Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (4): 1122-1132.doi: 10.13229/j.cnki.jdxbgxb.20210796

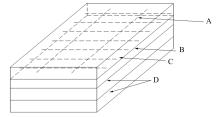

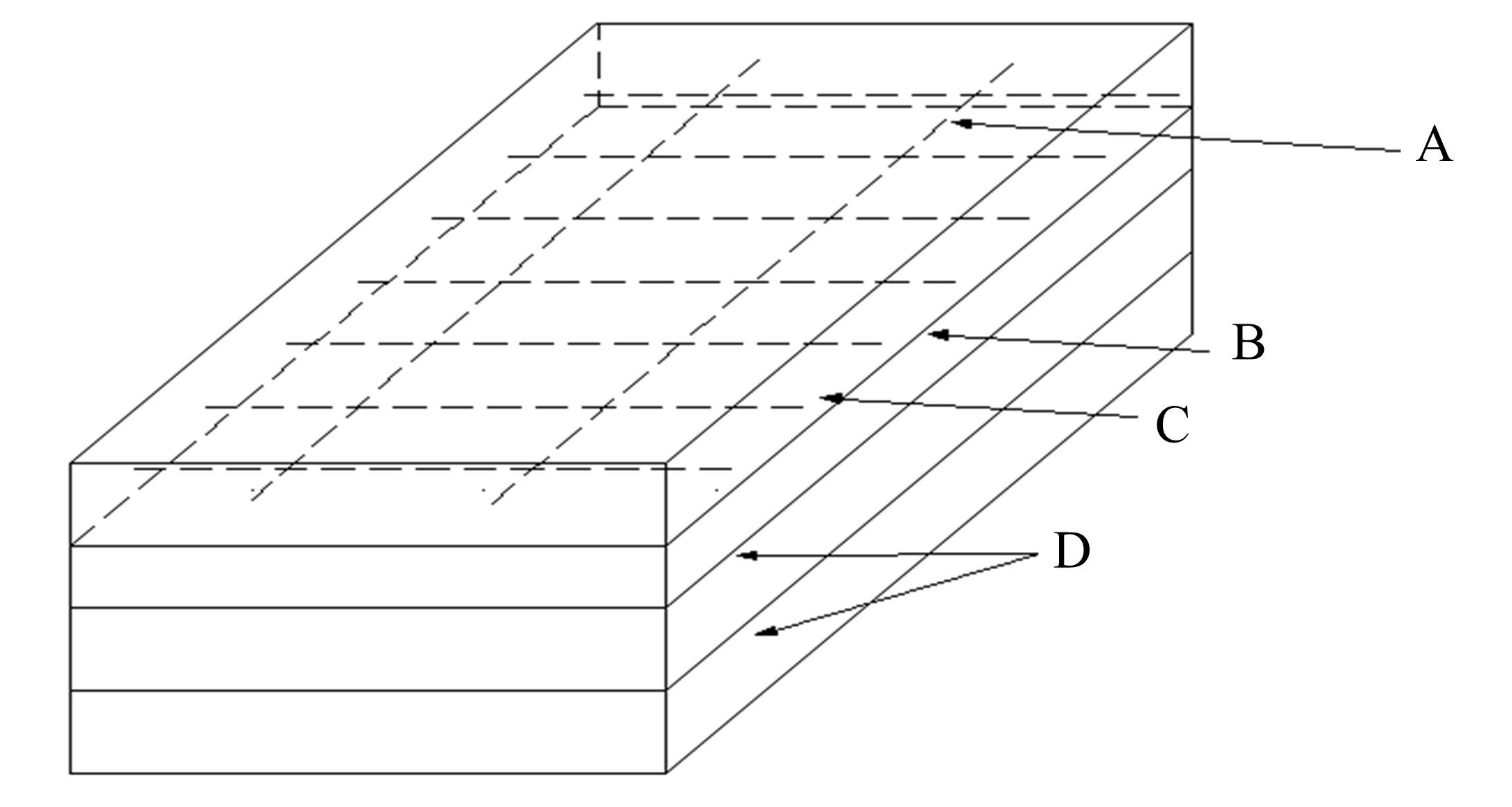

