Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (8): 2487-2500.doi: 10.13229/j.cnki.jdxbgxb.20231312

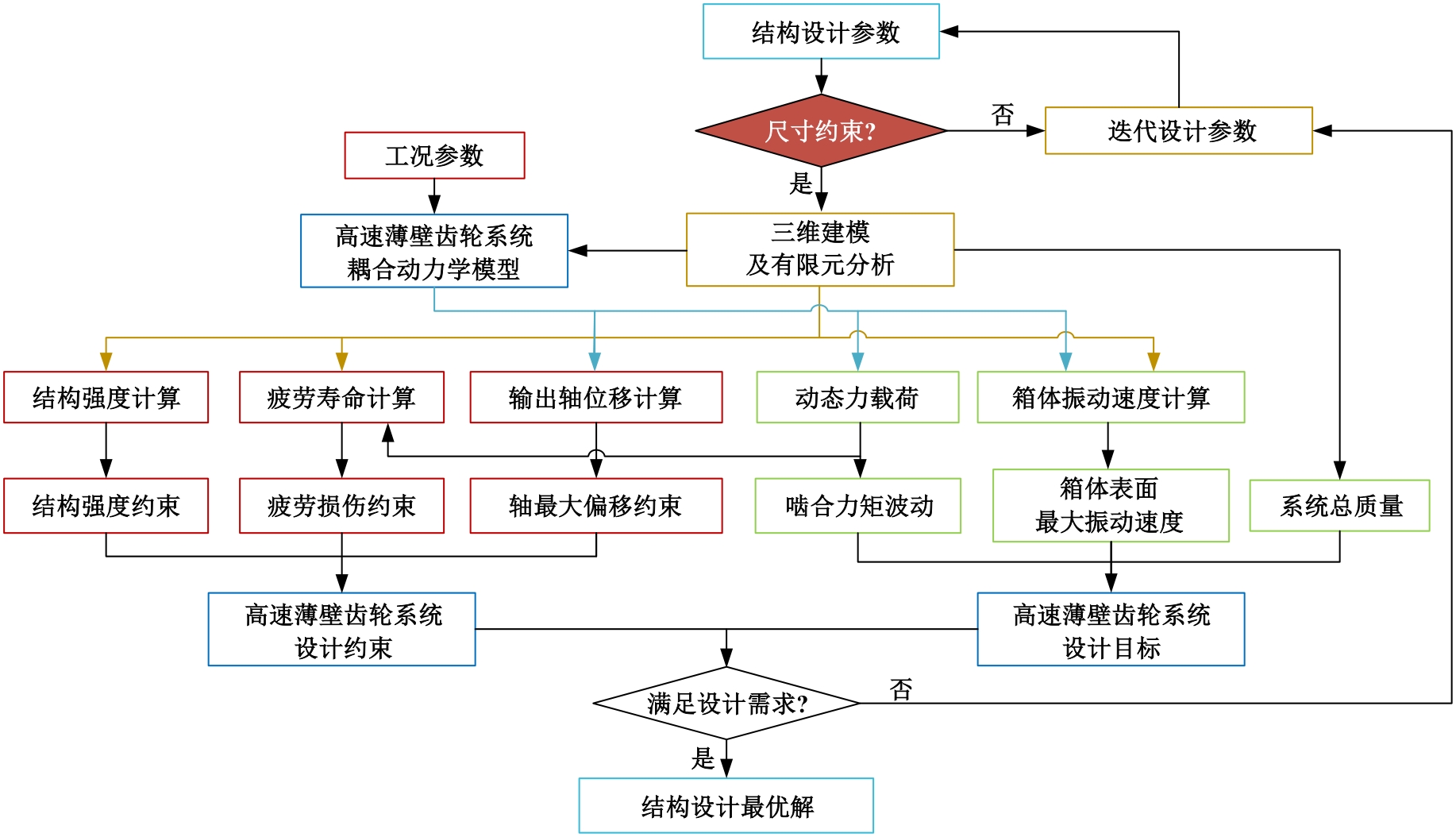

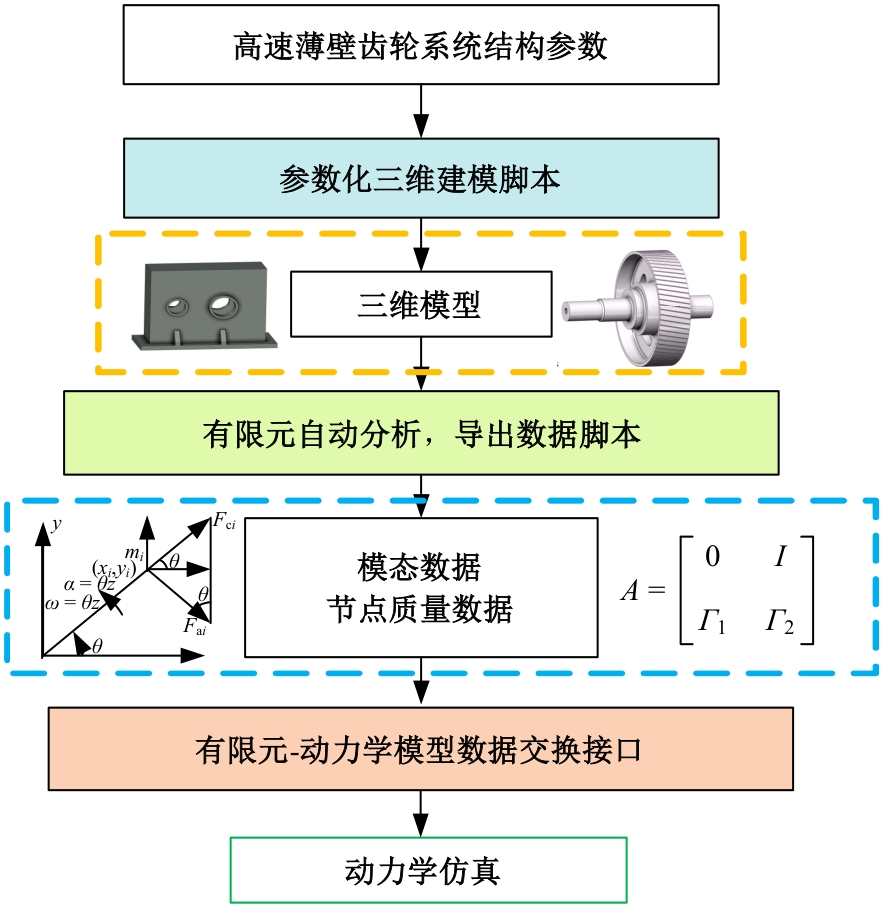

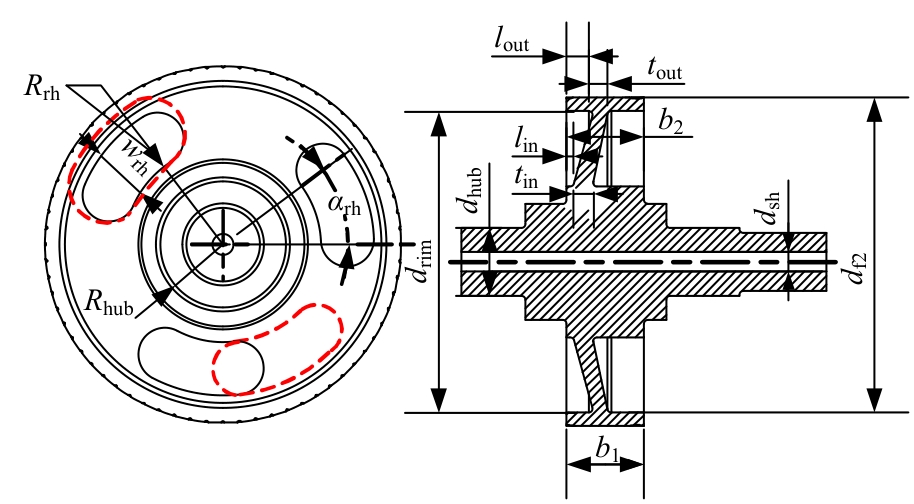

Multi-objective optimization of high-speed thin-walled gears considering dynamic performance

Chang-zhao LIU1,2( ),Jian SONG1,2,Zheng-qi LI1,2,Tie ZHANG1,2,Lei WANG1,2

),Jian SONG1,2,Zheng-qi LI1,2,Tie ZHANG1,2,Lei WANG1,2

- 1.State Key Laboratory of Mechanical Transmission for Advanced Equipment,Chongqing University,Chongqing 400044,China

2.College of Mechanical and Vehicle Engineering,Chongqing University,Chongqing 400030,China

CLC Number:

