Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (12): 3388-3396.doi: 10.13229/j.cnki.jdxbgxb.20220084

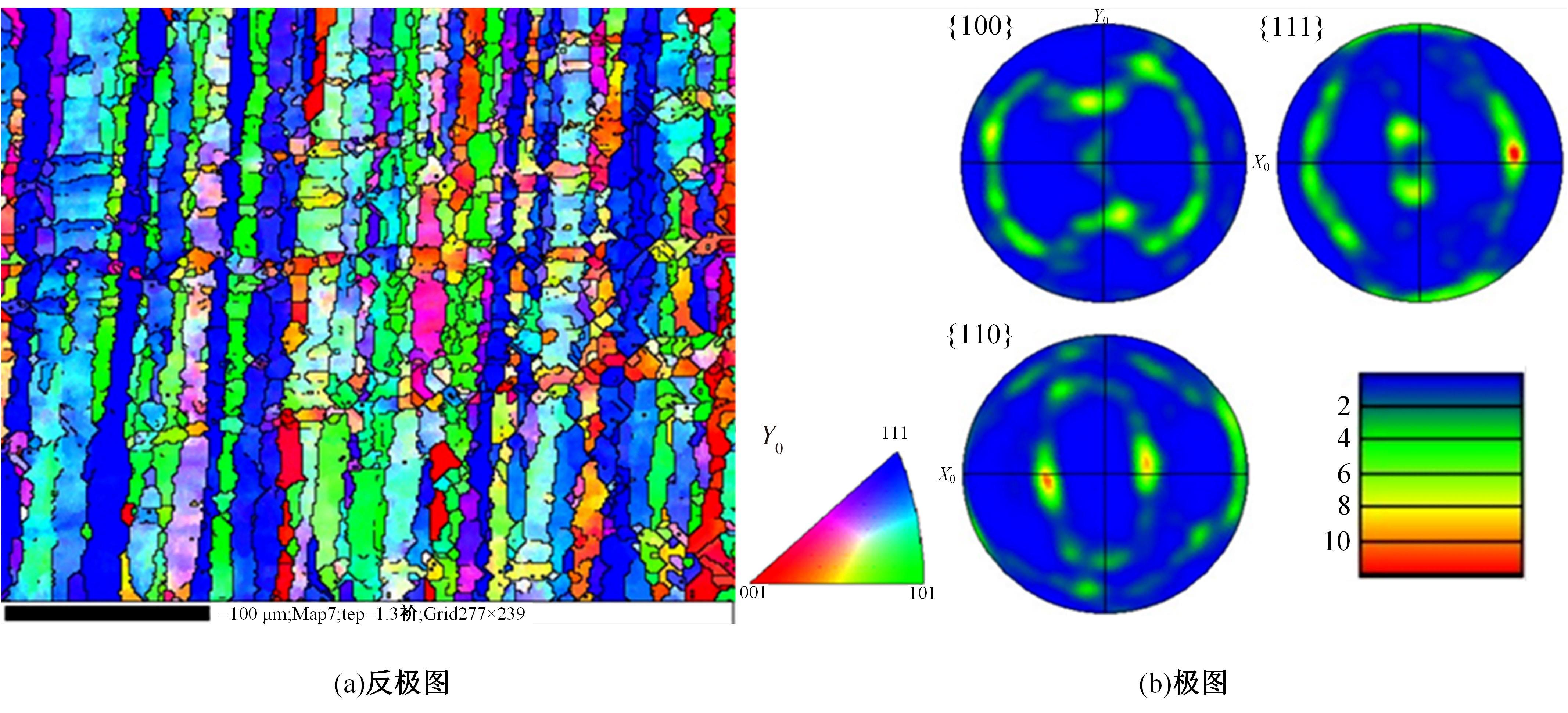

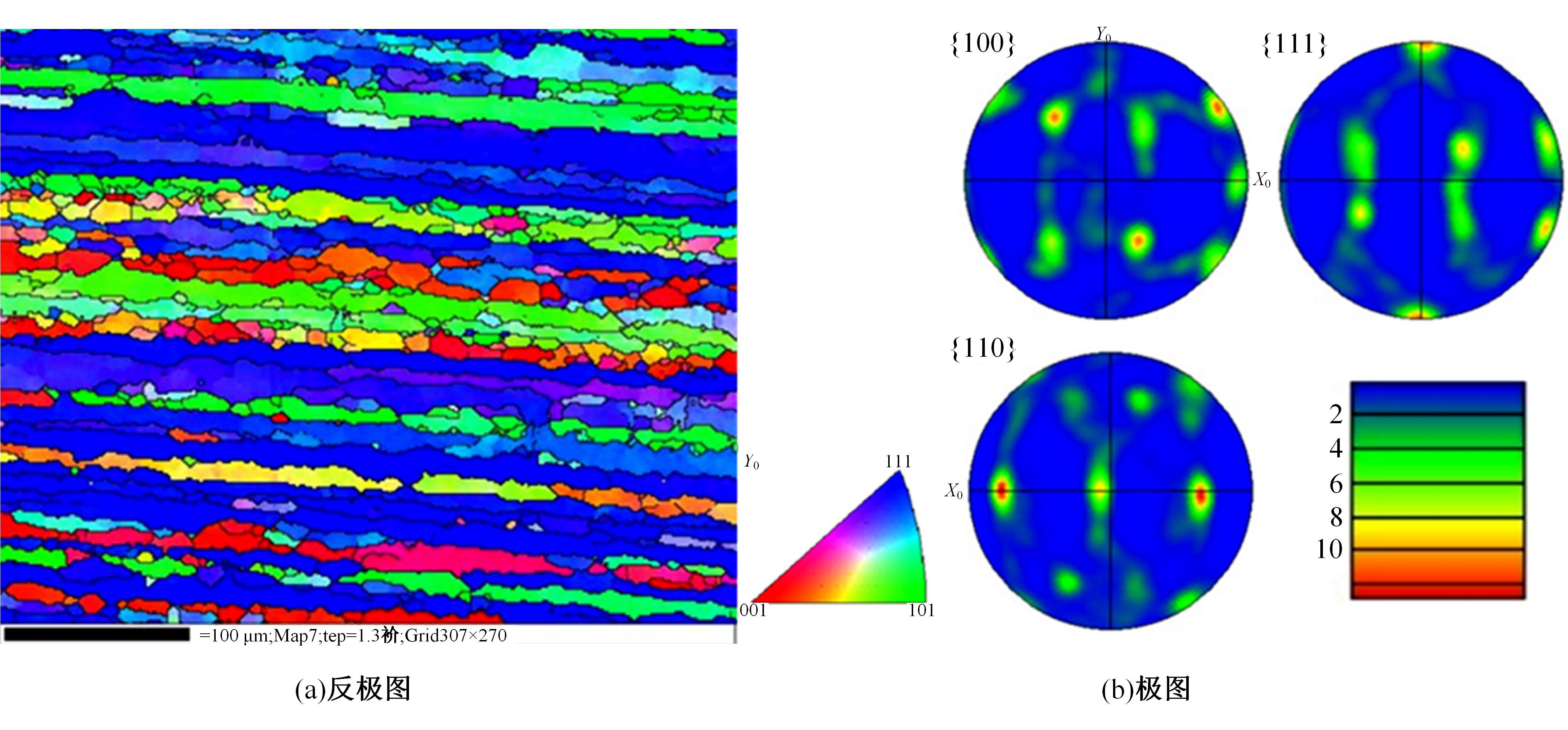

Prediction of fracture of aluminum alloy profiles in roll bending considering anisotropy

Chun-guo LIU1,2( ),Zi-tong LI1,2,Xue-guang ZHANG3,Ming LI1,2

),Zi-tong LI1,2,Xue-guang ZHANG3,Ming LI1,2

- 1.Roll-forging Research Institute,Jilin University,Changchun 130022,China

2.School of Materials Science and Engineering,Jilin University,Changchun 130022,China

