吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 865-871.doi: 10.13229/j.cnki.jdxbgxb20180309

具有负压缩性的铰接八面体结构的有限元分析

- 1. 吉林大学 机械与航空航天工程学院,长春 130022

2. 吉林大学 大数据和网络管理中心, 长春 130022

Finite element analysis of hinging octahedron structure withnegative compressibility

Xiao⁃qin ZHOU1( ),Lu YANG1,Lei ZHANG1,Li⁃jun CHEN2(

),Lu YANG1,Lei ZHANG1,Li⁃jun CHEN2( )

)

- 1. College of Mechanical Science and Aerospace Engineering, Jinlin University, Changchun 130022, China

2. Big Data and Network Management Center, Jilin University, Changchun 130022, China

摘要:

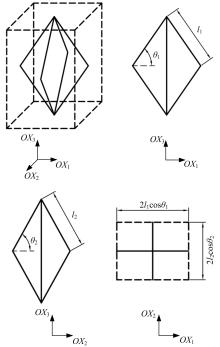

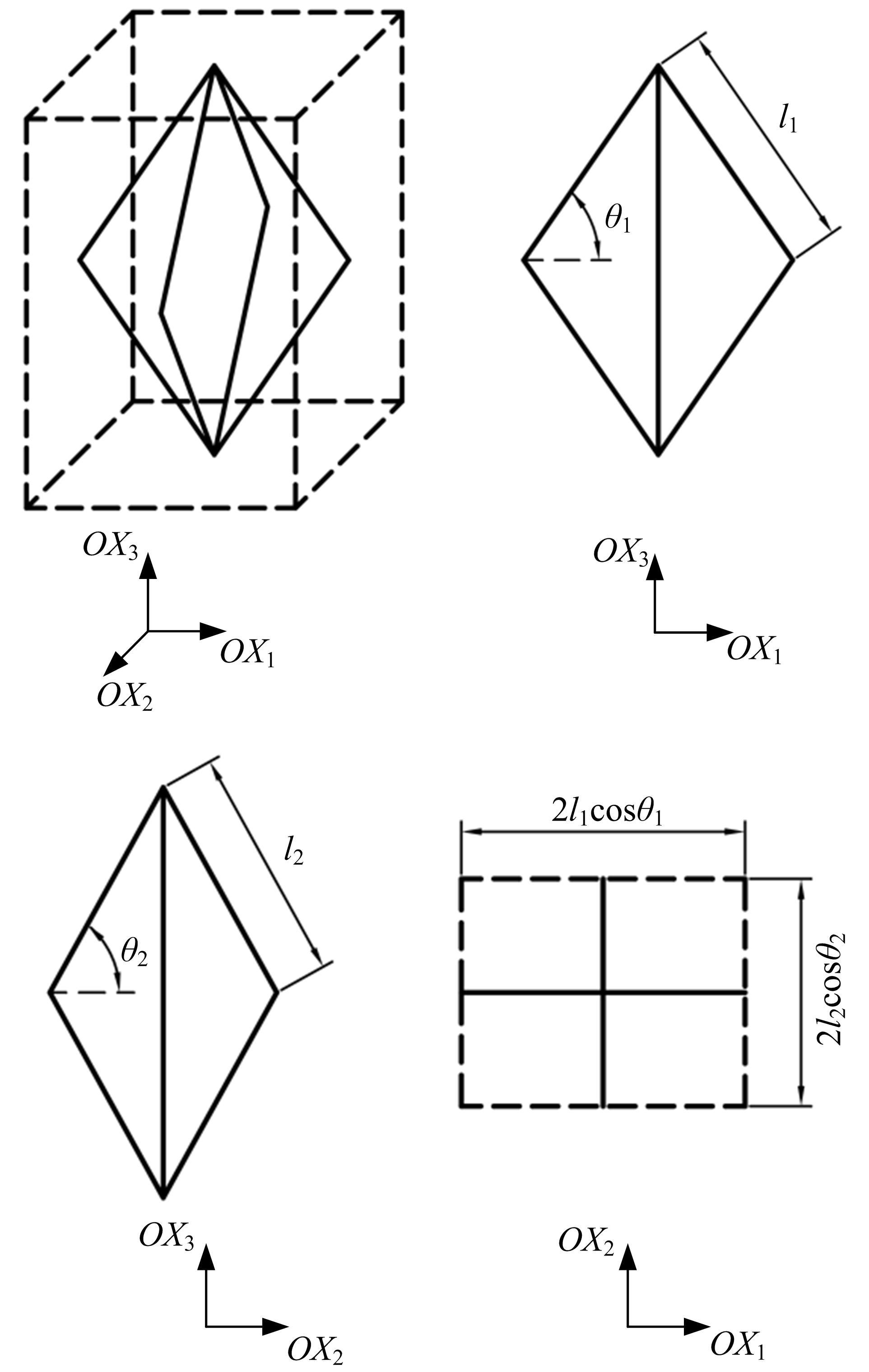

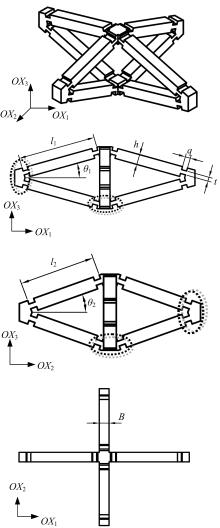

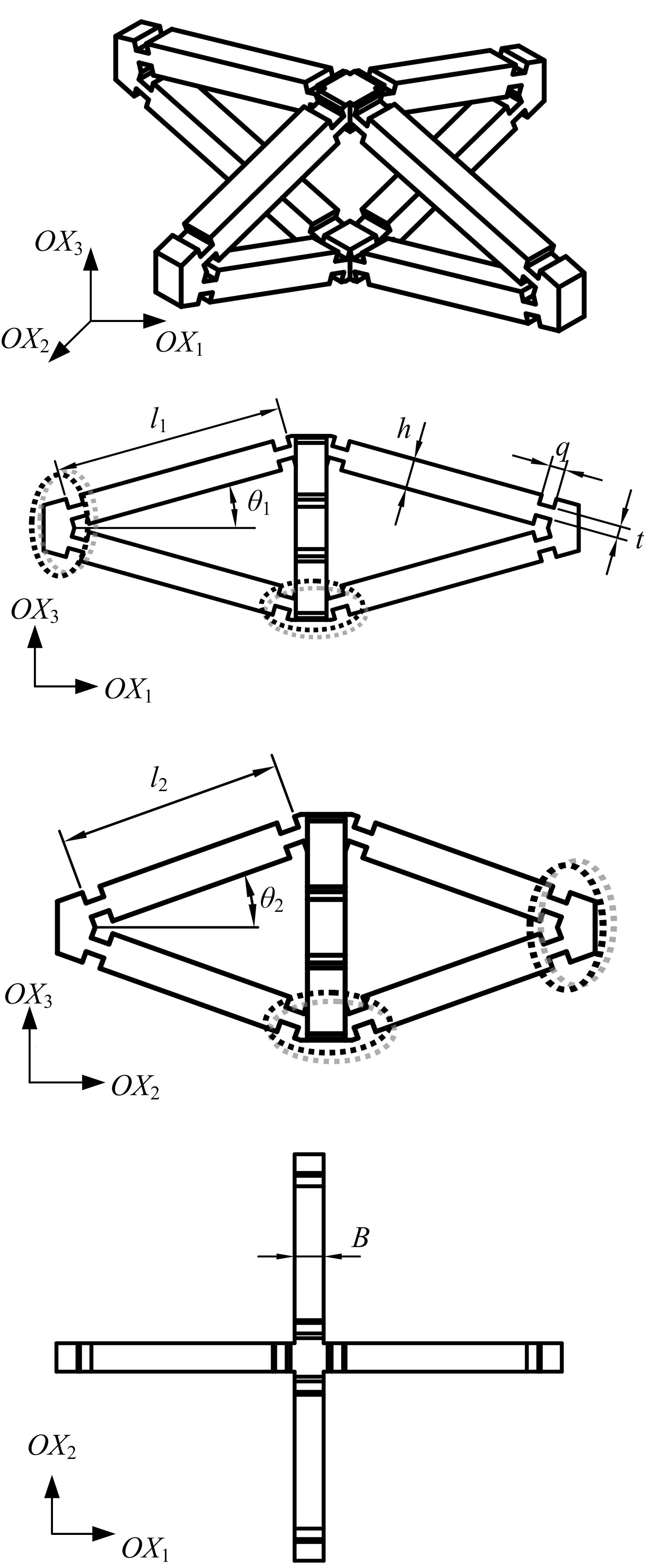

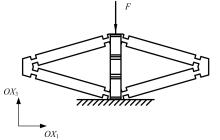

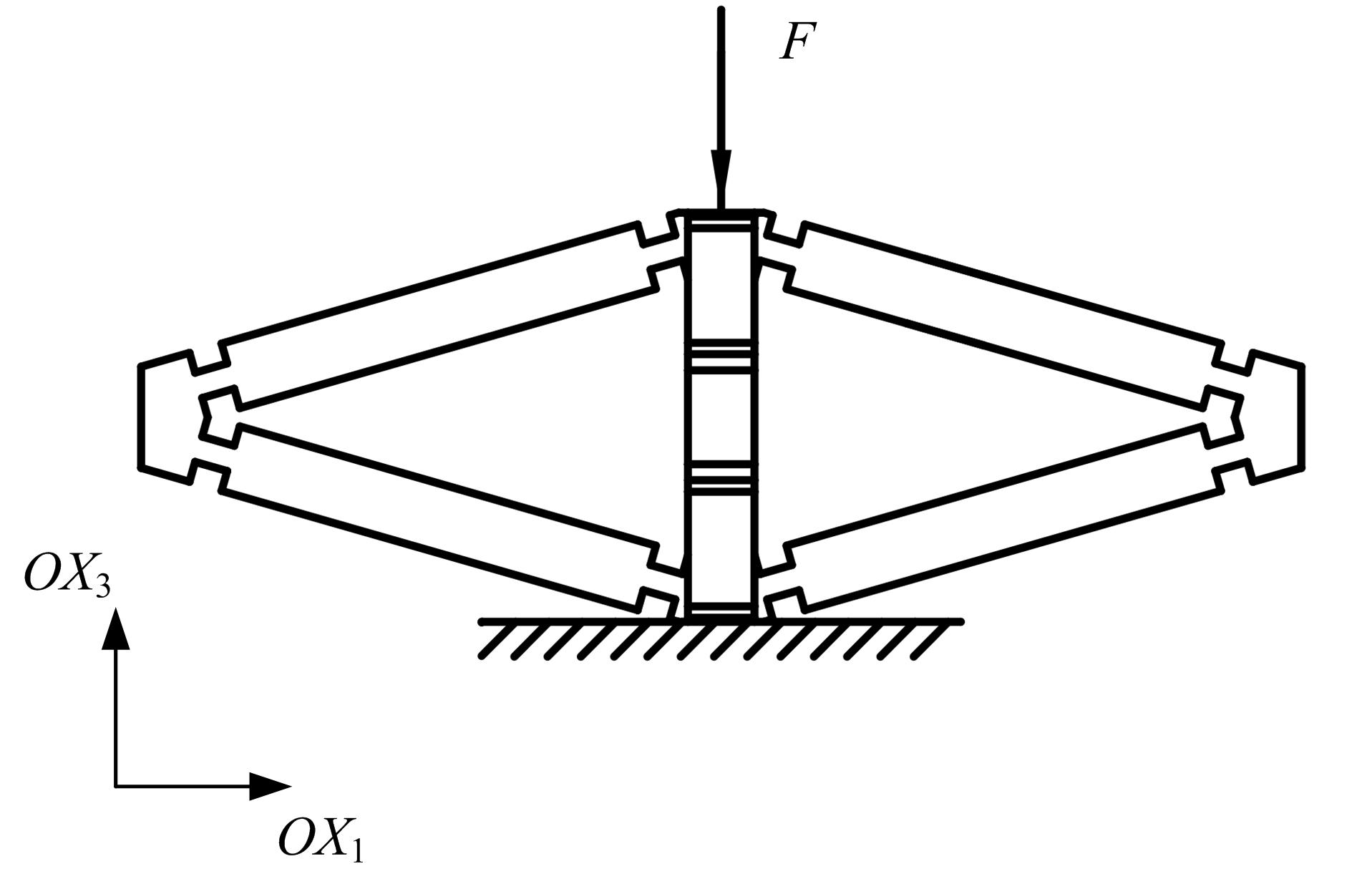

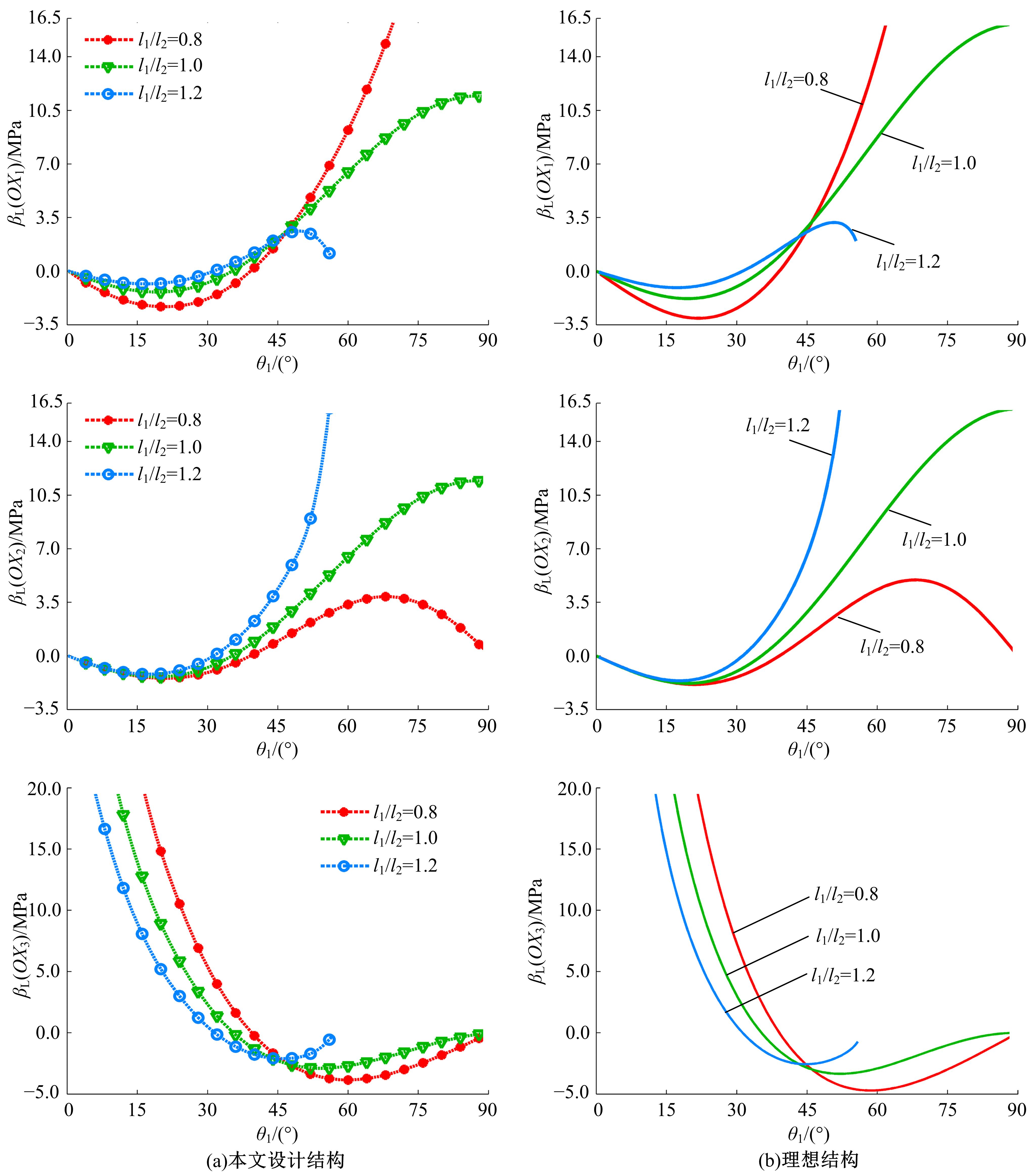

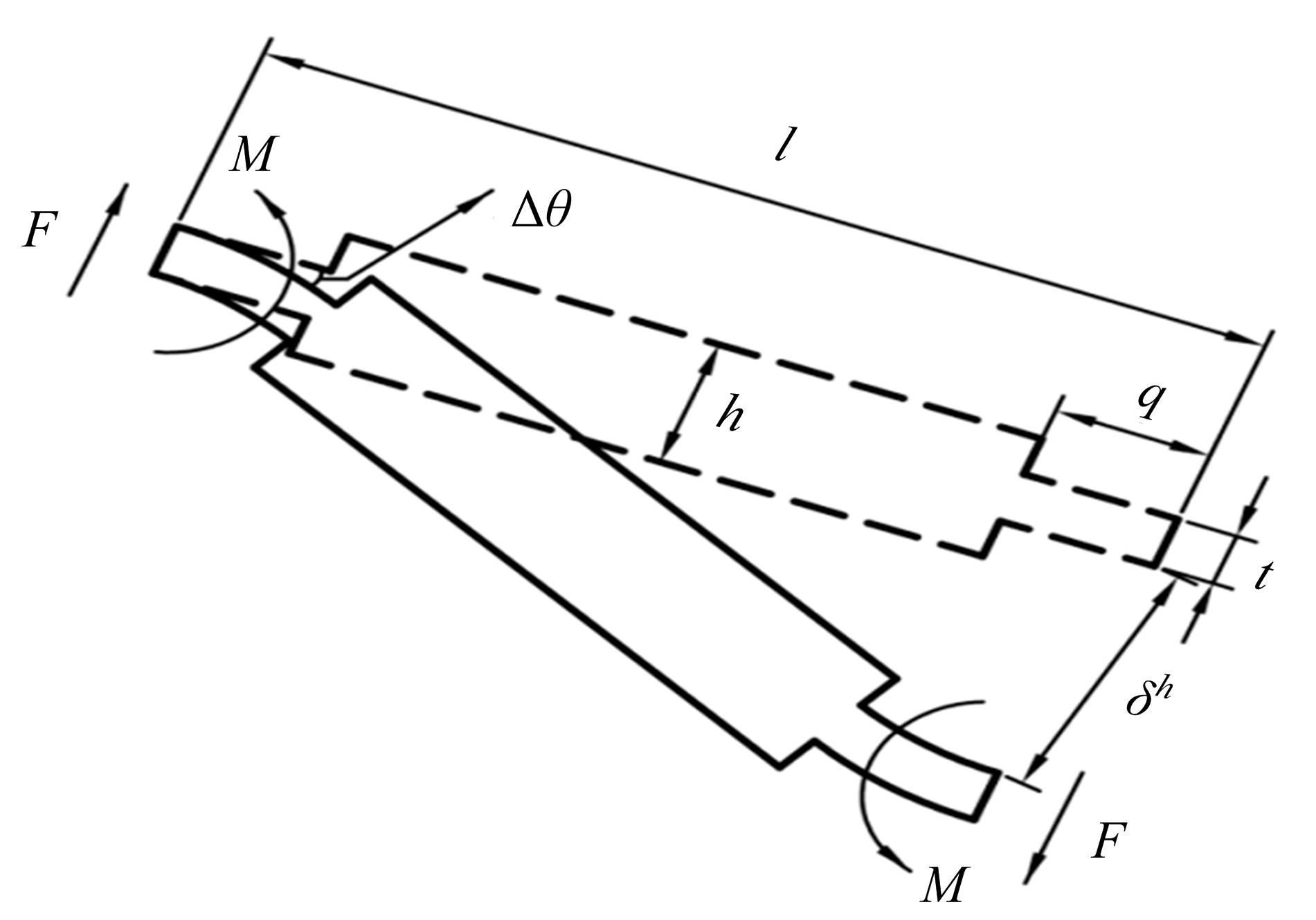

为探究铰接八面体结构的线压缩性与模型几何参数之间的内在关联,对该三维结构进行了有限元分析。在保证其他几何尺寸不变的前提下,通过改变杆长比l1/l2和杆件夹角θ1,建立了不同的有限元模型。具体讨论了杆长比和杆件夹角对该结构轴向线负压缩性(即NLC)大小和范围的影响。研究发现,通过合理地选择几何参数,该结构在3个轴线方向上均可存在线负压缩性,其中杆件夹角θ1的大小决定了线压缩性的正负,杆长比l1/l2的大小则决定了负压缩性的大小和存在范围。

中图分类号:

- O342

