吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 866-876.doi: 10.13229/j.cnki.jdxbgxb.20230550

C80列车长大下坡周期制动踏面疲劳寿命预测

- 1.常熟理工学院 机械工程学院,江苏 常熟 215500

2.燕山大学 机械工程学院,河北 秦皇岛 066004

Fatigue life prediction of brake treads for C80 trains with long downhill cycles

Jian-feng SONG1( ),Xin-lei HUANG2,Si-ran WANG2,Guang-yao XIE2,Yong-gang DONG1(

),Xin-lei HUANG2,Si-ran WANG2,Guang-yao XIE2,Yong-gang DONG1( )

)

- 1.School of Mechanical Engineering,Changshu Institute of Technology,Changshu 215500,China

2.School of Mechanical Engineering,Yanshan University,Qinhuangdao 066004,China

摘要:

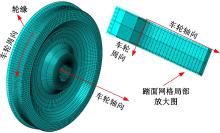

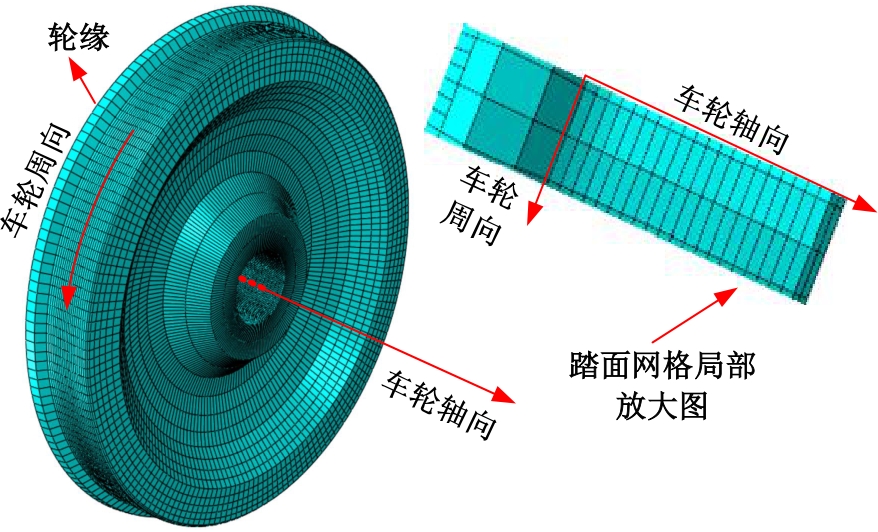

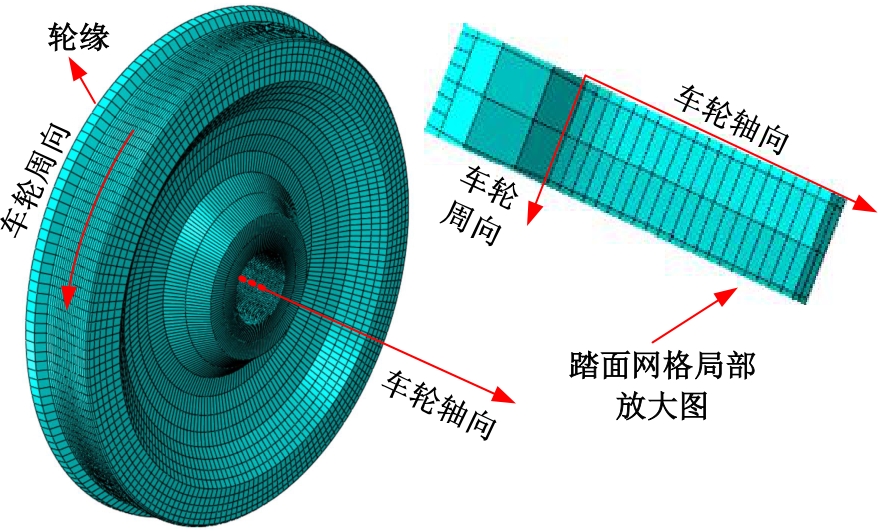

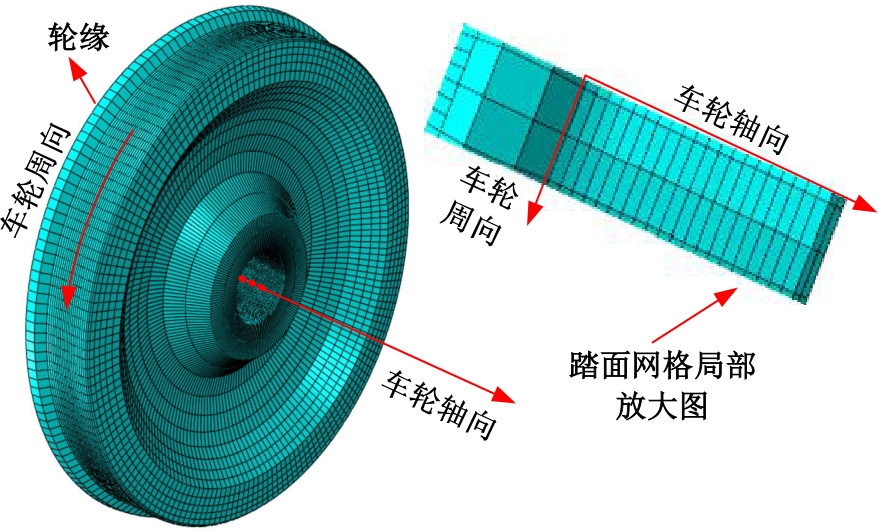

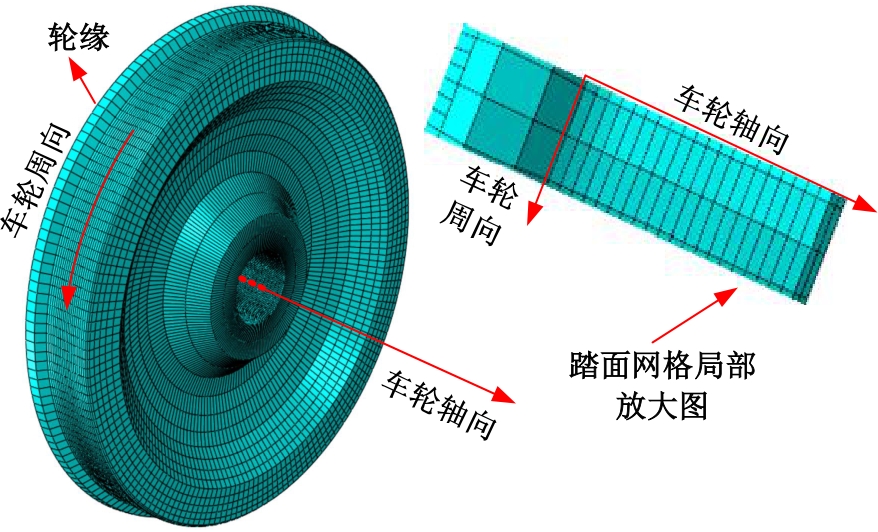

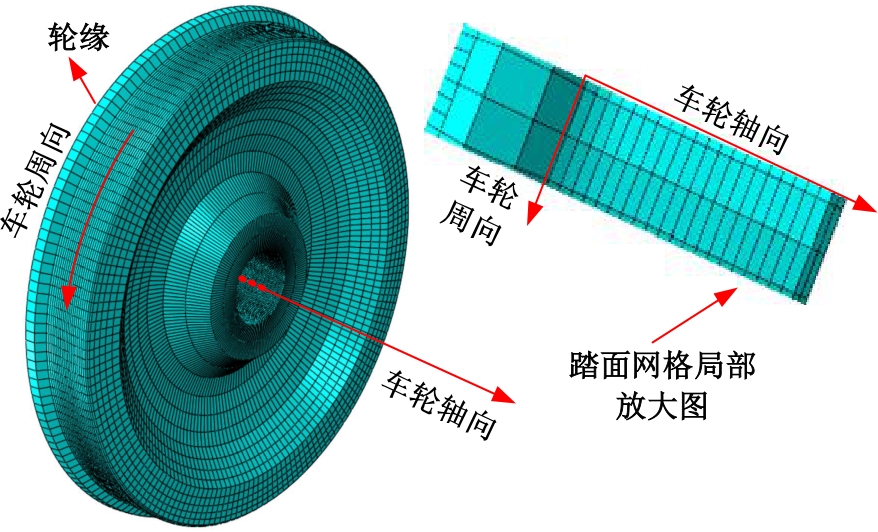

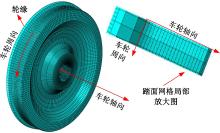

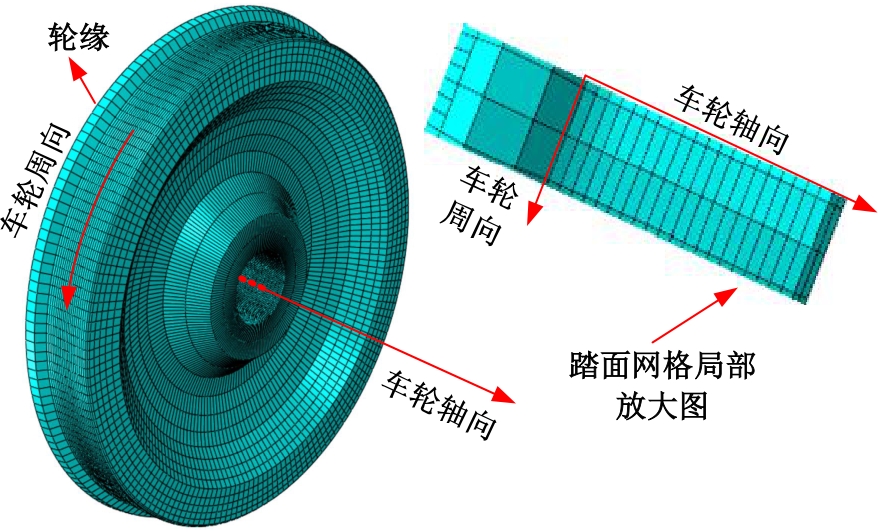

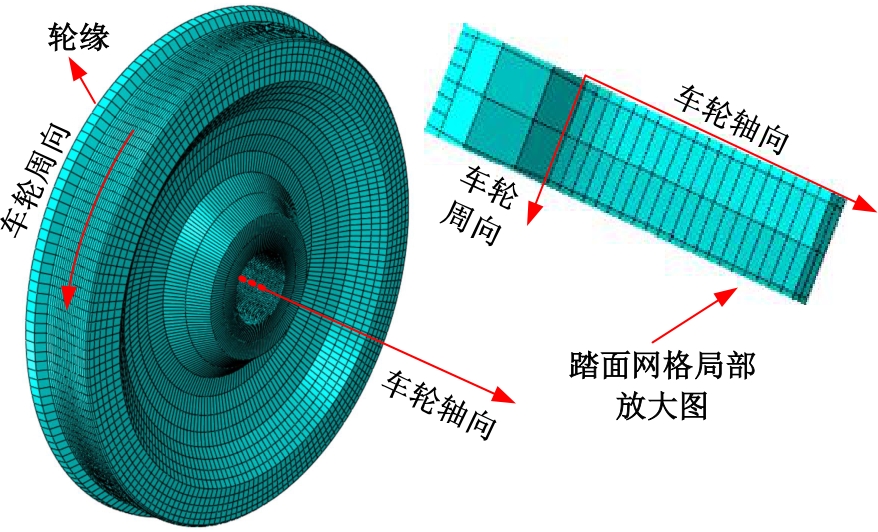

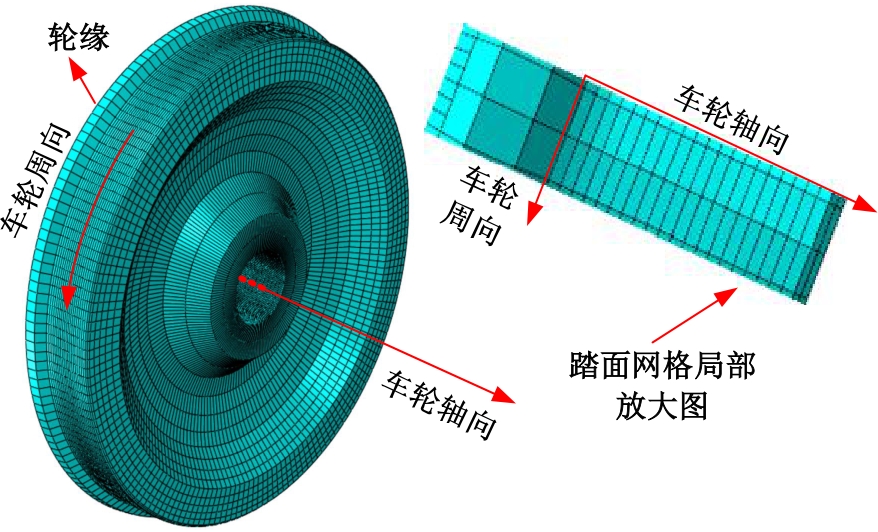

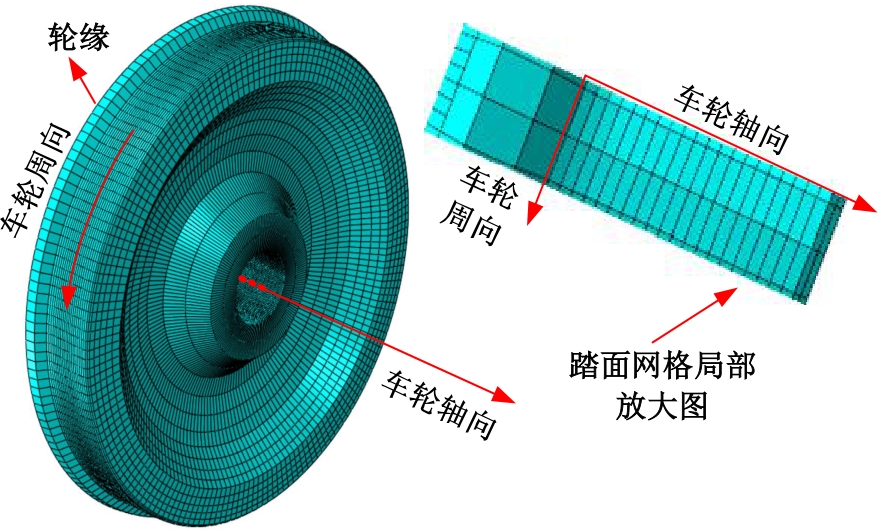

