吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 730-738.doi: 10.13229/j.cnki.jdxbgxb20190569

• 农业工程·仿生工程 • 上一篇

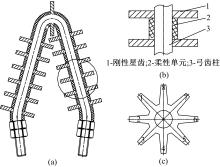

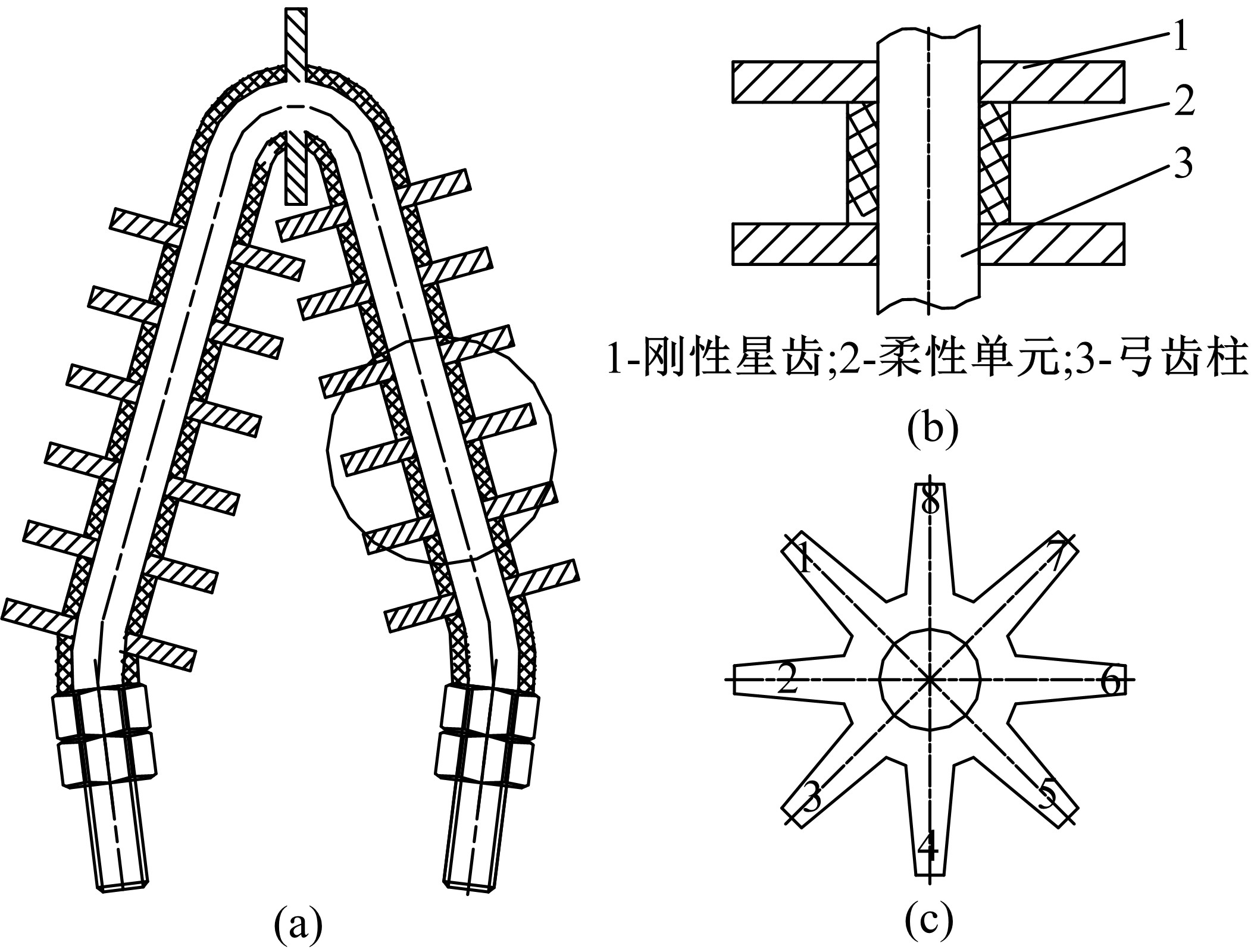

刚柔耦合式小麦脱粒弓齿设计及试验

付君1,2,3( ),张屹晨1,2,程超1,2,陈志2,3,唐心龙4(

),张屹晨1,2,程超1,2,陈志2,3,唐心龙4( ),任露泉1,2

),任露泉1,2

- 1.吉林大学 工程仿生教育部重点实验室,长春 130022

2.吉林大学 生物与农业工程学院,长春 130022

3.中国农业机械化科学研究院,北京 100083

4.吉林大学 农业实验基地,长春 130062

Design and experiment of bow tooth of rigid flexible coupling for wheat threshing

