Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (1): 70-78.doi: 10.13229/j.cnki.jdxbgxb20200738

Previous Articles Next Articles

Influence on thermal stress of autobody steel-aluminum clinch-adhesive connection structure

Wei-min ZHUANG( ),Shen CHEN,Nan WANG

),Shen CHEN,Nan WANG

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- U270.4

| 1 | 李永兵, 马运五, 楼铭, 等. 轻量化多材料汽车车身连接技术进展[J]. 机械工程学报, 2016, 52(24): 1-23. |

| Li Yong-bing, Ma Yun-wu, Lou Ming, et al. Advances in welding and joining processes of multi-material lightweight car body[J]. Journal of Mechanical Engineering, 2016, 52(24): 1-23. | |

| 2 | Markus P. Manufacturing of high strength steel and aluminum for a mixed material body in white[J]. Advanced Materials Research, 2005, 6-8: 109-126. |

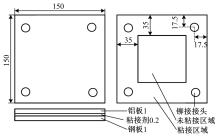

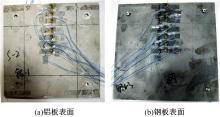

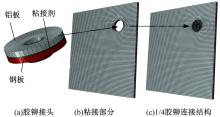

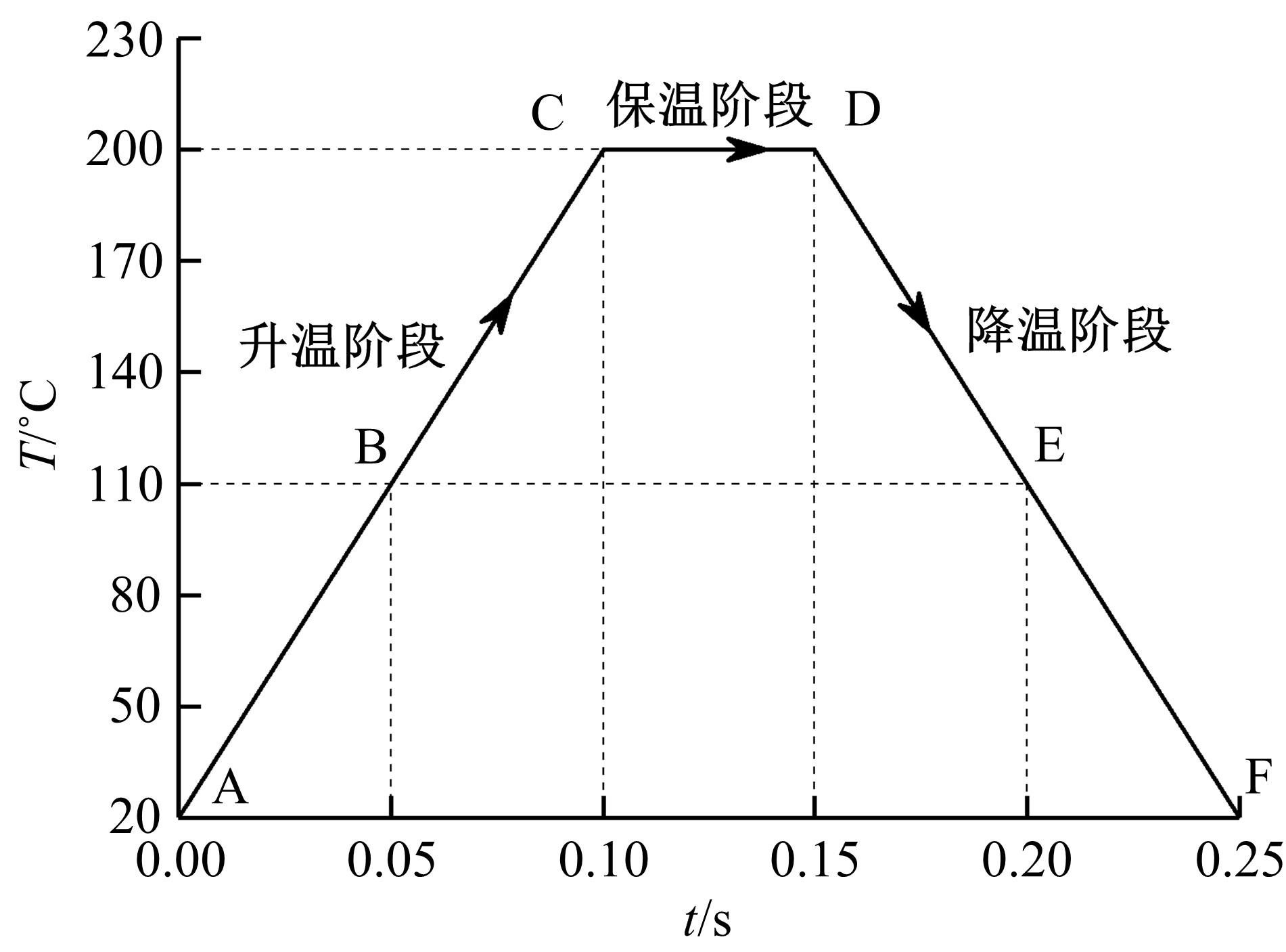

| 3 | 庄蔚敏, 施宏达, 解东旋, 等. 钢铝异质无铆钉粘铆复合连接胶层厚度分布[J]. 吉林大学学报:工学版, 2020, 50(1): 100-106. |

| Zhuang Wei-min, Shi Hong-da, Xie Dong-xuan, et al. Thickness distribution of adhesive layer in dissimilar clinch-adhesive hybrid joint with steel and aluminum alloy[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 100-106. | |

| 4 | Meschut G, Hahn O, Janzen V, et al. Innovative joining technologies for multi-material structures[J]. Welding in the World, 2014, 58(1): 65-75. |