- TH132.4

| [1] | 刘更. 齿轮传动装置低噪声设计理论和方法[M]. 北京: 科学出版社, 2021. |

| [2] | Arakere N K, Nataraj C. Vibration of high-speed spur gear webs[J]. Journal of Vibration and Acoustics (Transactions of the Asme), 1998, 120(3):791-800. |

| [3] | Taskinoglu E E, Ozturk V Y, Paca Y. Gear web and rim thickness optimization to improve vibration and fatigue reliability of a rotary UAV gearbox[C]∥Proceedings of the International Conference on Noise and Vibration Engineering (ISMA)/International Conference on Uncertainty in Structural Dynamics (USD) Leuven: Katholieke Universiteit Leuven, 2012: 1361-1371. |

| [4] | Vahabi H, Panahi M S, Shirazinezhad R P, et al. A neuro-genetic approach to the optimal design of gear-blank lightening holes[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 38(1): 277-286. |

| [5] | Yang J R, Zhang Y H, Lee C H. Multi-parameter optimization-based design of lightweight vibration- reduction gear bodies[J]. Journal of Mechanical Science and Technology, 2022, 36(4): 1879-1887. |

| [6] | Cosco F, Adduci R, Muzzi L, et al. Multiobjective design optimization of lightweight gears[J]. Machines, 2022, 10(9): 1-15. |

| [7] | 宗长富, 任明辉, 万滢, 等. 变速器斜齿轮宏观参数减振优化设计[J]. 吉林大学学报:工学版, 2016, 46(6): 1772-1779. |

| Zong Chang-fu, Ren Ming-hui, Wan Ying, et al. Optimization of macro-geometric parameters of helical gears of transmissions to reduce vibration[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(6): 1772-1779. | |

| [8] | 杨红波, 史文库, 陈志勇, 等. 基于NSGA-Ⅱ的斜齿轮宏观参数多目标优化[J]. 吉林大学学报: 工学版, 2023, 53(4): 1007-1018. |

| Yang Hong-bo, Shi Wen-ku, Chen Zhi-yong, et al. Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ [J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(4): 1007-1018. | |

| [9] | 陈营利. 增速齿轮箱体有限元分析及其结构优化[D]. 哈尔滨:哈尔滨工程大学机电工程学院, 2009. |

| Chen Ying-li. The finite element analysis and optimization for speed-increasing gearbox housing[D]. Harbing: School of Mechanical and Electrical Engineering, Harbin Engineering University, 2009. | |

| [10] | 薛云伟. 航空齿轮的结构轻量化设计及其动力学分析[D]. 太原:太原理工大学机械工程学院, 2018. |

| Xue Yun-wei. Lightweight desion and dynamic analysis of aviation gear[D]. Taiyuan: School of Mechanical Engineering, Taiyuan University of Technology, 2018. | |

| [11] | 王雁东, 陈思雨, 唐进元. 一种基于OptiStruct-Abaqus的航空齿轮腹板轻量化设计方法[J]. 机械传动, 2019, 43(7): 60-65. |

| Wang Yan-dong, Chen Si-yu, Tang Jin-yuan. A lightweight design method for aviation gear web based on OptiStruct-Abaqus[J]. Journal of Mechanical Transmission, 2019, 43(7): 60-65. | |

| [12] | Ambarisha V K, Parker R G. Nonlinear dynamics of planetary gears using analytical and finite element models[J]. Journal of Sound and Vibration, 2007, 302(3): 577-595. |

| [13] | Bettaieb M N, Velex P, Ajmi M. A static and dynamic model of geared transmissions by combining substructures and elastic foundations-applications to thin-rimmed gears[J]. Journal of Mechanical Design, 2007, 129(2): 184-194. |

| [14] | Wu X, Parker R G. Modal properties of planetary gears with an elastic continuum ring gear[J]. Journal of Applied Mechanics, 2008, 75(3): 031014. |

| [15] | Guilbert B, Velex P, Dureisseix D, et al. Modular hybrid models to simulate the static and dynamic behaviour of high-speed thin-rimmed gears[J]. Journal of Sound and Vibration, 2018, 438: 353-380. |

| [16] | Sun Z, Tang J Y, Chen S Y, et al. Mesh stiffness and dynamic response analysis of modified gear system with thin web and weight reduction holes[J]. Journal of Sound and Vibration, 2023, 546: 117437. |

