Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (7): 2203-2211.doi: 10.13229/j.cnki.jdxbgxb.20231161

Temperature resistance mechanism of high-early-strength cement mortar modified with waterborne epoxy resin

Yao-gang TIAN1( ),Jing JIANG1,Cheng ZHAO2,Xiao-min YANG3,Jun ZHANG4,Kan JIA1

),Jing JIANG1,Cheng ZHAO2,Xiao-min YANG3,Jun ZHANG4,Kan JIA1

- 1.School of Materials Science and Engineering,Chang’an University,Xi’an 710064,China

2.Northwest Civil Aviation Airport Construction Group Co. ,Ltd,Xi’an 710065,China

3.Concrete Branch of Xi'an Railway Engineering Co. ,Ltd. of China Railway Seventh Bureau Group,Xi’an 710032,China

4.School of Engineering Machinery,Chang'an University,Xi’an 710064,China

CLC Number:

- TU528

| [1] | Shi C, Zou X W, Yang L, et al. Influence of humidity on the mechanical properties of polymer-modified cement-based repair materials[J]. Construction and Building Materials, 2020, 261: No.119928. |

| [2] | 宿晓萍, 王清. 复合盐浸-冻融-干湿多因素作用下的混凝土腐蚀破坏[J]. 吉林大学学报: 工学版, 2015, 45(1): 112-120. |

| Su Xiao-ping, Wang Qing. Corrosion damage of concrete under multi-salt soaking, freezing-thawing and dry-wet cycles[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(1): 112-120. | |

| [3] | Pang B, Zhang Y S, Liu G J. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste[J]. Construction and Building Materials, 2018, 167: 831-845. |

| [4] | Luo J L, Li Q Y, Zhao T J, et al. Bonding and toughness properties of PVA fibre reinforced aqueous epoxy resin cement repair mortar[J]. Construction and Building Materials, 2013, 49: 766-711. |

| [5] | Marouani S, Curtil L, Hamelin P. Ageing of carbon/epoxy and carbon/vinylester composites used in the reinforcement and/or the repair of civil engineering structures[J]. Composites Part B: Engineering, 2012, 43(4): 2020-2030. |

| [6] | 董玉强, 夏正斌, 刘桂芝, 等. 水性环氧树脂固化剂的研究进展[J]. 涂料工业, 2019, 49(7): 70-75. |

| Dong Yu-qiang, Xia Zheng-bin, Liu Gui-zhi, et al. Research progress in waterborne epoxy resin curing agent[J]. Paint & Coatings Industry, 2019, 49(7): 70-75. | |

| [7] | Aggarwal L K, Thapliyal P C, Karade S R. Properties of polymer-modified mortars using epoxy and acrylic emulsions[J]. Construction and Building Materials, 2007, 21(2): 379-383. |

| [8] | 梁会忠, 韩飞, 钱慧丽, 等. 低掺量水性环氧树脂对高性能混凝土抗冻耐久性的研究[J]. 混凝土与水泥制品, 2012(1): 9-12. |

| Liang Hui-zhong, Han Fei, Qian Hui-li, et al. Study on the effects of low volume waterborne epoxy resin on freezing resistance durability of high performance concrete[J]. China Concrete and Cement Products, 2012(1): 9-12. | |

| [9] | 黄展魏, 陈伟, 李秋, 等. 水性环氧树脂改性水泥砂浆力学性能及微观结构[J]. 硅酸盐通报, 2017, 36(8): 2530-2535, 2540. |

| Huang Zhan-wei, Chen Wei, Li Qiu, et al. Mechanical properties and microstructure of waterborne epoxy resin modified cement mortar[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(8): 2530-2535, 2540. | |

| [10] | 田甜. 水性环氧树脂乳液改性水泥砂浆性能的研究[D]. 长沙: 湖南大学土木工程学院, 2007. |

| Tian Tian. Study on properties of waterborne epoxy resin emulsion modified cement mortar[D]. Changsha: School of Civil Engineering, Hunan University, 2007. | |