| 5 | Gómez S, Oñoro J, Pecharromán J. A simple mechanical model of a structural hybrid adhesive/riveted single lap joint[J]. International Journal of Adhesion and Adhesives, 2006, 27(4): 263-267. |

| 6 | 邢保英, 何晓聪, 王玉奇, 等. 多铆钉自冲铆接头力学性能机理[J]. 吉林大学学报: 工学版, 2015, 45(5): 1488-1494. |

| Xing Bao-ying, He Xiao-cong, Wang Yu-qi, et al. Mechanism of mechanical properties of self-piercing riveted joints with multiple rivets[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(5): 1488-1494. | |

| 7 | Adams R D, Coppendale J, Mallick V, et al. The effect of temperature on the strength of adhesive joints[J]. International Journal of Adhesion and Adhesives, 1992, 12(3): 185-190. |

| 8 | 周江奇, 潘海涛, 楼铭, 等. 结构胶对铝钢异种金属自冲铆接工艺影响研究[J]. 汽车工程学报, 2015, 5(5): 313-320. |

| Zhou Jiang-qi, Pan Hai-tao, Lou Ming, et al. Impact of structural adhesive on self-piercing riveted aluminum to steel joints[J]. Chinese Journal of Automotive Engineering, 2015, 5(5): 313-320. | |

| 9 | Sadowski T, Kneć M, Golewski P. Experimental investigations and numerical modelling of steel adhesive joints reinforced by rivets[J]. International Journal of Adhesion and Adhesives, 2009, 30(5): 338-346. |

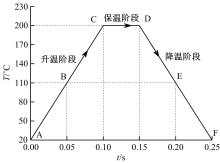

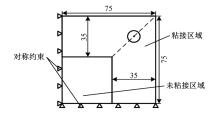

| 10 | 胡平, 韩啸, 李伟东, 等. 考虑汽车车身涂装工艺影响的非平衡胶接接头强度[J]. 机械工程学报, 2012, 48(20): 93-102. |

| Hu Ping, Han Xiao, Li Wei-dong, et al. Influence of automobile body coating process on the strength of unbalanced adhesive joints[J]. Journal of Mechanical Engineering, 2012, 48(20): 93-102. | |

