吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2781-2791.doi: 10.13229/j.cnki.jdxbgxb.20221612

• 车辆工程·机械工程 • 上一篇

加筋板结构可靠性拓扑优化与工程化设计

余建星1,2( ),韦明秀1,2,余杨1,2,崔宇朋1,2,潘宇1,2

),韦明秀1,2,余杨1,2,崔宇朋1,2,潘宇1,2

- 1.天津大学 水利工程仿真与安全国家重点实验室,天津 300072

2.天津大学 天津市港口与海岸工程重点 实验室,天津 300072

Reliability-based topology optimization and engineering design of stiffened plates

Jian-xing YU1,2( ),Ming-xiu WEI1,2,Yang YU1,2,Yu-peng CUI1,2,Yu PAN1,2

),Ming-xiu WEI1,2,Yang YU1,2,Yu-peng CUI1,2,Yu PAN1,2

- 1.State Key Laboratory of Hydraulic Engineering Simulation and Safety,Tianjin University,Tianjin 300072,China

2.Tianjin Key Laboratory of Port and Ocean Engineering,Tianjin University,Tianjin 300072,China

摘要:

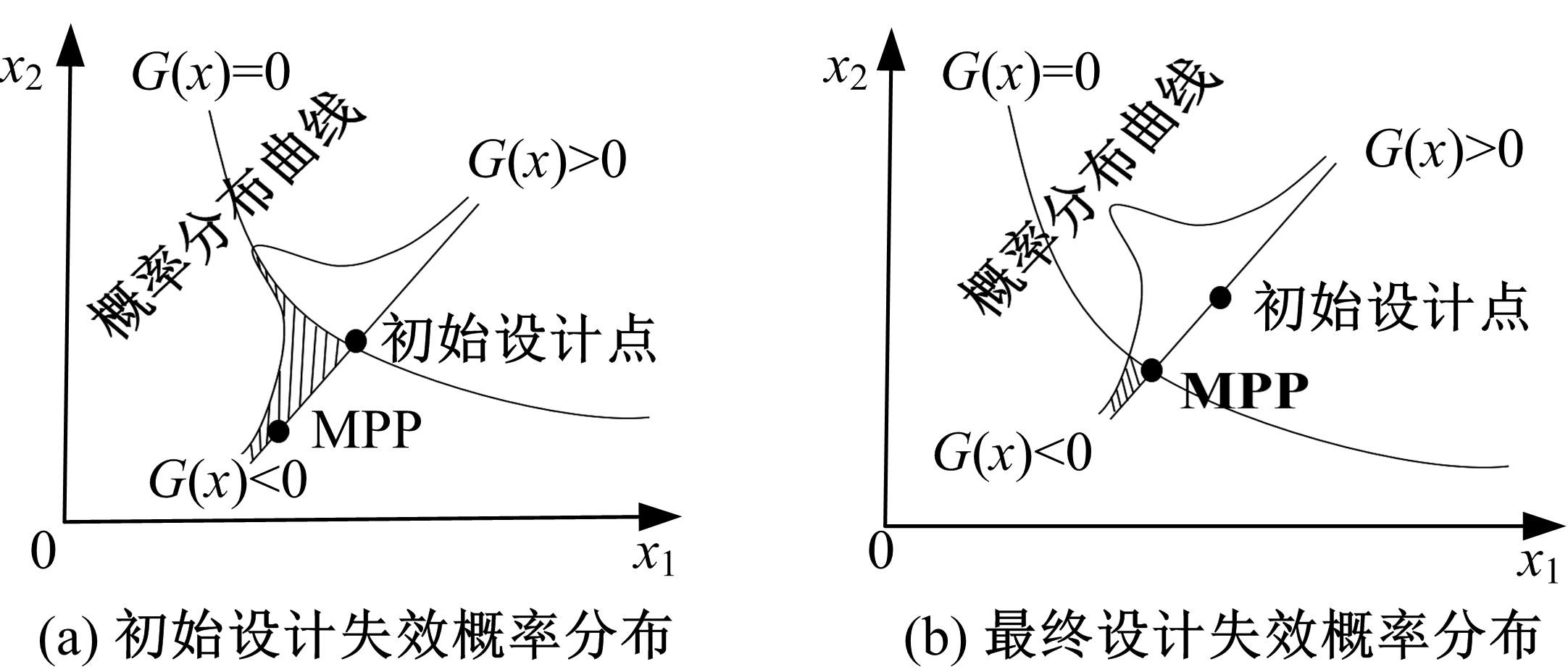

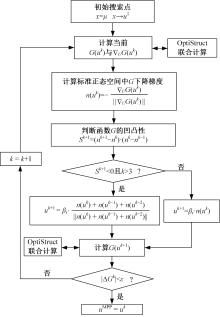

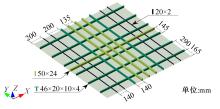

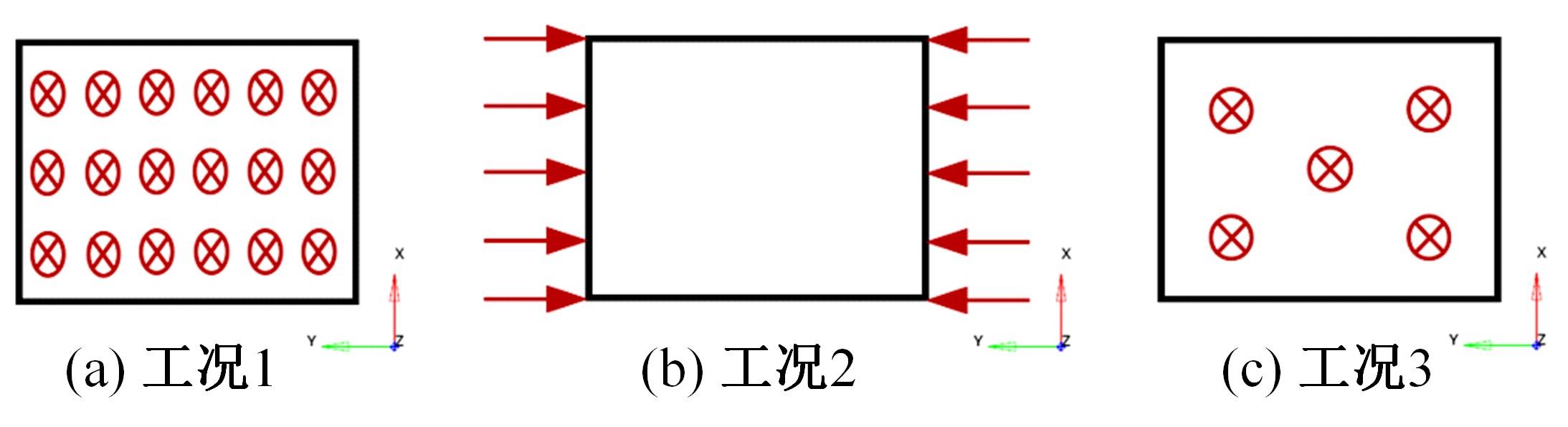

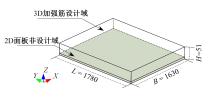

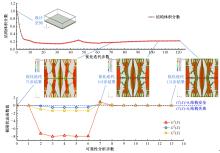

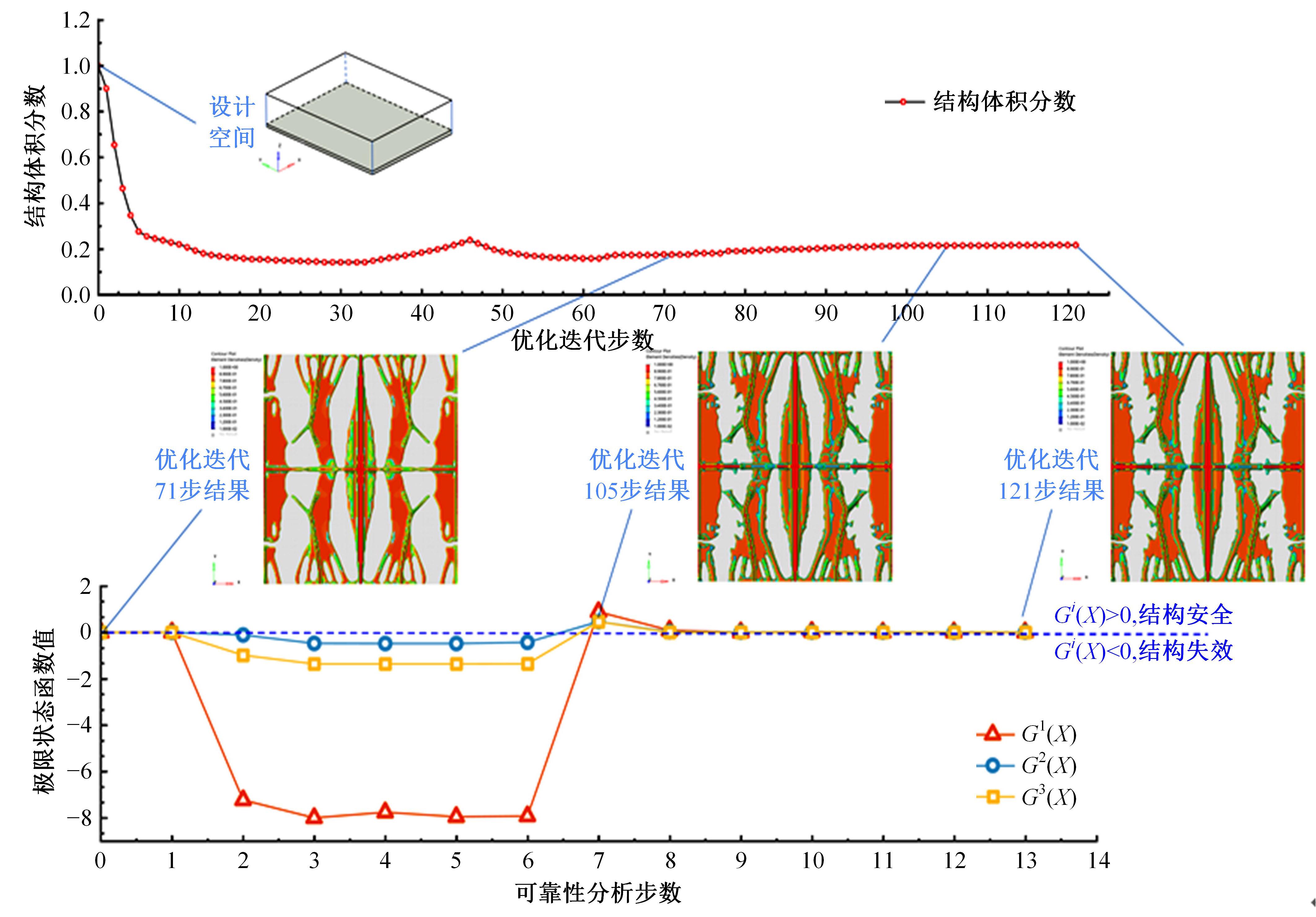

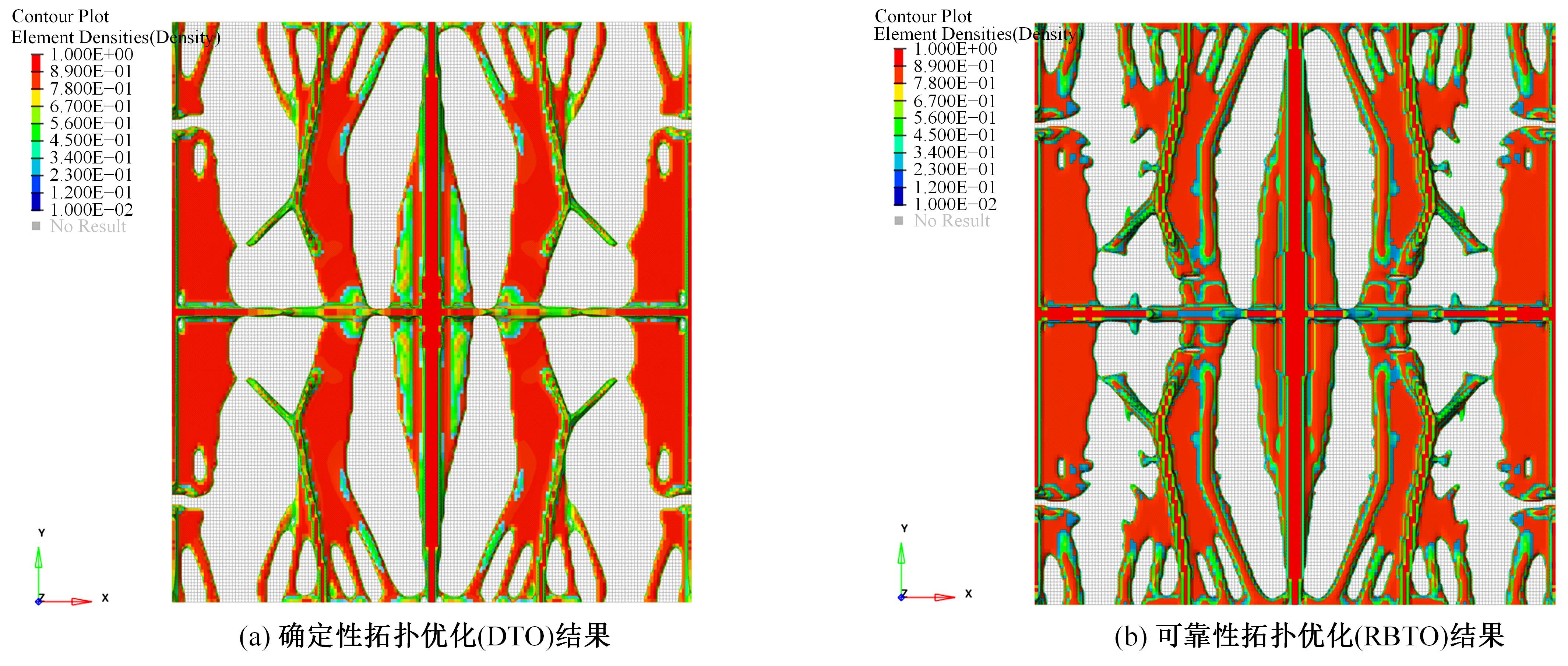

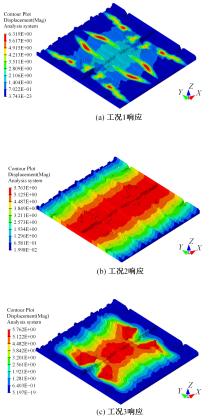

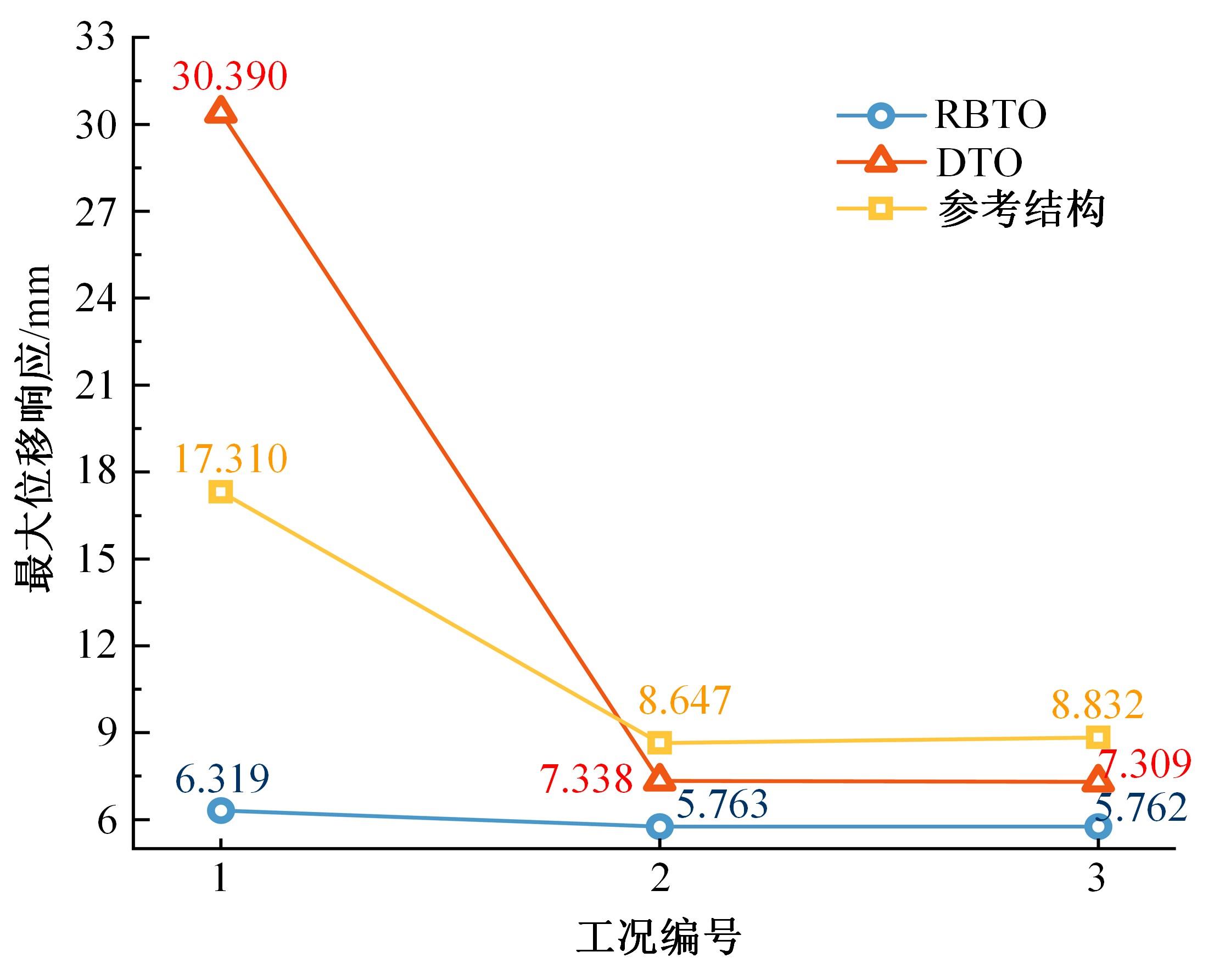

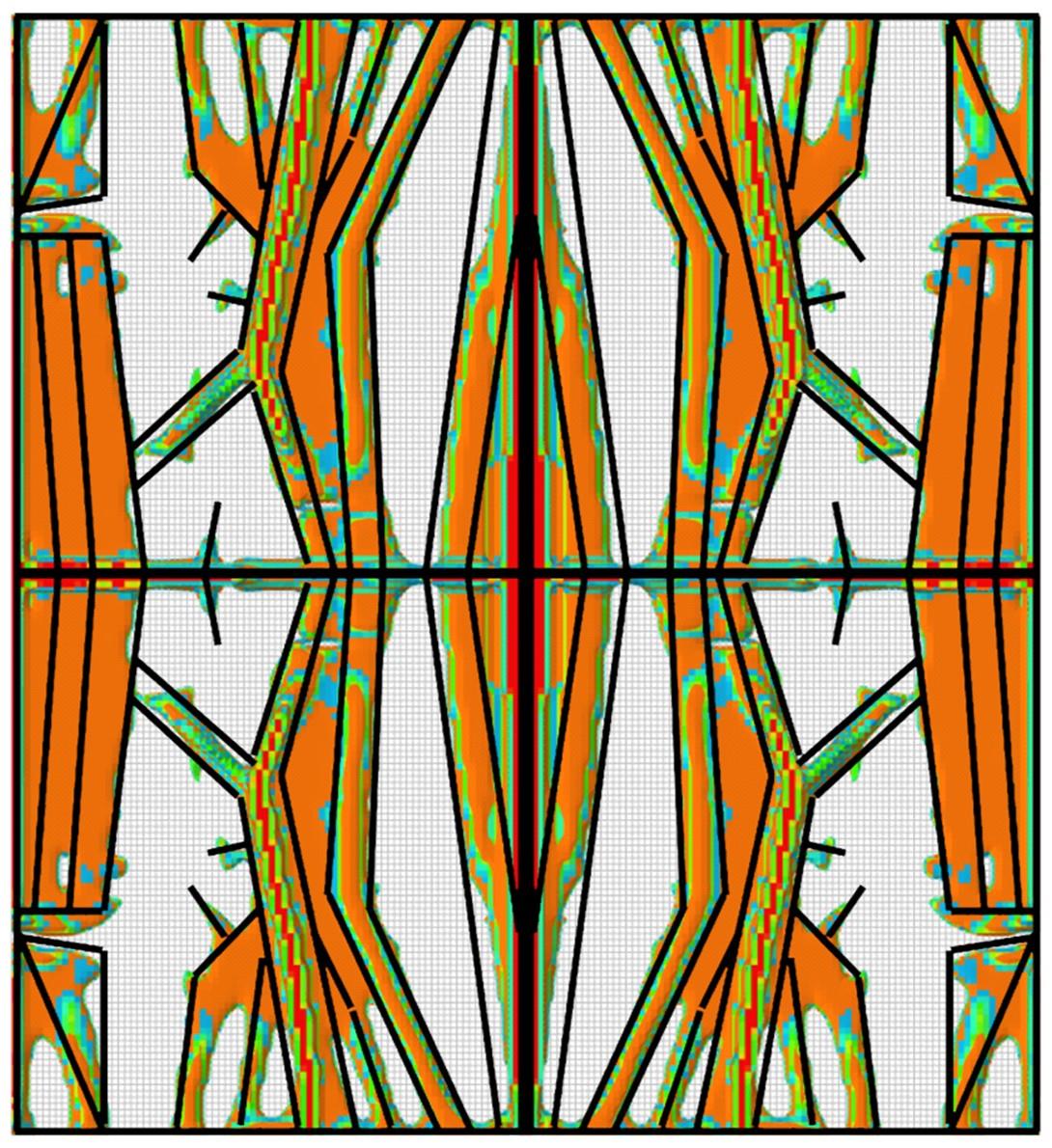