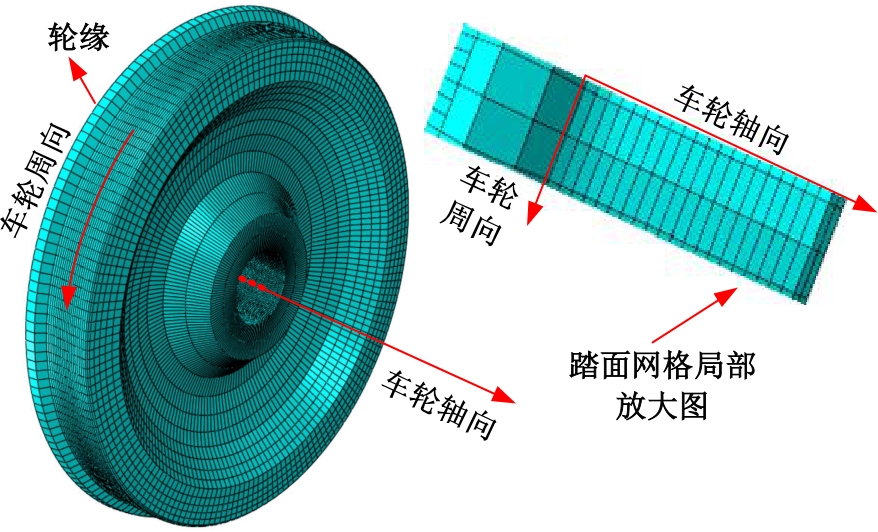

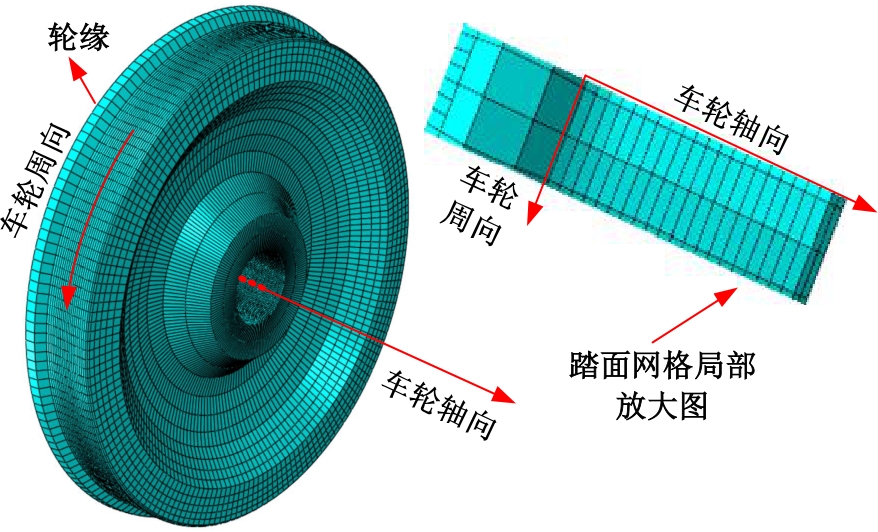

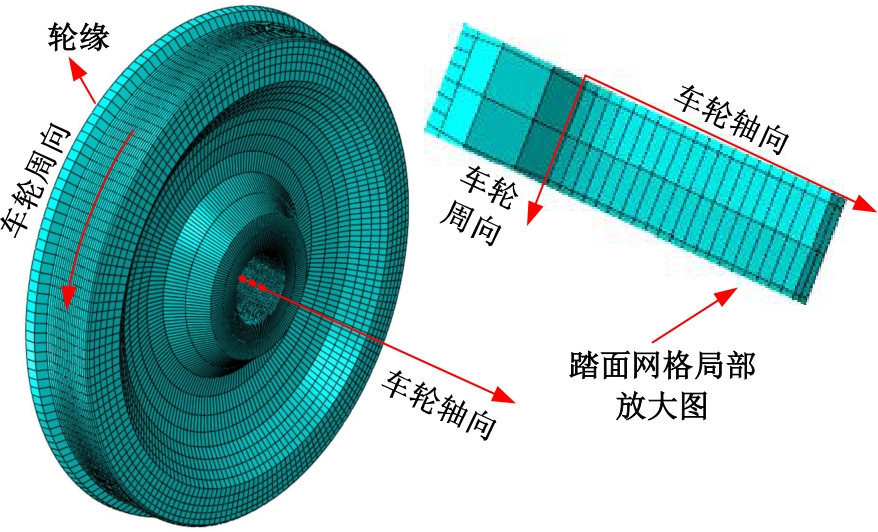

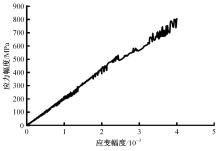

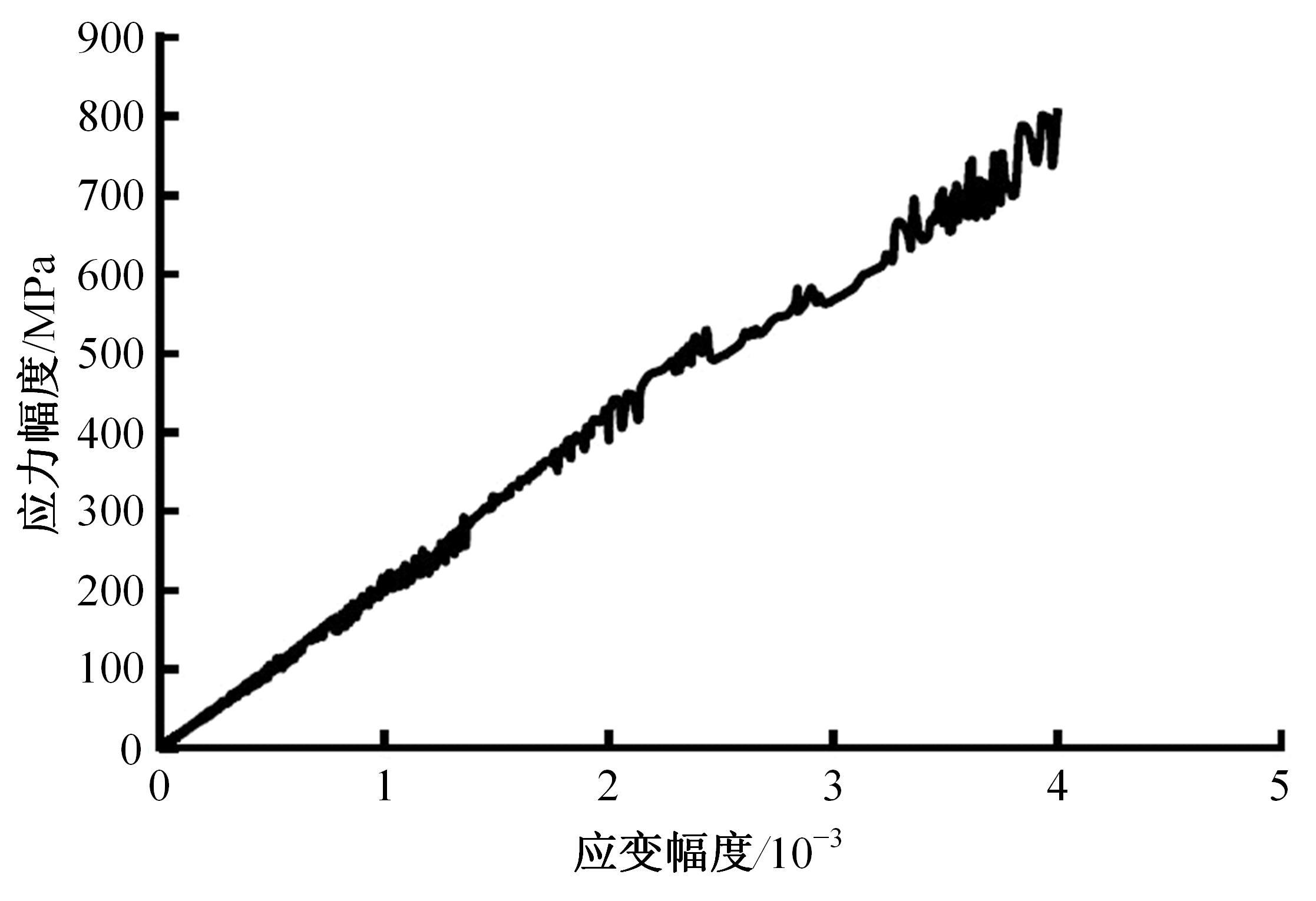

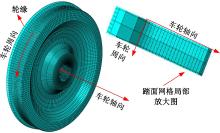

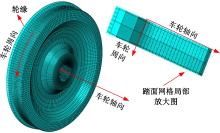

为预测C80列车长大下坡周期制动过程的车轮踏面疲劳寿命,在Abaqus软件中建立车轮有限元模型,通过高温拉伸试验确定CL60车轮钢26~500 ℃温度区间内的材料力学参数,同时考虑对流换热、轮轨接触传热、热辐射作用及行车阻力,利用功能转换关系、Hertz接触理论得到列车制动及惰行阶段作用在踏面上的热流载荷、法向载荷和切向载荷。开发子程序控制载荷、传热属性对踏面旋转加载,并对列车长大下坡周期制动过程进行热-机械耦合分析,得到并分析踏面温度、Mises应力-时间历程。