吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2499-2507.doi: 10.13229/j.cnki.jdxbgxb.20211265

基于AMESim的恒流量控制阀流量特性分析

王佳怡1( ),刘昕晖1,王展2,陈晋市1(

),刘昕晖1,王展2,陈晋市1( ),韩亚方3,王禹琪1

),韩亚方3,王禹琪1

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.北京博科测试系统股份有限公司,北京 101102

3.中国商飞上海飞机设计研究院,上海 200232

Flow characteristics analysis of constant flow control valve based on AMESim

Jia-yi WANG1( ),Xin-hui LIU1,Zhan WANG2,Jin-shi CHEN1(

),Xin-hui LIU1,Zhan WANG2,Jin-shi CHEN1( ),Ya-fang HAN3,Yu-qi WANG1

),Ya-fang HAN3,Yu-qi WANG1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.BBK Test Systems Co. ,Ltd. ,Beijing 101102,China

3.Shanghai Aircraft Design and Research Institute,Shanghai 200232,China

摘要:

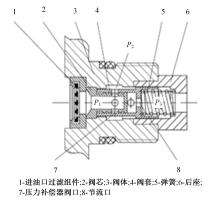

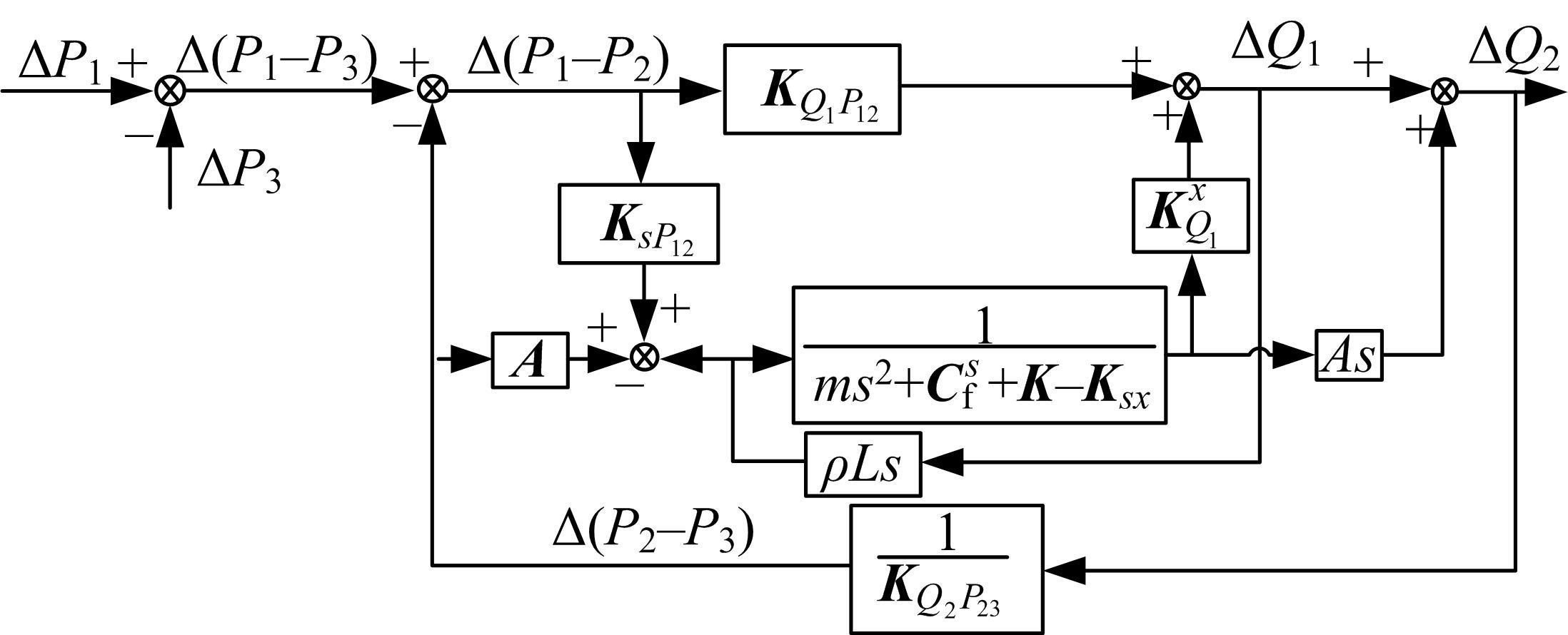

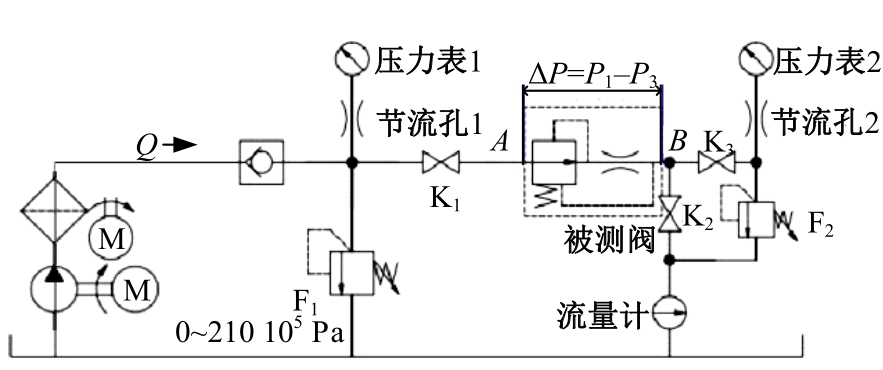

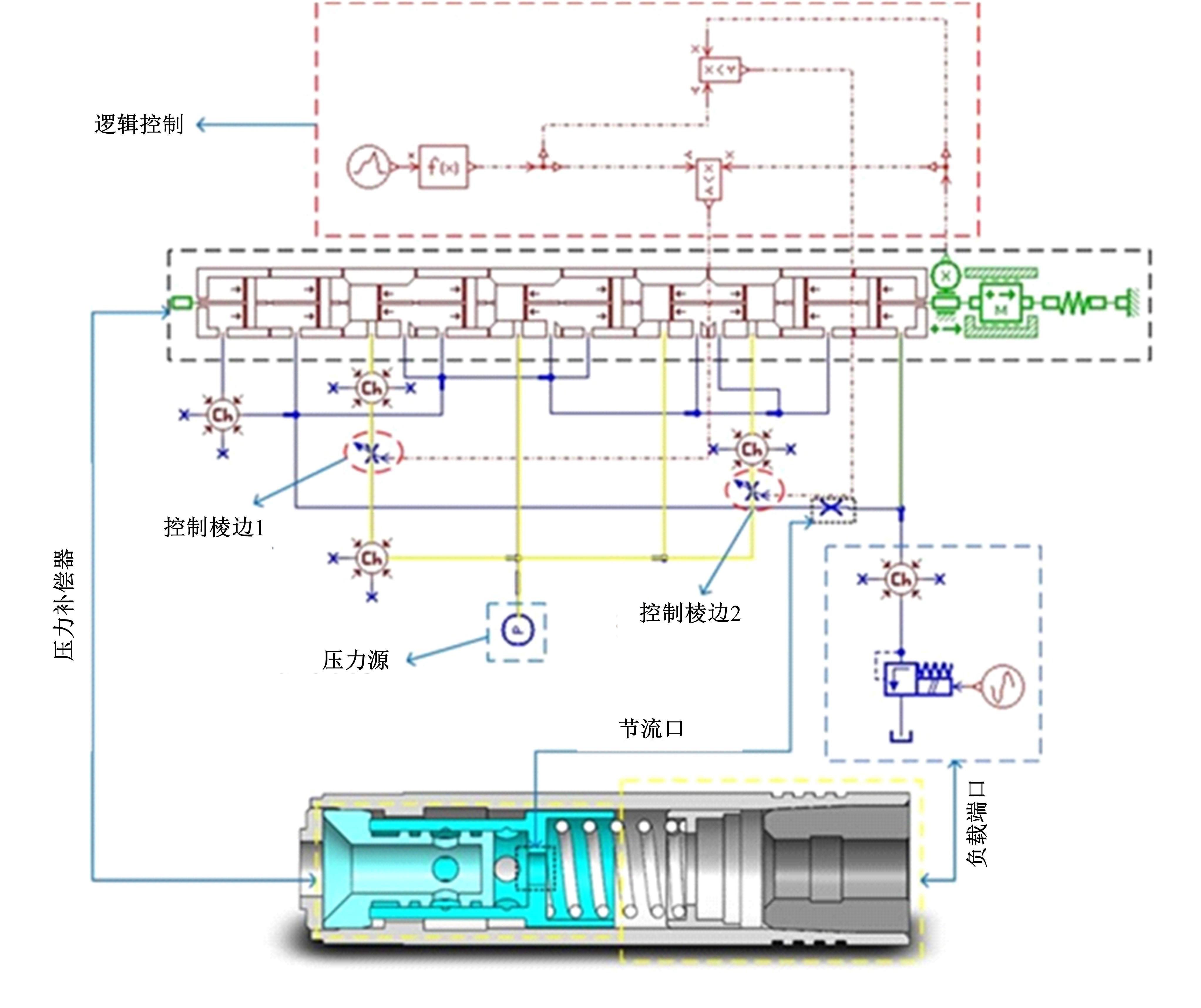

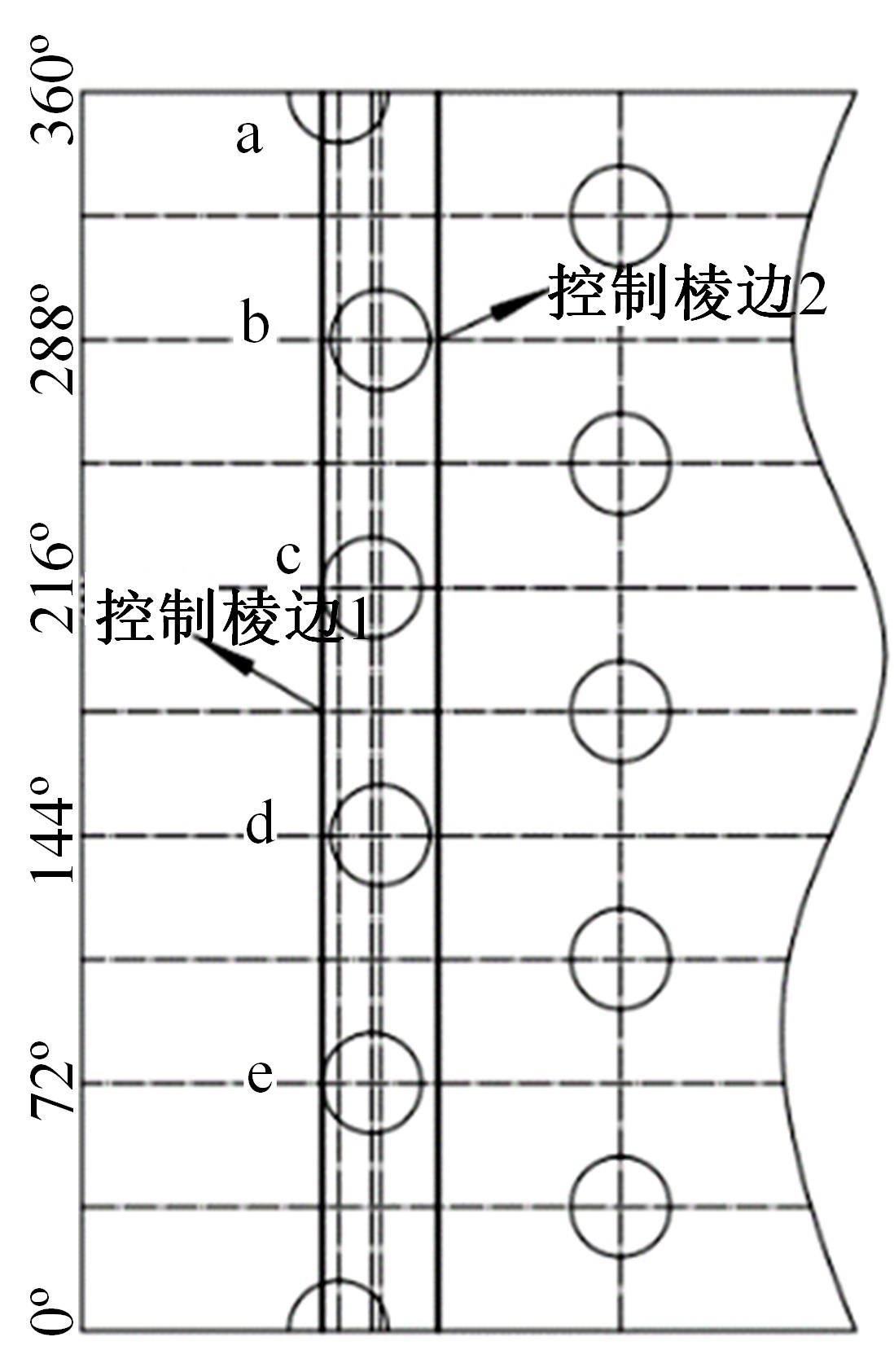

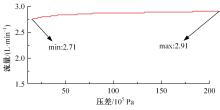

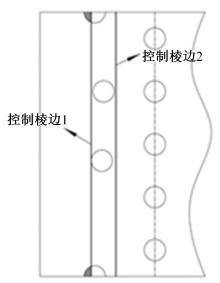

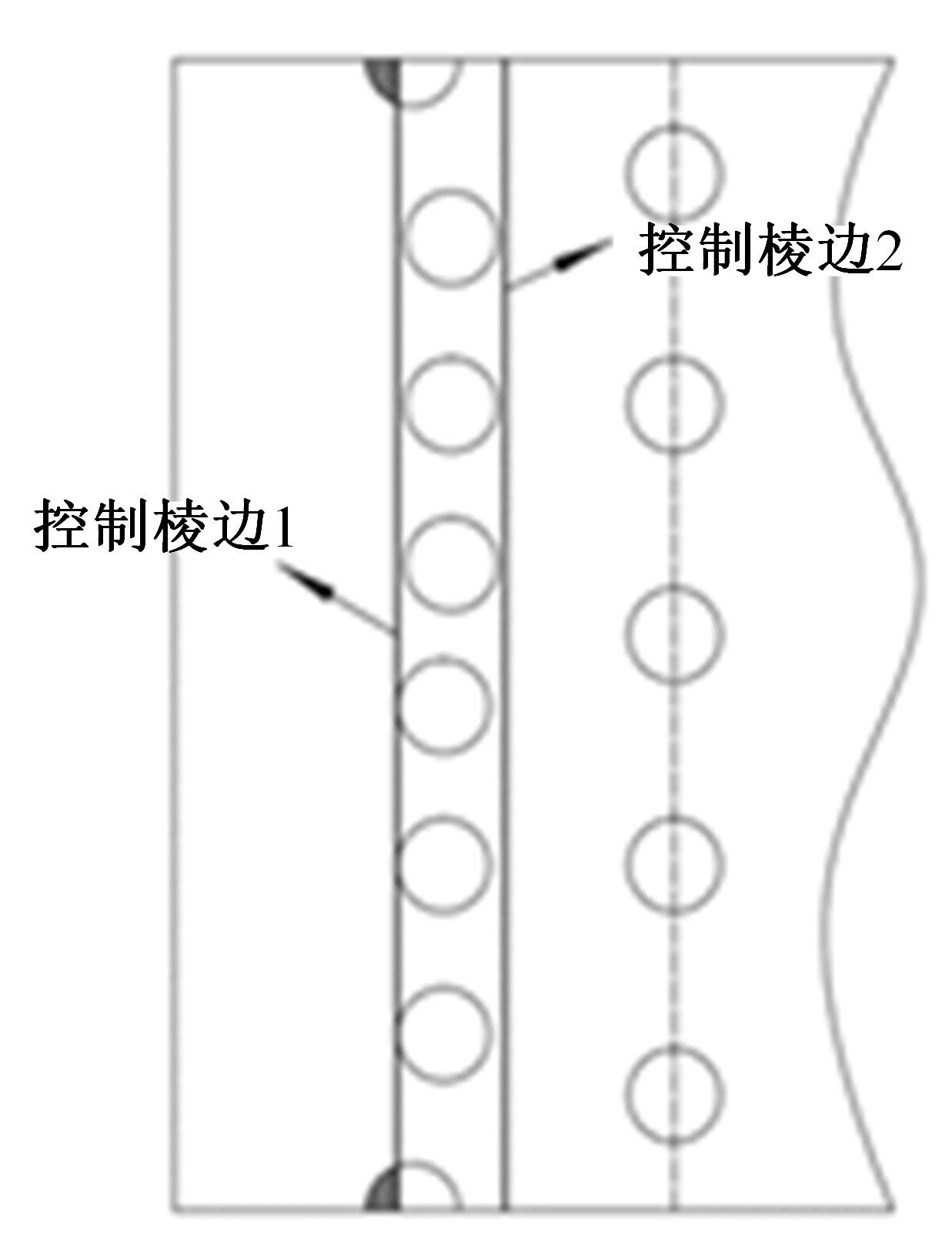

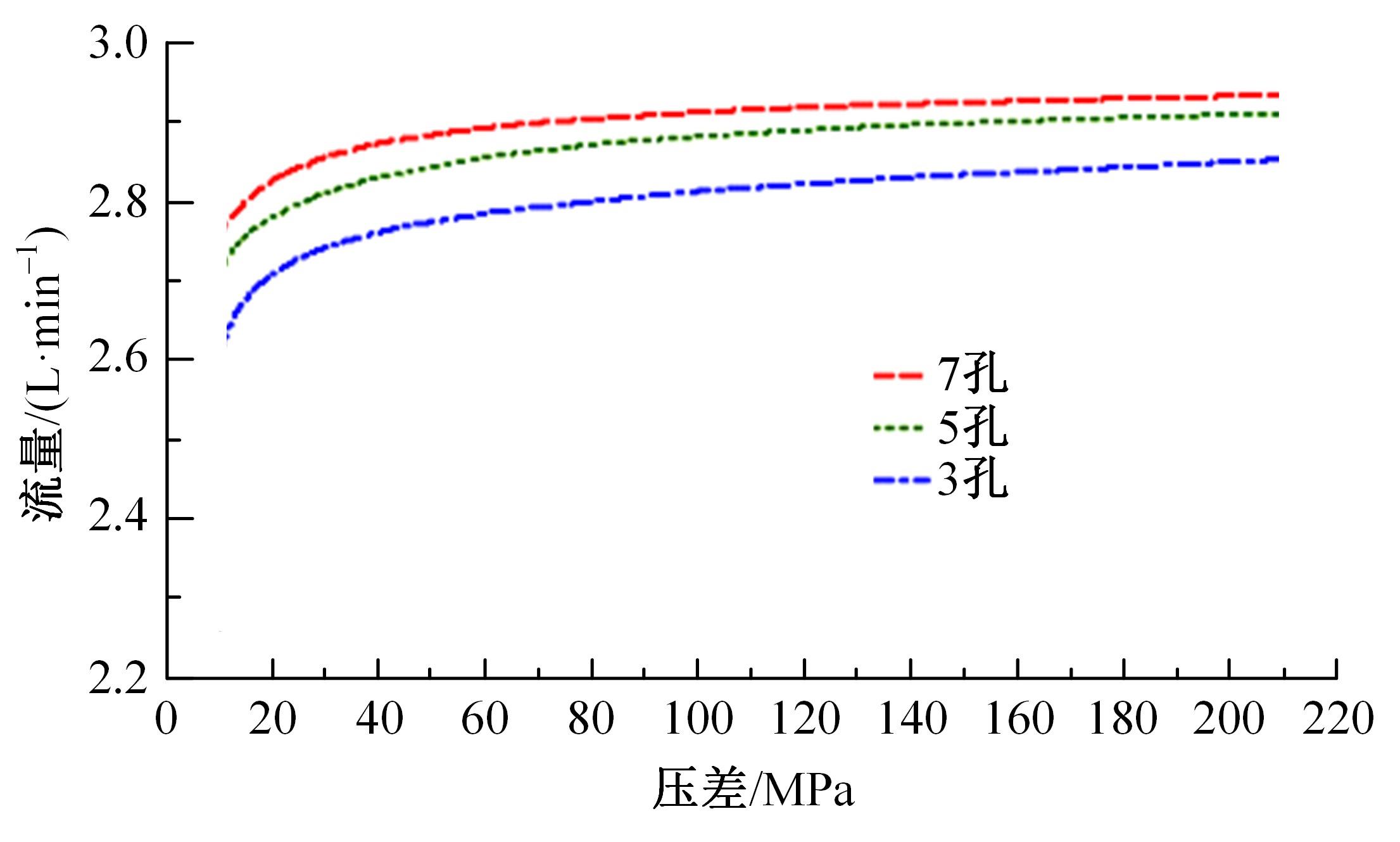