3.Engineering Planning and Development Department,CRRC Changchun Railway Vehicles Co. ,Ltd. ,Changchun 130051,China

CLC Number:

- TG386

| 1 | Shi L, Wen J B, Ren C. The prediction of microstructure evolution of 6005A aluminum alloy in a P-ECAP extrusion study[J]. Journal of Materials Engineering and Performance, 2018, 27(5): 2566-2575. |

| 2 | 韩飞, 刘继英, 艾正青, 等. 辊弯成型技术理论及应用研究现状[J]. 塑性工程学报, 2010, 17(5): 53-60. |

| Han Fei, Liu Ji-ying, Ai Zheng-qing, et al. Research status of roll forming technology theory and application[J]. Chinese Journal of Plastic Engineering, 2010, 17(5): 53-60. | |

| 3 | Yan Y, Wang H B, Li Q. The inverse parameter identification of Hill 48 yield criterion and its verification in press bending and roll forming process simulations[J]. Journal of Manufacturing Processes, 2015, 20(1): 46-53. |

| 4 | Li S, Engler O, Houtte P V. Plastic anisotropy and texture evolution during tensile testing of extruded aluminium profiles[J]. Modelling and Simulation in Materials Science and Engineering, 2005, 13(5): 783-795. |

| 5 | Lian J, Shen F, Jia X, et al. An evolving non-associated Hill48 plasticity model accounting for anisotropic hardening and r-value evolution and its application to forming limit prediction[J]. International Journal of Solids and Structures, 2018, 151: 20-44. |

| 6 | Basak S, Panda S K, Lee M-G. Formability and fracture in deep drawing sheet metals: Extended studies for pre-strained anisotropic thin sheets[J]. International Journal of Mechanical Sciences, 2020, 170: No. 105346. |

| 7 | Achani D, Hopperstad O S, Lademo O G. Influence of advanced yield criteria on predictions of plastic anisotropy for aluminium alloy sheets[J]. International Journal of Material Forming, 2009, 2(Sup.1): 487-490. |

| 8 | Dick R E, Yoon J W. Plastic anisotropy and failure in thin metal: Material characterization and fracture prediction with an advanced constitutive model and polar EPS (effective plastic strain) fracture diagram for AA 3014-H19[J]. International Journal of Solids and Structures, 2018, 151: 195-213. |

| 9 | Lou Y, Yoon J W. Alternative approach to model ductile fracture by incorporating anisotropic yield function[J]. International Journal of Solids and Structures, 2019, 164: 12-24. |

| 10 | Grytten F, Holmedal B, Hopperstad O S, et al. Evaluation of identification methods for YLD2004-18p[J]. International Journal of Plasticity, 2008, 24(12): 2248-2277. |

| 11 | Bate P, An Y. Plastic anisotropy in AA5005 Al-1Mg: predictions using crystal plasticity finite element analysis[J]. Scripta Materialia, 2004, 51(10): 973-977. |

| 12 | Wei P, Lu C, Liu H, et al. Study of anisotropic plastic behavior in high pressure torsion of aluminum single crystal by crystal plasticity finite element method[J]. Crystals, 2017, 7(12): 362-372. |

| 13 | 黄建科. 金属成形过程的细观损伤力学模型及韧性断裂准则研究[D]. 上海:上海交通大学材料科学与工程学院, 2009. |

| Huang Jian-ke. Research on meso-scale damage mechanics model and ductile fracture criterion of metal forming process[D]. Shanghai: School of Materials Science and Engineering, Shanghai Jiaotong University, 2009. | |

| 14 | 高付海, 桂良进, 范子杰. 基于韧性准则的金属板料冲压成形断裂模拟[J]. 工程力学, 2010, 27(2): 204-208. |

| Gao Fu-hai, Gui Liang-jin, Fan Zi-jie. Fracture simulation of sheet metal stamping based on toughness criterion[J]. Engineering Mechanics, 2010, 27(2): 204-208. | |