| 11 | 韩啸, 李伟东, 胡平. 非平衡胶接接头循环温度场强度退化研究[J]. 机械工程学报, 2012, 48(18): 97-103. |

| Han Xiao, Li Wei-dong, Hu Ping. Research on the strength degradation of unbalanced adhesive joints subjected to cyclic-temperature environment[J]. Journal of Mechanical Engineering, 2012, 48(18): 97-103. | |

| 12 | Pirondi A, Moroni F. Science of clinch–adhesive joints[J]. Advanced Structured Materials, 2011, 6: 109-147. |

| 13 | da Silva L F M. Technology of mixed adhesive joints[J]. Advanced Structured Materials, 2011, 6: 283-309. |

| 14 | 干勇. 钢铁材料手册[M]. 北京: 化学工业出版社, 2009. |

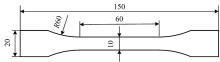

| 15 | 树脂浇注体性能试验方法[S]. |

| 16 | 金属材料热膨胀特征参数的测定[S]. |

| 17 | Moroni F, Pirondi A, Kleiner F. Experimental analysis and comparison of the strength of simple and hybrid structural joints[J]. International Journal of Adhesion and Adhesives, 2010, 30(5): 367-379. |

| 18 | Meschut G, Hahn O, Teutenberg D, et al. Influence of the curing process on joint strength of a toughened heat-curing adhesive[J]. Welding in the World, 2015, 59(2): 209-216. |

| [1] | Liang DUAN,Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU. State recognition in bearing temperature of high-speed train based on machine learning algorithms [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 53-62. |

| [2] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [3] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [4] | Yong LUO,Yong-heng WEI,Huan HUANG,Ren-jie XIAO,Lin REN,Huan-yu CUI. Starting control of P2.5 plug⁃in hybrid configuration dual⁃clutch based on driver's intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1575-1582. |

| [5] | Xiao-hua ZENG,Mei-jie SONG,Da-feng SONG,Yue WANG. Data processing method of bus driving cycle based on vehicular network information [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1692-1699. |

| [6] | Chao MA,Yun-kai GAO,Zhe LIU,Yue-xing DUAN,Lin-li TIAN. Optimization of multi⁃material and beam cross⁃sectional shape and dimension of skeleton⁃type body [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [7] | Feng-chong LAN,Ji-wen LI,Ji-qing CHEN. DG-SLAM algorithm for dynamic scene compound deep learning and parallel computing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1437-1446. |

| [8] | Jian YANG,Qi XIA,Hai-chao ZHOU,Guo-lin WANG. Noise reduction mechanism of truck radial tire based on modified carcass string contour design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1198-1203. |

| [9] | Jiang-qi LONG,Jin-tao XIANG,Ping YU,Jun-cheng WANG. Linear disturbance observer suitable for sliding mode control of nonlinear active suspension [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1230-1240. |

| [10] | Xin CHEN,Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG. Equivalent modeling of tensile-shear behavior for friction stir spot welding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1190-1197. |

| [11] | Da-feng SONG,Li-li YANG,Xiao-hua ZENG,Xing-qi WANG,Wei-zhi LIANG,Nan-nan YANG. Battery life optimization of hybrid electric vehicle based on driving cycle construction [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 781-791. |

| [12] | Ren HE,Xiao-cong ZHAO,Yi-bin YANG,Jian-qiang WANG. Man⁃machine shared driving model using risk⁃response mechanism of human driver [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 799-809. |

| [13] | Jia-xu ZHANG,Xin-zhi WANG,Jian ZHAO,Zheng-tang SHI. Path planning and discrete sliding mode tracking control for high⁃speed lane changing collision avoidance of vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1081-1090. |

| [14] | Bo WANG,Yang-yang HE,Bing-bing NIE,Shu-cai XU,Jin-huan ZHANG. Abdominal injury of vehicle occupant in underbody blast events [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 792-798. |

| [15] | Wei-min ZHUANG,Peng-yue WANG,Rui-juan GAO,Dong-xuan XIE. Effect of hot forming on static mechanical properties of AA5754 aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 847-854. |

|

||