| [11] | Rashid K, Ueda T, Zhang D, et al. Experimental and analytical investigations on the behavior of interface between concrete and polymer cement mortar under hygrothermal conditions[J]. Construction and Building Materials, 2015, 94: 414-425. |

| [12] | 雪凯旺, 苗苗, 周健. 高强混凝土高温爆裂行为改善措施的研究进展[J]. 硅酸盐通报, 2016, 35(10): 3209-3214. |

| Xue Kai-wang, Miao Miao, Zhou Jian. Improvement measures of high temperature explosive spalling of high strength concrete[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(10): 3209-3214. | |

| [13] | 李黎. 高温后多尺度纤维水泥基材料性能演化规律与微观机理[D]. 大连: 大连理工大学土木工程学院, 2019. |

| Li Li. Evolutionary and micro mechanisms of multi-scale fiber reinforced cementitious composites after high temperature exposure[D]. Dalian: School of Civil Engineering, Dalian University of Technology, 2019. | |

| [14] | Kim J, Lee G P, Moon D Y. Evaluation of mechanical properties of steel-fibers reinforced concrete exposed to high temperature by double-punch test[J]. Construction and Building Materials, 2015, 79: 182-191. |

| [15] | Abedalqader A, Shatarat N, Ashteyat A, et al. Influence of temperature on mechanical properties of recycled asphalt pavement aggregate and recycled coarse aggregate concrete[J]. Construction and Building Materials, 2021, 269: No.121285. |

| [16] | 陈双, 莫忧, 胡建. 高温尾喷作用下水泥混凝土道面的疲劳损伤[J]. 西安建筑科技大学学报: 自然科学版, 2021, 53 (2): 194-201. |

| Chen Shuang, Mo You, Hu Jian. Fatigue damage of cement concrete pavement under high temperature tail spray[J]. Journal of Xi'an University of Architecture and Technology(Natural Science Edition), 2021, 53(2): 194-201. | |

| [17] | Qin J H, Qian J S, You C, et al. Bond behavior and interfacial micro-characteristics of magnesium phosphate cement onto old concrete substrate[J]. Construction and Building Materials, 2018, 167: 166-176. |

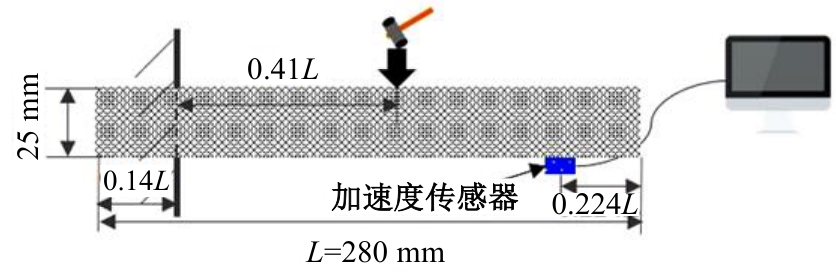

| [18] | Tian Y G, Lu D, Zhou J W, et al. Damping property of cement mortar incorporating damping aggregate[J]. Materials, 2020, 13(3): 792-804. |

| [19] | Tian Y G, Yan X H, Zhang M Y, et al. Effect of the characteristics of lightweight aggregates presaturated polymer emulsion on the mechanical and damping properties of concrete[J]. Construction and Building Materials, 2020, 253: No.119154. |

| [20] | Ma Q M, Guo R X, Zhao Z M, et al. Mechanical properties of concrete at high temperature: A review[J]. Construction and Building Materials, 2015, 93: 371-383. |

| [21] | Yang Y M, Xian G J, Li H, et al. Thermal aging of an anhydride-cured epoxy resin[J]. Polymer Degradation and Stability, 2015, 118: 111-119. |

| [22] | Yang J S, Ma L, Schmidt R, et al. Hybrid lightweight composite pyramidal truss sandwich panels with high damping and stiffness efficiency[J]. Composite Structures, 2016,148: 85-96. |

| [23] | Chi L, Lu S, Yao Y. Damping additives used in cement-matrix composites: a review[J]. Composites Part B: Engineering, 2019, 164: 26-36. |

| [24] | Sanaei Ataabadi H, Zare A, Rahmani H, et al. Lightweight dense polymer concrete exposed to chemical condition and various temperatures: An experimental investigation[J]. Journal of Building Engineering, 2021, 34: No.101878. |

