Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (5): 1400-1410.doi: 10.13229/j.cnki.jdxbgxb.20210883

Mechanical behavior on friction energy dissipation reduced beam section connection of steel beams

Wei-hua WANG1,2( ),Yong-bin ZHU1,3,Shen-jun QI1,Jing-si HUO1,2(

),Yong-bin ZHU1,3,Shen-jun QI1,Jing-si HUO1,2( ),Xiu-quan GUO1,2,Zhen-an ZHONG4

),Xiu-quan GUO1,2,Zhen-an ZHONG4

- 1.College of Civil Engineering,Huaqiao University,Xiamen 361021,China

2.Xiamen Engineering Research Center for Fire Resistance and Disaster Prevention,Huaqiao University,Xiamen 361021,China

3.Fujian Yancheng Construction Engineering Co. ,Ltd. ,Xiamen 361016,China

4.Xiamen Hansen Curtain Wall Decoration Engineering Co. ,Ltd. ,Xiamen 361009,China

CLC Number:

- TU391

| 1 | 黄炳生.日本神户地震中建筑钢结构的震害及启示[J]. 建筑结构, 2000, 30(9): 24-25. |

| Huang Bing-sheng. Earthquake damage of steel structure in Kobe earthquake and its enlightenment[J]. Building Structure, 2000, 30(9): 24-25. | |

| 2 | 周福霖, 李振宝, 安部重孝, 等. 东日本大地震灾害考察报告[J]. 建筑结构, 2012, 42(4): 1-20. |

| Zhou Fu-lin, Li Zhen-bao, Shigetakas A B E, et al. Inspection report of the disaster of the east Japan earthquake by Sino-Japanese joint mission[J]. Building Structure, 2012, 42(4): 1-20. | |

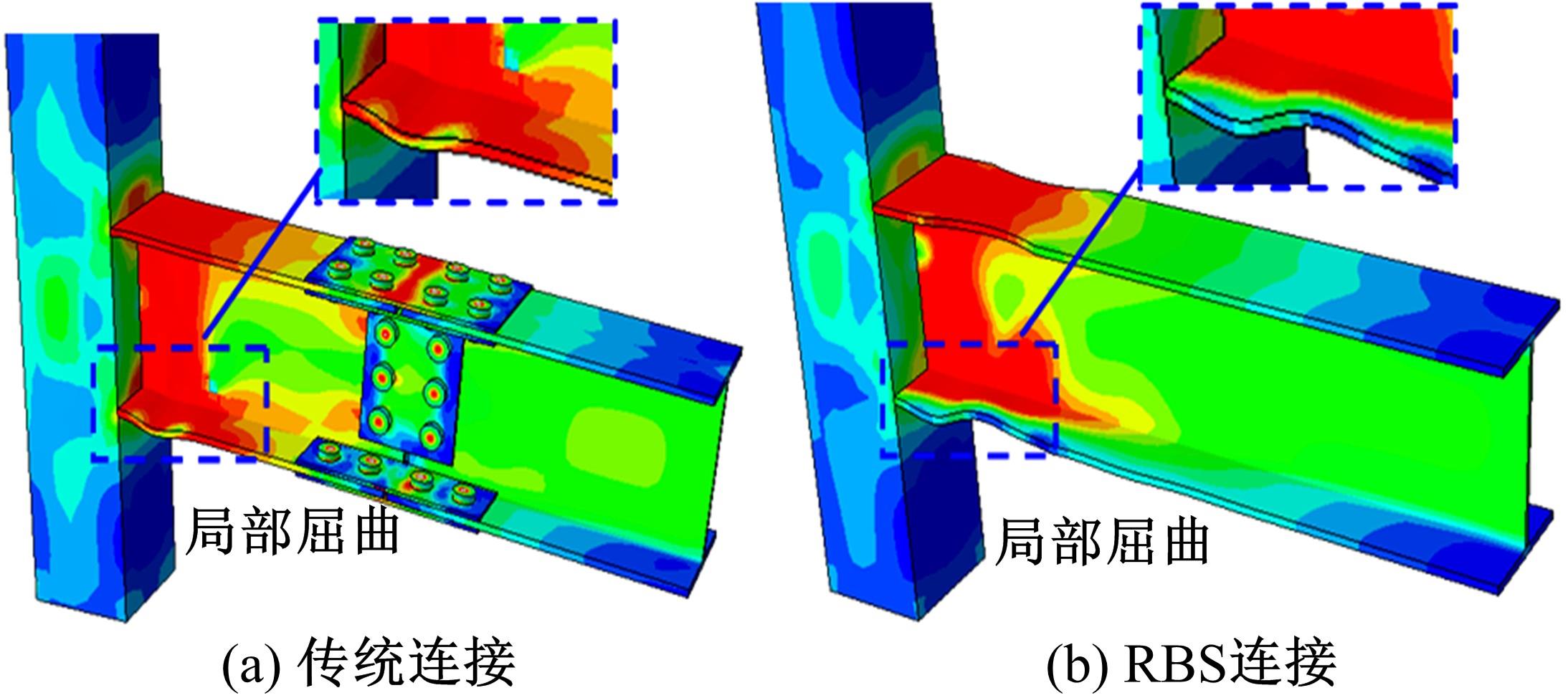

| 3 | Lee C H, Kim J H. Seismic design of reduced beam section(RBS) steel moment connections with bbolted web attachment[J]. Journal of Constructional Steel Research, 2007, 63(4): 522-531. |