分别基于N.E.损伤、R.W.损伤公式开发疲劳寿命程序,得到两种损伤下的踏面疲劳寿命,并分析闸瓦压力对疲劳寿命的影响。结果表明:踏面温度、Mises应力历程在同一循环后达到稳定;轮轨接触中心为踏面危险点,两种损伤下车轮服役转数误差百分比为1.28%;闸瓦压力越大,危险点温度越高,Mises应力越大,疲劳寿命越短。

中图分类号:

- U211.5

| 1 | 王延朋, 丁昊昊, 邹强, 等. 列车车轮踏面滚动接触疲劳研究进展[J]. 表面技术, 2020, 49(5): 121-122. |

| Wang Yan-peng, Ding Hao-hao, Zhou Qiang, et al. Research progress on rolling contact fatigue of railway wheel treads[J]. Surface Technology, 2020, 49(5): 121-122. | |

| 2 | 黄龙文, 李正美, 安琦. 轮轨滚动接触疲劳寿命的计算方法[J]. 华东理工大学学报: 自然科学版, 2018, 44(6): 918-927. |

| Huang Long-wen, Li Zheng-mei, An Qi. Calculation method of wheel/rail rolling contact fatigue life[J]. Journal of East China University of Science and Technology(Natural Science Edition), 2018, 44(6): 918-927. | |

| 3 | 黄龙文. 轮轨滚动接触力学分析及疲劳寿命预测方法分析[D].上海: 华东理工大学机械学院, 2018. |

| Huang Long-wen. Mechanics analysis and fatigue life prediction method for wheel/rail rolling contact[D].Shanghai: School of Mechanical Engineering, East China University of Science and Technology, 2018. | |

| 4 | 范新光. 列车车轮滚动接触疲劳裂纹萌生及扩展研究[D].北京: 北京交通大学机械与电子控制工程学院, 2019. |

| Fan Xin-guang. Study of fatigue crack initiation and propagation of railroad wheel under rolling contact[D].Beijing: School of Mechanical and Electronic Control Engineering, Beijing Jiaotong University, 2019. | |

| 5 | 赵吉中,徐祥,丁立,等. 高速列车车轮踏面滚压强化有限元分析[J]. 西南交通大学学报, 2020, 55(6): 1338-1345. |

| Zhao Ji-zhong, Xu Xiang, Ding Li, et al. Finite element analysis of rolling strengthening process for wheel tread of high-speed trains[J]. Journal of Southwest Jiaotong University, 2020, 55(6): 1338-1345. | |

