吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (10): 2785-2794.doi: 10.13229/j.cnki.jdxbgxb.20211337

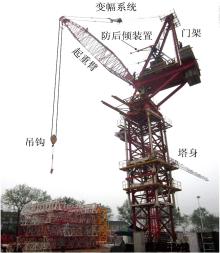

动臂塔机防后倾缓冲力计算方法

- 湖南师范大学 工程与设计学院,长沙 410081

Calculation method of anti-backward-tilting buffer force of luffing jib tower crane

- College of Engineering and Design,Hunan Normal University,Changsha 410081,China

摘要:

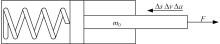

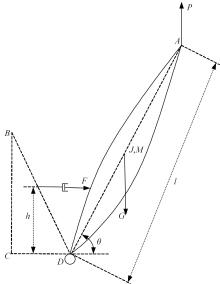

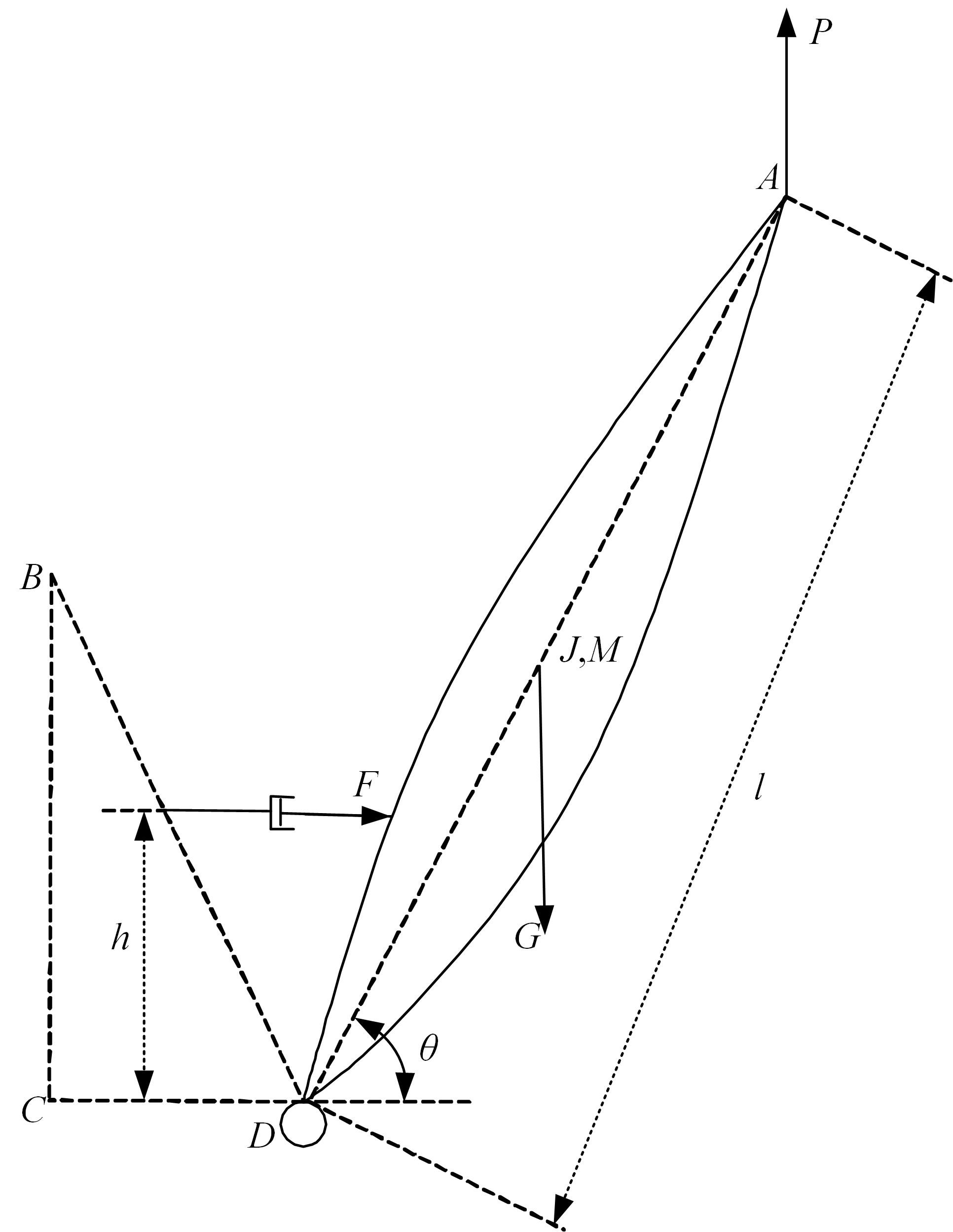

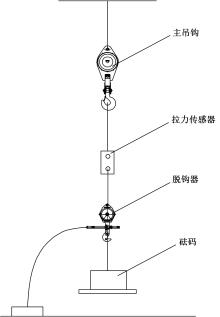

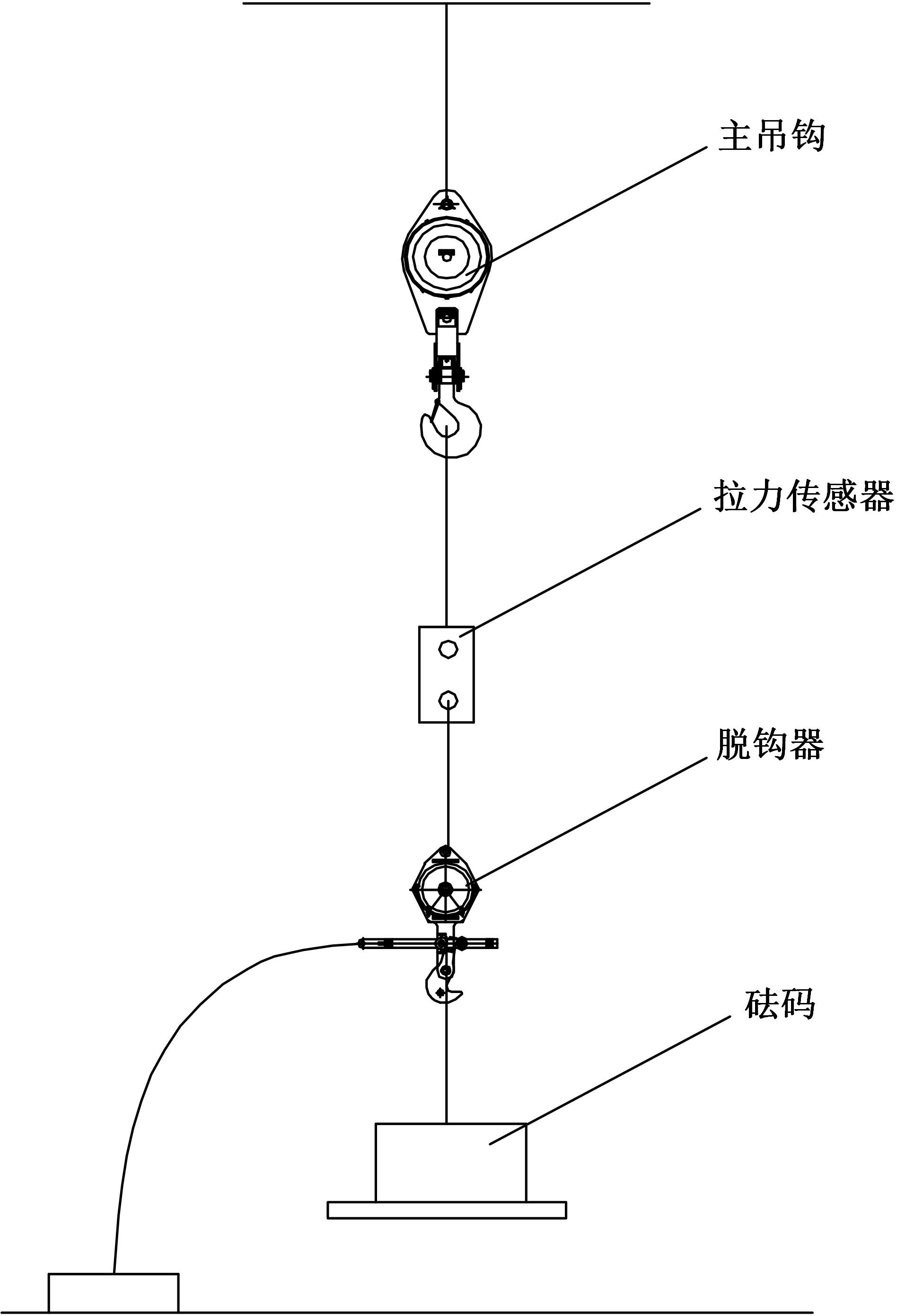

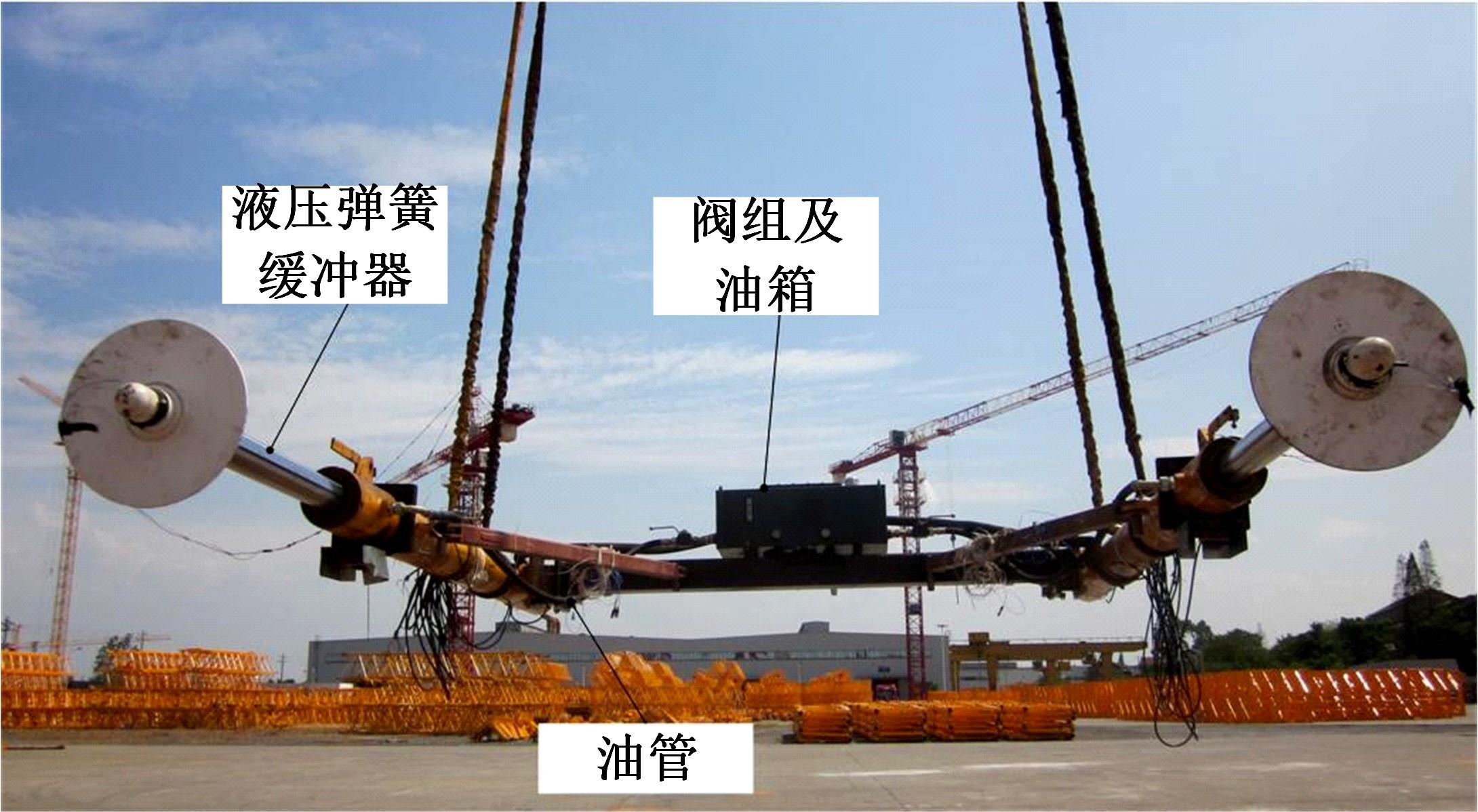

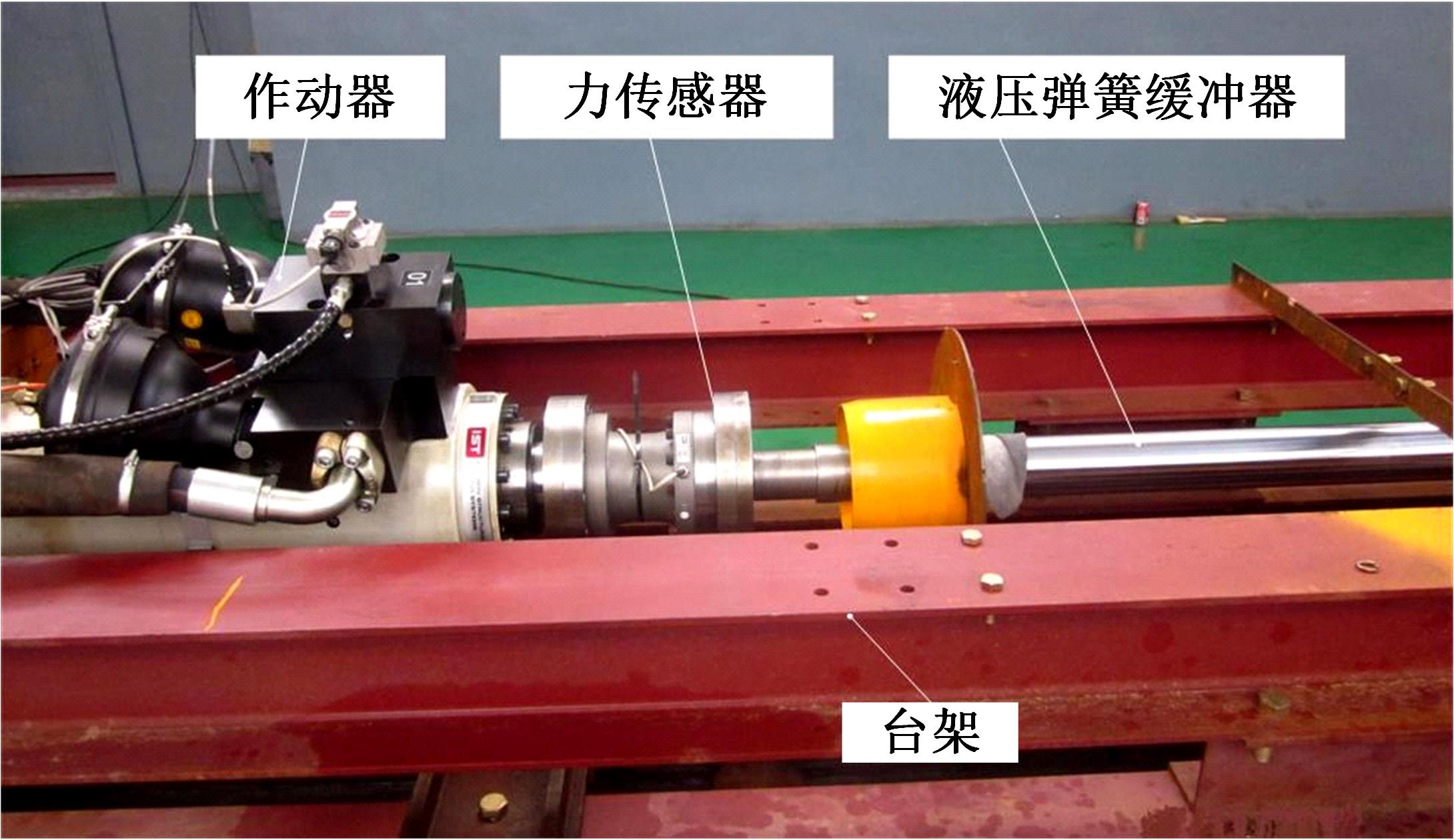