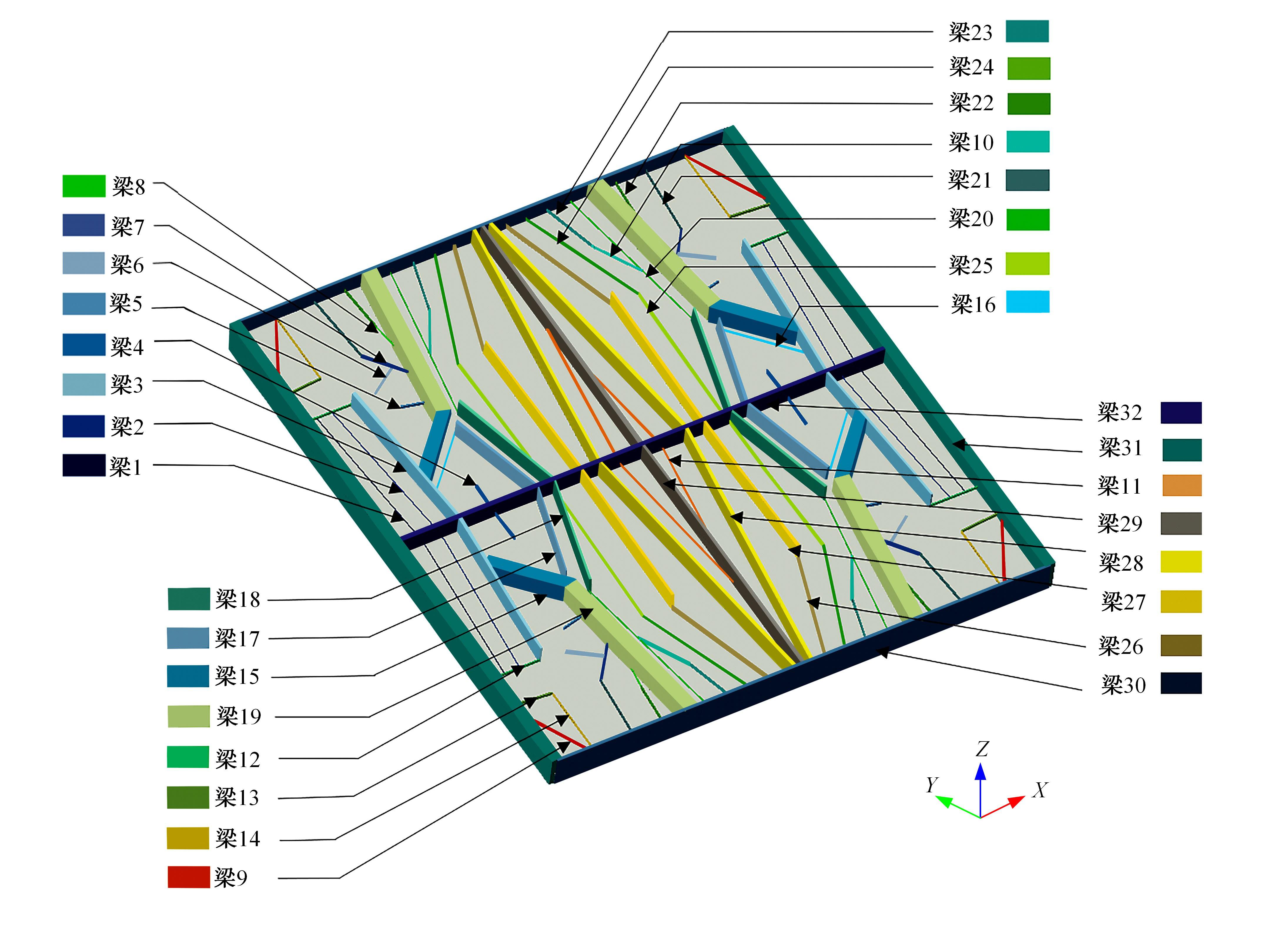

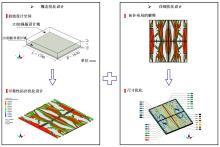

针对三维加筋板结构,为在保证其安全及可靠性的前提下实现轻量化与工程化设计,提出一种非嵌套的可靠性拓扑优化方法,并开展可靠性概念-详细组合优化设计。该方法借助序列优化及可靠性评估算法的解耦特性,应用变密度法内核下的外部优化软件进行确定性拓扑优化以提升优化效率;考虑载荷及材料随机性,将混合均值法应用于可靠性评估阶段的最可能失效点搜寻。进一步地,对可靠性概念设计进行布局解释并开展尺寸优化设计以实现工程化应用。研究表明:相较于确定性的拓扑优化方法,本文提出的可靠性拓扑优化方法,可兼顾可靠性与轻量化要求。可靠性概念-详细组合优化策略在简化布局并保证性能的同时,使加筋板结构材料成本降低21.40%。

中图分类号:

- P751

| 1 | Chu S, Featherston C, Kim H A. Design of stiffened panels for stress and buckling via topology optimization[J]. Structural and Multidisciplinary Optimization, 2021, 64: 3123-3146. |