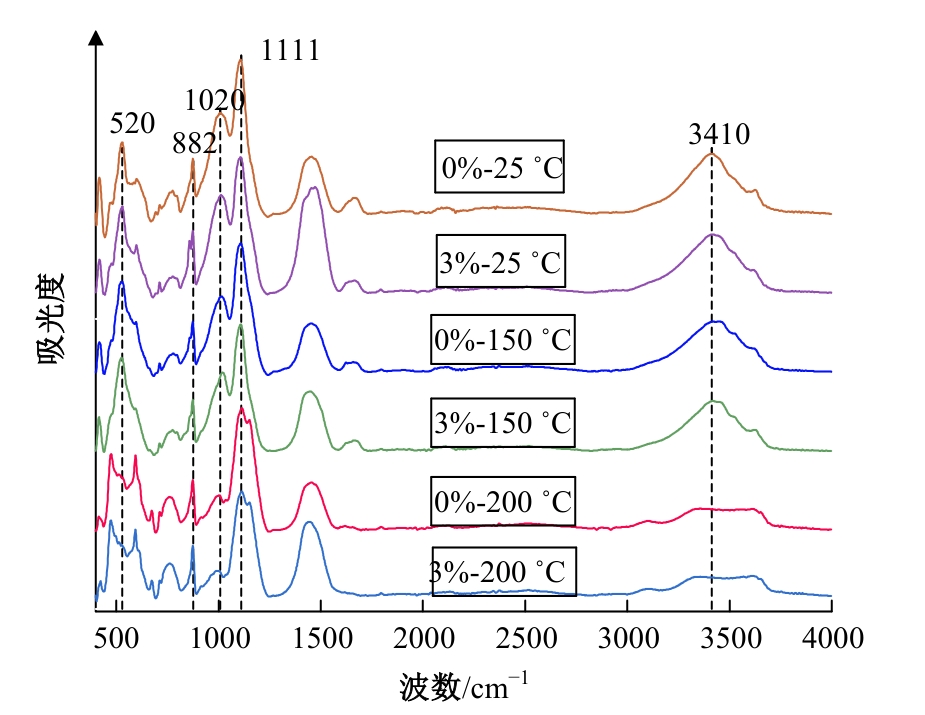

| [25] | 李德栋. 硫铝酸盐水泥的红外光谱研究[J]. 硅酸盐学报, 1984, 12(1): 119-125. |

| Li De-dong. Infrared spectroscopy study of sulfoaluminate cement[J]. Journal of the Chinese Ceramic Society, 1984, 12(1): 119-125. | |

| [26] | 刘娟红, 马翼, 王祖琦, 等. 石膏种类对富水充填材料凝结硬化性能与机理的影响[J]. 工程科学学报, 2015, 37(12): 1557-1563. |

| Liu Juan-hong, Ma Yi, Wang Zu-qi, et al. Impact of gypsum type on the setting and hardening performance and mechanism of water-rich filling materials[J]. Chinese Journal of Engineering, 2015, 37(12): 1557-1563. | |

| [27] | 熊志远, 王士军, 张龙, 等. 阻尼结构减振性能的测试及分析[J]. 机械设计与制造, 2020(8): 64-67. |

| Xiong Zhi-yuan, Wang Shi-jun, Zhang Long, et al. Test and analysis of damping properties of damping structures[J]. Machinery Design & Manufacture, 2020(8): 64-67. | |

| [28] | 李亦东, 于翘. 阻尼结构与高聚物阻尼材料[J]. 材料科学与工程, 1995, 13 (2):1-13. |

| Li Yi-dong, Yu Qiao. Damping structures and high polymer damping materials[J]. Materials Science & Engineering, 1995, 13(2):1-13. | |