| 6 | 刘颍宾. 列车车轮踏面滚动接触疲劳损伤机制研究[D]. 合肥: 中国科学技术大学化学与材料科学学院, 2020. |

| Liu Ying-bin. Research on rolling contact fatigue damage mechanism of train wheel tread[D]. Hefei: School of Chemistry and Materials Science, University of Science and Technology of China, 2020. | |

| 7 | 杨柳青,胡明,赵德明,等. CRH5动车组车轮低温概率疲劳寿命研究[J]. 中国机械工程, 2018, 29(9): 1115-1118. |

| Yang Liu-qing, Hu Ming, Zhao De-ming, et al. Research on probabilistic fatigue life of CRH5 EMU wheels at low temperature[J]. China Mechanical Engineering, 2018, 29(9): 1115-1118. | |

| 8 | 扬大巍. CRH5型动车组轮轨滚动接触行为及疲劳寿命研究[D].兰州: 兰州理工大学材料科学与工程学院, 2017. |

| Yang Da-wei. Study on rolling contact behavior and fatigue life of CRH5 type EMU[D].Lanzhou: School of Materials Science and Engineering, Lanzhou University of Technology, 2017. | |

| 9 | Chong T, Liu X L, Wu S, et al. Study on damage tolerance and remain fatigue life of shattered rim of railway wheels[J]. Engineering Fatigue Analysis, 2021, 12(2): 20-28. |

| 10 | Nejad R M, Berto F. Fatigue fracture and fatigue life assessment of railway wheel using non-linear model for fatigue crack growth[J]. International Journal of Fatigue, 2021, 30(3): 13-15. |

| 11 | Lima E A, Martins T S, Santos A A. Effect of manufacturing residual stress on the fatigue life of railway wheels for heavy-haul transportation[J]. Procedia Structural Integrity, 2019, 33(8): 246-253. |

| 12 | 孔昌昌, 秦凤明, 张晓峰, 等. 含Mo元素CL60钢CCT曲线的测定及分析[J]. 材料热处理学报, 2019, 40(8): 139-141. |

| Kong Chang-chang, Qin Feng-ming, Zhang Xiao-feng, et al. Determination and analysis of CCT curve of CL60 steel containing Mo element[J]. Journal of Materials Heat Treatment, 2019, 40(8): 139-141. | |

| 13 | 马红萍. 重载列车长大下坡制动过程优化控制研究[D]. 南昌: 华东交通大学电气与自动化工程学院, 2019. |

| Ma Hong-ping. Research on optimal braking process control of heavy-haul train on long steep down grade[D]. Nanchang: School of Electrical and Automation Engineering, East China Jiaotong University, 2019. | |

| 14 | 卢立丽. 货车车轮踏面制动热损伤研究[D]. 北京: 北京交通大学机械与电子控制工程学院, 2007. |

| Lu Li-li. Research on tread brake heat injury of freight wheel[D]. Beijing: School of Mechanical and Electronic Control Engineering, Beijing Jiaotong University, 2007. | |

| 15 | 王铎, 孙毅, 程靳. 理论力学[M]. 北京: 高等教育出版社, 2016. |

| 16 | 雷国军. 重载列车车轮表面对流传热特性的数值研究[D]. 兰州: 兰州交通大学车辆工程学院, 2020. |

| Lei Guo-jun. Numerical study on convective heat transfer characteristics on the wheel surface of heavy-duty train[D]. Lanzhou: School of Vehicle Engineering, Lanzhou Jiaotong University, 2020. | |

| 17 | 包辰铭. 重载列车踏面制动车轮温度场分析及制动故障诊断研究[D].北京: 北京交通大学机械与电子控制工程学院, 2020. |

| Bao Chen-ming. Temperature field analysis of brake wheels on heavy-duty train treads research on brake fault diagnosis[D]. Beijing: School of Mechanical and Electronic Control Engineering, Beijing Jiaotong University, 2020. | |

| 18 | Chen S, Zhao G T, Wang H Y, et al. Study of wheel wear influenced by tread temperature rising during tread braking[J]. Wear, 2019, 32(3): 1-10. |

| 19 | 李辉平, 贺连芳, 赵国群,等. 硼钢B1500HS界面传热系数与压力关系的研究[J]. 机械工程学报, 2013, 49(16): 78-82. |

| Li Hui-ping, He Lian-fang, Zhao Guo-qun, et al. Research on the surface heat transfer coefficient depending on surface pressure of boron steel B1500HS[J]. Journal of Mechanical Engineering, 2013, 49(16): 78-82. | |

