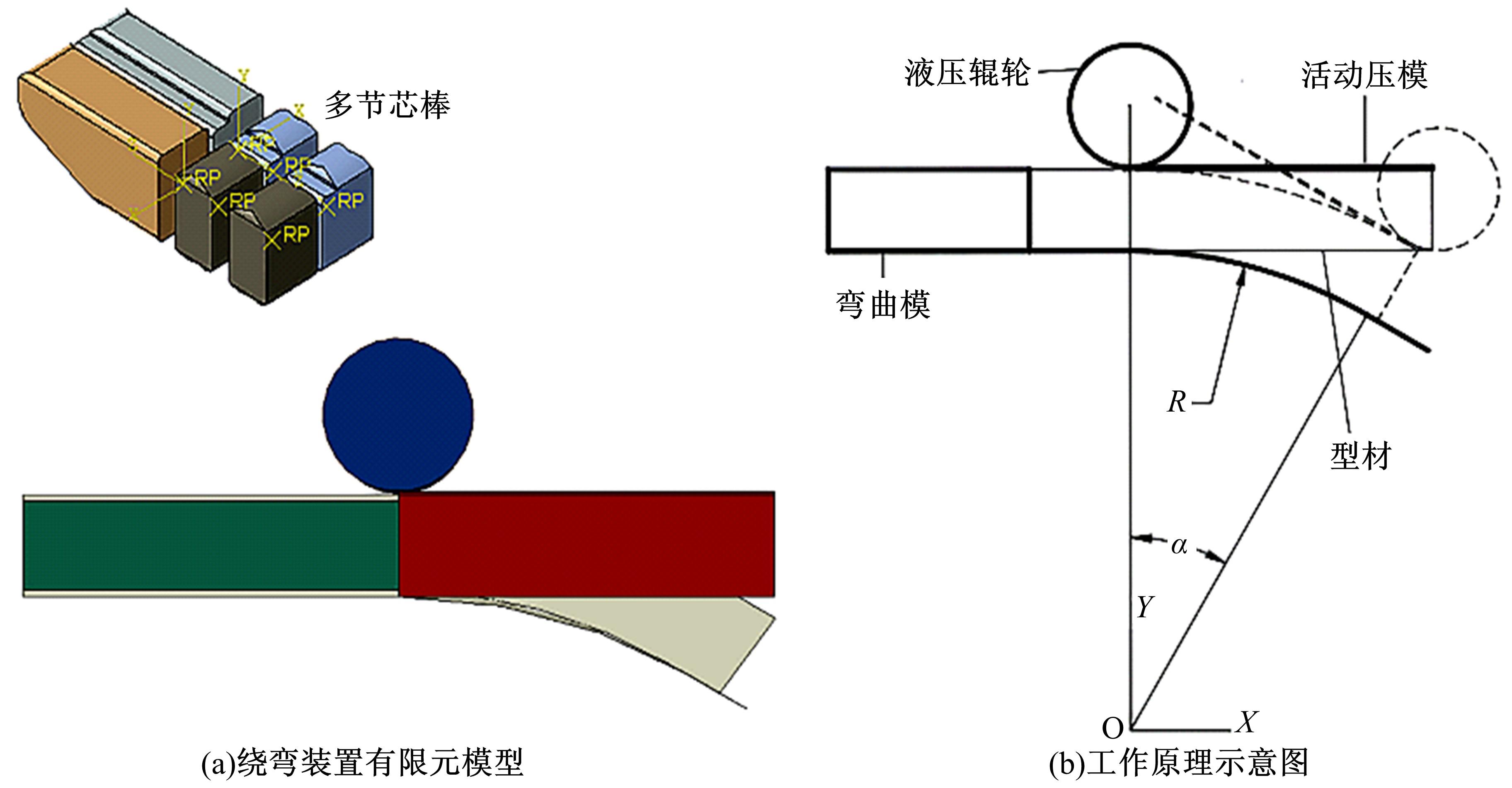

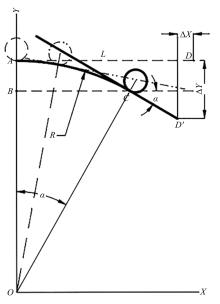

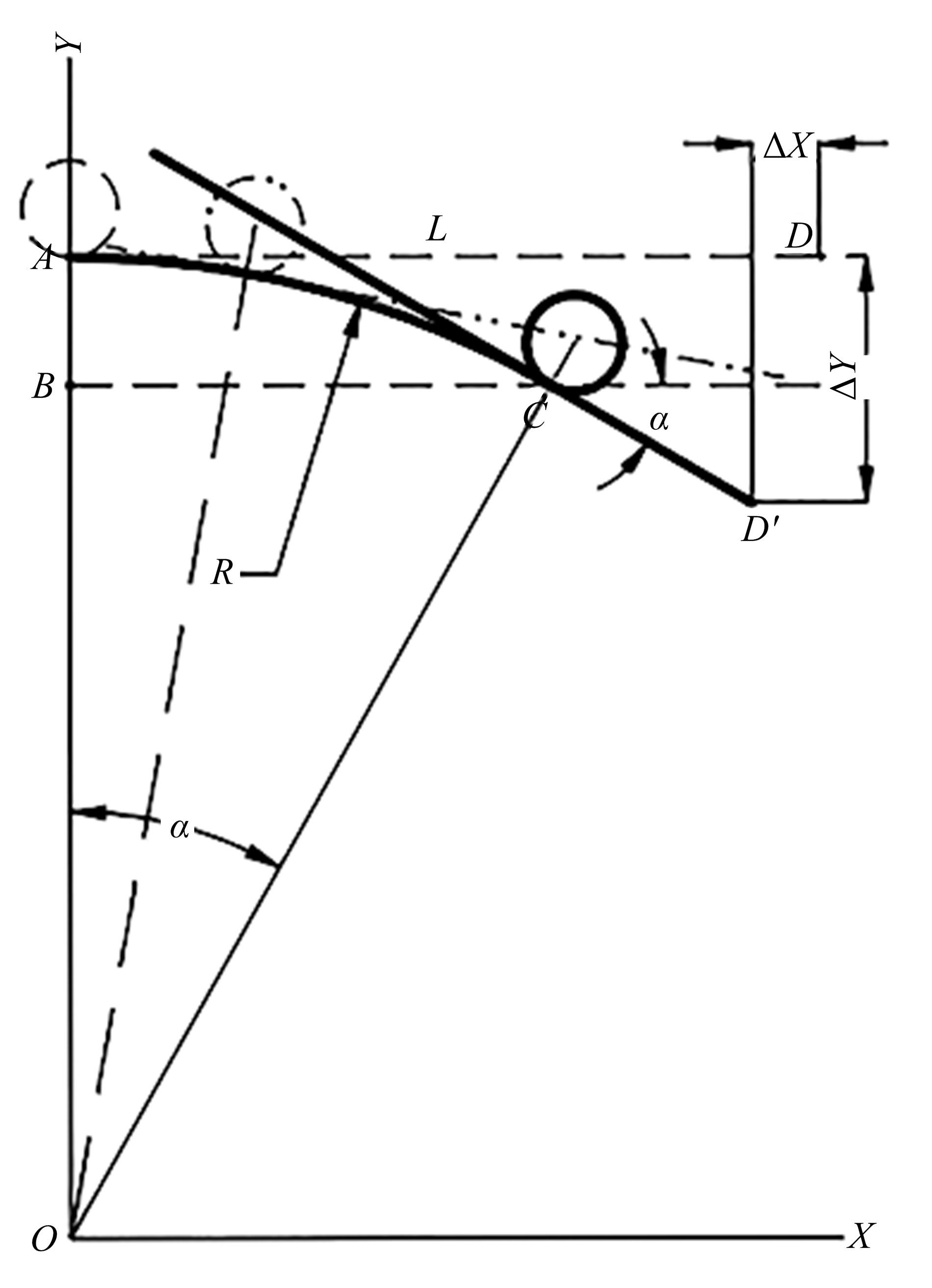

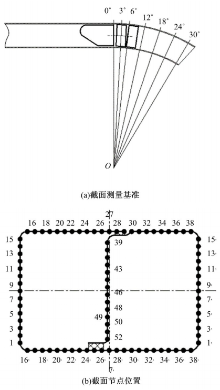

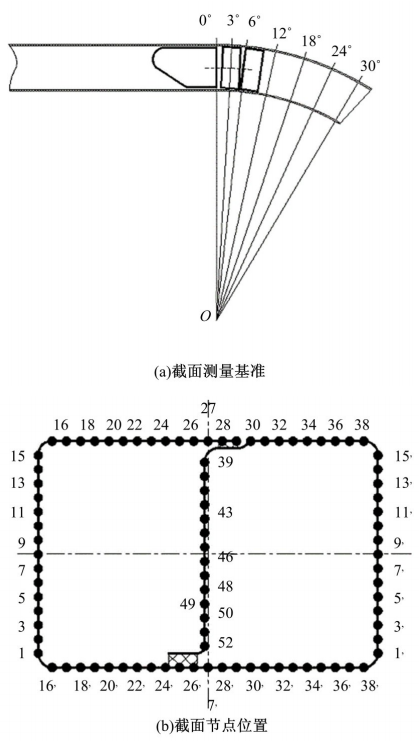

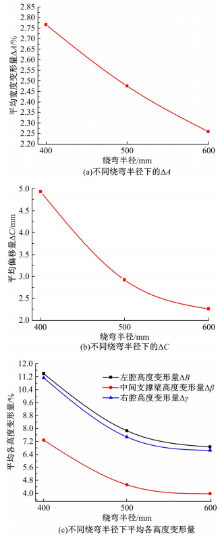

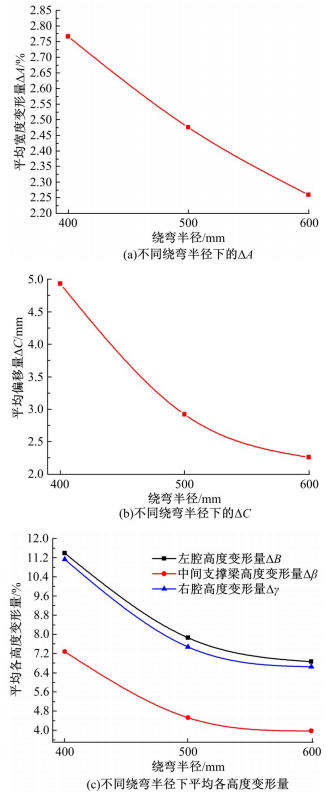