Jun FU1,2,3( ),Yi-chen ZHANG1,2,Chao CHENG1,2,Zhi CHEN2,3,Xin-long TANG4(

),Yi-chen ZHANG1,2,Chao CHENG1,2,Zhi CHEN2,3,Xin-long TANG4( ),Lu-quan REN1,2

),Lu-quan REN1,2

- 1.Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022, China

2.College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

3.Chinese Academy of Agricultural Mechanization Sciences, Beijing 100083, China

4.Agriculture Test Station, Jilin University, Changchun 130062, China

摘要:

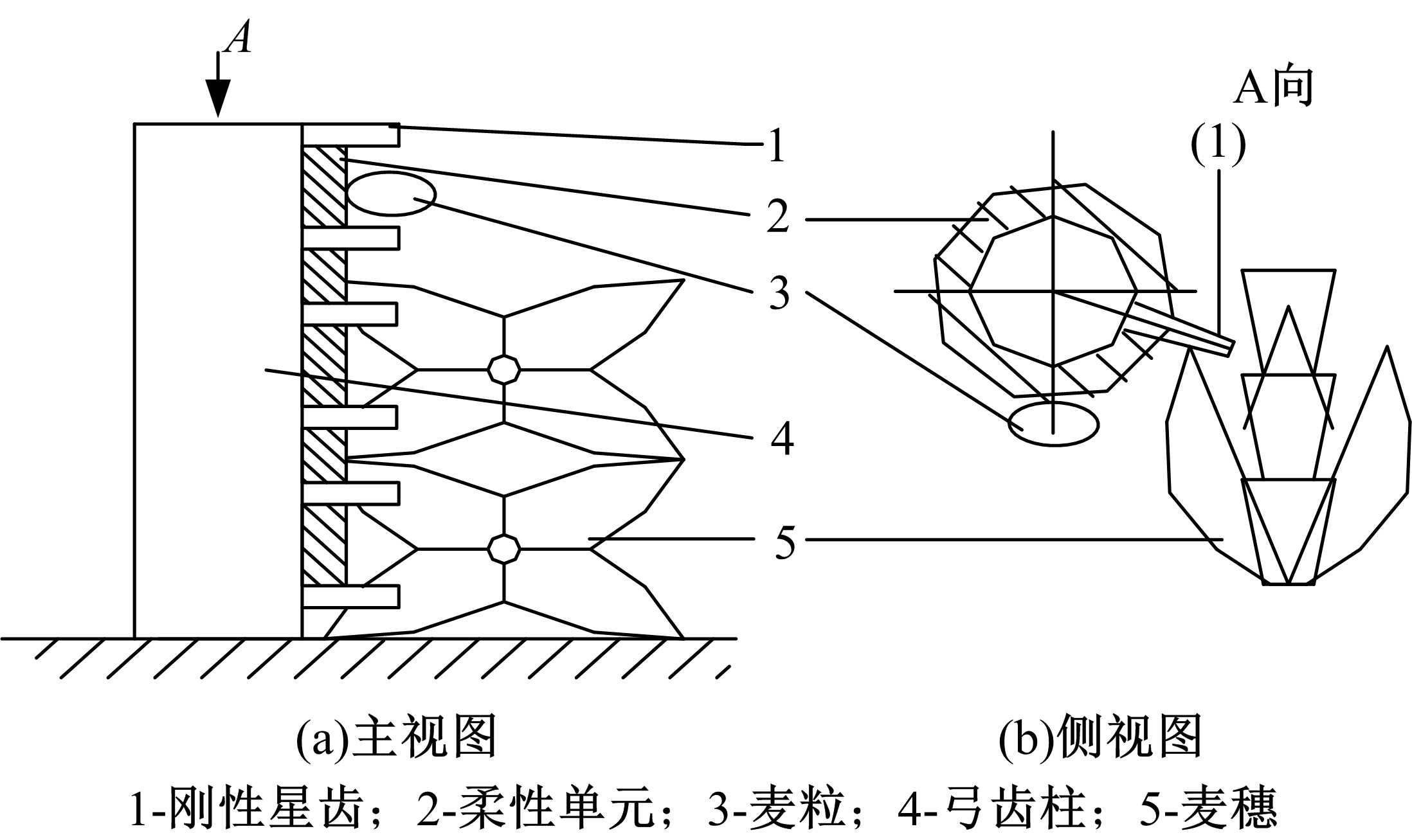

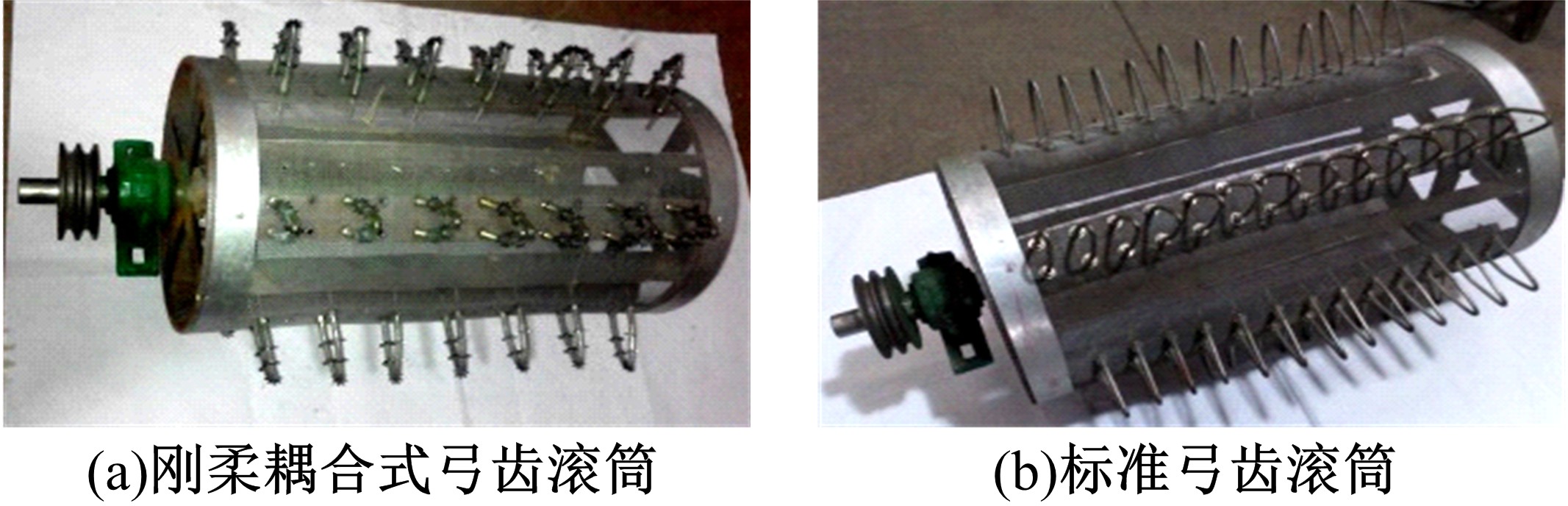

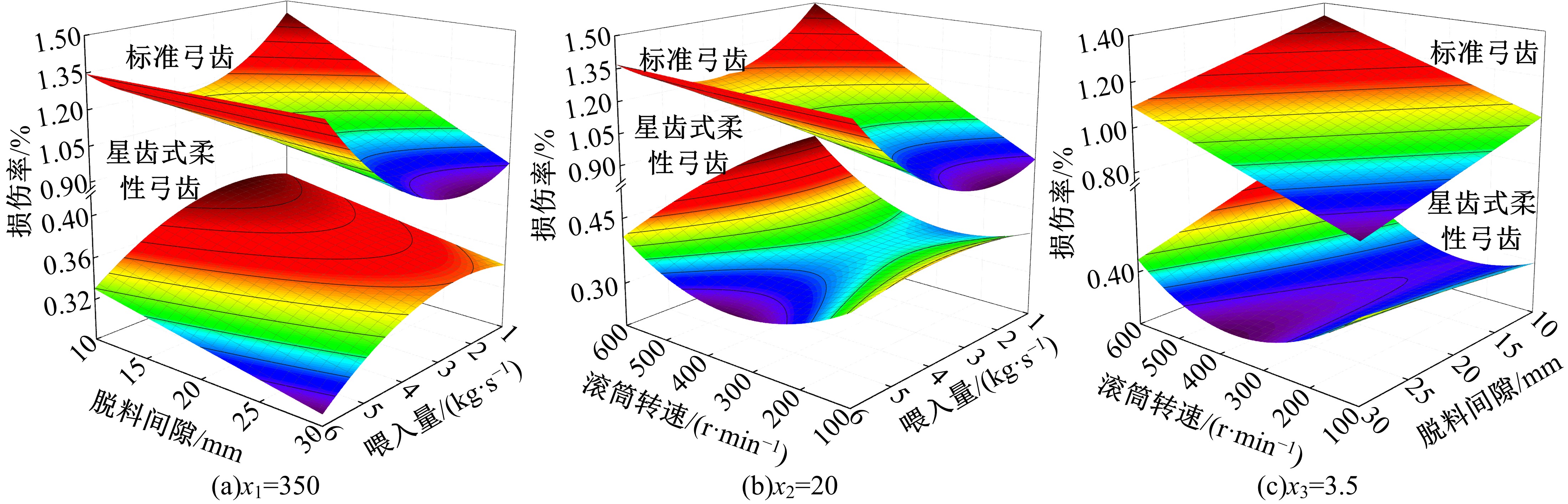

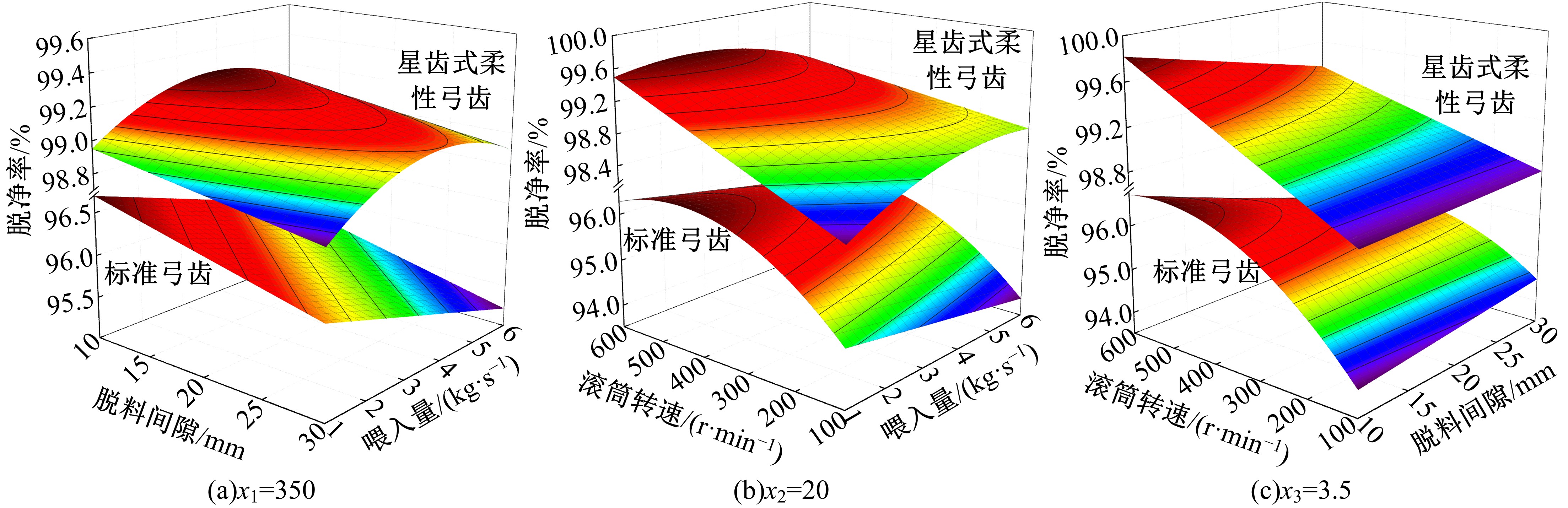

为解决小麦脱粒中脱净率低、损伤率高的问题,对小麦脱粒标准弓齿进行创新设计,并对其脱粒界面进行分析。设计刚柔耦合式弓齿小麦脱粒试验台,开展二次回归正交对比试验,损伤率明显降低,降幅最大可达到1.04%,脱净率明显提高,增幅最大可达到4.64%。试验因素对刚柔耦合式弓齿损伤率的影响程度由大到小依次为滚筒转速、喂入量和脱粒间隙,得到损伤率最优作业参数组合:滚筒转速为350 r/min,脱粒间隙为30 mm,喂入量为6 kg/s。试验因素对刚柔耦合式弓齿脱净率的影响程度由大到小依次为滚筒转速、脱粒间隙和喂入量,得到脱净率最优作业参数组合:滚筒转速为600 r/min,脱粒间隙为10 mm,喂入量为3.5 kg/s。