| 15 | Rice J R, Tracey D M. On the ductile enlargement of voids in triaxial stress fields[J]. Journal of the Mechanics and Physics of Solids, 1969, 17(3): 201-217. |

| 16 | Liu C, Li M, Yue T. Thick anisotropy analysis for AA7B04 aluminum plate using CPFEM and its application for springback prediction in multi-point bending[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(4): 1139-1153. |

| [1] | Jue LI,An-shun ZHANG,Jun-hui ZHANG,Jun-feng QIAN. Model testing and numerical analysis of dynamic response of graded crushed rock base structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1782-1789. |

| [2] | Heng ZHANG,Zhi-gang ZHAN,Ben CHEN,Pang-chieh SUI,Mu PAN. Anisotropic transport properties of gas diffusion layer based on pore⁃scale model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2055-2062. |

| [3] | Hui-shuang JI,Yan PENG,Yang LIU,Yan-bo YANG,Kun GAO,Li-min ER. Solidification behavior and quality control of molten copper in SCR production line [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2021-2030. |

| [4] | Hong-liang XIANG,Sheng-tao CHEN,Li-ping DENG,Wei ZHANG,Tu-sheng ZHAN. Microstructure and properties of microalloying 2205 duplex stainless steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1645-1652. |

| [5] | Xiao-yan GU,Dong-feng LIU,Jing LIU,Da-qian SUN,Hui-feng MA. Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1600-1607. |

| [6] | Zhuo YI,Wen-zhi FU,Ming-zhe LI. Numerical simulation and experiment on double⁃layered split ultrahigh pressure die [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1593-1599. |

| [7] | Xue⁃guang ZHANG,Ming⁃meng JIA,Chun⁃guo LIU,Guang⁃zhong HE. Trajectory design and FE simulation for profile stretch bending based on incremental control method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1272-1279. |

| [8] | WANG Chun-sheng, ZOU Li, YANG Xin-hua. Analysis of fatigue life factors of aluminum alloy welded joints based on neighborhood rough set theory [J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [9] | WANG Hui, ZHOU Jie, XIONG Yu, TAO Ya-ping, XIANG Rong. Springback compensation for stamping part with complex surface based on reverse engineering [J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [10] | HU Kan, YU Ye, YING Liang, HU Ping, HOU Wen-bin. Optimization design of hot-stamping beam structure considering rollover crash safety of school bus [J]. 吉林大学学报(工学版), 2017, 47(3): 884-890. |

| [11] | LUN Feng-yan, FU Wen-zhi, LI Ming-zhe, YI Zhuo, WANG Xin-tong, CHEN Xue. Forming of flexible rolling of three-dimensional surface based on bended rolls [J]. 吉林大学学报(工学版), 2017, 47(3): 876-883. |

| [12] | HU Zhi-qing,ZHEN Jiao-jiao,FENG Zeng-ming,ZHOU Shu-hong. Flexible rolling and stretch forming surface technology and numerical simulation [J]. 吉林大学学报(工学版), 2014, 44(3): 701-707. |

| [13] | WANG Mi, CAI Zhong-yi, LI Ming-zhe, WANG Da-ming. Calculation of bending deformation of flexible roll forming for three-dimensional surface parts and numerical simulation [J]. 吉林大学学报(工学版), 2014, 44(2): 404-408. |

| [14] | CAO Jun-hui, FU Wen-zhi, LI Ming-zhe, PENG He-li. Influence factors on dimpling in multi-point thermoforming for polymer sheet [J]. 吉林大学学报(工学版), 2013, 43(06): 1536-1540. |

| [15] | LI Ren-jun, LI Ming-zhe, XUE Peng-fei, CAI Zhong-yi, QIU Ning-jia. Method of flexible rolling for surface sheet metal [J]. 吉林大学学报(工学版), 2013, 43(06): 1529-1535. |

|

||