| 4 | Chen C C, Lin C C. Seismic performance of steel beam-to-column moment connections with tapered beam flanges[J]. Engineering Structures, 2013, 48: 588-601. |

| 5 | 刘占科, 苏明周, 申林, 等. 钢结构梁端翼缘腋形扩大式刚性梁柱连接试验研究[J]. 建筑结构学报, 2007, 28(3): 8-14. |

| Liu Zhan-ke, Su Ming-zhou, Shen Lin, et al. Experimental study on steel moment resistant frame connections with enlarged beam flange welded to column[J]. Journal of Building Structures, 2007, 28(3): 8-14. | |

| 6 | 戴岩, 聂少锋, 周天华.带环梁的方钢管约束钢骨混凝土柱-钢梁节点滞回性能有限元分析[J].吉林大学学报: 工学版, 2018, 48(5): 1426-1435. |

| Dai Yan, Nie Shao-feng, Zhou Tian-hua. Finite element analysis of hysteretic behavior of square steel tube confined steel reinforced concrete column steel frame ring beam joint[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1426-1435. | |

| 7 | 苟海刚, 刘杰, 卢林枫. 箱形节点域H形柱弱轴削弱型连接的设计方法[J]. 钢结构, 2018, 33(8): 62-66. |

| Gou Hai-gang, Liu Jie, Lu Lin-feng. Design method of weak axis RBS connection of H-section column with box-shaped panel zone[J]. Steel Construction, 2018, 33(8): 62-66. | |