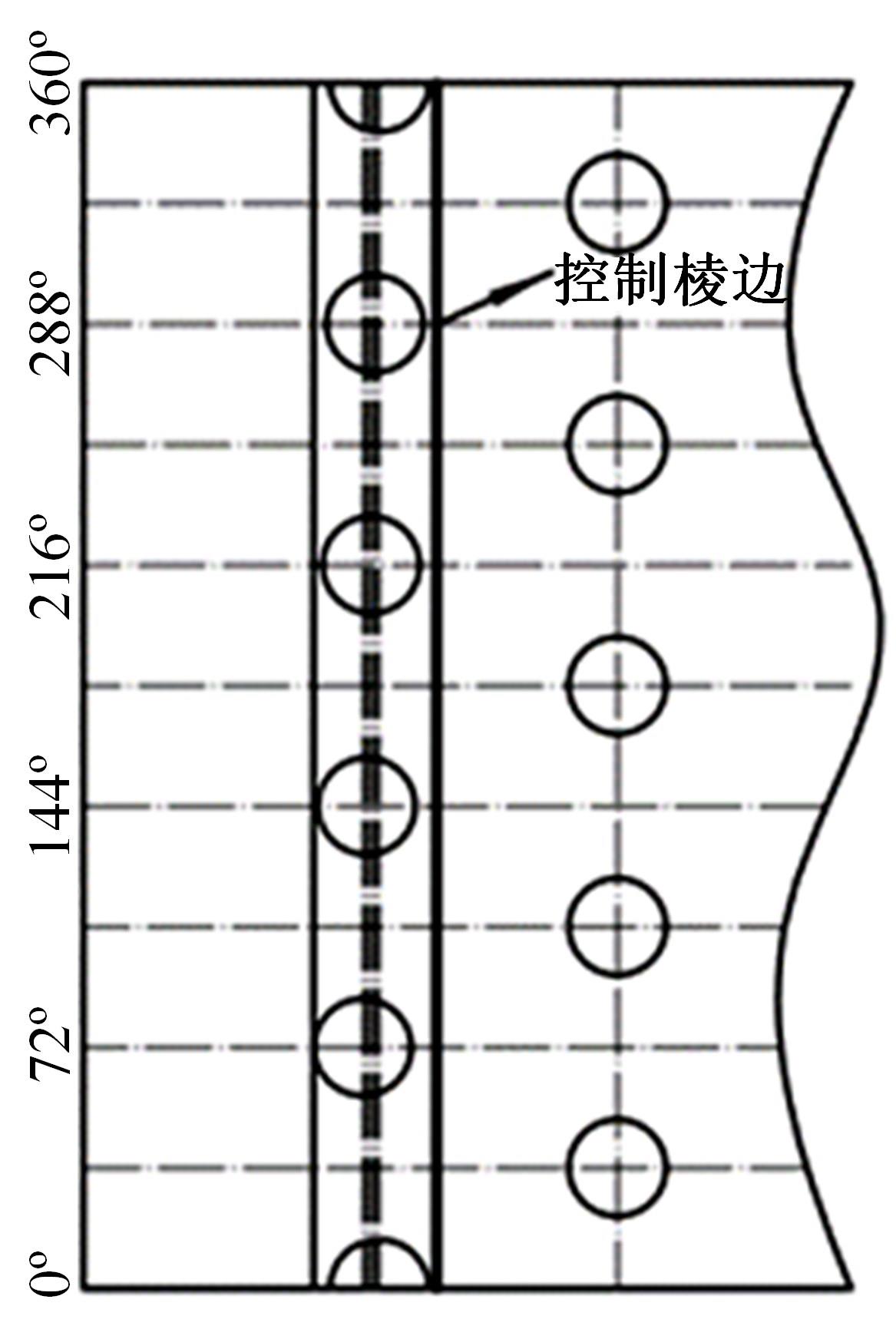

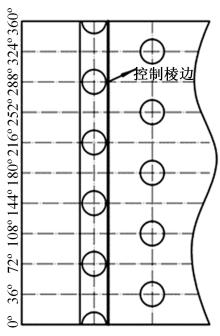

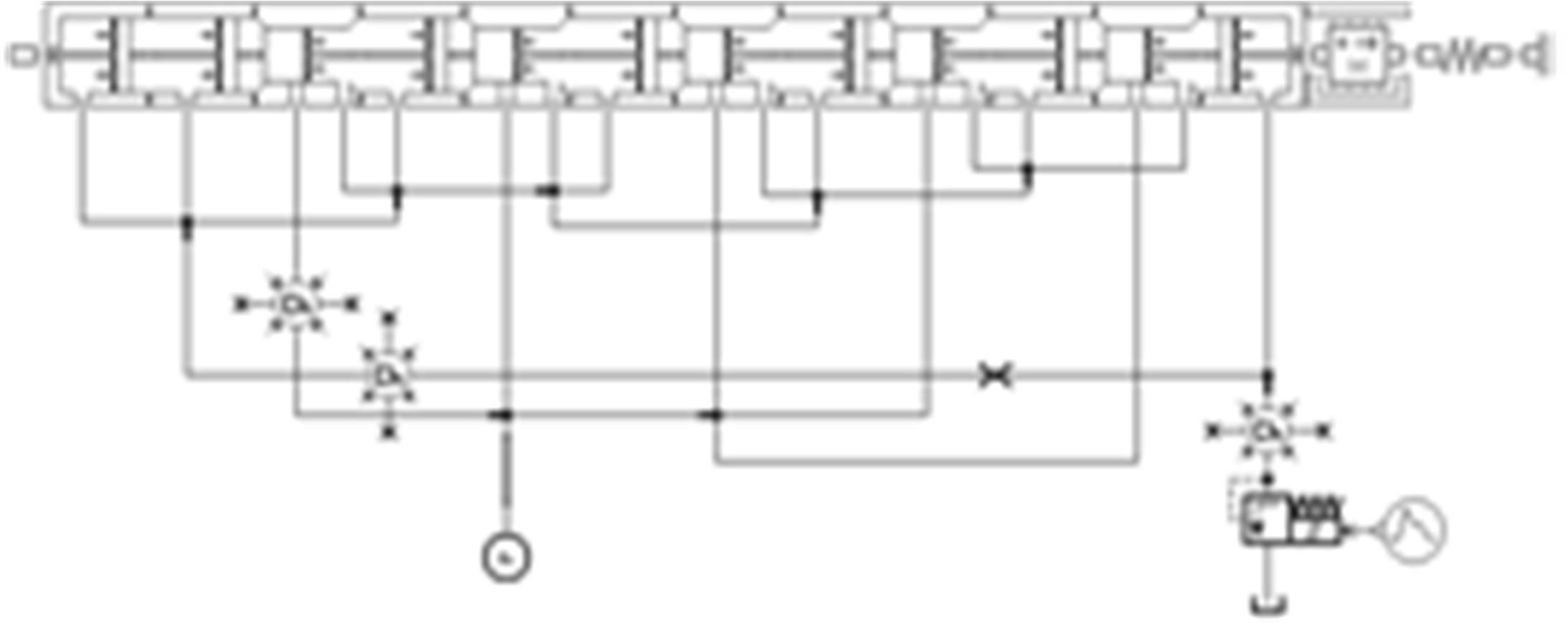

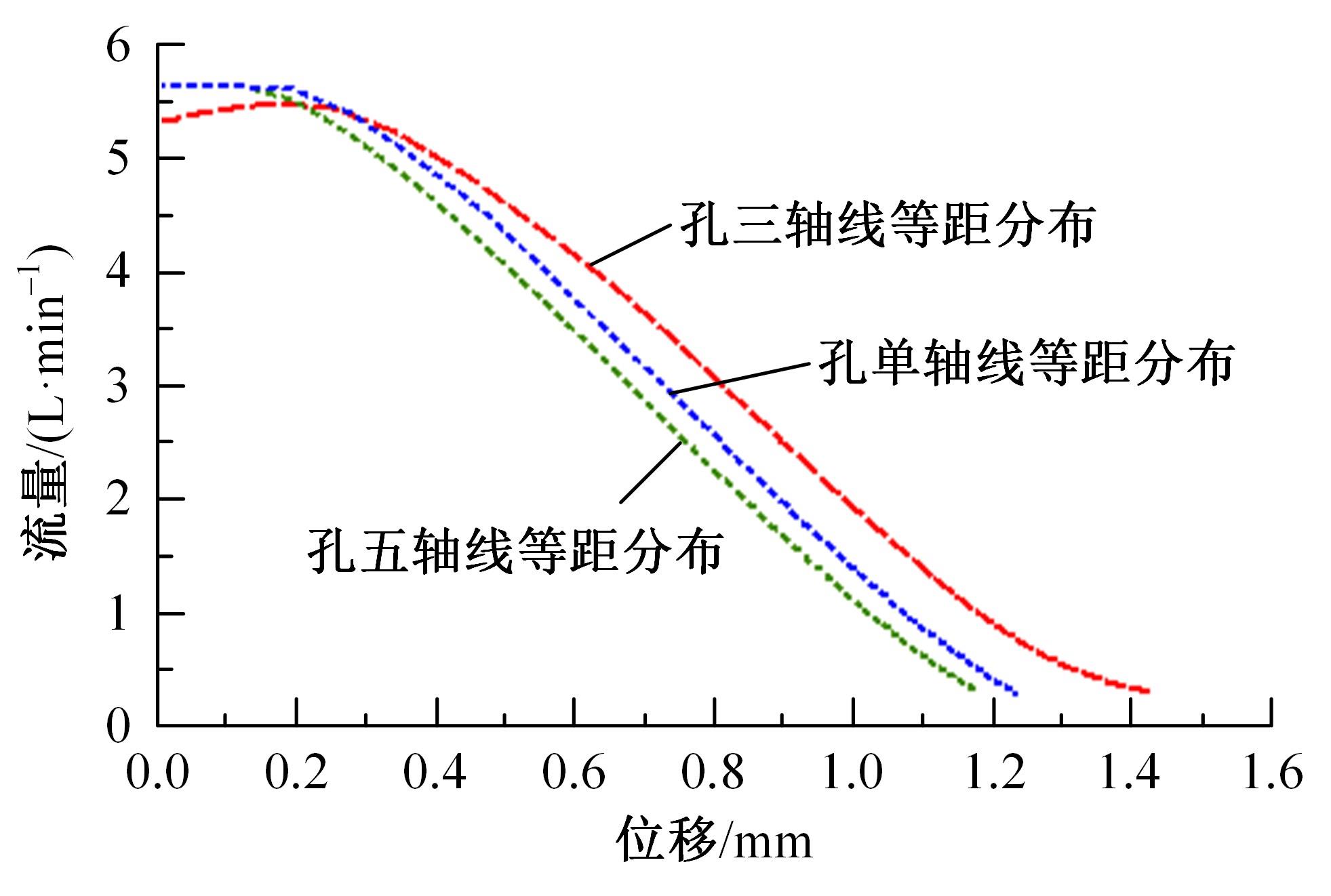

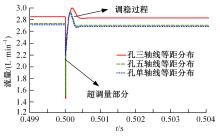

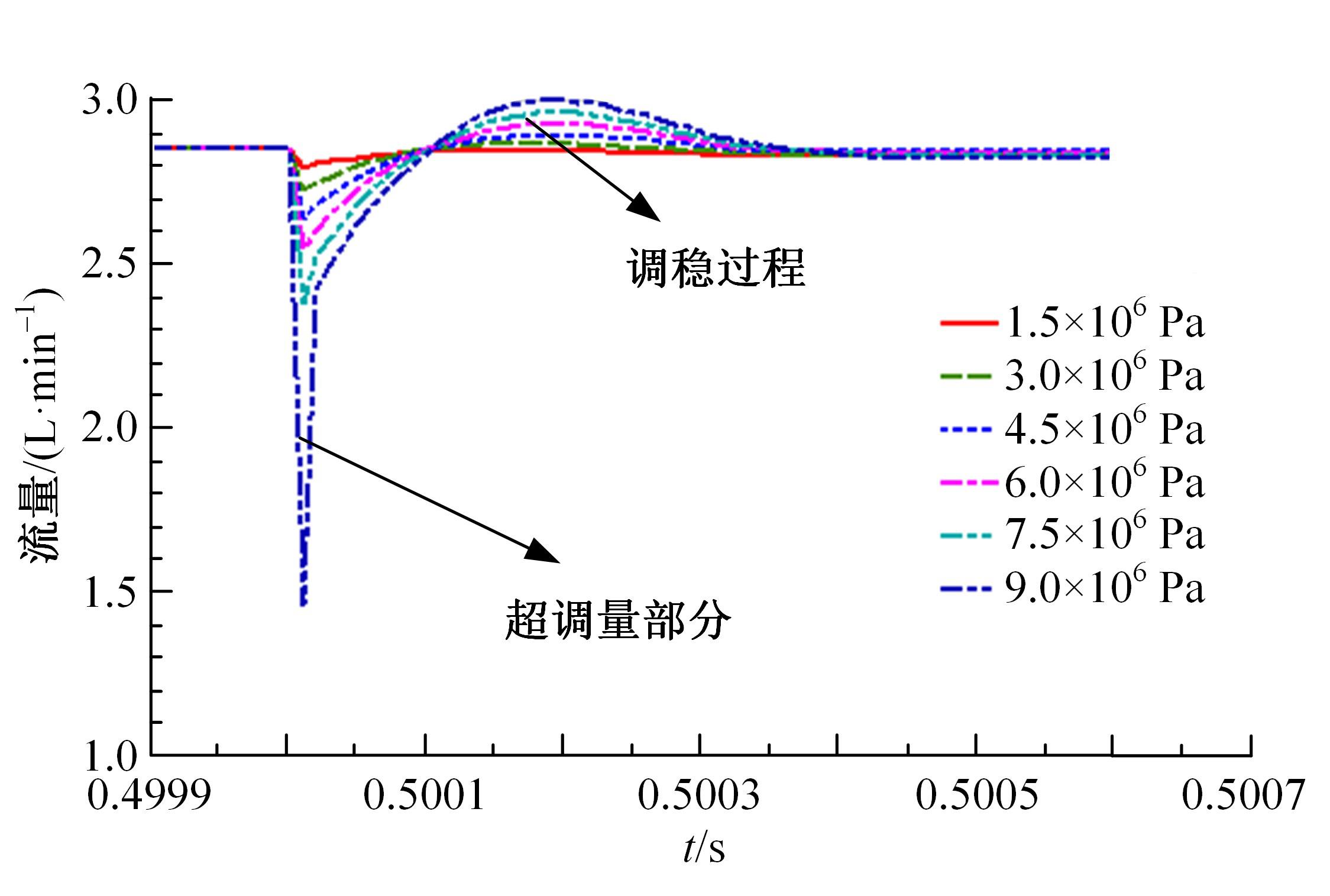

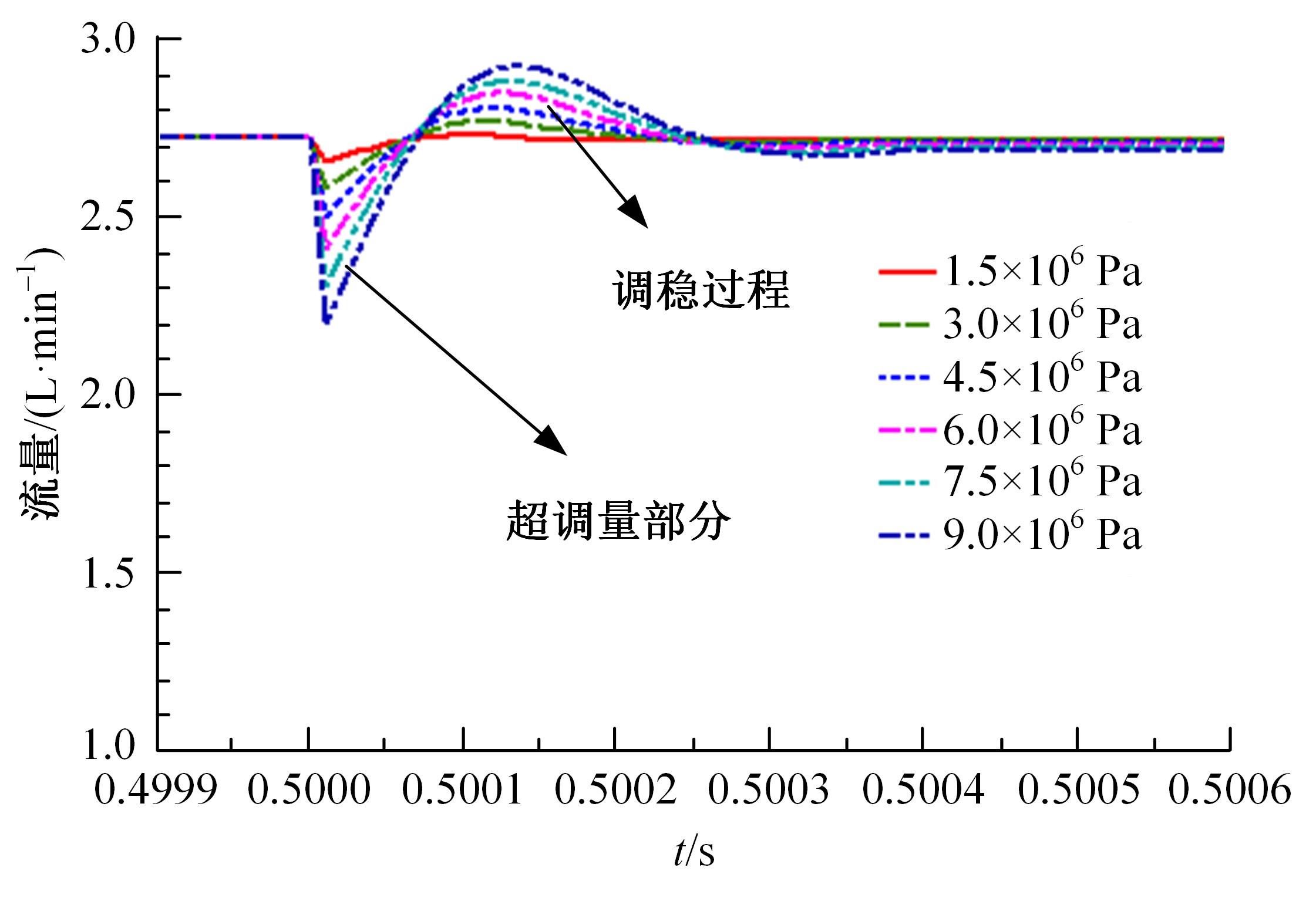

为研究恒流量控制阀的流量恒定机理,依据某型号阀的实际结构对影响恒流量控制阀特性的阀口过流面积及梯度因素进行分析。