Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (10): 3253-3261.doi: 10.13229/j.cnki.jdxbgxb.20231432

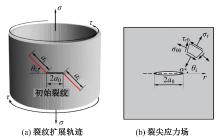

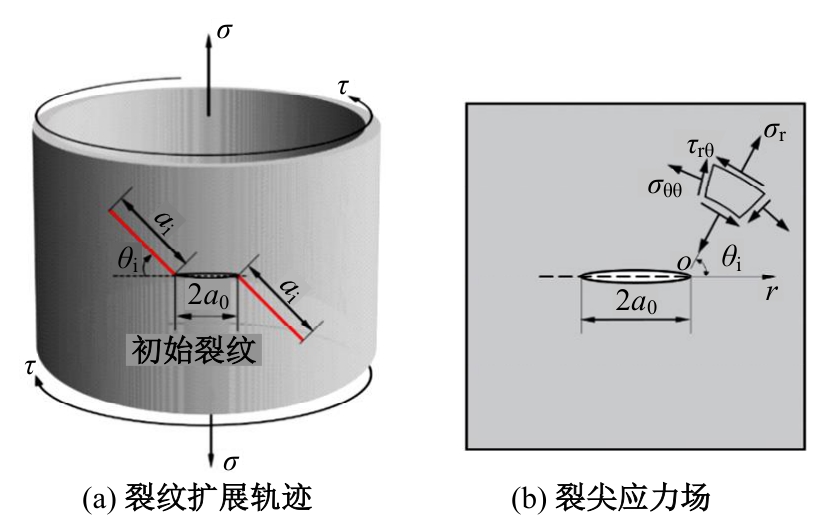

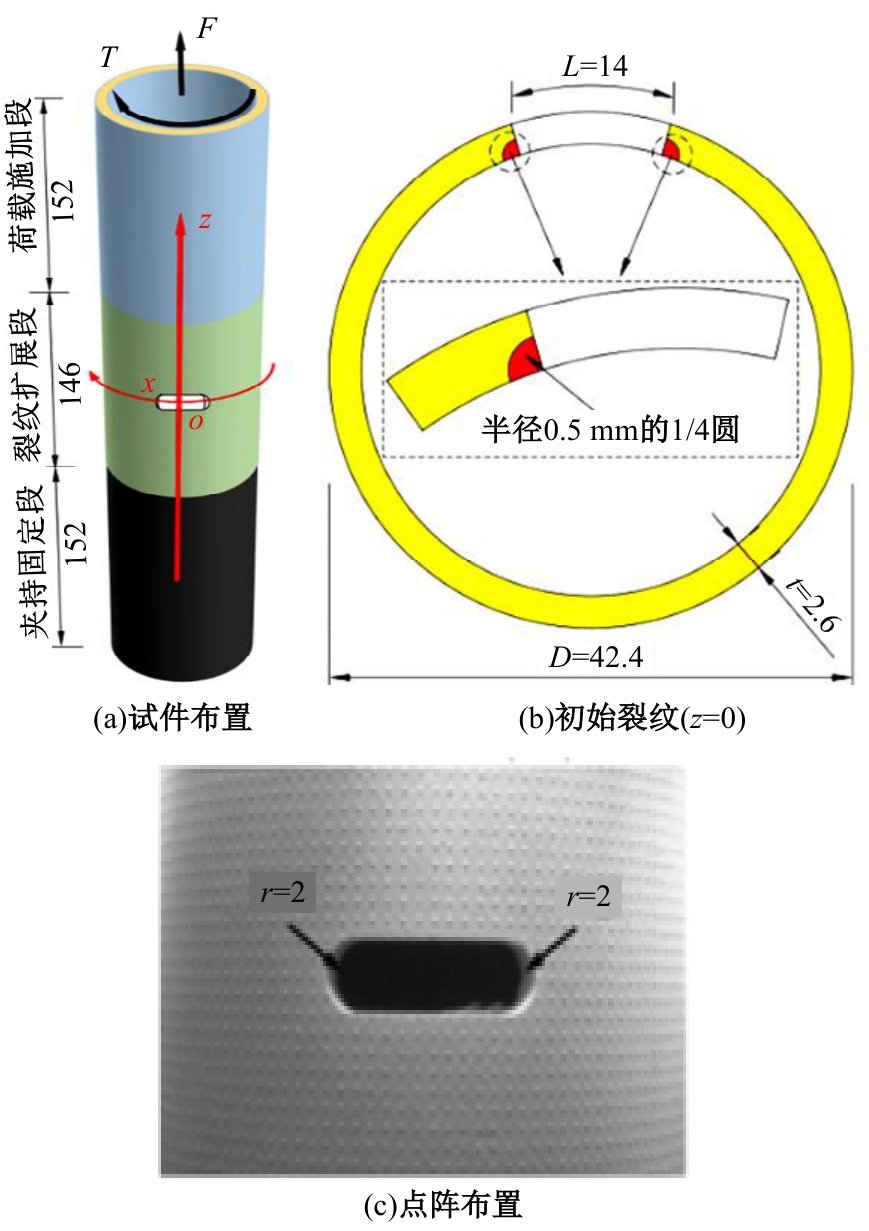

Fatigue crack propagation mechanism of thin-walled steel circular tube under tension-torsion proportional mixed mode loading

Hua-wen YE1,2( ),Jia-lin DENG1,Zhi-hao FENG1,Zhe YANG1,Wei-zhou PAN1

),Jia-lin DENG1,Zhi-hao FENG1,Zhe YANG1,Wei-zhou PAN1

- 1.School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.State Key Laboratory of Bridge Intelligent and Green Construction,Southwest Jiaotong University,Chengdu 611756,China

CLC Number:

- TU391

| [1] | 陈以一, 王伟, 周锋. 钢管结构:新需求驱动的形式拓展和性能提升[J]. 建筑结构学报, 2019, 40(3): 1-20. |

| Chen Yi-yi, Wang Wei, Zhou Feng. Steel tubular structures: configuration innovation and performance improvement driven by new requirements[J]. Journal of Building Structures, 2019, 40(3): 1-20. | |

| [2] | 韩林海, 牟廷敏, 王法承, 等. 钢管混凝土混合结构设计原理及其在桥梁工程中的应用[J]. 土木工程学报, 2020, 53(5): 1-24. |

| Han Lin-hai, Mu Ting-min, Wang Fa-cheng, et al. Design theory of CFST (concrete-filled steel tubular) mixed structures and its applications in bridge engineering[J]. China Civil Engineering Journal, 2020, 53(5): 1-24. | |