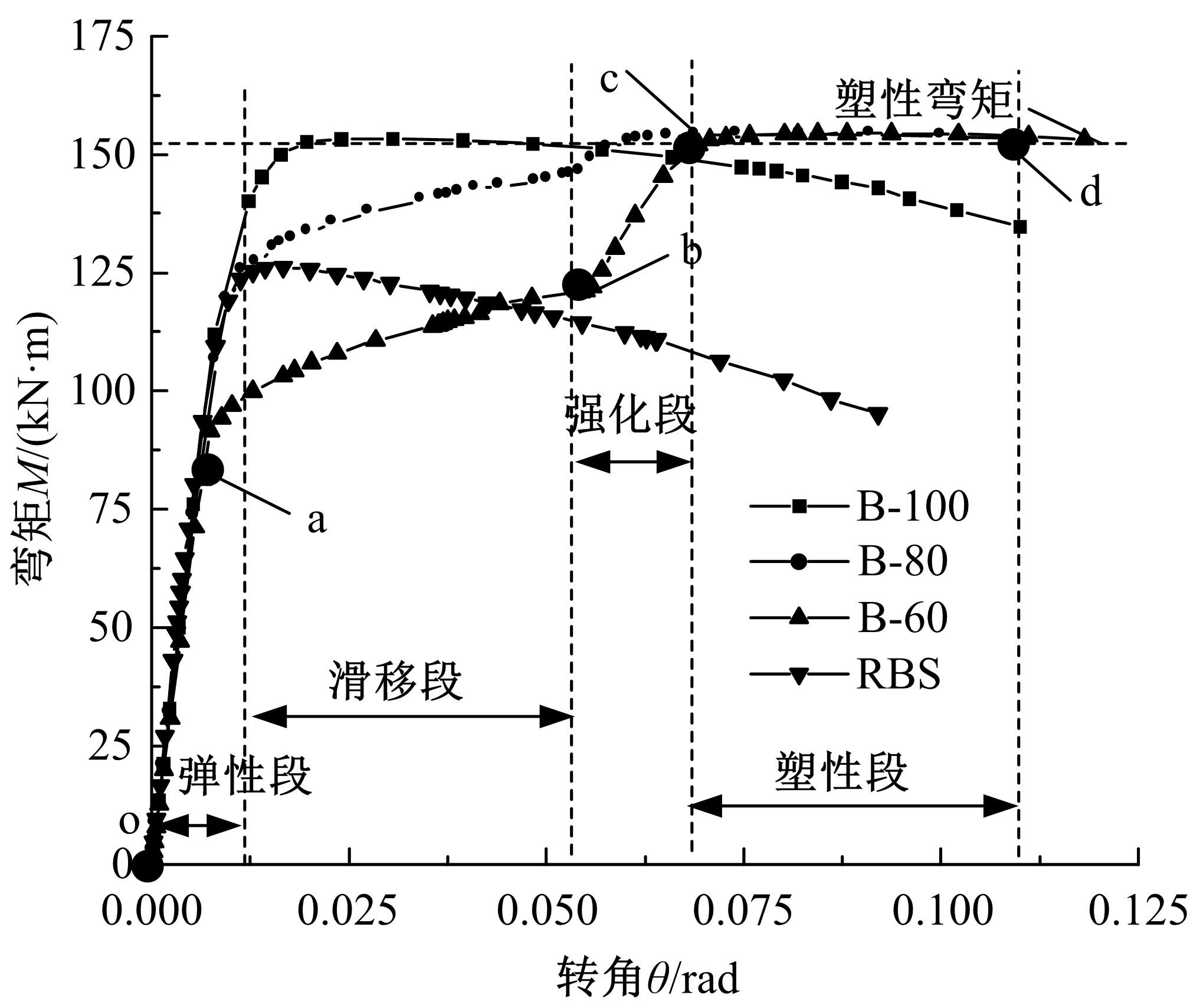

| 8 | 郁有升, 王燕. 钢框架梁翼缘削弱型节点力学性能的试验研究[J]. 工程力学, 2009, 26(2): 168-175. |

| Yu You-sheng, Wang Yan. Experimental study on the mechanical property of reduced beam section connections of steel frames[J]. Engineering Mechanics, 2009, 26(2): 168-175. | |

| 9 | FEMA 350. Recommended seismic design criteria for new steel moment-frame buildings[R]. Washington DC: SAC Joint Venture, 2000. |

| 10 | 高强, 黄天立, 陈龙, 等. 螺栓超欠拧对钢桁梁桥节点拼接接头受力的影响[J]. 中南大学学报: 自然科学版, 2019, 50(10): 163-173. |

| Gao Qiang, Huang Tian-li, Chen Long, et al. Influence of over-under-tightening of bolts on mechanical properties of connections of steel truss girder bridge[J]. Journal of Central South University(Science and Technology), 2019, 50(10): 163-173. | |

| 11 | 廖静平, 张建富,郁鼎文, 等.基于虚拟梯度材料的螺栓结合面建模方法[J].吉林大学学报: 工学版, 2016, 46(4): 1149-1155. |

| Liao Jing-ping, Zhang Jian-fu, Yu Ding-wen, et al. Modeling method of bolted joint interface based on gradient virtual materials[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(4): 1149-1155. | |

| 12 | 兰志文, 林新鹏, 吕超, 等. 预紧力变化对高强螺栓摩擦型连接板应变分布的影响[J]. 南昌大学学报: 工科版, 2017, 39(1): 43-49. |

| Lan Zhi-wen, Lin Xin-peng, Lv Chao, et al. Influence of friction high-strength bolt connection strain distribution under varietal preload[J]. Journal of Nanchang University(Engineering&Technology), 2017, 39(1): 43-49. | |

| 13 | 张德莹. 摩擦型高强螺栓传力性能及缺失的非线性分析[J]. 广西大学学报: 自然科学版, 2015, 40(1): 19-27. |

| Zhang De-ying. Nonlinear analysis on load-transfer performance and bolt missing of frictional high strength bolted connections[J]. Journal of Guangxi University(Natural Science Edition), 2015, 40(1): 19-27. | |

| 14 | Astaneh-Asl A. Seismic Design of Steel Column-Tree Moment-Resisting Frames[M]. Moraga: Structural Steel Educational Council, 1997. |

| 15 | 李启才, 苏明周, 顾强, 等. 带悬臂梁段拼接的梁柱连接循环荷载试验研究[J]. 建筑结构学报, 2003, 24(4): 54-59. |

| Li Qi-cai, Su Ming-zhou, Gu Qiang, et al. Experimental study of beam-to-column connection with cantilever beam splicing under cyclic loading[J]. Journal of Building Structures, 2003, 24(4): 54-59. | |

| 16 | 周殿文. 树状柱框架钢梁拼接处产生塑性铰的设计方法研究[D].西安: 西安建筑科技大学土木工程学院, 2008. |

| Zhou Dian-wen. A study on design method of plastic hinge appear in the splicing location of beam in column-tree frame[D]. Xi'an: College of Civil Engineering, Xi'an University of Architecture and Technology, 2008. | |

| 17 | 张爱林, 郭志鹏, 刘学春, 等. 带Z字形悬臂梁段拼接的装配式钢框架节点抗震性能试验研究[J]. 工程力学, 2017, 34(8): 31-41. |