首先,建立其数学模型、控制理论模型和动态系统传函框图,定性分析了这些因素对恒流量控制阀特性的影响;然后,建立其AMESim仿真模型,分析了这些因素对该阀稳态特性和动态特性的影响机理,并通过实验验证了仿真模型的可靠性。结果表明:恒流量控制阀结构存在级间负反馈,补偿节流孔两侧压差可降低流量调节偏差;调节压力补偿器阀口过流面积有助于改善恒流量控制阀的稳态特性;调整压力补偿器阀口过流面积梯度可显著改善恒流量控制阀的静、动态特性。

中图分类号:

- TH137.5

| 1 | 陈晋市, 王国强, 龚勋, 等. 插装式单向溢流阀特性[J]. 吉林大学学报:工学版,2016,46(2): 467-468. |

| Chen Jin-shi, Wang Guo-qiang, Gong Xun, et al. Characteristics of cartridge one-way relief valve[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 467-468. | |

| 2 | Lu Z, Zhang J, Xu B, et al. Deadzone compensation control based on detection of micro flow rate in pilot stage of proportional directional valve[J]. ISA Transactions, 2019, 94: 234-245. |

| 3 | Coskun G, Kolcuoglu T, Dogramacı T, et al. Analysis of a priority flow control valve with hydraulic system simulation model[J]. Journal of the Brazilian Society of Mechanical Sciences & Engineering, 2017, 39(5): 1597-1605. |

| 4 | Gu F, Jiang J H, Meng D, et al. The modeling and simulation of hydraulic actuated control system of helicopter in volumetric speed control[J]. Applied Mechanics and Materials, 2015, 779: 169-174. |