| 1 | MorosinB, SchirberJ E. Linear compressibilities and the pressure dependence of the atomic positional parameter of As[J]. Solid State Communications, 1972, 10(3): 249⁃251. |

| 2 | SkeltonE F, FeldmanJ L, LiuC Y, et al. Study of the pressure⁃induced phase transition in paratellurite (TeO2)[J]. Physical Review B, 1976, 13(6): 2605⁃2613. |

| 3 | MariathasanJ W E, FingerL W, HazenR M. High⁃pressure behavior of LaNbO4[J]. Acta Crystallographica Section B: Structural Science, 1985, 41(3): 179⁃184. |

| 4 | FortesA D, SuardE, KnightK S. Negative linear compressibility and massive anisotropic thermal expansion in methanol monohydrate[J]. Science, 2011, 331(6018): 742⁃746. |

| 5 | BaughmanR H, StafstromS, CuiC, et al. Materials with negative compressibility in one or more dimensions[J]. Science, 1998, 279(5356): 1522⁃1524. |

| 6 | GrimaJ N, AttardD, Caruana⁃GauciR, et al. Negative linear compressibility of hexagonal honeycombs and related systems[J]. Scripta Materialia, 2011, 65(7): 565⁃568. |

| 7 | BarnesD L, MillerW, EvansK E, et al. Modelling negative linear compressibility in tetragonal beam structures[J]. Mechanics of Materialia, 2012, 46: 123⁃128. |