| [3] | 秦荣, 谢肖礼, 彭文立, 等. 钢管混凝土拱桥钢管开裂事故分析[J]. 土木工程学报, 2001, 34(3): 74-77. |

| Qin Rong, Xie Xiao-li, Peng Wen-li, et al. Analysis for cracking accidents of concrete-filled-steel-tube arch bridge[J]. China Civil Engineering Journal, 2001, 34(3): 74-77. | |

| [4] | 黄汉辉, 陈康明, 吴庆雄, 等. 某中承式钢管混凝土桁式拱肋节点疲劳开裂分析[J]. 工程力学, 2017, 34(): 167-173. |

| Huang Han-hui, Chen Kang-ming, Wu Qing-xiong, et al. Study on fatigue cracking of joint in a half-through CFST truss arch rib joint[J]. Engineering Mechanics, 2017, 34(Sup.1): 167-173. | |

| [5] | Wang Q, Nakamura S, Chen B C, et al. Fatigue damage of a half-through concrete-filled steel tubular trussed arch bridge in China[C]∥Proceedings of the World Congress on Advances in Structural Engineering and Mechanics. Wrocław, Poland, 2015:1169-1182. |

| [6] | 姜磊, 刘永健, 王康宁. 焊接管节点结构形式发展及疲劳性能对比[J]. 建筑结构学报, 2019, 40(3):180-191. |

| Jiang lei, Liu Yong-jian, Wang Kang-ning. Development of welded tubular joints and comparison of fatigue behaviour[J]. Journal of Building Structures, 2019, 40(3): 180-191. | |

| [7] | 廖芳芳, 王伟, 李文超, 等. 钢结构节点断裂的研究现状[J]. 建筑科学与工程学报, 2016, 33(1): 67-75. |

| Liao Fang-fang, Wang Wei, Li Wen-chao, et al. Review on research status of connection fracture of steel structures[J]. Journal of Architecture and Civil Engineering, 2016, 33(1): 67-75. | |

