Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1645-1652.doi: 10.13229/j.cnki.jdxbgxb20190550

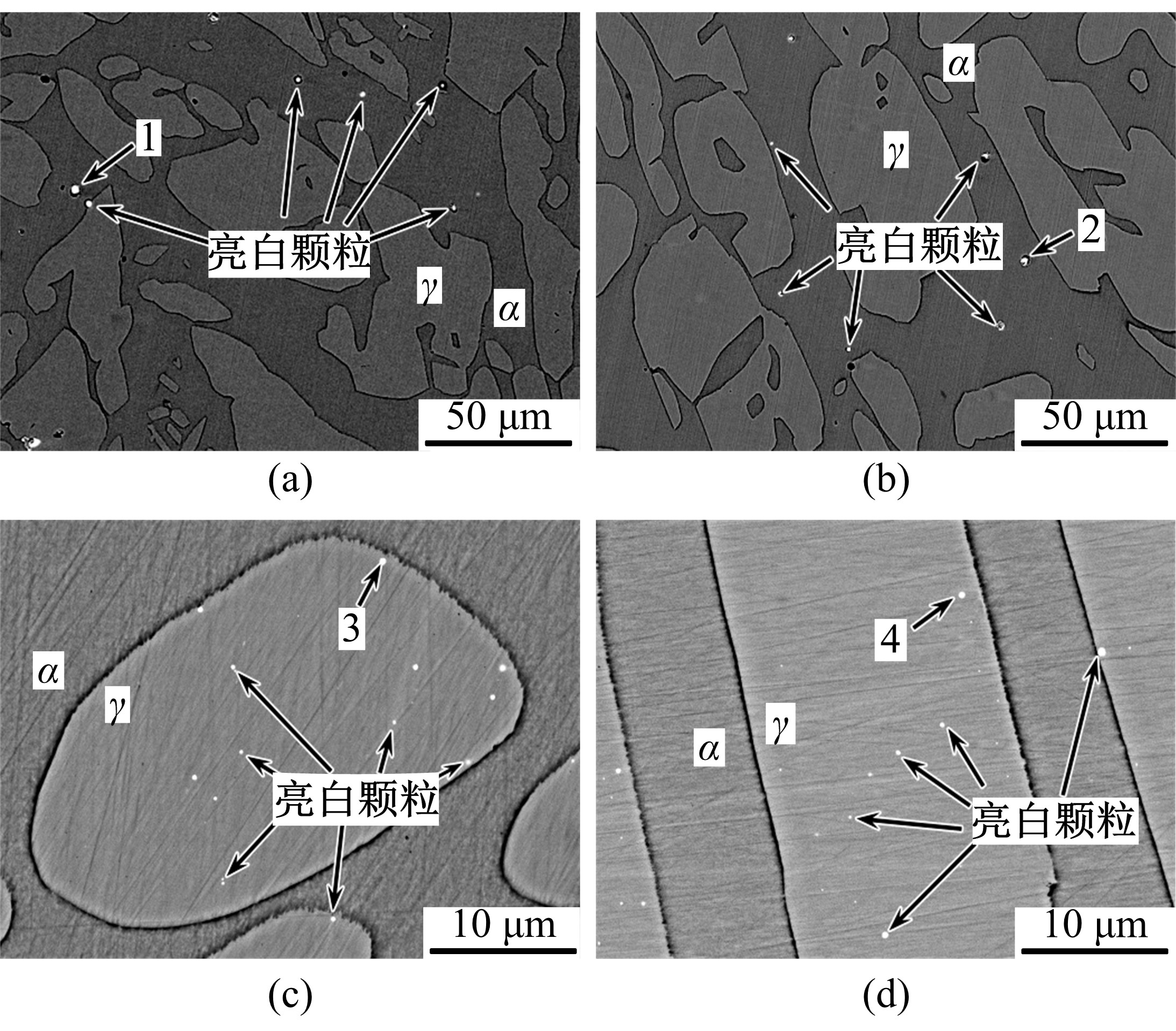

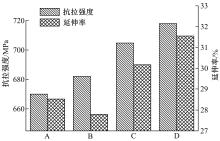

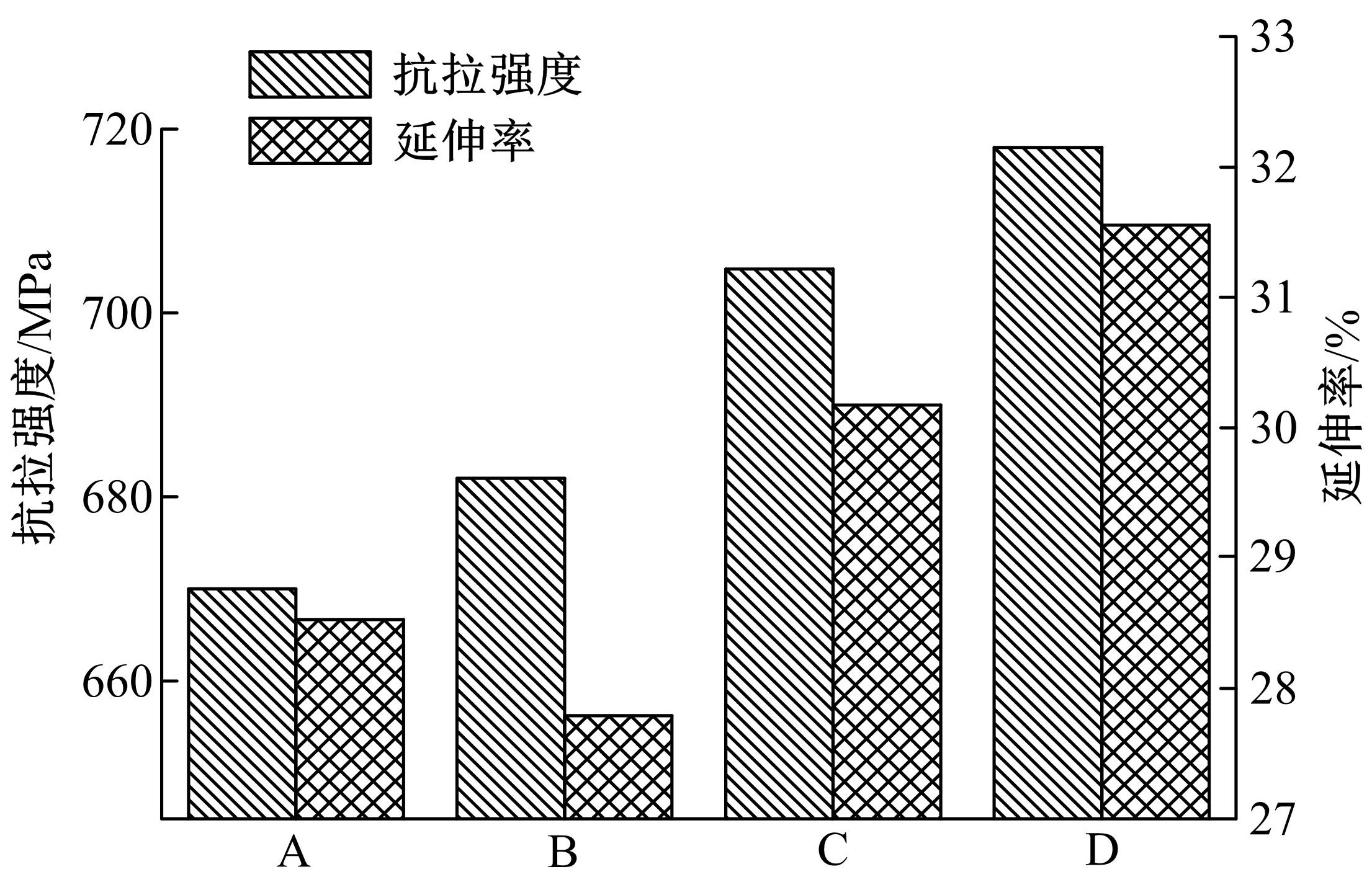

Microstructure and properties of microalloying 2205 duplex stainless steel

Hong-liang XIANG1,2( ),Sheng-tao CHEN1,Li-ping DENG1,Wei ZHANG3,Tu-sheng ZHAN4

),Sheng-tao CHEN1,Li-ping DENG1,Wei ZHANG3,Tu-sheng ZHAN4

- 1.School of Mechanical Engineering and Automation, Fuzhou University, Fuzhou 350108, China

2.School of Advanced Manufacturing, Fuzhou University, Jinjiang 362200, China

3.Technology Center, China Baowu Steel Group,Shanghai 201900, China

4.Baosteel-desheng Co. , Ltd. , Fuzhou 350600, China

CLC Number:

- TG172

| 1 | 吴玖. 双相不锈钢[M]. 北京: 冶金工业出版社, 1999. |

| 2 | Li M, Li N, Xu D, et al. Antibacterial performance of a Cu-bearing stainless steel against microorganisms in tap water[J]. Journal of Materials Science & Technology, 2015, 31(3): 243-251. |

| 3 | Oguzie E E, Li J, Liu Y, et al. Electrochemical corrosion behavior of novel Cu-containing antimicrobial austenitic and ferritic stainless steels in chloride media[J]. Journal of Materials Science, 2010, 45(21): 5902-5909. |

| 4 | Dan Z, Ni H, Xu B, et al. Microstructure and antibacterial properties of AISI 420 stainless steel implanted by copper ions[J]. Thin Solid Films, 2005, 492(1/2): 93-100. |

| 5 | Xi T, Yang C, Babar S M, et al. Study of the processing map and hot deformation behavior of a Cu-bearing 317LN austenitic stainless steel[J]. Materials & Design, 2015, 87: 303-312. |

| 6 | 南黎, 刘永前, 杨伟超, 等. 含铜抗菌不锈钢的抗菌特性研究[J]. 金属学报, 2007, 43(10): 1065-1070. |

| Nan Li, Liu Yong-qian, Yang Wei-chao, et al. Study on antibacterial properties of copper-containing antibacterial stainless steels[J]. Acta Metallurgica Sinica, 2007, 43(10): 1065-1070. | |

| 7 | 向红亮, 范金春, 刘东, 等. 抗菌时效处理对含Cu双相不锈钢组织和性能的影响 Ⅰ.富Cu相的微观结构及演变规律[J]. 金属学报, 2012, 48(9): 1081-1088. |

| Xiang Hong-liang, Fan Jin-chun, Liu Dong, et al. Effects of antibacterial aging treatment on microstructure and properties of copper-containing duplex stainless steel Ⅰ. microstructure and evolution of copper-rich phase [J]. Acta Metallurgica Sinica, 2012, 48(9): 1081-1088. | |

| 8 | 良维杰. SUS430含铜抗菌不锈钢之性质研究[D]. 台湾: 国立台湾大学工学院, 2000. |

| Liang Wei-jie. Performance study of Cu-containing antibacterial SUS 430 stainless steel[D]. Taiwan: School of Engineering, National Taiwan University, 2000. | |

| 9 | Yokata T, Tochihara M, Ohta M. Silver dispersed stainless steel with antibacterial property[J]. Kawasaki Steel Technical Report, 2001, 2(33): 88-91. |

| 10 | Xuan Y, Zhang C, Fan N Q, et al. Antibacterial property and precipitation behavior of Ag-added 304 austenitic stainless steel[J]. Acta Metallurgica Sinica(English Letters), 2014, 27(3): 539-545. |

| 11 | 杨柯, 董加胜, 陈四红, 等. 含Cu抗菌不锈钢的工艺与耐蚀性能[J]. 材料研究学报, 2006, 20(5): 523-527. |

| Yang Ke, Dong Jia-sheng, Chen Si-hong, et al. The craftwork performance and resistance to corrosion of the Cu-containing antibacterial stainless steels[J]. Chinese Journal of Materials Research, 2006, 20(5): 523-527. | |

| 12 | 向红亮, 范金春, 刘东, 等. 抗菌时效处理对含Cu双相不锈钢组织和性能的影响 Ⅱ.耐蚀及抗菌性能[J]. 金属学报, 2012, 48(9): 1089-1096. |

| Xiang Hong-liang, Fan Jin-chun, Liu Dong, et al. Effects of antibacterial aging treatment on microstructure and properties of copper-containing duplex stainless steel II. corrosion resistance and antibacterial properties[J]. Acta Metallurgica Sinica, 2012, 48(9): 1089-1096. | |

| 13 | 郑至轩. 添加金属铜对SUS304不锈钢显微组织及抗菌性质影响[D]. 台湾: 台北科技大学工程学院, 2011. |

| Zheng Zhi-xuan. Microstructure and antibacterial properties of Cu-modified SUS 304 stainless steel[D]. Taiwan: School of Engineering, National Taipei University of Technology, 2011. | |

| 14 | Sreekumari K R, Kanavillil N, Takao K, et al. Silver containing stainless steel as a new outlook to abate bacterial adhesion and microbiologically influenced corrosion[J]. ISIJ International2003, 43(11): 1799-1806. |

| 15 | Chiang W C, Tseng I S, Moller P, et al. Influence of silver additions to type 316 stainless steels on bacterial inhibition, mechanical properties, and corrosion resistance[J]. Materials Chemistry & Physics, 2010, 119(1/2): 123-130. |

| 16 | Huang C F, Chiang H J, Lan W C, et al. Development of silver-containing austenite antibacterial stainless steels for biomedical applications. Part I: microstructure characteristics, mechanical properties and antibacterial mechanisms[J]. Biofouling, 2011, 27(5): 449-457. |