| 8 | GrimaJ N, Caruana⁃GauciR, WojciechowskiK W, et al. Smart hexagonal truss systems exhibiting negative compressibility through constrained angle stretching[J]. Smart Materials and Structures, 2013, 22(8): 84015. |

| 9 | GrimaJ N, AttardD, GattR. Truss⁃type systems exhibiting negative compressibility[J]. Physical Status Solidi, 2008, 245(11): 2405⁃2414. |

| 10 | ChoiJ B, LakesR S. Analysis of elastic modulus of conventional foams and of re⁃entrant foam materials with a negative Poisson's ratio[J]. International Journal of Mechanical Science, 1995, 37(1): 51⁃59. |

| 11 | ChoiJ B, LakesR S. Nonlinear analysis of the Poisson's ratio of negative Poisson's ratio foams[J]. Journal of Composite Materials, 1995, 29(1): 113⁃128. |

| 12 | LuZ X, LiuQ, YangZ Y. Predictions of Young's modulus and negative Poisson's atio of auxetic foams[J]. Physica Status Solidi B, 2011, 248: 167⁃174. |

| 13 | LiK, GaoX L, RoyA K. Micromechanics model for three⁃dimensional open⁃cell foams using a tetrakaidecahedral unit cell and Castigliano's second theorem[J]. Composites Science and Technology, 2003, 63(12): 1769⁃1781. |