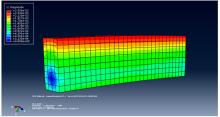

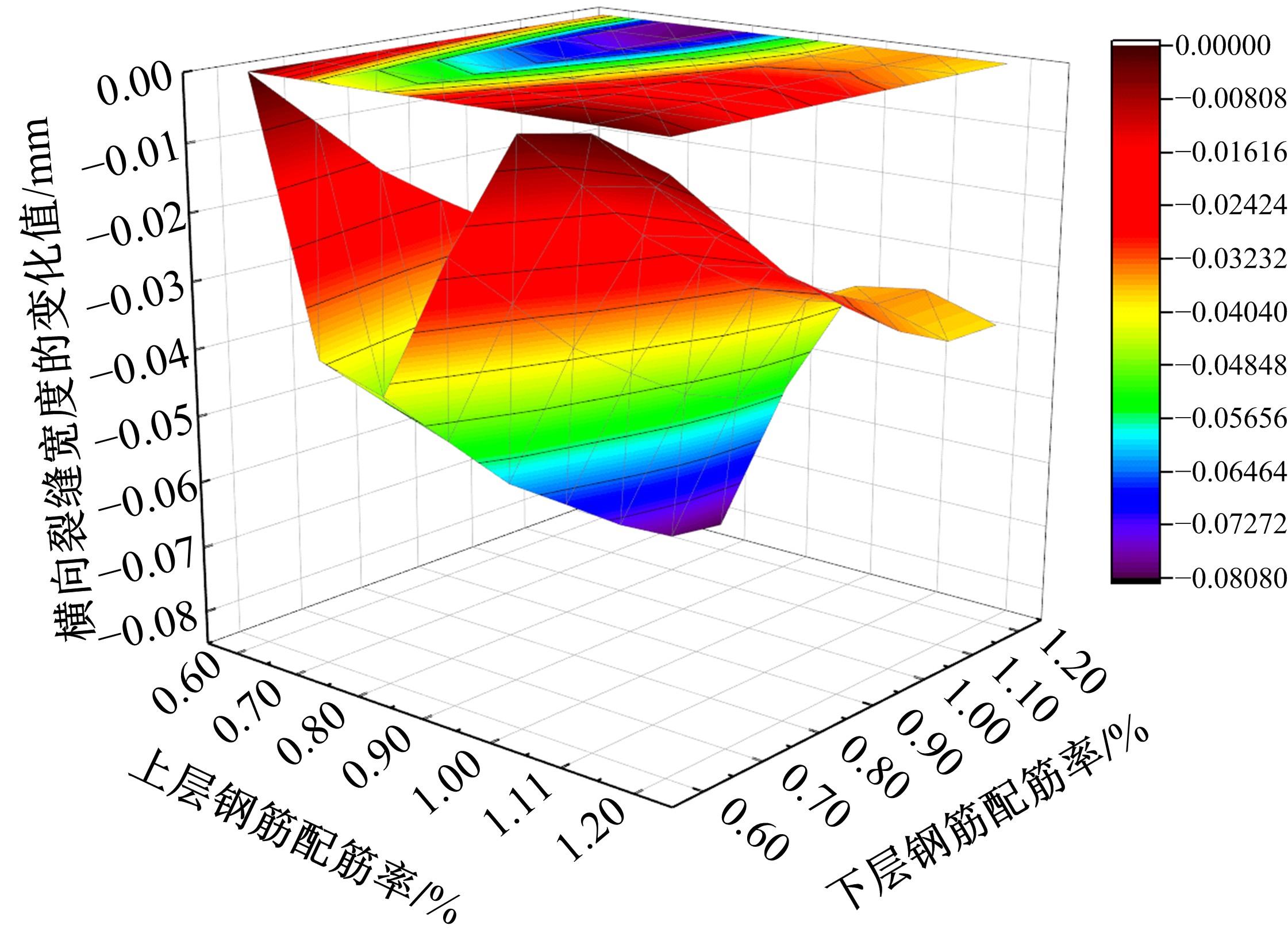

Numerical simulation of continuously reinforced concrete pavement with double⁃layer reinforcement under effect of temperature shrinkage

