吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1561-1573.doi: 10.13229/j.cnki.jdxbgxb20210114

• 交通运输工程·土木工程 • 上一篇

机翼结构超声除冰系统数值模拟与实验

- 哈尔滨工程大学 航天与建筑工程学院,哈尔滨 150001

Numerical simulation and experiment on ultrasonic deicing system of airfoil structure

Zhong-hua SHI( ),Quan-wei SONG,Zhen-hang KANG,Qiang XIE,Ji-feng ZHANG(

),Quan-wei SONG,Zhen-hang KANG,Qiang XIE,Ji-feng ZHANG( )

)

- College of Aerospace and Civil Engineering,Harbin Engineering University,Harbin 150001,China

摘要:

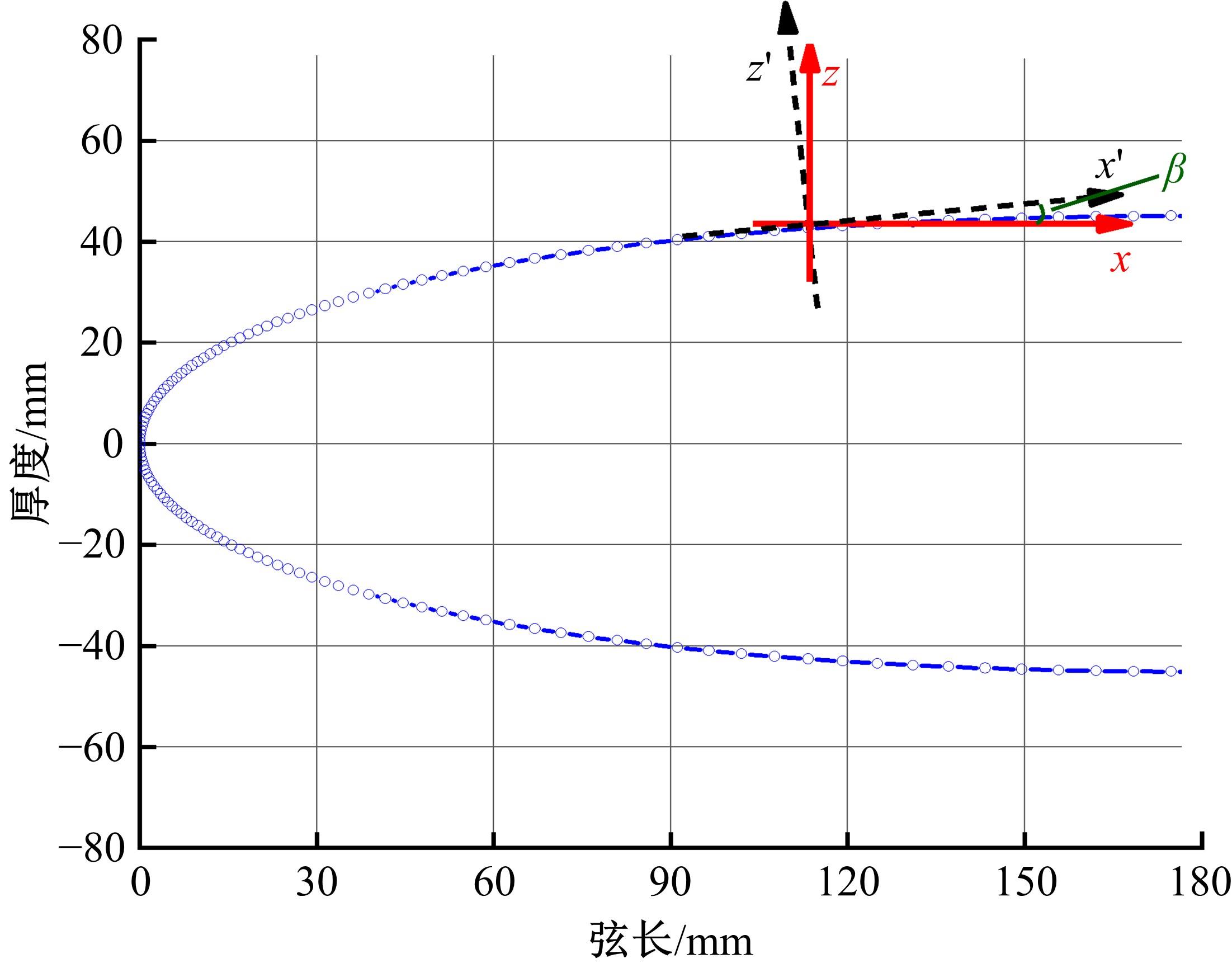

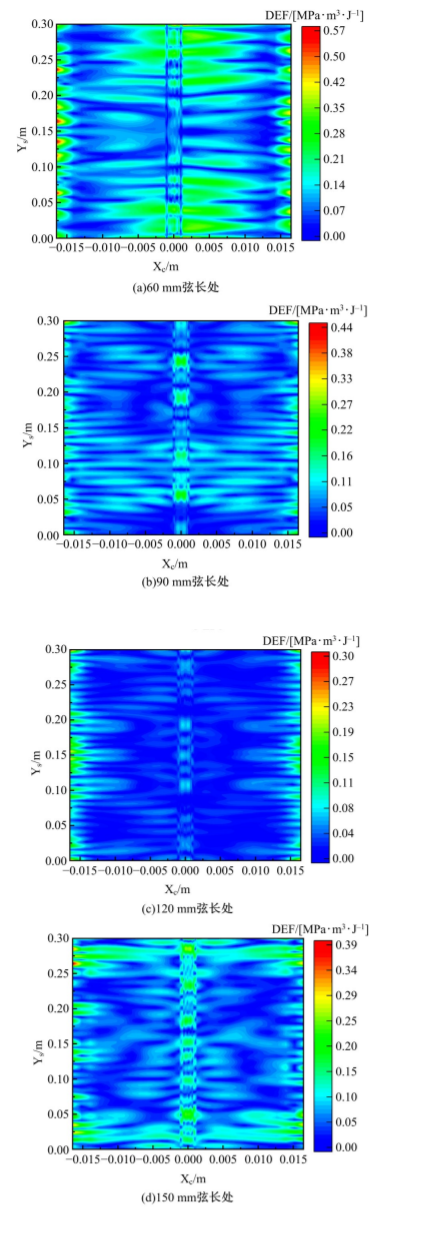

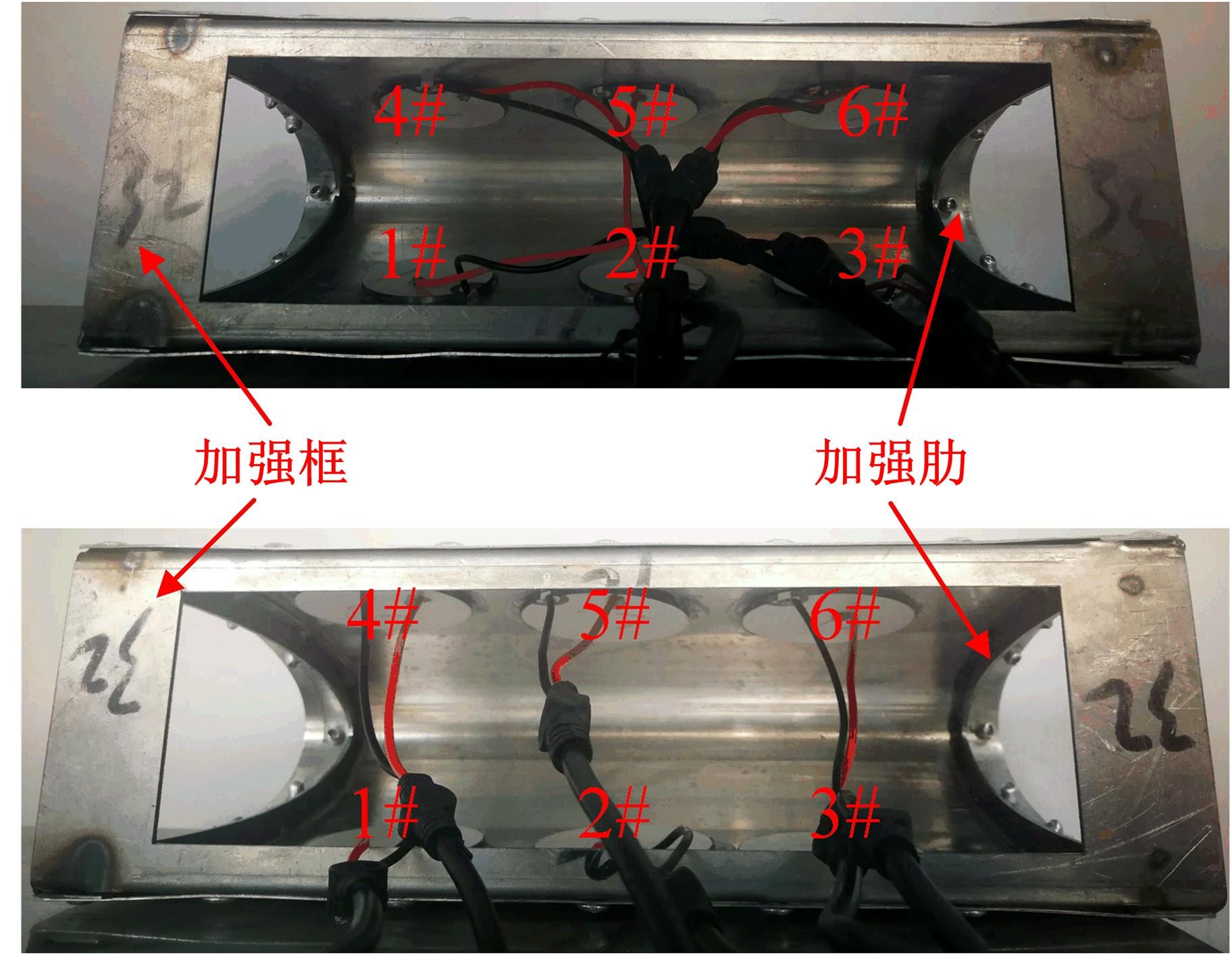

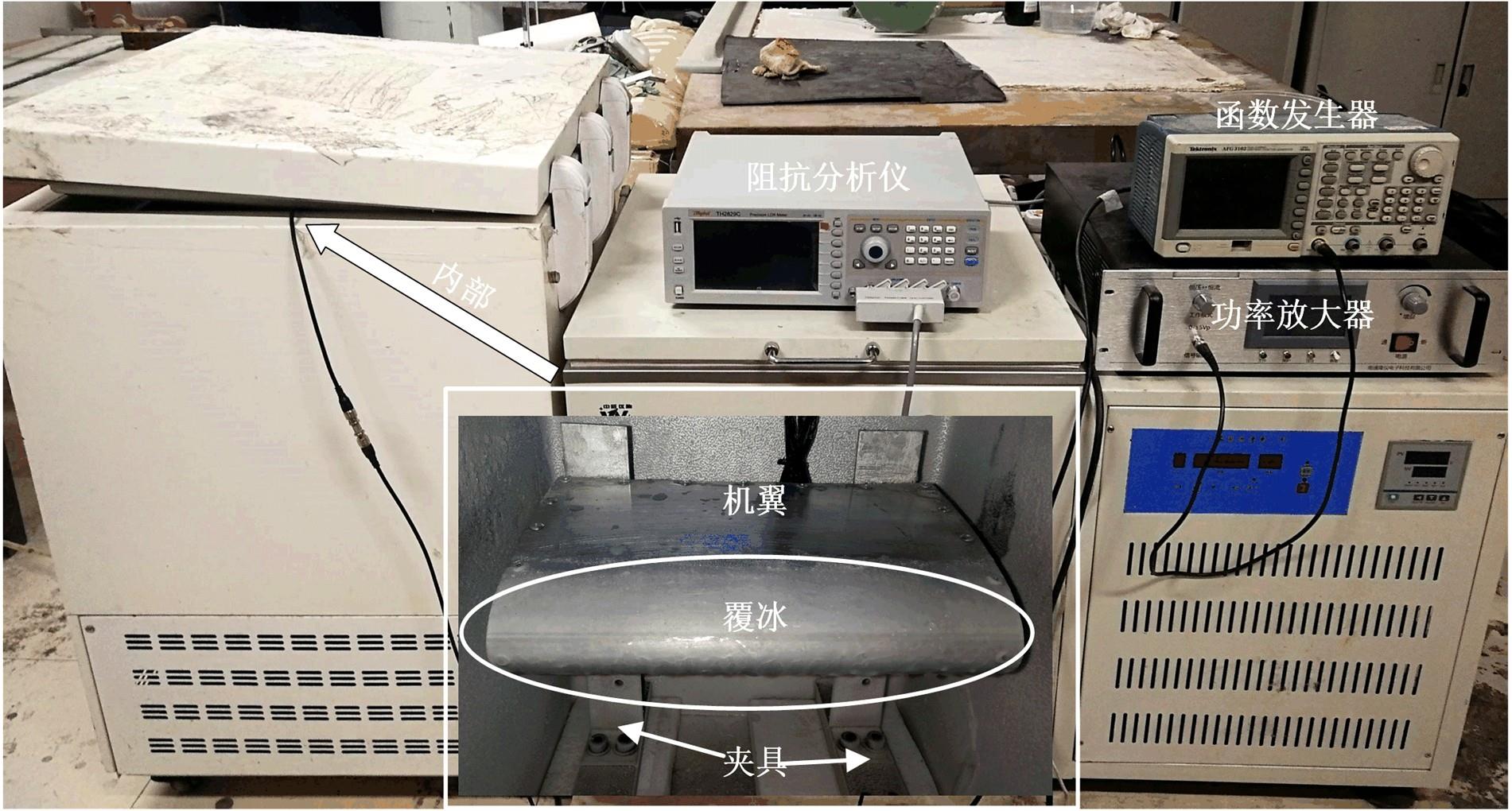

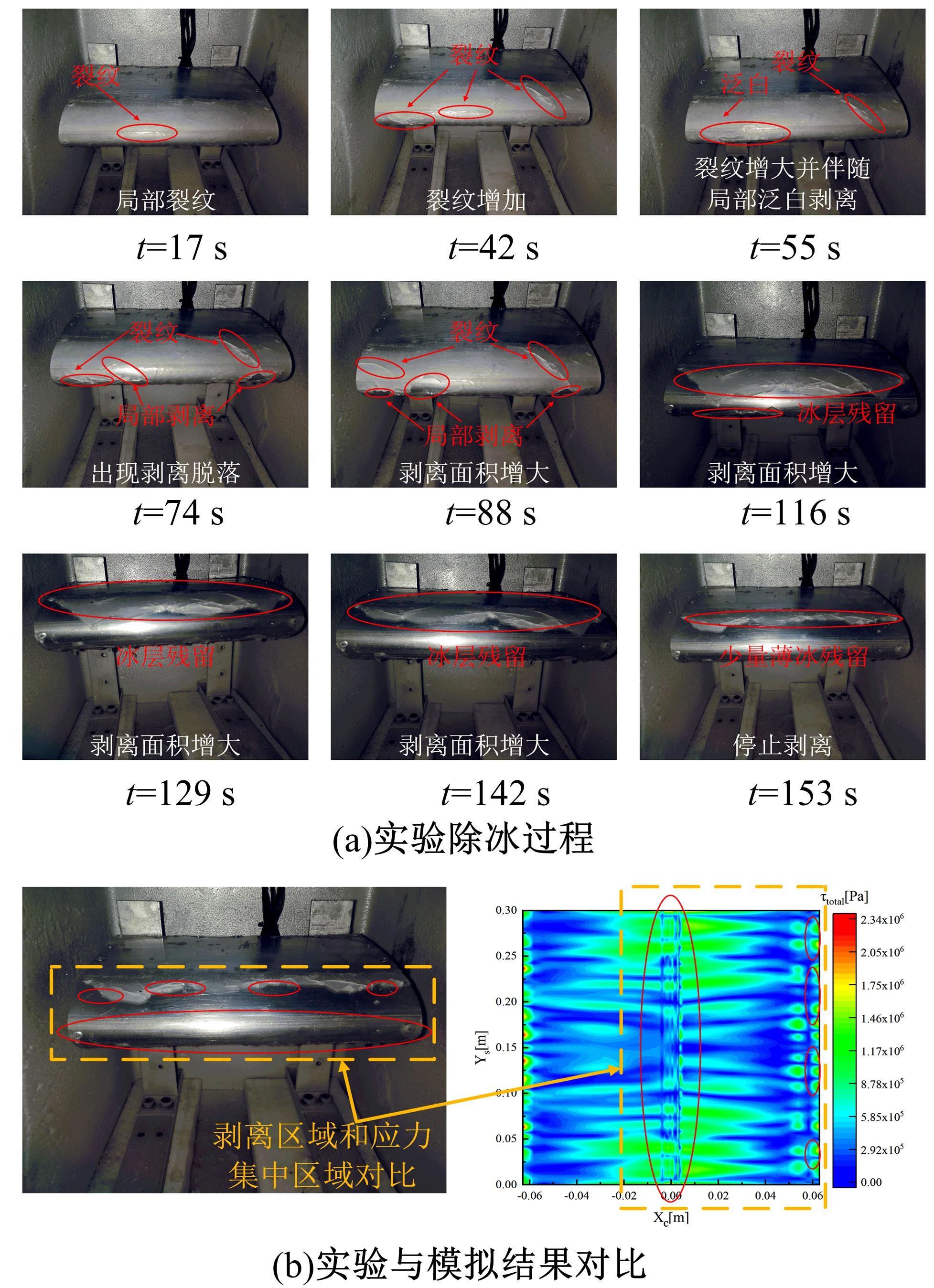