| 5 | Hao Q, Wu W, Liang X, et al. Effects of structure parameters on abnormal opening of pilot-operated relief valve under alternating pressure[J]. IEEE Access, 2019, 7: 33932-33942. |

| 6 | Zhang J, Lu Z, Xu B, et al. Investigation on the dynamic characteristics and control accuracy of a novel proportional directional valve with independently controlled pilot stage[J]. ISA Transactions, 2019, 93(3): 218-230. |

| 7 | Amirante R, Vescovo G D, Lippolis A. Flow forces analysis of an open center hydraulic directional control valve sliding spool[J]. Energy Conversion and Management, 2006, 47(1): 114-131. |

| 8 | Tao X X, Li T, Huang J H, et al. Characteristic analysis of the digital pilotflow control valve[J]. Machine Tool & Hydraulics, 2016, 44(6): 25-29. |

| 9 | Okhotnikov I, Noroozi S, Sewell P, et al. Evaluation of steadyflow torques and pressure losses in a rotaryflow control valve by means of computational fluid dynamics[J]. International Journal of Heat and Fluid Flow, 2017, 64(16): 89-102. |

| 10 | Xie H B, Liu J B, Yang H Y, et al. Design of pilot-assisted load control valve with load velocity control ability and fast opening feature[J]. Advances in Mechanical Engineering, 2015, 7(11): 1-9. |

| 11 | Lisowski E, Filo G, Rajda J. Analysis offlow forces in the initial phase of throttle gap opening in a proportional control valve[J]. Flow Measurement and Instrumentation, 2017, 59: 157-167. |

| 12 | Lisowski E, Filo G. Analysis of a proportional control valveflow coefficient with the usage of a CFD method[J]. Flow Measurement and Instrumentation, 2017, 53: 269-278. |

| 13 | Zhang J, Lu Z, Xu B, et al. Investigation on the dynamic characteristics and control accuracy of a novel proportional directional valve with independently controlled pilot stage[J]. ISA Transactions, 2019, 93: 218-230. |

| 14 | Wen R W, Yue L Y. Characteristics analysis of proportional control valve on vane damp[J]. Applied Mechanics and Materials, 2014, 541-542: 1266-1270. |

| 15 | 彭刚, 周维科. 一种新型二通调速阀的结构分析与应用[J]. 液压气动与密封, 2011, 31(1): 53-55. |

| Peng Gang, Zhou Wei-ke. Structure analysis and application of a new two-way speed regulating valve[J]. Hydraulics Pneumatics & Seals, 2011, 31(1): 53-55. | |

| 16 | 王琦, 张江兵, 饶军,等. 恒流量控制阀的数值模拟和优化设计[J]. 液压与气动, 2013(12): 38-41. |

| Wang Qi, Zhang Jiang-bing, Rao Jun, et al. Numerical simulation and optimization design of constant flow control valve[J]. Chinese Hydraulics & Pneumatics, 2013(12): 38-41. | |

| 17 | 王书翰,杨伟,李晓东,等. 8挡自动变速器系统压力与流量控制阀设计及动态仿真[J]. 西华大学学报:自然科学版, 2020, 39(5): 84-90. |

| Wang Shu-han, Yang Wei, Li Xiao-dong, et al. Design and dynamic simulation of system pressure valva in FWD 8AT[J]. Journal of Xihua University (Natural Science Edition), 2020, 39(5): 84-90. | |

| 18 | 佘翔. 基于AMESim的汽车发动机冷却系统仿真分析[D]. 西安: 长安大学汽车学院, 2014. |

| She Xiang. Research of cooling system of automobile engine based on AMESim[D]. Chang' an: School of Automobile, Chang' an University, 2014. | |

| 19 | 罗艳蕾, 李渊, 邱雪, 等. 基于AMESim的挖掘机负荷传感多路阀建模和仿真[J]. 机床与液压, 2012, 40(3): 142-144. |

| Luo Yan-lei, Li Yuan, Qiu Xue, et al. Modeling and Simulation of hydraulic excavator load-sensing multi-passage valve based on AMESim[J]. Machine Tool & Hydraulics, 2012, 40(3): 142-144. |

| [1] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [2] | 黄贤振,孙楷铂,栾晓刚,胡兵. 螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2219-2226. |

| [3] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [4] | 都京,赵洪辉,王宇鹏,丁天威,魏凯,王恺,韩令海. 基于AMESim模型的燃料电池发动机排氢策略优化及整车搭载验证[J]. 吉林大学学报(工学版), 2022, 52(9): 2069-2076. |

| [5] | 刘洋. 动臂塔机卸载冲击仿真及试验[J]. 吉林大学学报(工学版), 2022, 52(6): 1292-1300. |

| [6] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [7] | 程亚兵,陈璐翔,葛平玉,杨泽宇,曹鹏宇. 双相正时套筒链的动力学仿真分析及磨损失效[J]. 吉林大学学报(工学版), 2022, 52(4): 781-788. |

| [8] | 赵洋,肖洋,孙皓,霍文浩,冯松,廖勇. 基于围道积分的润滑接触齿轮微点蚀损伤特征模拟[J]. 吉林大学学报(工学版), 2022, 52(4): 799-810. |

| [9] | 张朋成,彭斌,张宇波. 基于圆渐开线建立变截面涡旋齿的方法与理论[J]. 吉林大学学报(工学版), 2022, 52(4): 789-798. |

| [10] | 张龙,徐天鹏,王朝兵,易剑昱,甄灿壮. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 368-376. |

| [11] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [12] | 田晓超,王海刚,王虎,王志聪,赵剑,杨志刚,吴越. 悬臂式压电振子宽频发电装置设计及测试[J]. 吉林大学学报(工学版), 2021, 51(6): 1953-1958. |

| [13] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [14] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [15] | 姚宗伟,高旭东,刘刚,毕秋实. 基于数值仿真的大型塔式磨机工作特性分析[J]. 吉林大学学报(工学版), 2021, 51(5): 1642-1650. |

|