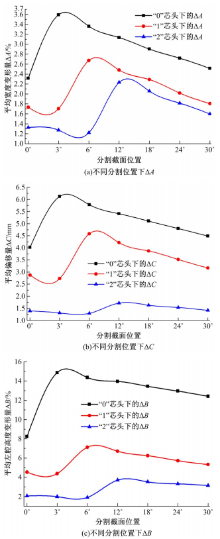

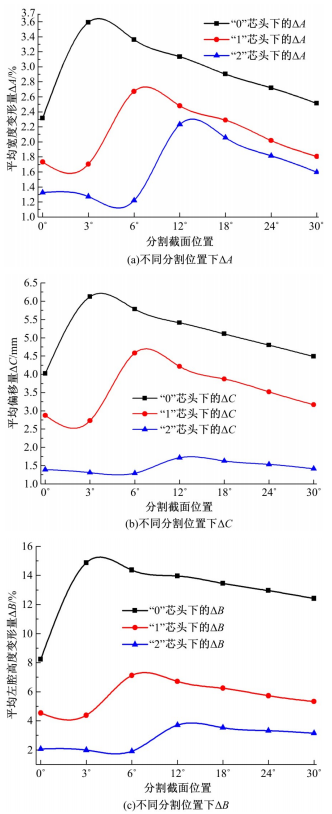

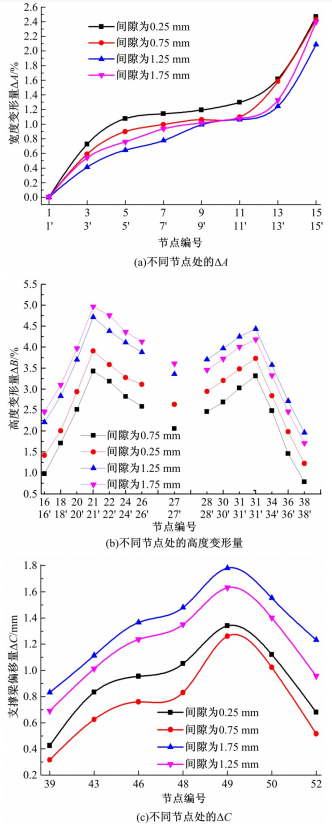

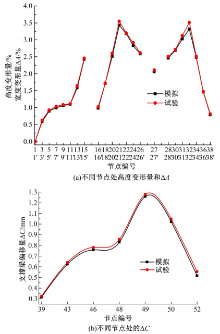

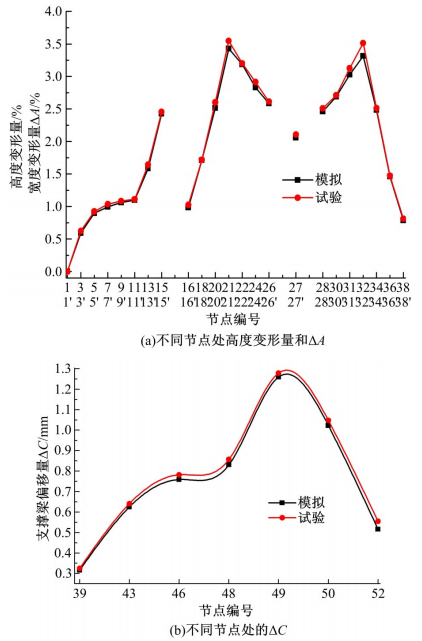

针对“日”字截面型材在绕弯成汽车防护梁过程中产生的截面变形缺陷,基于自主研发的绕弯装置,利用有限元分析软件ABAQUS和正交试验模拟方法,探究了工艺参数中绕弯半径,芯棒的芯头数及芯模间隙对截面变形的综合影响规律。结果表明:最大变形截面位置受芯头个数的影响;截面的各变形量都随绕弯半径和芯头个数的增加而减小,随芯模间隙先减小后增大;工艺参数组合为绕弯半径600 mm,芯头数为2,间隙为0.75 mm的防护梁成形方案减轻截面变形效果较好,并且通过试验验证了模拟结果的有效性。

中图分类号:

- TG356

| 1 | 刘丽亚,苏玉萍,郭立群,等. 商用车前下部防护法规和国外典型设计案例分析[J]. 汽车技术, 2008(7): 15-18. |

| Liu Li-ya, Su Yu-ping, Guo Li-qun, et al. Lower front part protective regulations for commercial vehicles and analysis of the typical design structure abroad[J]. Automobile Technology, 2008(7): 15-18. | |

| 2 | Liang Ji-cai,Chen Chuan-dong,Liang Ce,et al. One-time roll-forming technology for high-strength steel profiles with "日" section[J]. Advances in Materials Science and Engineering, 2019, No. 6505914: 1-10. |