| 2 | Li L, Liu C, Zhang W, et al. Combined model-based topology optimization of stiffened plate structures via MMC approach[J]. International Journal of Mechanical Sciences, 2021, 208: No.106682. |

| 3 | Wang Z, Yang C, Xu X, et al. Layout design of stiffened plates for large-scale box structure under moving loads based on topology optimization[J]. Mathematical Problems in Engineering, 2020(40): No.8843657. |

| 4 | Liu H, Li B, Yang Z, et al. Topology optimization of stiffened plate/shell structures based on adaptive morphogenesis algorithm[J]. Journal of Manufacturing Systems, 2017, 43: 375-384. |

| 5 | Dugré A, Vadean A, Chaussée J. Challenges of using topology optimization for the design of pressurized stiffened panels[J]. Structural and Multidisciplinary Optimization, 2016, 53: 303-320. |

| 6 | Perl M, Steiner M. 3-D stress intensity factors due to full autofrettage for inner radial or coplanar crack arrays and ring cracks in a spherical pressure vessel[J]. Engineering Fracture Mechanics, 2015, 138: 233-249. |

| 7 | 崔宇朋, 余杨, 余建星, 等. 大跨度无支撑甲板拓扑-尺寸-材料联合优化设计[J]. 中国机械工程, 2022,33(23):2879-2897. |