| 20 | 孙晓冉,宋月,谷秀锐,等. 汽车用SPHC热轧薄钢板的低周疲劳特性[J]. 机械工程材料, 2021, 45(4): 58-60. |

| Sun Xiao-ran, Song Yue, Gu Xiu-rui, et al. Low cycle fatigue characteristics of SPHC hot-rolled steel sheet for automobile[J]. Materials for Mechanical Engineering, 2021, 45(4): 58-60. | |

| 21 | 张然治. 疲劳试验测试分析理论与实践[M]. 北京: 国防工业出版社, 2011. |

| 22 | 秦大同. 现代机械设计手册[M]. 北京: 化学工业出版社, 2011. |

| 23 | 黄协思. 疲劳约束下航空发动机涡轮盘结构优化设计[D]. 成都: 电子科技大学机械与电气工程学院, 2020. |

| Huang Xie-si. Structural optimization design of aero engine turbine disc under fatigue constraint[D]. Chengdu: School of Mechanical and Electrical Engineering, University of Electronic Science and Technology of China, 2020. | |

| 24 | 卢碧红, 徐超, 郭宏远. C80型铁路货车制动装置运用性能预测[J]. 交通运输工程学报, 2021, 21(6): 289-297. |

| Lu Bi-hong, Xu Chao, Guo Hong-yuan. Operation performance prediction of C80 railway freight car braking device[J]. Journal of Traffic and Transportation Engineering, 2021, 21(6): 289-297. |

| [1] | 王淑坤,冯育泽,张景然,张心明,郑龙. 仿清道夫下唇结构除污性能分析[J]. 吉林大学学报(工学版), 2025, 55(1): 392-400. |

| [2] | 黄贤振,于瑞,刘慧珍,唐继武. 考虑轴承非线性恢复力的主轴振动可靠性分析[J]. 吉林大学学报(工学版), 2025, 55(1): 116-124. |

| [3] | 王琛,雒特,惠倩倩,王忠昊,王方方. 面向分体式飞行汽车对接锁定的机电系统设计与验证[J]. 吉林大学学报(工学版), 2024, 54(8): 2130-2140. |

| [4] | 刘洋. 橡胶鞋底弹性打磨仿真及试验[J]. 吉林大学学报(工学版), 2024, 54(8): 2167-2173. |

| [5] | 王磊,李东侠,周松,回丽,沈振鑫. 2024-O铝合金搅拌摩擦焊接头疲劳裂纹扩展行为及寿命预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1563-1569. |

| [6] | 刘洋,江涛. 计及安装角的六自由度平台虎克铰干涉计算模型[J]. 吉林大学学报(工学版), 2024, 54(6): 1519-1527. |

| [7] | 谭晓丹,王勇澎,Hall Robert,徐天爽,黄庆学. 面向电铲自主装卸的矿用自卸车斗型优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1227-1236. |

| [8] | 王世俊,罗冠炜. 含多种碰撞约束振动系统的周期运动转迁特性[J]. 吉林大学学报(工学版), 2024, 54(4): 902-916. |

| [9] | 孙伟,杨俊. 等角贴敷压电分流片圆柱壳有限元建模及减振分析[J]. 吉林大学学报(工学版), 2024, 54(2): 365-374. |

| [10] | 胡斌,蔡一全,罗昕,毛自斌,李俊伟,郭孟宇,王剑. 基于种群胁迫的有限齿侧空间高速充种理论与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 574-588. |

| [11] | 余建星,韦明秀,余杨,崔宇朋,潘宇. 加筋板结构可靠性拓扑优化与工程化设计[J]. 吉林大学学报(工学版), 2024, 54(10): 2781-2791. |

| [12] | 程亚兵,杨泽宇,李岩,安立持,徐泽辉,曹鹏宇,陈璐翔. 基于混合动力汽车正时齿形链系统的振动噪声特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2465-2473. |

| [13] | 王佳怡,刘昕晖,王展,陈晋市,韩亚方,王禹琪. 基于AMESim的恒流量控制阀流量特性分析[J]. 吉林大学学报(工学版), 2023, 53(9): 2499-2507. |

| [14] | 黄贤振,孙楷铂,栾晓刚,胡兵. 螺栓预紧连接可靠性灵敏度分析[J]. 吉林大学学报(工学版), 2023, 53(8): 2219-2226. |

| [15] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

|

||