| 3 | 徐智伟. 高强钢矩形截面管弯曲成形研究[D]. 哈尔滨:哈尔滨工业大学机电学院, 2014. |

| Xu Zhi-wei. Research on bend forming of rectangular section tube for high strength steel[D]. Harbin:School of Electrical and Mechanical Sciences, Harbin Institute of Technology, 2014. | |

| 4 | 李海平,刘郁丽,朱英霞,等. 芯模对双脊矩形管绕弯成形截面畸变的影响[J]. 材料科学与工艺,2014, 22(3): 46-53. |

| Li Hai-ping, Liu Yu-li, Zhu Ying-xia, et al. Influence of mandrel on cross section deformation of double-ridge rectangular tube in rotary-draw bending process[J]. Materials Science and Technology, 2014,22(3):46-53. | |

| 5 | Paulsen F, Welo T. A design method for prediction of dimensions of rectangular hollow sections formed in stretch bending[J]. Journal of Materials Processing Technology, 2002, 128(1): 48-66. |

| 6 | 方军,鲁世强,王克鲁,等. 管模间隙对21-6-9高强不锈钢管数控绕弯成形质量的影响[J]. 北京理工大学学报, 2015, 35(9): 886-891. |

| Fang Jun, Lu Shi-qiang, Wang Ke-lu, et al. Effect of clearance between tube and dies on forming quality in nc bending process of high strength 21-6-9 stainless steel tube[J]. Transactions of Beijing Institute of Technology, 2015, 35(9): 886-891. | |

| 7 | 刘郁丽,卢彩红,赵刚要,等. 间隙对薄壁矩形管绕弯成形截面畸变影响的研究[J]. 中国机械工程,2008, 19(16): 1972-1975. |

| Liu Yu-li, Lu Cai-hong, Zhao Gang-yao, et al. Effect of clearance on cross section distortion of thin-walled rectangular tube in rotary draw bending press[J]. China Mechanical Engineering, 2008, 19(16): 1972-1975. | |

| 8 | 王子昂,刘俊. 基于正交试验设计的弯管芯棒形状参数优化[J]. 塑性工程学报, 2020, 27(6): 59-65. |

| Wang Zi-ang, Liu Jun. Shape parameter optimization of mandrel for tube bending based on orthogonal expermental design[J]. Journal of Plasticity Engineering, 2020, 27(6): 59-65. | |

| 9 | 王爱成. 商用车防护梁辊弯与绕弯成形技术研究[D]. 长春:吉林大学材料科学与工程学院, 2019. |

| Wang Ai-cheng. Research on roll forming and pure rolling rotary draw bending technologies of commercial vehicle bumper beam[D]. Changchun: School of Materials Science and Engineering, Jilin University, 2019. | |

| 10 | Liang Ji-cai, Li Jian-dong, Wang Ai-cheng, et al. Study on the influence of different cores on section quality in the process of pure rolling rotary draw beding wrinkling of profiles with"日"-shape section[J]. International Journal of Advanced Manufacturing Technology, 2020, 110(1/2): 471-479. |

| 11 | 张洪烈. 考虑各向异性本构的H96双脊矩形管E弯截面变形研究[D]. 西安:西北工业大学材料学院, 2018. |

| Zhang Hong-lie. Study on the cross sectional deformation of double-ridged rectangular H96 tube in E-type bending considering anisotropic constitutive[D]. Xi'an:School of Materials Science,Northwestern Polytechnical University, 2018. | |

| 12 | 李佳佳,刘郁丽,赵刚要,等. 工艺参数对薄壁矩形管绕弯成形失稳起皱影响的显著性分析[J]. 热加工工艺,2010, 39(13): 77-80. |

| Li Jia-jia, Liu Yu-li, Zhao Gang-yao, et al. Study on significant influence of process parameters on wrinkling of rotary-draw bending formation of thin walled rectangular tube[J]. Hot Working Technology, 2010,39(13): 77-80. | |