| Cui Yu-peng, Yu Yang, Yu Jian-xing, et al. Topology-size-material joint optimization design of long-span unsupported deck[J]. China Mechanical Engineering, 2022,33(23): 2879-2897. | |

| 8 | 曹迈, 王泽宇, 李全旺, 等. 基于SORA算法的混凝土结构尺寸优化[C]//第30届全国结构工程学术会议论文集, 广州,2021: 214-219. |

| 9 | 李海燕, 井元伟. 基于SORA的多学科协同优化可靠性优化方法[J].东北大学学报:自然科学版, 2018, 39(1): 1-5. |

| Li Hai-yan, Jing Yuan-wei. Multidisciplinary collaborative optimization reliability optimization method based on SORA[J]. Journal of Northeastern University (Natural Science) 2018, 39(1): 1-5. | |

| 10 | 胡新明, 王德禹.基于迭代均值组合近似模型和序贯优化与可靠性评估法的船舶结构优化设计[J].上海交通大学学报, 2017, 51(2): 150-156. |

| Hu Xin-ming, Wang De-yu. Optimization design of ship structure based on iterative mean combination approximation model and sequential optimization and reliability evaluation method[J]. Journal of Shanghai Jiaotong University, 2017, 51(2): 150-156. | |

| 11 | 王宇, 余雄庆, 杜小平. 基于支持向量机的序列可靠性优化方法[J].计算力学学报, 2013, 30(4): 485-490. |

| Wang Yu, Yu Xiong-qing, Du Xiao-ping. Sequence reliability optimization method based on support vector machine[J]. Journal of Computational Mechanics, 2013, 30(4): 485-490. | |