| [29] | 吕平, 盖盼盼, 伯仲维, 等. 阻尼层厚度对结构阻尼性能的影响[J]. 噪声与振动控制, 2013(2): 101-104. |

| Lv Ping, Gai Pan-pan, Bo Zhong-wei, et al. Influence of damping layer's thickness on vibration damping performance of structures[J]. Noise and Vibration Control, 2013(2): 101-104. |

| [1] | Wan-feng WEI,Hong-gang ZHANG,Yang-peng ZHANG,Fan YANG,Bo-ming TANG,Ling-yun KONG. Research progress on modification mechanism, preparation and performance of waste rubber powder modified asphalt [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1834-1853. |

| [2] | Zhen YANG,Rui-ping ZHENG,Zhe GONG. Highway infrastructure performance and traffic state prediction on road network [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1973-1983. |

| [3] | An-shun ZHANG,Wei FU,Jun-hui ZHANG,Feng GAO. Shear properties and stress-strain relationships characterization of Changsha compacted clay [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1604-1616. |

| [4] | Li-ming WANG,Zi-kun SONG,Hui ZHOU,Wen WEI,Hao YUAN. Rheological response and response mechanism of petroleum asphalt treated with ultrasound [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1346-1355. |

| [5] | Jing-yang YU,Dong-zhao LI,Zhi-qing ZHANG,Zhen WANG,Hai-lin SUN,Hai-ling BU,Ming-chun LI. Evolution of damage to performance of environment⁃friendly salt storage asphalt mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 888-898. |

| [6] | Jun-peng XU,Chuan-feng ZHENG,Yan-tao DU,Yu-hang WANG,Zheng LU,Wen-jun FAN. Damage effects of water⁃heat⁃force coupling in permeable asphalt mixture in cold region [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 877-887. |

| [7] | Teng-fei NIAN,Zhao HAN,Zhi-qiang WEI,Guo-wei WANG,Jin-guo GE,Ping LI. Mesoscopic numerical modeling method of asphalt mix considering aggregate morphology [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 639-652. |

| [8] | Yan-hai YANG,Bai-chuan LI,Ye YANG,Chong-hua WANG,Liang YUE. Aggregate ellipsoidal surface base reconstruction with virtual splitting tests [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 653-663. |

| [9] | Wan-feng WEI,Ling-yun KONG,Wei-an XUAN,Fan YANG,Peng GUO. Review of characteristics of asphalt foaming and moisture sensitivity of warm mix mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 20-35. |

| [10] | Feng-chun GUO,Hai-peng BI,Hai-tao WANG,Shu-zheng WU,Hong-yu YANG. Viscoelastic behavior of carbon nano powder modified asphalt based on time-temperature equivalence [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 221-229. |

| [11] | Ying-li GAO,Xiao-lei GU,Mei-jie LIAO,Xin-lang HU,Yu-tong XIE. Rheological properties and modification mechanism of SiO2 aerogel/reactive elastomer terpolymer/Polyphosphoric acid composite modified asphalt [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1978-1987. |

| [12] | Ya-ning CUI,Chun-di SI,Tao-tao FAN,Fei WANG. Analysis on crack propagation of asphalt bridge deck pavement under water-force coupling action [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1988-1996. |

| [13] | Yong-li XU,Xu-lan YANG,Ji-sen ZHOU,Song-han YANG,Ming-gang SUN. Asphalt fume composition of warm mix asphalt and smoke suppression performance of warm mix agent [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1701-1707. |

| [14] | Xiao-kang ZHAO,Zhe HU,Zhen-xing NIU,Jiu-peng ZHANG,Jian-zhong PEI,Yong WEN. Meso-cracking behavior of cement-stabilized macadam materials based on heterogeneous model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1258-1266. |

| [15] | Tong-tong WAN,Hai-nian WANG,Wen-hua ZHENG,Po-nan FENG,Yu CHEN,Chen ZHANG. Thermal contraction deformation behavior of asphalt mixture overlay with coordination of unbound aggregate layer [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1045-1057. |

|

||