| 13 | 贾美慧,唐承统,王文刚. 工艺参数对管材绕弯成形质量的显著性影响分析[J]. 机床与液压,2012, 40(21): 29-33. |

| Jia Mei-hui, Tang Cheng-tong, Wang Wen-gang. Significant influence of process parameters on tube forming quality in rotary-draw bending[J]. Machine Tool and Hydrulics, 2012, 40(21): 29-33. | |

| 14 | 刘郁丽,杨合,崔姗姗,等. 薄壁矩形管弯曲过程截面畸变的三维有限元分析[J]. 塑性工程学报,2007,14(3): 72-75. |

| Liu Yu-li, Yang He, Cui Shan-shan, et al. 3-D FEM analysis of section distortion in bending process of the thin-walled rectangular tube[J]. Journal of Plasticity Engineering, 2007,14(3): 72-75. |

| [1] | 梁继才,廖雁飞,滕菲,梁策,李义. 矩形截面型材三维多点拉弯成形减薄率[J]. 吉林大学学报(工学版), 2021, 51(1): 163-171. |

| [2] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [3] | 孙博华, 邓伟文, 朱冰, 吴坚, 王姗姗. 基于反应式行为的车辆运动意图辨识[J]. 吉林大学学报(工学版), 2018, 48(1): 36-43. |

| [4] | 张泽星, 陈国迎, 宗长富. 基于灵敏度分析的EPS转向性能试验客观评价指标[J]. 吉林大学学报(工学版), 2015, 45(4): 1043-1048. |

| [5] | 齐龙, 谭祖庭, 马旭, 陈国锐, 谢俊锋, 邝健霞. 气动振动式匀种装置工作参数的优化及试验[J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [6] | 董立春1,韩志武2,吕尤2,牛士超2,马荣峰2,任露泉2. 凹坑型仿生形态环块样件耐磨性能[J]. 吉林大学学报(工学版), 2011, 41(6): 1659-1663. |

| [7] | 韦大川, 王云鹏, 李世武, 孙文财, 杨志发. 橡胶粉/SBS复合改性沥青吸声系数试验[J]. 吉林大学学报(工学版), 2010, 40(增刊): 199-0203. |

| [8] | 任丽丽, 周江, 佟金. 烯基琥珀酸酐表面改性淀粉膜羟基取代度的影响因素[J]. 吉林大学学报(工学版), 2010, 40(06): 1624-1628. |

| [9] | 高峰;黄河;任露泉 . 新疆岩蜥三元耦合耐冲蚀磨损特性及其仿生试验[J]. 吉林大学学报(工学版), 2008, 38(03): 586-0590. |

| [10] | 王京春,陈丽莉,任露泉,谷松涛,丛茜 . 仿生注射器针头减阻试验研究[J]. 吉林大学学报(工学版), 2008, 38(02): 379-0382. |

| [11] | 任露泉, 彭宗尧, 陈庆海, 赵国如, 王涛杰 . 离心式水泵仿生非光滑增效的试验研究[J]. 吉林大学学报(工学版), 2007, 37(03): 575-0581. |

| [12] | 赵国如, 任露泉, 田丽梅, 韩志武, 张世村, 都金丹. 利用逆向制造系统集成技术开发仿生防粘鞋底[J]. 吉林大学学报(工学版), 2005, 35(06): 649-0653. |

| [13] | 任露泉, 张成春, 田丽梅. 仿生非光滑用于旋成体减阻的试验研究[J]. 吉林大学学报(工学版), 2005, 35(04): 431-436. |

| [14] | 王 军,刘勇兵,杨晓红,王相虎. 压铸镁合金AZ91D钻削力经验公式[J]. 吉林大学学报(工学版), 2005, 35(02): 145-0147. |

| [15] | 戴文跃, 梁昊. 装载机工作装置的动力学仿真与综合优化设计[J]. 吉林大学学报(工学版), 2004, (4): 602-605. |

|

||