Fan YANG1( ),Chen-chen LI1,2,Sheng LI3(

),Chen-chen LI1,2,Sheng LI3( ),Hai-lun LIU1

),Hai-lun LIU1

- 1.Key Laboratory of Road and Traffic Engineering of the Ministry of Education,Tongji University,Shanghai 201804,China

2.Institute of Highway Engineering,RWTH Aachen University,Aachen 52074,Germany

3.State Engineering Laboratory of Highway Maintenance Technology,Changsha University of Science and Technology,Changsha 410114,China

CLC Number:

- U416.216

| 1 | Huang Y. Pavement Design and Analysis[M]. New York: Printice Hall, 2003. |

| 2 | 王秉纲. 水泥混凝土路面的配筋设计[J]. 公路, 2002, 46(8): 30-33. |

| Wang Bing-gang. Reinforcement design for cement concrete pavement[J]. Highway, 2002, 46(8): 30-33. | |

| 3 | 张洪亮, 左志武. 连续配筋混凝土路面[M].北京:人民交通出版社, 2010. |

| 4 | 王巍. 极重荷载下双层CRCP应力、应变及裂缝现场测试与分析[D]. 武汉: 华中科技大学土木与水利工程学院, 2016. |

| Wang Wei. Field test and analysis of stress, strain and crack of double-layer CRCP under extreme heavy load [D]. Wuhan: School of Civil and Hydraulic Engineering, Huazhong University of Science and Technology, 2016. | |

| 5 | 王晓帆. 温湿耦合对双层连续配筋混凝土路面纵向配筋率设计的影响研究[D]. 长沙: 长沙理工大学土木工程学院, 2017. |

| Wang Xiao-fan. Study on the influence of temperature humidity coupling on the design of longitudinal reinforcement ratio of double-layer continuous reinforced concrete pavement[D]. Changsha: College of Civil Engineering, Changsha University of Technology, 2017. | |

| 6 | Wu Fan, Dai Yi-Qing, Ni Fu-jian. Mid-depth punch-out research of continuously reinforced concrete pavement[C]∥The 17th COTA International Conference of Transportation Professionals, Shanghai, China, 2018. |

| 7 | Sun R J, Cobos L, Won M C. Behavior of the longitudinal construction joint of continuously reinforced concrete pavement[J]. Geotechnical Special Publication, 2011, 205(212): 200-207. |

| 8 | 占逸, 吴瑞麟, 陈旭, 等. 基于ANSYS的双层配筋CRCP温度翘曲应力数值分析[J]. 土木工程与管理学报, 2019, 36(3): 177-182, 189. |

| Zhan Yi, Wu Rui-lin, Chen Xu, et al. Simulation analysis of the bilayer reinforcement CRCP's temperature warping stress based on ANSYS[J]. Journal of Civil Engineering and Management, 2019, 36(3): 177-182, 189. | |

| 9 | 吴瑞麟, 王巍, 杨梅梅, 等. 基于实测数据的双层CRCP横向裂缝研究[J]. 华中科技大学学报: 自然科学版, 2017, 45(1): 1-5. |

| Wu Rui-lin, Wang Wei, Yang Mei-mei, et al. Research on transverse cracks of bilayer CRCP based on actual data[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2017, 45(1): 1-5. | |

| 10 | 吴春蕾, 吴瑞麟, 占逸, 等. 板底脱空状态下车辆荷载对双层配筋CRCP钢筋应力的影响[J]. 土木工程与管理学报, 2018, 35(3): 173-178. |

| Wu Chun-lei, Wu Rui-lin, Zhan Yi, et al. Influence of vehicle load under slab hollow condition on bilayer continuous reinforced concrete pavement steel stress[J]. Journal of Civil Engineering and Management, 2018, 35(3): 173-178. | |