| 14 | GrimaJ N, Caruana⁃GauciR, AttardD,et al. Three⁃dimensional cellular structures with negative Poisson's ratio and negative compressibility properties[J]. Proceedings of the Royal Society A: Mathematical Physical and Engineering Sciences, 2012, 468(2146): 3121⁃3138. |

| 15 | XieY M, YangX Y, ShenJ H et. al. Designing orthotropic materials for negative or zero compressibility[J]. International Journal of Solids and Structures, 2014, 51(23/24): 4038⁃4051. |

| 16 | ZhouX Q, ZhangL, ZhangH, et al. 3D cellular models with negative compressibility through the wine⁃rack⁃type mechanism: 3D cellular models with negative compressibility[J]. Physica Status Solidi, 2016, 253(10): 1977⁃1993. |

| 17 | MastersI G, EvansK E. Models for the elastic deformation of honeycombs[J]. Composite Structures, 1996, 35: 403⁃422. |

| [1] | 刘程, 史文库, 陈志勇, 何伟, 荣如松, 宋怀兰. 汽车驱动桥准双曲面齿轮齿根弯曲应力预测与试验[J]. 吉林大学学报(工学版), 2017, 47(2): 344-352. |

| [2] | 闫光, 庄炜, 刘锋, 祝连庆. 具有增敏效果的光纤光栅应变传感器的预紧封装及传感特性[J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [3] | 胡玉明, 黄音, 古海东. 排桩支护结构内力与变形三维有限元数值分析[J]. 吉林大学学报(工学版), 2016, 46(2): 445-450. |

| [4] | 肖湘, 黄恩厚, 尼颖升. 预应力混凝土梁板体系有效翼缘的理论分析及试验[J]. 吉林大学学报(工学版), 2015, 45(6): 1784-1790. |

| [5] | 庄蔚敏, 解东旋, 余天明, 于皖东. 基于损伤-相变本构模型的高强钢热成形数值模拟分析[J]. 吉林大学学报(工学版), 2015, 45(4): 1206-1212. |

| [6] | 孟广伟,李霄琳,李锋,周立明,王晖. 裂隙介质渗流的光滑多尺度有限元法[J]. 吉林大学学报(工学版), 2015, 45(2): 481-486. |

| [7] | 马彪1, 赵家昕1, 李和言1, 宁克炎2, 何春平3. 离合器结构参数对其热弹性不稳定性的影响[J]. 吉林大学学报(工学版), 2014, 44(4): 933-938. |

| [8] | 李晓军,梁路路,谢诚伟,杨硕. 沥青混凝土虚拟力学仿真模型自动生成及应用[J]. 吉林大学学报(工学版), 2014, 44(3): 655-660. |

| [9] | 庄蔚敏, 曹德闯, 叶辉. 基于连续介质损伤力学预测7075铝合金热冲压成形极限图[J]. 吉林大学学报(工学版), 2014, 44(2): 409-414. |

| [10] | 彭勇, 孙立军. 集料水平向分布状态对沥青混合料劈裂试验影响数值模拟[J]. 吉林大学学报(工学版), 2013, 43(04): 891-896. |

| [11] | 张强, 张璐, 刘宪军, 于路路, 贾洪雷. 基于有限元法的仿生钩形深松铲耕作阻力[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 117-121. |

| [12] | 邓兆祥, 高书娜. 结构声腔耦合系统的振型耦合特性分析及应用[J]. , 2012, 42(05): 1120-1126. |

| [13] | 庄蔚敏, 陈延红. 基于连续损伤力学的表面涂层损伤模拟[J]. , 2012, 42(04): 857-862. |

| [14] | 闫清东, 崔红伟, 魏巍. 新型液力变矩减速装置变矩工况叶轮有限元强度分析[J]. 吉林大学学报(工学版), 2012, 42(02): 365-371. |

| [15] | 孙钟雷, 孙永海, 方旭君, 刘晶晶. 仿齿冠压头破碎物料试验及模拟[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 236-240. |

|

||