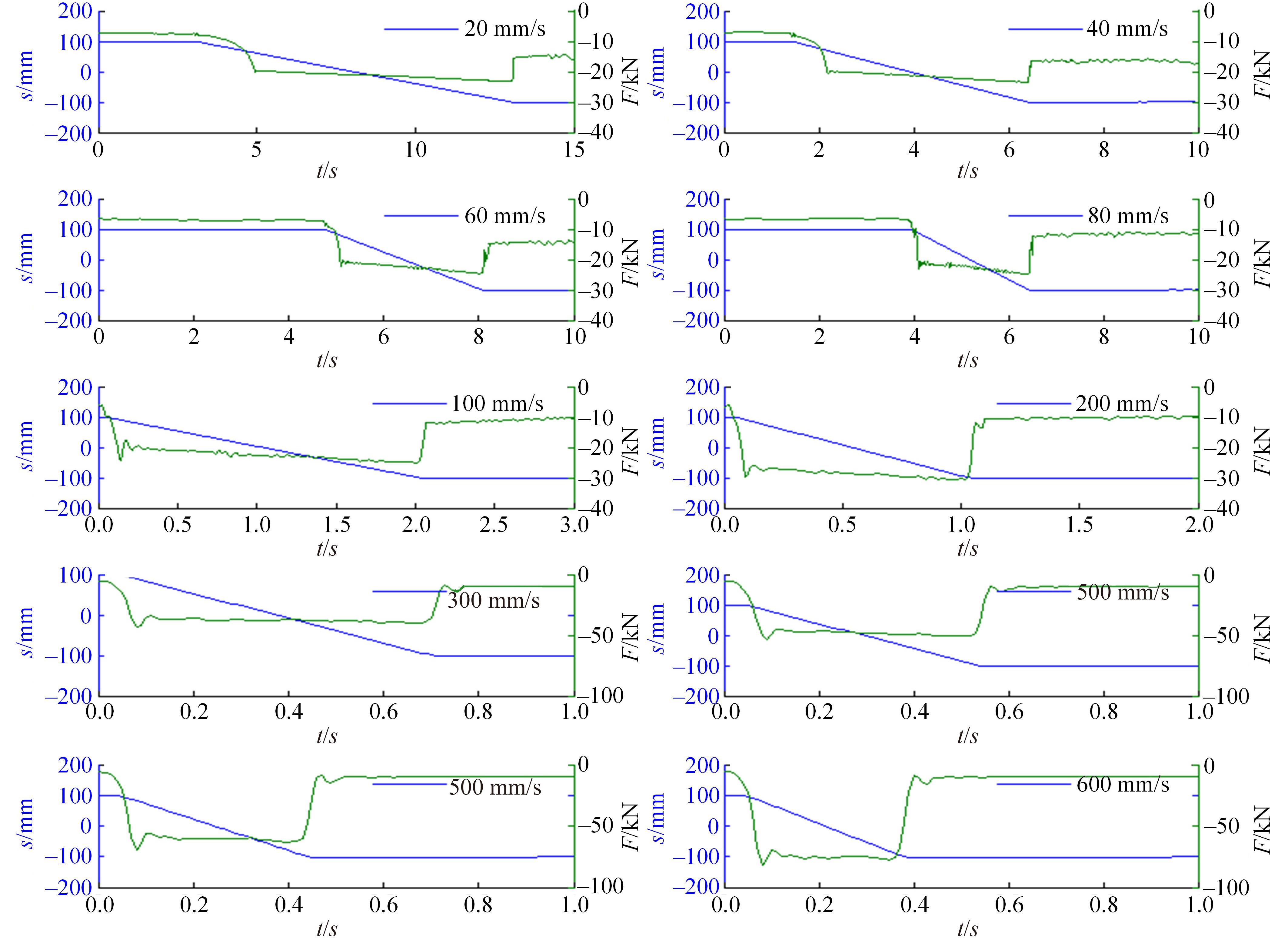

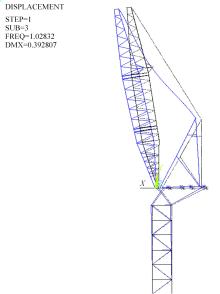

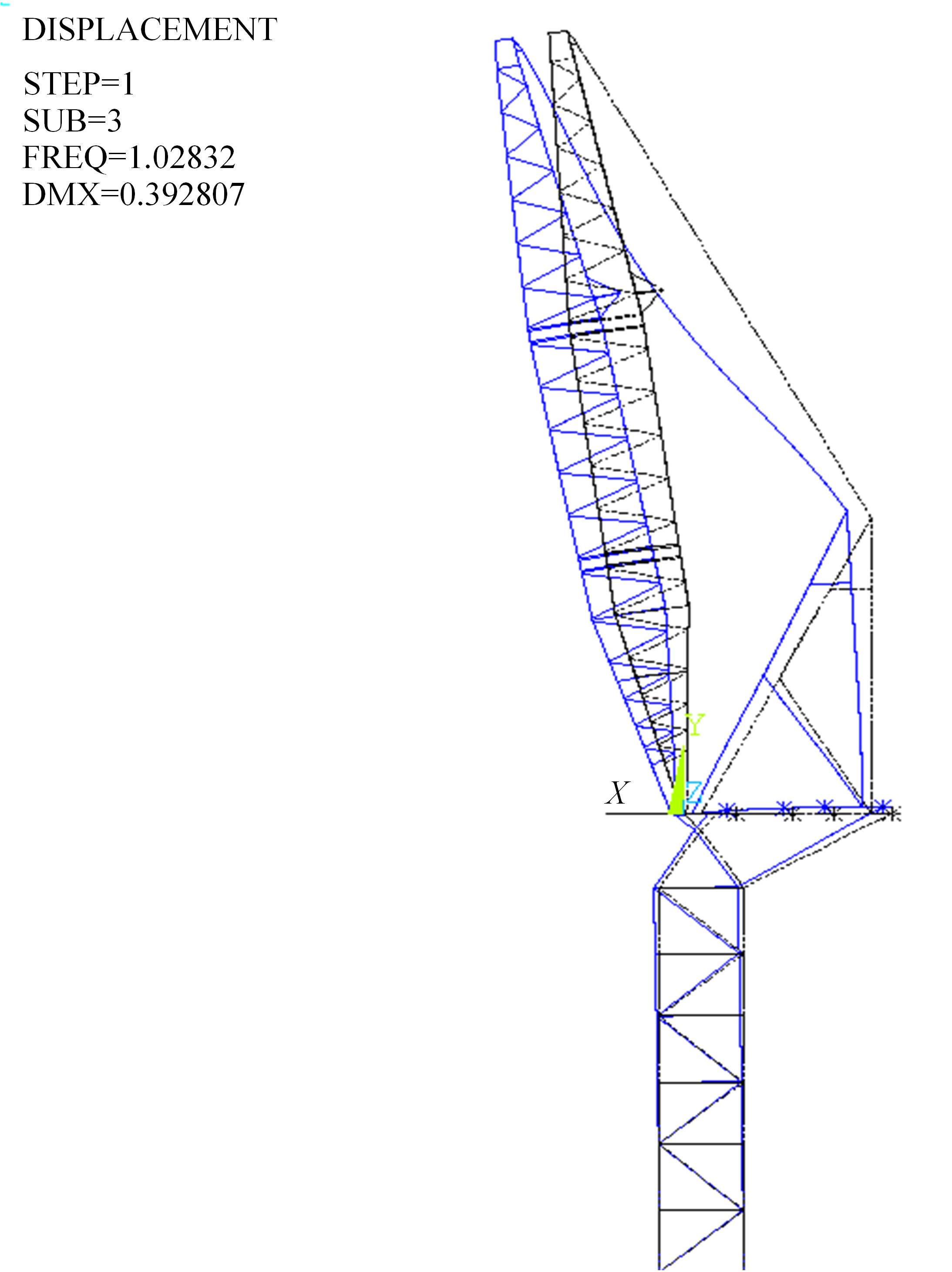

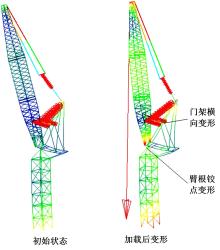

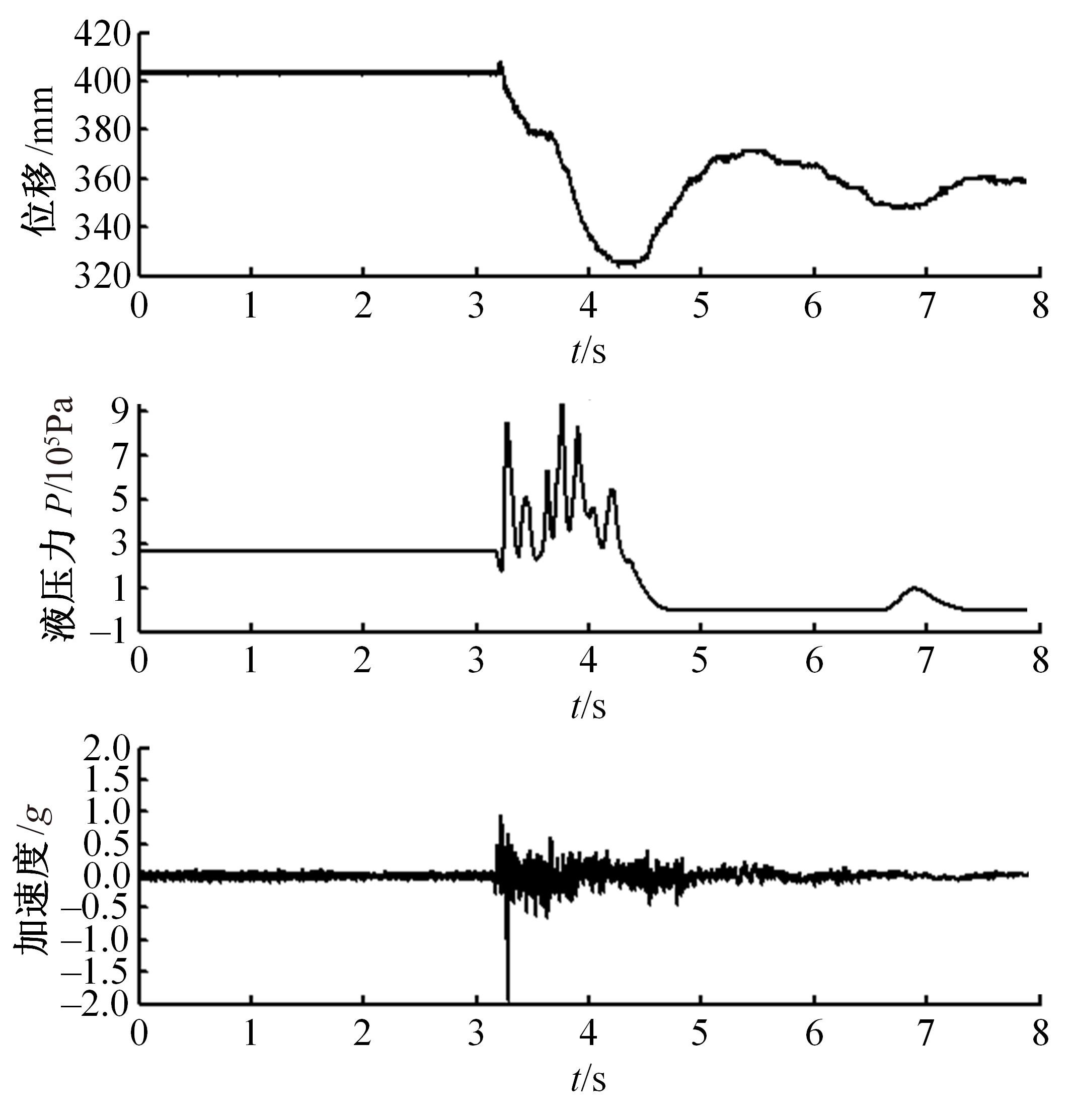