| 11 | 李盛, 杨帆, 刘萌, 等. 新型双层CRCP结构及在城市道路中的应用[J]. 中南大学学报: 自然科版, 2019, 50(4): 983-989. |

| Li Sheng, Yang Fan, Liu Meng, et al. Structure of continuously reinforced concrete pavement with double-layer reinforced and its application in urban road[J]. Journal of Central South University(Science and Technology), 2019, 50(4): 983-989. | |

| 12 | 左志武. 连续配筋混凝土路面横向裂缝分布和冲断预估研究[D]. 西安:长安大学公路学院, 2010. |

| Zuo Zhi-wu. Study on distribution of transverse cracks and punch out prediction of continuously reinforced concrete pavement[D]. Xi'an: School of Highway, Chang'an University, 2010. | |

| 13 | Kohler E R, Roesler J R. Repeated load behavior of continuously reinforced concrete pavements[J] Civil and Environmental Engineering, 2005,8(2): 621-638. |

| 14 | Beeldens A, Rens L. CRCP applications in Belgium: recent evolutions towards an optimised cracking pattern[C]∥Australian Society for Concrete Pavements Conference, Kingscliff, Australia, 2017. |

| 15 | 张翛, 胡圣能, 赵鸿铎, 等. 连续配筋混凝土路面裂缝间距特性[J].交通运输工程学报, 2013, 13(4): 1-7. |

| Zhang Xiao, Hu Sheng-neng, Zhao Hong-duo, et al. Characteristic of crack spacing for continuously reinforced concrete pavement[J]. Journal of Traffic and Transportation Engineering, 2013, 13(4): 1-7. | |

| 16 | AA .Guide for Design of Pavement Structure[S]. |

| 17 | 中交公路规划设计院. JTG D40-2011:公路水泥混凝土路面设计规范[M].北京:人民交通出版社, 2011. |

| 18 | 鲁昌河, 邱志雄, 蔡业青, 等. 双层与单层连续配筋混凝土路面设计与施工探讨[J]. 中外公路, 2006, 26(3): 83-86. |

| Lu Chang-he, Qiu Zhi-xiong, Cai Ye-qing. Discussion on design and construction of double-layer and single-layer continuously reinforced concrete pavement[J]. Journal of China & Foreign Highway, 2006, 26(3): 83-86. | |

| 19 | 陈小兵. 基于裂缝形成规律的连续配筋混凝土路面结构设计方法研究[D]. 南京: 东南大学交通学院, 2013. |

| Chen Xiao-bing. Structural design method of CRCP baesd on the chracteristics of cracking[D]. Nanjing: School of Transportation, Southeast University, 2013. | |

| 20 | 陈锋锋, 黄晓明, 单景松. 复合式路面CRCP疲劳损耗临界荷位处荷载应力研究[J]. 中国市政工程, 2008, 32(3): 4-6, 93. |

| Chen Feng-feng, Huang Xiao-ming, Shan Jing-song. Studies on load stress at loading position critical to fatigue loss on CRCP composite pavemen[J]. China Municipal Engineering, 2008, 32(3): 4-6, 93. | |

| 21 | 曹东伟. 连续配筋混凝土路面结构研究[D]. 西安:长安大学公路学院, 2001. |

| Cao Dong-wei. Study on the structure of continuous reinforced concrete pavement[D]. Xi'an: School of Highway, Chang'an University, 2010. | |

| 22 | 陈锋锋, 黄晓明, 秦永春. 连续配筋混凝土路面横向裂缝分布模型的研究[J].公路交通科技, 2006, 23(6): 18-21. |

| Chen Feng-feng, Huang Xiao-ming, Qin Yong-chun. Study on the probability distribution model of continuously reinforced concrete pavement transverse cracks[J]. Journal of Highway and Transportation Research and Development, 2006, 23(6): 18-21. | |