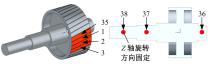

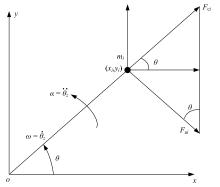

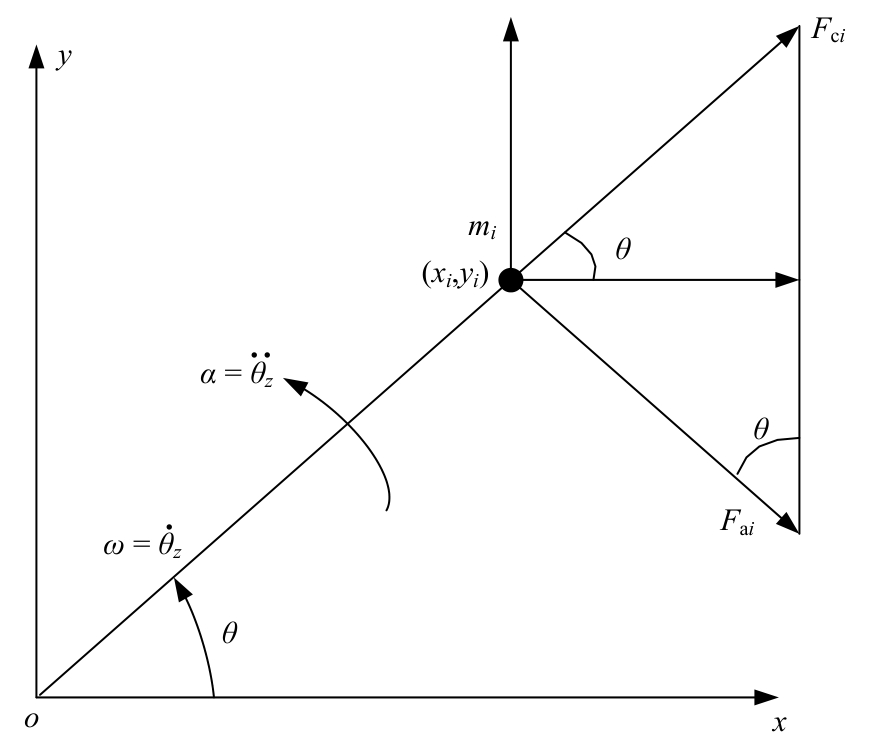

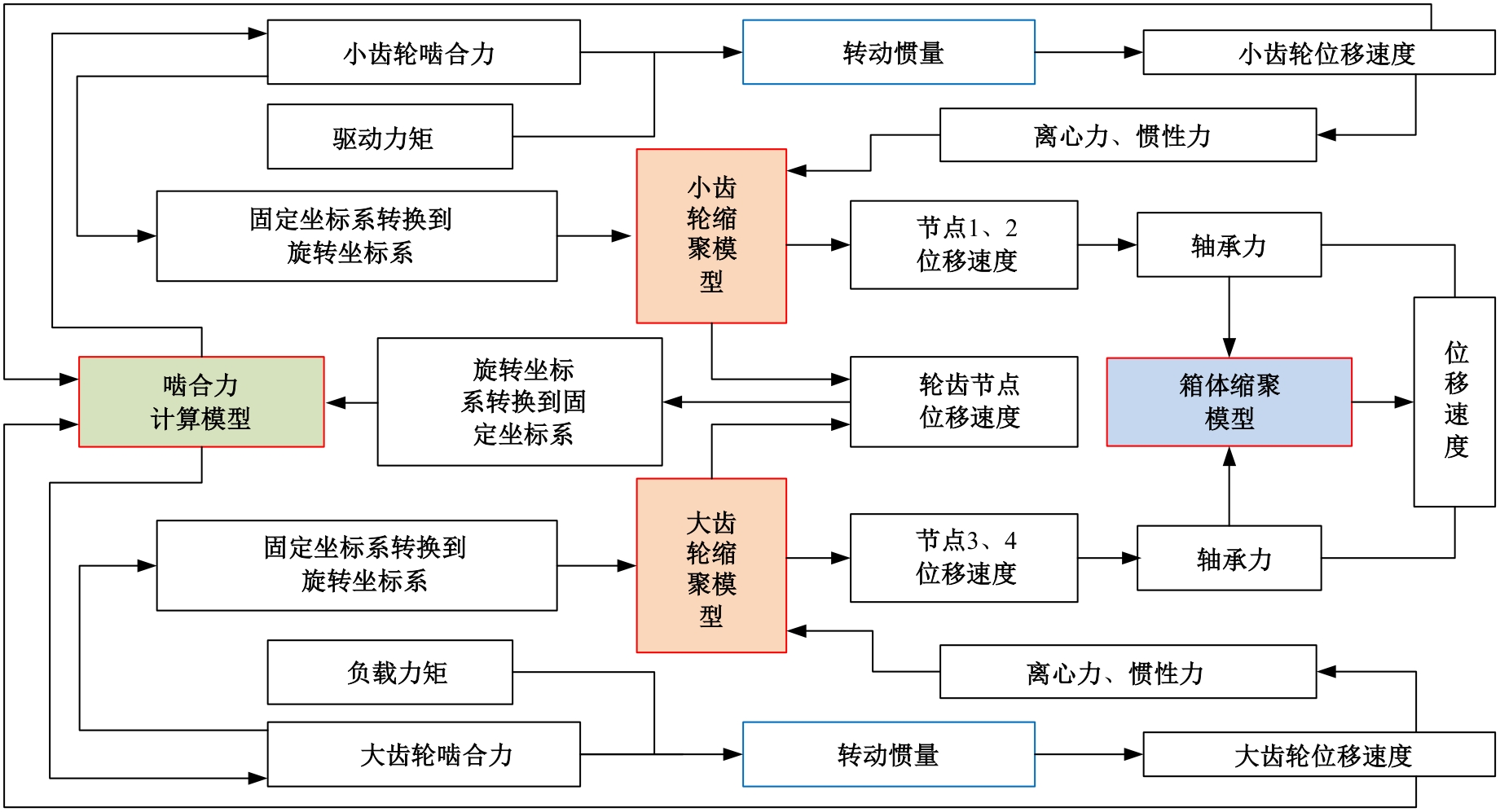

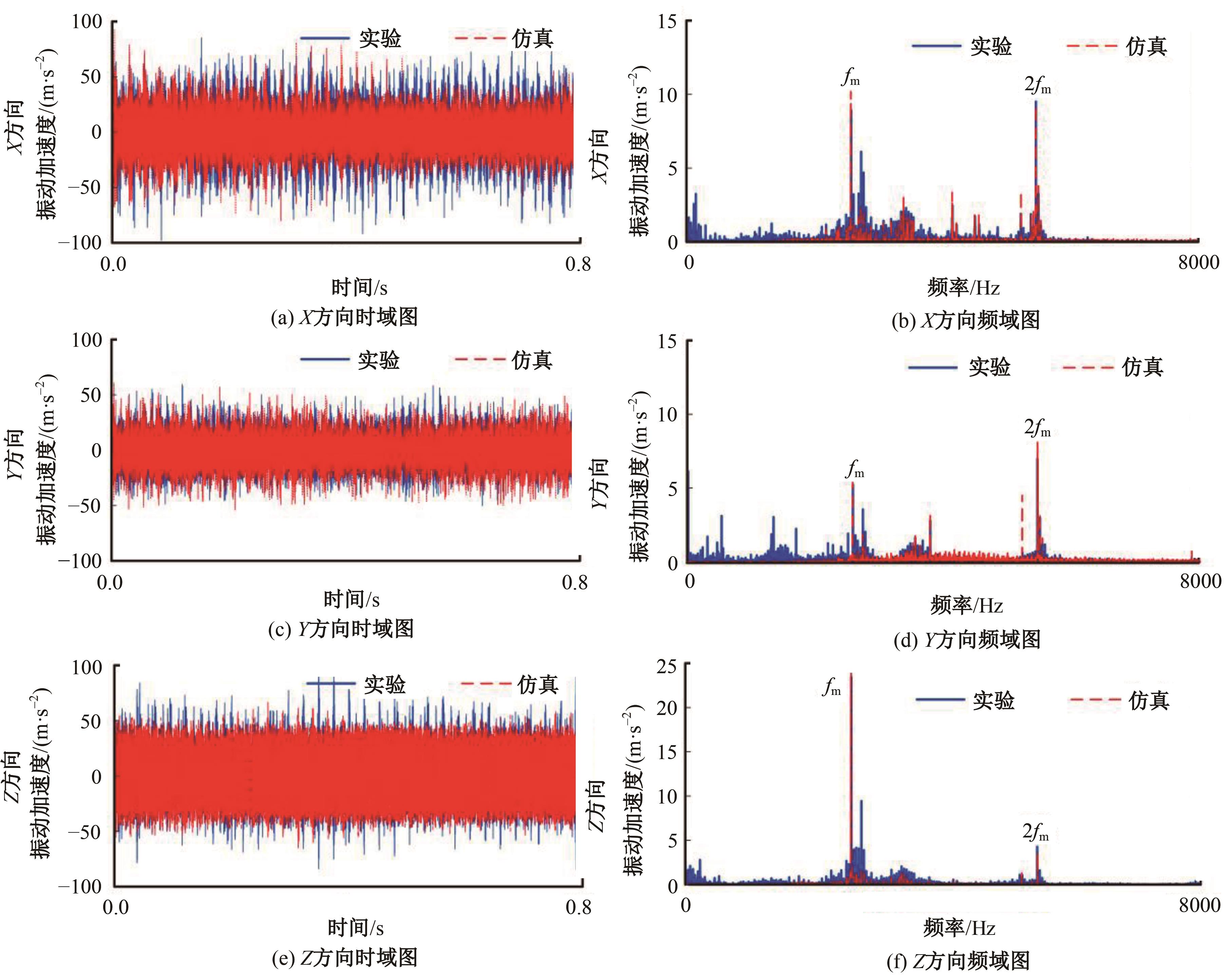

| [17] | Liu C, Zhao Y, Wang Y, et al. Hybrid dynamic modeling and analysis of high-speed thin-rimmed gears[J]. Journal of Mechanical Design, 2021, 143(12): 1-23. |

| [18] | 石嫄嫄, 和庆冬, 吴衍剑, 等. 基于多失效模式的海上浮式风电机组结构可靠性研究[J]. 太阳能学报, 2022, 43(9): 236-241. |

| Shi Yuan-yuan, He Qing-dong, Wu Yan-jian, et al. Multi-mode reliability analysis on structural of offshore floating wind turbine[J]. Acta Energiae Solaris Sinica, 2022, 43(9): 236-241. | |

| [19] | 唐鑫,朱如鹏,廖梅军,等. 第三代航空齿轮钢圆柱齿轮弯曲疲劳强度性能测试分析[J]. 航空动力学报, 2021, 36(8): 1756-1764. |

| Tang Xin, Zhu Ru-peng, Liao Mei-jun, et al. Analyse bending fatigue strength test of cylindrical gear of third-generation aviation gear steel[J]. Journal of Aerospace Power, 2021, 36(8): 1756-1764. |

| [1] | Zhi-gang FENG,Shou-qi WANG,Ming-yue YU. Rolling bearing fault diagnosis based on variational mode extraction and lightweight network [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1883-1891. |