| 17 | 轩阳. 含银304奥氏体不锈钢中富银相析出行为研究[D]. 北京: 清华大学材料学院, 2014. |

| Xuan Yang. Study of the silver precipitation behavior in silver-contain 304 austenitic stainless steel [D]. Beijing: School of Materials Science and Engineering, Tsinghua University, 2014. | |

| 18 | 向红亮, 郭培培, 刘东. 含Ag抗菌双相不锈钢组织及抗菌性能研究[J]. 金属学报, 2014, 50(10): 1210-1216. |

| Xiang Hong-liang, Guo Pei-pei, Liu Dong. Microstructure and antibacterial properties of Ag-bearing duplex stainless steel[J]. Acta Metallurgica Sinica, 2014, 50(10): 1210-1216. | |

| 19 | 郭培培, 向红亮, 李敬鑫, 等. Cu-Ag合金雾化工艺研究[J]. 特种铸造及有色合金, 2013, 33(5): 470-473. |

| Guo Pei-pei, Xiang Hong-liang, Li Jing-xin, et al. Atomization of Cu-Ag alloy[J]. Special Casting & Nonferrous Alloys, 2013, 33(5): 470-473. | |

| 20 | 朱峰成. 银含量对2205双相不锈钢显微组织及高温机械性质影响之研究[D]. 台湾: 国立高雄大学工学院, 2010. |

| Zhu Feng-cheng. Effect of silver content on microstructure and high temperature mechanical properties of 2205 duplex stainless steel[D]. Taiwan: School of Engineering, National University of Kaohsiung, 2010. | |

| 21 | 杨才福, 张永权. 铜含量对低碳HSLA钢力学性能的影响[J]. 特殊钢, 1999, 20(1): 27-30. |

| Yang Cai-fu, Zhang Yong-quan. Effect of Cu content on mechanical properties of low carbon HSLA steel[J]. Special Steel, 1999, 20(1): 27-30. | |

| 22 | 牛绍蕊. 不锈钢的电化学腐蚀性能研究[D]. 兰州: 兰州理工大学材料科学与工程学院, 2010. |

| Niu Shao-rui. The research of eleetrochemical corrosion resistance of stainless steel[D]. Lanzhou: School of Materials Science and Engineering, Lanzhou University of Technology, 2010. | |

| 23 | Sourisseau T, Chauveau E, Baroux B. Mechanism of copper action on pitting phenomena observed on stainless steels in chloride media[J]. Corrosion Science, 2005, 47(5): 1097-1117. |

| [1] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [2] | Qing-feng GUAN,Xin-wen YAO,Yang YANG,Ling-yan ZHANG,Di LIU,Chen LI,Peng LYU. Preparation and property of Cr alloying layer on TC4 after surface alloying induced by high current pulsed electron beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2002-2009. |

| [3] | Xin TONG,Ya-jiao ZHANG,Yu-shan HUANG,Zheng-zheng HU,Qing WANG,Zhi-hui ZHANG. Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1615-1621. |

| [4] | Xiao-yan GU,Dong-feng LIU,Jing LIU,Da-qian SUN,Hui-feng MA. Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1600-1607. |

| [5] | Zhuo YI,Wen-zhi FU,Ming-zhe LI. Numerical simulation and experiment on double⁃layered split ultrahigh pressure die [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1593-1599. |

| [6] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [7] | Xue⁃guang ZHANG,Ming⁃meng JIA,Chun⁃guo LIU,Guang⁃zhong HE. Trajectory design and FE simulation for profile stretch bending based on incremental control method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1272-1279. |

| [8] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [9] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [10] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [11] | GUAN Qing-feng, DONG Shu-heng, ZHENG Huan-huan, LI Chen, ZHANG Cong-lin, LV-Peng. Cr surface alloying of 45# steel by high-current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [12] | WANG Chun-sheng, ZOU Li, YANG Xin-hua. Analysis of fatigue life factors of aluminum alloy welded joints based on neighborhood rough set theory [J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [13] | WANG Hui, ZHOU Jie, XIONG Yu, TAO Ya-ping, XIANG Rong. Springback compensation for stamping part with complex surface based on reverse engineering [J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [14] | GUAN Qing-feng, ZHANG Yuan-wang, SUN Xiao, ZHANG Chao-ren, LYU Peng, ZHANG Cong-lin. Surface alloying of Al-W alloy by high current pulsed electron beam treatment [J]. 吉林大学学报(工学版), 2017, 47(4): 1171-1178. |

| [15] | HU Kan, YU Ye, YING Liang, HU Ping, HOU Wen-bin. Optimization design of hot-stamping beam structure considering rollover crash safety of school bus [J]. 吉林大学学报(工学版), 2017, 47(3): 884-890. |

|

||