| 23 | 黄优, 刘朝晖, 李盛. 不同层间结合状态下刚柔复合式路面的剪应力分析[J].公路交通科技, 2015, 32(6): 32-38, 61. |

| Huang You, Liu Zhao-hui, Li Sheng. Analysis of shear stress of rigid-flexible composite pavement under different interlaminar bonding conditions[J]. Journal of Highway and Transportation Research and Development, 2015, 32(6): 32-38, 61. | |

| 24 | 曹前, 刘青, 刘朝晖, 等. 双层连续配筋混凝土路面荷载应力分析[J]. 公路, 2016, 61(8): 22-26. |

| Cao Qian, Liu Qing, Liu Zhao-hui, et al. Load stress analysis of double-layer continuously reinforced concrete pavement[J]. Highway, 2016, 61(8): 22-26. | |

| 25 | 刘朝晖, 黄优, 李盛. 层间结合状态对刚柔复合式路面剪应力的影响分析[J].公路, 2015, 60(1): 1-6. |

| Liu Zhao-hui, Huang You, Li Sheng. Impact analysis of interlayer bonding condition on shear stress of rigid-flexible composite pavement[J]. Highway, 2015, 60(1): 1-6. |

| [1] | Bo-wen GUAN,Wen-jin DI,Fa-ping WANG,Jia-yu WU,Shuo-wen ZHANG,Zhi-xun JIA. Damage of concrete subjected to sulfate corrosion under dry⁃wet cycles and alternating loads [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1112-1121. |

| [2] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [3] | Hai-bin WEI,Zi-peng MA,Hai-peng BI,Han-tao LIU,Shuan-ye HAN. Conductive rubber composite pavement paving technology based on mechanical response analysis method [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 531-537. |

| [4] | Cheng-lin SHI,Yong WANG,Chun-li WU,Wen-zhu SONG. Modification of calculation method for active earth pressure on embankment retaining wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1394-1403. |

| [5] | Qing-lin GUO,Qiang LIU,Chun-li WU,Li-li LI,Yi-ming LI,Fu-chun LIU. Local temperature field and healing level of crack in conductive asphalt and mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1386-1393. |

| [6] | Yu-quan YAO,Jian-gang YANG,Jie GAO,Liang SONG. Optimal design on recycled hot⁃mix asphalt mixture based on performance⁃cost model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 585-595. |

| [7] | Quan-ping XIA,Jiang-ping GAO,Hao-yuan LUO,Qi-gong ZHANG,Zhi-jie LI,Fei YANG. Low⁃temperature performance of composite modified hard asphalt used in high modulus asphalt concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 541-549. |

| [8] | Fen YE,Shi-yuan HU. Mechanical properties of ultra⁃thin overlay considering load transfer capacity of old cement pavement joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2636-2643. |

| [9] | Xiao-he YU,Rong LUO,Zi-yao LIU,Ting-ting HUANG,Yu SHU. Numerical simulation of humidity field of typical cracks in asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2343-2351. |

| [10] | Yan-hai YANG,Hong CUI,Ye YANG,Huai-zhi ZHANG,He LIU. Effect of freeze-thaw cycle on performance of unsaturated emulsified asphalt cold recycled mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2352-2359. |

| [11] | Wu-ping RAN,Hui-min CHEN,Ling LI,Li-qun FENG. Evolution law and model estimation and modification of resilience modulus of coarse grained soil subgrade under wet and dry cycle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2079-2086. |

| [12] | Wei-zhi DONG,Shuang ZHANG,Fu ZHU. Evaluation of pavement performance of asphalt mixture based on extension analytic hierarchy process [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2137-2143. |

| [13] | Zhe-pu XU,Qun YANG. Short⁃term maintenance operation start time optimization based on real⁃time traffic map data [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1763-1774. |

| [14] | Chang-ping WEN,Huan-xia REN. Constitutive relation with double yield surfaces of bioenzyme⁃treated expansive soil based on Lade model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1716-1723. |

| [15] | Yuan-yuan WANG,Lu SUN,Wei-dong LIU,Jin-shun XUE. Constraint improvement of binocular reconstruction algorithm used to measure pavement three-dimensional texture [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1342-1348. |

|

||