| 12 | 罗文俊, 王德禹. 基于兴趣子域动态代理模型的船舶结构可靠性优化[J].中国舰船研究, 2021, 16(4): 96-107. |

| Luo Wen-jun, Wang De-yu. Reliability optimization of ship structure based on interest-based subdomain dynamic proxy model[J]. China Ship Research, 2021, 16(4): 96-107. | |

| 13 | Deaton J D, Grandhi R V. A survey of structural and multidisciplinary continuum topology optimization: Post 2000[J]. Structural and Multidisciplinary Optimization, 2014, 49: 1-38. |

| 14 | Du X, Chen W. Sequential optimization and reliability assessment method for efficient probabilistic design[J]. J Mech Des, 2004, 126(2): 225-233. |

| 15 | Aoues Y, Chateauneuf A. Benchmark study of numerical methods for reliability-based design optimization[J]. Structural and Multidisciplinary Optimization, 2010, 41(2): 277-294. |

| 16 | Du X, Chen W. A most probable point-based method for efficient uncertainty analysis[J]. Journal of Design & Manufacturing Automation, 2001, 4(1):47-66. |

| 17 | Wu Y T, Millwater H R, Cruse T A. Advanced probabilistic structural analysis method for implicit performance functions[J]. AIAA Journal, 1990, 28(9):1663-1669. |

| 18 | Choi K K, Youn B D. Hybrid analysis method for reliability-based design optimization[J].Journal of Mechanical Design, 2003, 125(2): 221-232. |

| 19 | 徐龙坤,何勇,金伟良.基于可靠度深海浮式平台加筋板优化设计方法[J].海洋工程,2010,28(3):17-23. |

| Xu Long-kun, He Yong, Jin Wei-liang. Reliability-based design optimization for stiffened panel of deep-water platform[J]. The Ocean Engineering, 2010, 28(3):17-23. |

| [1] | 王琛,雒特,惠倩倩,王忠昊,王方方. 面向分体式飞行汽车对接锁定的机电系统设计与验证[J]. 吉林大学学报(工学版), 2024, 54(8): 2130-2140. |

| [2] | 刘洋. 橡胶鞋底弹性打磨仿真及试验[J]. 吉林大学学报(工学版), 2024, 54(8): 2167-2173. |

| [3] | 王磊,李东侠,周松,回丽,沈振鑫. 2024-O铝合金搅拌摩擦焊接头疲劳裂纹扩展行为及寿命预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1563-1569. |

| [4] | 刘洋,江涛. 计及安装角的六自由度平台虎克铰干涉计算模型[J]. 吉林大学学报(工学版), 2024, 54(6): 1519-1527. |

| [5] | 谭晓丹,王勇澎,Hall Robert,徐天爽,黄庆学. 面向电铲自主装卸的矿用自卸车斗型优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1227-1236. |

| [6] | 王世俊,罗冠炜. 含多种碰撞约束振动系统的周期运动转迁特性[J]. 吉林大学学报(工学版), 2024, 54(4): 902-916. |

| [7] | 孙伟,杨俊. 等角贴敷压电分流片圆柱壳有限元建模及减振分析[J]. 吉林大学学报(工学版), 2024, 54(2): 365-374. |

| [8] | 胡斌,蔡一全,罗昕,毛自斌,李俊伟,郭孟宇,王剑. 基于种群胁迫的有限齿侧空间高速充种理论与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 574-588. |

| [9] | 王佳怡,刘昕晖,王展,陈晋市,韩亚方,王禹琪. 基于AMESim的恒流量控制阀流量特性分析[J]. 吉林大学学报(工学版), 2023, 53(9): 2499-2507. |

| [10] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [11] | 黄贤振,孙楷铂,栾晓刚,胡兵. 螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2219-2226. |

| [12] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [13] | 宋剑锋,黄鑫磊,仪帅,杨振熙,董永刚,李树林. 列车制动过程踏面温度场及应力⁃应变分布特性[J]. 吉林大学学报(工学版), 2023, 53(10): 2773-2784. |

| [14] | 刘洋. 动臂塔机防后倾缓冲力计算方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2785-2794. |

| [15] | 刘洋. 动臂塔机卸载冲击仿真及试验[J]. 吉林大学学报(工学版), 2022, 52(6): 1292-1300. |

|

||