中图分类号:

- S225.39

| 1 | 王显仁, 李耀明. 脱粒原理与脱粒过程的研究现状与趋势[J]. 农机化研究, 2010, 32(1): 218-221. |

| Wang Xian-ren, Li Yao-ming. Actualities of researches and developing trends of threshing mechanism and threshing process[J]. Journal of Agricultural Mechanization Research, 2010, 32(1): 218-221. | |

| 2 | Harrison H P. Grain separation and damage of an axial-flow combine[J]. Canadian Agricultural Engineering, 1992, 34(1): 49-53. |

| 3 | 徐立章, 李耀明. 稻谷与钉齿碰撞损伤的有限元分析[J]. 农业工程学报, 2011, 27(10): 27-32. |

| Xu Li-zhang, Li Yao-ming. Finite element analysis on damage of rice kernel impacting on spike tooth[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(10): 27-32. | |

| 4 | Miu P I, Kutzbach H D. Modeling and simulation of grain threshing and separation in threshing units-part I[J]. Computers and Electronics in Agriculture, 2008, 60(1): 96-104. |

| 5 | Miu P I,Kutzbach H D. Modeling and simulation of grain threshing and separation in threshing units-part II[J]. Computers and Electronics in Agriculture, 2008, 60(1): 105-109. |

| 6 | 谢方平, 罗锡文, 苏爱华, 等. 刚性弓齿与杆齿及柔性齿的脱粒对比试验[J]. 湖南农业大学学报: 自然科学版, 2005, 31(6): 648-651. |

| Xie Fang-ping, Luo Xi-wen, Su Ai-hua, et al. Contrastive experiment on threshing by using rigid wire-loop,rigid pole tooth and flexible pole tooth[J]. Journal of Hunan Agricultural University (Natural Sciences), 2005, 31(6): 648-651. | |

| 7 | 谢方平, 罗锡文, 卢向阳, 等. 柔性杆齿滚筒脱粒机理[J]. 农业工程学报, 2009, 25(8): 110-114. |

| Xie Fang-ping, Luo Xi-wen, Lu Xiang-yang, et al. Threshing principle of flexible pole-teeth roller for paddy rice[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(8): 110-114. | |

| 8 | 唐忠, 李耀明, 徐立章, 等. 不同脱粒元件对切流与纵轴流水稻脱粒分离性能的影响[J]. 农业工程学报, 2011, 27(3): 93-97. |

| Tang Zhong, Li Yao-ming, Xu Li-zhang, et al. Effects of different threshing components on grain threshing and separating by tangential-axial test device[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(3): 93-97. | |

| 9 | 师清翔, 姬江涛, 刘师多, 等. 小麦的控速喂入柔性脱粒试验研究[J]. 农业工程学报, 1995, 11(2): 183-188. |

| Shi Qing-xiang, Ji Jiang-tao, Liu Shi-duo, et al. The experimental studies on speed-controlled feed and soft threshing for wheat[J]. Transactions of the Chinese Society of Agricultural Engineering, 1995, 11(2): 183-188. | |

| 10 | 苏媛, 刘浩, 徐杨, 等. 轴流式玉米脱粒装置钉齿元件优化与试验[J]. 农业机械学报, 2018, 49(增刊1): 258-265. |

| Su Yuan, Liu Hao, Xu Yang, et al. Optimization and experiment of spike-tooth elements of axial flowcorn threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1): 258-265. | |

| 11 | 樊晨龙, 崔涛, 张东兴, 等. 低损伤组合式玉米脱粒分离装置设计与试验[J]. 农业机械学报, 2019, 50(4): 113-123. |

| Fan Chen-long, Cui Tao, Zhang Dong-xing, et al. Design and test of low-damage combined corn threshing and separating devices[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(4): 113-123. | |

| 12 | 李心平, 李玉柱, 高吭, 等. 种子玉米籽粒仿生脱粒机理分析[J]. 农业机械学报, 2011, 42(2): 99-103. |

| Li Xin-ping, Li Yu-zhu, Gao Hang, et al. Bionic threshing process analysis of seed corn kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(2): 99-103. | |

| 13 | 李心平, 马义东, 金鑫, 等. 玉米种子仿生脱粒机设计与试验[J]. 农业机械学报, 2015, 46(7): 97-101. |

| Li Xin-ping, Ma Yi-dong, Jin Xin, et al. Design and test of corn seed bionic thresher[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 97-101. | |