| Zhang Ai-lin, Guo Zhi-peng, Liu Xue-chun, et al. Experimental study on aseismic behavior of prefabricated steel-frame-joints with Z-shaped cantilever-beam splicing[J]. Engineering Mechanics, 2017, 34(8): 31-41. | |

| 18 | . 钢结构设计标准 [S]. |

| 19 | 张耀春. 钢结构设计原理[M]. 北京: 高等教育出版社, 2004. |

| 20 | 童根树, 任涛. 工字梁的抗剪极限承载力[J]. 土木工程学报, 2006(8): 60-67. |

| Tong Gen-shu, Ren Tao. Shear resistance of slender webs in I-girders[J]. China Civil Engineering Journal, 2006(8): 60-67. | |

| 21 | 冯鹏, 强翰霖, 叶列平. 材料,构件,结构的"屈服点"定义与讨论[J]. 工程力学, 2017(3): 36-46. |

| Feng Peng, Qiang Han-lin, Ye Lie-ping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics, 2017(3): 36-46. | |

| 22 | 纪晓东, 马琦峰, 王彦栋, 等. 钢连梁可更换消能梁段抗震性能试验研究[J]. 建筑结构学报, 2014, 35(6): 1-11. |

| Ji Xiao-dong, Ma Qi-feng, Wang Yan-dong, et al. Cyclic tests of replaceable shear links in steel coupling beams[J]. Journal of Building Structures, 2014, 35(6): 1-11. |

| [1] | Qing-feng YAN,Ji-gang ZHANG,Tao WANG,De-gang CHEN,You-sheng YU,Ying-chun YANG. Seismic performance of connection joints between prefabricated prefinished volumetric construction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 505-514. |

| [2] | Xue-yun CHEN,Xue-yu BEI,Qu YAO,Xin JIN. Pedestrian segmentation and detection in multi-scene based on G-UNet [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 925-933. |

| [3] | Xiu-fang WANG,Shuang SUN,Chun-yang DING. Real⁃time detection of embedded bearing faults based on 1D⁃RSCNN [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 310-317. |

| [4] | You-zhi WANG,Wen-shuai ZHAO,Jin-zhang LIU,Kai QIU,Sen JIA. Mechanical performance of under⁃bridge connectors of cable⁃stayed system strengthened bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2376-2384. |

| [5] | Wei-min ZHUANG,Shen CHEN,Nan WANG. Influence on thermal stress of autobody steel-aluminum clinch-adhesive connection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 70-78. |

| [6] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [7] | Ji-chang GUO,Jie WU,Chun-le GUO,Ming-hui ZHU. Image super-resolution reconstruction based on residual connection convolutional neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1726-1734. |

| [8] | MAO Yu, ZUO Shu-guang, LIN Fu, CAO Jia-nan, ZHENG Yu-ping. Longitudinal vibration characteristics analysis of electric wheel based on elastic coupling structure [J]. 吉林大学学报(工学版), 2018, 48(1): 74-82. |

| [9] | WEN De-sheng, LIU Qiao-yan, LIU Zhong-xun, GAO Jun-feng, ZHOU Rui-bin. Rotor radial force of double-stator single-acting motor [J]. 吉林大学学报(工学版), 2015, 45(6): 1825-1830. |

| [10] | WEN De-sheng, ZHENG Zhen-quan, WANG Yuan, YANG Jie, ZHANG Kai-ming, ZHANG San-xi. Analysis of rotational speed and torque of differential connection of asymmetric multi-speed hydraulic motor [J]. 吉林大学学报(工学版), 2014, 44(5): 1342-1346. |

| [11] | LI Jian,OUYANG Ji-hong,ZHU Jia-bin,LIAO Meng-lan,ZHAO Hui. Representation and reasoning for topological relations between simple broad boundary region and simple region [J]. 吉林大学学报(工学版), 2014, 44(3): 771-775. |

| [12] | LI Jian, OUYANG Ji-hong, WANG Zhen-xin, WANG Wei. Representation model of topological relationship among three simple regions [J]. 吉林大学学报(工学版), 2013, 43(01): 117-122. |

| [13] | ZHANG Chi, XU Pei-juan, He Dong-ye, NIE Xuan. Research on the transverse knurling connection mechanism of assembled camshaft and numerical simulation analysis on the press mounting and torsion process [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 216-220. |

| [14] | QIN Gui-he, NAN Yang, CHEN Yun-han, CANG Chen-yang, HE Wei-min. Connection management strategy in media oriented systems transport network [J]. , 2012, 42(04): 963-970. |

| [15] | WANG Sheng-sheng, LIU Da-you, GU Fang-ming, LIU Dong, YANG Feng, LIU Hui-wu. Solution for semi-qualitative constraint satisfaction problems [J]. , 2012, 42(04): 942-946. |

|

||