利用数值和实验方法,对NACA 0015机翼结构超声除冰系统进行了研究。针对覆冰双层板模型,通过全局矩阵法(GMM)研究了覆冰厚度和覆冰弹性模量对冰层界面剪应力集中系数(ISCC)和除冰频率的影响;同时,对压电激励器进行了参数设计,并应用阻抗曲线验证了设计结果的准确性。最后,根据NACA 0015机翼的几何特点,对压电激励器布置和除冰效率进行了研究,并开展了除冰实验,验证了NACA 0015机翼结构超声除冰系统的可行性,实验结果表明:该机翼结构的除冰功耗仅为传统电热除冰的16%左右。

中图分类号:

- V244.1

| 1 | Cao Y, Tan W, Wu Z. Aircraft icing: an ongoing threat to aviation safety[J]. Aerospace Science and Technology, 2018, 75: 353-385. |

| 2 | Pei B, Xu H, Xue Y. Flight-safety space and cause of incident under icing conditions[J]. Journal of Guidance, Control, and Dynamics, 2017, 40(11): 2983-2990. |

| 3 | Pouryoussefi S G, Mirzaei M, Nazemi M-M, et al. Experimental study of ice accretion effects on aerodynamic performance of an NACA 23012 airfoil[J]. Chinese Journal of Aeronautics, 2016, 29(3): 585-595. |