| 14 | 李心平, 马磊, 耿令新, 等. 玉米种子仿生脱粒机性能试验与参数优化[J]. 农业工程学报, 2017, 33(5): 62-69. |

| Li Xin-ping, Ma Lei, Geng Ling-xin, et al. Performance test and parameter optimization of corn seed bionic thresher[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(5): 62-69. | |

| 15 | 高连兴, 郑世妍, 陈瑞祥, 等. 喂入辊轴流滚筒组合式大豆种子脱粒机设计与试验[J]. 农业机械学报, 2015, 46(1): 112-118. |

| Gao Lian-xing, Zheng Shi-yan, Chen Rui-xiang, et al. Design and experiment on soybean breeding thresher of double feeding roller and combined threshing cylinder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(1): 112-118. | |

| 16 | 陈海涛, 滕宇娇, 王业成, 等. 柔性差速带式单株大豆脱粒装置设计与试验[J]. 农业机械学报, 2018, 49(9): 96-104. |

| Chen Hai-tao, Teng Yu-jiao, Wang Ye-cheng, et al. Design and experiment on single-plant soybean threshing device with differential speed flexible belts[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(9): 96-104. | |

| 17 | GB/T 5798—1986. 脱粒弓齿[S]. |

| 18 | 任露泉. 回归设计及其优化[M]. 北京: 科学出版社,2009. |

| 19 | 田径, 刘忠长, 刘金山, 等. 基于燃烧边界参数响应曲面设计的柴油机性能优化[J]. 吉林大学学报: 工学版, 2018, 48(1): 159-165. |

| Tian Jing,Liu Zhong-chang,Liu Jin-shan,et al. Performance optimization of diesel engine based on response surface methodology of multi-boundary combustion conditions[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(1): 159-165. | |

| 20 | 王利民, 肖志刚, 刘宇欣, 等. 响应面法优化板栗基营养米挤压加工参数[J]. 吉林大学学报: 工学版,2013, 43(2): 550-556. |

| Wang Li-min, Xiao Zhi-gang, Liu Yu-xin, et al. Optimization of extrusion process parameters of nutritious rice rich in chestnut by response surface method[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(2): 550-556. | |

| 21 | NY/T 1014—2006, 脱粒机质量评价技术规范[S]. |

| [1] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [2] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [3] | 杨方飞, 闫光, 郝云霄, 刘克格. 基于刚柔耦合仿真模型的高地隙喷雾机转向机构特性[J]. 吉林大学学报(工学版), 2015, 45(3): 857-863. |

| [4] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [5] | 陈书明, 彭登志, 王登峰, 梁杰. 车内低频噪声声固耦合及试验优化设计[J]. 吉林大学学报(工学版), 2014, 44(6): 1550-1556. |

| [6] | 宋学伟, 吴永飞, 沈传亮, 陈书明. 三通管内高压成形载荷路径试验优化设计[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 57-61. |

| [7] | 付宏, 吕游, 李艳双, 于建群. 基于离散元法的玉米脱粒过程分析[J]. , 2012, 42(04): 997-1002. |

| [8] | 王孝兰, 王荣本. 基于刚柔耦合模型的月球车振动特性仿真[J]. 吉林大学学报(工学版), 2012, 42(02): 279-284. |

| [9] | 陈修龙1,贾帅帅1,邓昱1,赵永生2. 新型4-UPS-UPU并联坐标测量机刚柔耦合动力学性态[J]. 吉林大学学报(工学版), 2011, 41(4): 1020-1024. |

| [10] | 符升平, 项昌乐, 姚寿文, 武景燕. 基于刚柔耦合动力学的齿轮传动系统动态特性[J]. 吉林大学学报(工学版), 2011, 41(02): 382-0386. |

| [11] | 韩志武,张俊秋,戈超,王超飞,任露泉. 仿生形态表面气固冲蚀磨损性能[J]. 吉林大学学报(工学版), 2009, 39(06): 1512-1515. |

| [12] | 张志辉, 任露泉, 周宏, 佟鑫, 王蕾. 抗热疲劳仿生耦合制动毂的激光加工参数[J]. 吉林大学学报(工学版), 2009, 39(04): 953-958. |

| [13] | 钱志辉,任露泉,田丽梅,孙少明 . 仿生耦合功能表面应力-应变本构关系[J]. 吉林大学学报(工学版), 2008, 38(05): 1105-1109. |

|

||