为准确计算动臂塔机的防后倾缓冲力,考虑塔身弹性振动和起重臂刚体转动对防后倾装置动力学的影响,建立了描述防后倾缓冲器相对运动的数学模型,结合防后倾装置的缓冲特性模型,建立了描述防后倾缓冲力与起重机动态特性的数学关系。以一台装备液压防后倾装置的动臂塔机为研究对象,辨识了组成缓冲力计算模型的参数,通过系列工况的防后倾实验验证了防后倾缓冲力计算模型。根据防后倾缓冲力的实验值,计算了突然卸载工况的等效动载系数,验证了《起重机设计规范》中突然卸载工况的动载系数要求,可为动臂塔机设计的相关国家标准修订提供参考。

中图分类号:

- TH212

| 1 | 屈福政, 刘海涛. 履带起重机臂架后倾动力学仿真[J]. 起重运输机械, 2005(12): 40-43. |

| Qu Fu-zheng, Liu Hai-tao. Backward tilting dynamics simulation of crawler crane[J]. Hoisting and Conveying Machinery, 2005(12): 40-43. | |

| 2 | 王永新, 李鹏举. 动臂塔机防后倾装置的分析与应用[J]. 建筑机械化, 2011,32(3):33-36. |

| Wang Yong-xin, Li Peng-ju. Analysis and application of anti-backward-tipping device of luffing jib tower crane[J]. Construction Mechanization, 2011,32(3): 33-36. | |