| [8] | Wang Y, Wang W, Zhang B, et al. A review on mixed mode fracture of metals[J]. Engineering Fracture Mechanics, 2020: No.107126. |

| [9] | 童乐为, 顾敏, 朱俊, 等. 基于断裂力学的圆钢管混凝土T型焊接节点疲劳寿命预测[J]. 工程力学, 2013, 30(4): 331-336, 354. |

| Tong Le-wei, Gu Ming, Zhu Jun, et al. Prediction of fatigue life for welded t-joints of concrete-filled circular hollow sections based on fracture mechanics[J]. Engineering Mechanics, 2013, 30(4): 331-336, 354. | |

| [10] | 程睿, 陈阳, 崔佳, 等. 支管在轴向荷载作用下Q460C高强钢T型圆管节点疲劳性能试验研究[J]. 土木工程学报, 2017, 50(4): 57-63, 124. |

| Cheng Rui, Chen Yang, Cui Jia, et al. Experimental study on fatigue behavior of Q460C high strength steel welded tubular T-joints under axial loading[J]. China Civil Engineering Journal, 2017, 50(4): 57-63, 124. | |

| [11] | 吴庆雄, 罗健平, 杨益伦, 等. 钢管混凝土KK型节点疲劳性能试验[J].交通运输工程学报,2024,24(1):100-116. |

| Wu Qing-xiong, Luo Jian-ping, Yang Yi-lun, et al. Fatigue performance test of KK-type joints of concrete-filled steel tubes[J]. Journal of Traffic and Transportation Engineering, 24(1):100-116. | |

| [12] | 张道明, 梁力. 轴向拉伸钢管Ⅰ型裂纹尖端的应力场[J]. 力学与实践, 2015, 37(4): 513-517, 507. |

| Zhang Dao-ming, Liang Li. The stress field at mode I crack tip on steel pipe under axial tension[J]. Mechanics in Engineering, 2015, 37(4): 513-517, 507. | |

| [13] | Fu G, Yang W, Li C Q. Stress intensity factors for mixed mode fracture induced by inclined cracks in pipes under axial tension and bending[J]. Theoretical and Applied Fracture Mechanics, 2017, 89: 100-109. |

| [14] | Tanaka K, Takahash H, Akiniwa Y. Fatigue crack propagation from a hole in tubular specimens under axial and torsional loading[J]. International Journal of Fatigue, 2006, 28(4): 324-334. |

| [15] | Hos Y, Freire J, Vormwald M. Measurements of strain fields around crack tips under proportional and non-proportional mixed-mode fatigue loading[J]. International Journal of Fatigue, 2016, 89: 87-98. |

| [16] | 中国航空研究院. 应力强度因子手册[M]. 北京: 科学出版社, 1981. |

| [17] | ASTM. Standard test method for measurement of fatigue crack growth rates: ASTM E647-11[Z]. West Conshohocken, PA: ASTM, 2011. |

| [1] | Ya-ning CUI,Chun-di SI,Tao-tao FAN,Fei WANG. Analysis on crack propagation of asphalt bridge deck pavement under water-force coupling action [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1988-1996. |

| [2] | Lei WANG,Dong-xia LI,Song ZHOU,Li HUI,Zhen-xin SHEN. Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1563-1569. |

| [3] | Lei WANG,Xiao-peng LIU,Song ZHOU,Jin-lan AN,Hong-jie ZHANG,Jia-hui CONG. Effect of ultrasonic rolling on fatigue crack propagation behavior of 2024 aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3486-3495. |

| [4] | Sheng-tong DI,Chao JIA,Wei-guo QIAO,Kang LI,Kai TONG. Loading rate effect of meso⁃damage characteristics of crumb rubber concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1900-1910. |

| [5] | Yi-lun LIU,Qing WANG,Chi LIU,Song-bai LI,Jun HE,Xian-qiong ZHAO. Effect of creep and artificial aging on fatigue crack growth performance of 2524 aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1636-1643. |

| [6] | CAO Shan-shan, LEI Jun-qing. Fatigue life prediction of steel structure considering interval uncertainty [J]. 吉林大学学报(工学版), 2016, 46(3): 804-810. |

|

||