| 4 | Goraj Z. An overview of the deicing and anti-icing technologies with prospects for the future[C]∥The 24th International Congress of the Aeronautical Sciences, Yokohama, Japan, 2004. |

| 5 | Xie T, Dong J, Chen H, et al. Experimental investigation of deicing characteristics using hot air as heat source[J]. Applied Thermal Engineering, 2016, 107: 681-688. |

| 6 | Liu Y, Kolbakir C, Hu H, et al. A comparison study on the thermal effects in DBD plasma actuation and electrical heating for aircraft icing mitigation[J]. International Journal of Heat and Mass Transfer, 2018, 124: 319-330. |

| 7 | Muthumani A, Fay L, Akin M, et al. Correlating lab and field tests for evaluation of deicing and anti-icing chemicals: a review of potential approaches[J]. Cold Regions Science and Technology, 2014, 97: 21-32. |

| 8 | Wang Z. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft[J]. Energy and Buildings, 2017, 140: 42-49. |

| 9 | 白天, 朱春玲, 苗波,等. 平面铝板上的压电振动除冰方法[J]. 航空学报, 2015, 36(5):1564-1573 |

| Bai Tian, Zhu Chun-ling, Miao Bo, et al. Vibration de-icing method with piezoelectric actuators on flat aluminum plate[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(5): 1564-1573. | |

| 10 | Palacios J, Smith E, Rose J, et al. Ultrasonic de-icing of wind-tunnel impact icing[J]. Journal of Aircraft, 2011, 48(3): 1020-1027. |

| 11 | Shi Z, Kang Z, Xie Q, et al. Ultrasonic deicing efficiency prediction and validation for a flat deicing system[J]. Applied Sciences, 2020, 10(19): 6640. |

| 12 | Gao H, Rose J L. Ice detection and classification on an aircraft wing with ultrasonic shear horizontal guided waves[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2009, 56(2): 334-344. |

| 13 | Shi Z, Zhao Y, Ma C, et al. Parametric study of ultrasonic de-icing method on a plate with coating[J]. Coatings, 2020, 10(7): 631. |

| 14 | Palacios J, Zhu Y, Smith E, et al. Ultrasonic shear and lamb wave interface stress for helicopter rotor de-icing purposes[C]∥The 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and 14th AIAA/ASME/AHS Adaptive Structures Conference, Newport, USA, 2006: 2282. |