| 3 | . 塔式起重机设计规范 [S]. |

| 4 | . 起重机设计规范 [S]. |

| 5 | . Cranes-design principles for loads and load combinations-part 1: general(2nd ed) [S]. ISO: Geneva, Switzerland, 2012. |

| 6 | Ross Dieter K. The behaviour of a simple pendulum with uniformly shortening string length[J]. International Journal of Non-Linear Mechanics, 1979,14(3): 175-182. |

| 7 | Cveticanin L. Dynamic behavior of the lifting crane mechanism[J]. Mechanism and Machine Theory,1995, 30(1): 141-151. |

| 8 | 付玲, 喻乐康, 刘洋, 等. 细长型桁架起重臂卸载冲击动力学研究[J]. 起重运输机械, 2013(1):56-60. |

| Fu Ling, Yu Le-kang, Liu Yang, et al. Study of unloading impact dynamics on slender truss crane with luffing boom[J]. Lifting the Transport Machinery, 2013(1):56-60. | |

| 9 | Kang Zhong-yuan, Xu Ge-ning, Yang Heng, et al. Research on dynamic properties of crane boom under the condition of accidental unloading[J]. Advances in Engineering Research, 2016, 103: 576-584. |

| 10 | 李伟, 杨晨, 王桂录, 等. 基于瞬态动力学强夯机臂架折弯事故分析[J].中国工程机械学报,2020,18(2):184-188. |

| Li Wei, Yang Chen, Wang Gui-lu, et al. Based on transient analysis of an accident of arm structure[J]. Chinese Journal of Construction Machinery, 2020, 18(2):184-188. | |

| 11 | 刘洋, 李宇力,付英雄,等. 基于缓冲力设计的变阻尼防后倾装置特性研究[J]. 中国工程机械学报, 2013, 11(1):83-87. |

| Liu Yang, Li Yu-li, Fu Ying-xiong, et al. Study of variable damping hydraulic buffer for crane boom anti-backward-tipping based on buffer force design[J]. Chinese Journal of Construction Machine, 2013, 11(1):83-87. | |

| 12 | 刘洋. 液压防后倾装置特性建模及起重机防后倾研究[J]. 振动工程学报,2022,35(4):912-919. |

| Liu Yang. Characteristic modeling of hydraulic anti-backward tilting device and research on anti-backward tilting of crane[J]. Journal of Vibration Engineering, 2022,35(4):912-919. | |

| 13 | Dharankar Chandrashekhar S, Hada Mahesh Kumar, Sunil Chandel. Experimental identification of non-hysteresis algebraic force model of automotive hydraulic damper[J]. International Journal of Vehicle Performance, 2019, 5(2):213-231. |

| 14 | 王欣, 王逢全, 王锡良. 基于ADAMS的新型液压脱钩器系统仿真[J].建筑机械, 2006(3):59-61. |

| Wang Xin, Wang Feng-quan, Wang Xi-liang. Dynamic simulation for hydraulic self-release mechanism based on ADASM[J]. Construction Machinery, 2006(3): 59-61. | |

| 15 | Ju F, Choo Y S, Cui F S. Dynamic response of tower crane induced by the pendulum motion of the payload[J]. International Journal of Solids and Structures, 2006, 43(2):376-389. |

| 16 | Yang Qing-le, Qu Fu-zheng, Yu Zhi-yuan, et al. Stress and stability analysis of slewing motion for crawler crane[J]. Engineering Failure Analysis, 2019, 105: 817-827. |

| [1] | 刘洋. 动臂塔机卸载冲击仿真及试验[J]. 吉林大学学报(工学版), 2022, 52(6): 1292-1300. |

| [2] | 赵洋,肖洋,孙皓,霍文浩,冯松,廖勇. 基于围道积分的润滑接触齿轮微点蚀损伤特征模拟[J]. 吉林大学学报(工学版), 2022, 52(4): 799-810. |

| [3] | 郑伟,孙见君,马晨波,於秋萍,张玉言,牛韬. 汽车轮毂加工夹具的研究现状及展望[J]. 吉林大学学报(工学版), 2022, 52(1): 25-36. |

| [4] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [5] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [6] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [7] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [8] | 蔡仲昌, 刘辉, 项昌乐, 张喜清, 王明正. 车辆多级行星传动系统强迫扭转振动与动载特性[J]. 吉林大学学报(工学版), 2012, 42(01): 19-26. |

|

||