| [2] | Xian-zhen HUANG,Ming-fei MA,Chao LI,Xu WANG,Zhi-ming RONG. Global reliability sensitivity analysis of deformation for machine tool rotary table [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 1906-1914. |

| [3] | Xue-zhong FU,Hou-bing HE,Xu-dong LIU,Jing-zhen LI. Tooth width design of helical face gear with non-orthogonal offset modification integration [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1207-1214. |

| [4] | Jie YUAN,Jun-bo WANG,Xin CHEN,Xin HUANG,Ao-xiang ZHANG,An-qi CUI. Research progress on application of artificial intelligence in ultra⁃high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 771-789. |

| [5] | De-qiang CHENG,Gui LIU,Qi-qi KOU,Jian-ying ZHANG,He JIANG. Lightweight image super⁃resolution network based on adaptive large kernel attention fusion [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 1015-1027. |

| [6] | Jian-feng SONG,Xin-lei HUANG,Si-ran WANG,Guang-yao XIE,Yong-gang DONG. Fatigue life prediction of brake treads for C80 trains with long downhill cycles [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 866-876. |

| [7] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [8] | Hua-song DONG,Yuan-feng LIAN. Lightweight detection algorithm for lossless transcoding and heavy compression of massive digital media videos [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 741-747. |

| [9] | Shu-kun WANG,Yu-ze FENG,Jing-ran ZHANG,Xin-ming ZHANG,Long ZHENG. Analysis on decontamination performance of lower lip structure of imitation scavenger [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 392-400. |

| [10] | Xian-zhen HUANG,Rui YU,Hui-zhen LIU,Ji-wu TANG. Spindle vibration reliability analysis considering bearing nonlinear restoring force [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 116-124. |

| [11] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [12] | Yang LIU. Simulation and experiment of elastic roughing for rubber shoe [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2167-2173. |

| [13] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [14] | Lei WANG,Dong-xia LI,Song ZHOU,Li HUI,Zhen-xin SHEN. Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1563-1569. |

| [15] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

|

||