| 15 | Dassault Systemes Simulia Corp. Abaqus User Manual[M]. Pairs: Dassault Systemes Simulia Corp, 2020. |

| 16 | Borigo C J. A novel actuator phasing method for ultrasonic de-icing of aircraft structures[D]. Philadelphia: The Pennsylvania State University, 2014. |

| 17 | Cook R D. Concepts and Applications of Finite Element Analysis[M]. London: John Wiley & Sons, 2007. |

| 18 | Koivuluoto H, Stenroos C, Ruohomaa R, et al. Research on icing behavior and ice adhesion testing of icephobic surfaces[C]∥Proceedings of the International Workshop on Atmospheric Icing of Structures, Uppsala, Sweden, 2015. |

| 19 | Overmeyer A, Palacios J, Smith E. Actuator bonding optimization and system control of a rotor blade ultrasonic deicing system[C]∥The 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference and 20th AIAA/ASME/AHS Adaptive Structures Conference, Hawaii, USA, 2012: 1476. |

| [1] | 周晓勤,杨璐,张磊,陈立军. 具有负压缩性的铰接八面体结构的有限元分析[J]. 吉林大学学报(工学版), 2019, 49(3): 865-871. |

| [2] | 庄蔚敏, 解东旋, 余天明, 于皖东. 基于损伤-相变本构模型的高强钢热成形数值模拟分析[J]. 吉林大学学报(工学版), 2015, 45(4): 1206-1212. |

| [3] | 孟广伟,李霄琳,李锋,周立明,王晖. 裂隙介质渗流的光滑多尺度有限元法[J]. 吉林大学学报(工学版), 2015, 45(2): 481-486. |

| [4] | 庄蔚敏, 曹德闯, 叶辉. 基于连续介质损伤力学预测7075铝合金热冲压成形极限图[J]. 吉林大学学报(工学版), 2014, 44(2): 409-414. |

| [5] | 庄蔚敏, 陈延红. 基于连续损伤力学的表面涂层损伤模拟[J]. , 2012, 42(04): 857-862. |

| [6] | 徐涛, 邱冰, 程飞, 金延中, 蒋永洲, 赵世佳. 基于偶数行Epsilon加速的结构拓扑修改重分析算法[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 246-249. |

| [7] | 姜日花1,白爽1,戴跃2 ,赵梅生3. 瘢痕疙瘩的生物力学特性[J]. 吉林大学学报(工学版), 2011, 41(6): 1675-1677. |

| [8] | 蔡斌1,2,孟广伟2,3,董心2,李锋2. 基于模糊失效准则的混凝土结构横向裂纹可靠度[J]. 吉林大学学报(工学版), 2011, 41(4): 1029-1033. |

| [9] | 陈宇东1,裴春艳1,潘淑华2,刘晓军1,张俊兴1. 整车环境下商用车驾驶室模态刚度灵敏度[J]. 吉林大学学报(工学版), 2011, 41(4): 1025-1028. |

| [10] | 彭惠芬1,2,孟广伟1,周立明1,李锋1. 基于小波有限元法的虚拟裂纹闭合法[J]. 吉林大学学报(工学版), 2011, 41(05): 1364-1368. |

| [11] | 孟广伟, 周立明, 李锋. 含裂纹结构的模糊无网格伽辽金法[J]. 吉林大学学报(工学版), 2010, 40(增刊): 287-0292. |

| [12] | 孟广伟, 蔡斌, 李锋, 董心. 曲线拟合与蒙特卡洛法结合的结构可靠度分析方法[J]. 吉林大学学报(工学版), 2010, 40(增刊): 293-0296. |

| [13] | 孟广伟, 周立明, 李锋, 沙丽荣. 摄动随机局部正交无网格伽辽金法[J]. 吉林大学学报(工学版), 2010, 40(06): 1556-1561. |

| [14] | 吴登峰,徐涛,孙睿珩,杨荣,禤伟旗,吉野辰萌. 基于小波基函数的无网格方法[J]. 吉林大学学报(工学版), 2010, 40(03): 740-0744. |

| [15] | 孙睿珩, 徐涛, 左文杰, 杨洪秀, 刘大有. 表面凹坑对活塞缸套摩擦生热过程的影响[J]. 吉林大学学报(工学版), 2009, 39(05): 1234-1239. |

|

||