Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (12): 3486-3495.doi: 10.13229/j.cnki.jdxbgxb.20230166

Previous Articles Next Articles

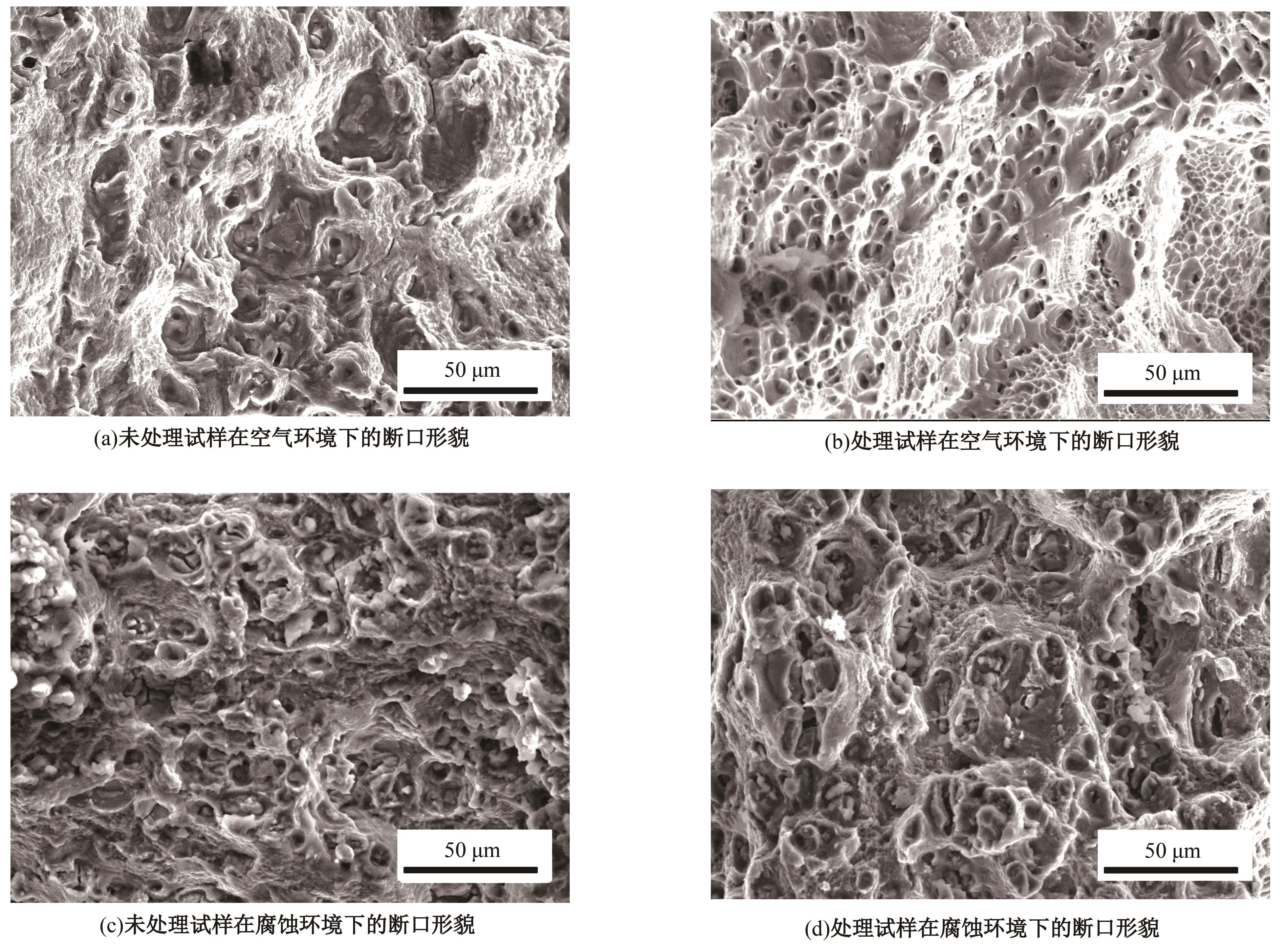

Effect of ultrasonic rolling on fatigue crack propagation behavior of 2024 aluminum alloy

Lei WANG1( ),Xiao-peng LIU2,Song ZHOU2,Jin-lan AN3,Hong-jie ZHANG2,Jia-hui CONG2

),Xiao-peng LIU2,Song ZHOU2,Jin-lan AN3,Hong-jie ZHANG2,Jia-hui CONG2

- 1.College of Mechanical Engineering,Suzhou University of Science and Technology,Suzhou 215009,China

2.School of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

CLC Number:

- TG146

| 1 | Moy C K S, Weiss M, Xia J H, et al. Influence of heat treatment on the microstructure, texture and formability of 2024 aluminium alloy[J]. Materials Science and Engineering A, 2012, 552: 48-60. |

| 2 | James C W, Edgar A, Starke J R. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775-5799. |

| 3 | 刘兵,彭超群,王日初,等. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(09): 1705-1715. |

| Liu Bing, Peng Chao-qun, Wang Ri-chu, et al. Recent development and prospects for giant plane aluminum alloys[J]. Chinese Journal of Nonferrous Metals, 2010, 20(09): 1705-1715. | |

| 4 | Bhuiyan M S, Mutoh Y, Murai T, et al. Corrosion fatigue behavior of extruded magnesium alloy AZ61 under three different corrosive environments[J]. International Journal of Fatigue, 2008, 30: 1756-1765. |

| 5 | 梁明辉,吴向清,谢发勤,等. Cl-浓度对阳极氧化5A06铝合金/1Cr18Ni9Ti不锈钢偶接件腐蚀行为的影响[J]. 表面技术, 2022, 51(7): 161-168. |

| Liang Ming-hui, Wu Xian-qing, Xie Fa-qin, et al. Effect of CI- concentration on corrosion behavior of anodized 5A06 aluminum alloy/1Cr18Ni9Ti stainless steel coupling[J]. Surface Technology, 2021, 51(7): 161-168. | |

| 6 | 罗开玉,邢月华,柴卿锋,等. 激光冲击强化对2Cr13不锈钢腐蚀疲劳性能的影响[J]. 吉林大学学报:工学版, 2019, 49(3): 850-858. |

| Luo Kai⁃yu, Xing Yue⁃hua, Chai Qing⁃feng, et al. Effects of laser shock peening on corrosion fatigue behaviour of 2Cr13 stainless steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 850-858. | |

| 7 | 刘阳,吕晓仁,张荣禄,等. 超音速微粒轰击表面纳米化及其对耐磨性的影响[J]. 中国表面工程, 2006(6): 20-24. |

| Liu Yang, Xiao-ren Lyu, Zhang Rong-lu, et al. Surface nanocrystallization using supersonic fine particles bombarding and its effect on the wear behaviors[J]. Chinese Surface Engineering, 2006(6): 20-24. | |

| 8 | Wu K, Yuan X, Hu Z, et al. Improvement of Al/steel tungsten inert gas welding brazing joint by high-energy shot peening[J]. Journal of Materials Engineering and Performance, 2019, 28(5): 2937-2945. |

| 9 | Rakita M, Wang M, Han Q, et al. Ultrasonic shot peening[J]. International Journal of Computational Materials Science and Surface Engineering, 2013, 5(3): 189-209. |

| 10 | 王婷,王东坡,刘刚,等. 40Cr超声表面滚压加工纳米化[J]. 机械工程学报, 2009 (5): 177-183. |

| Wang Ting, Wang Dong-po, Liu Gang, et al. 40Cr nano-crystallization by ultrasonic surface rolling extrusion processing[J]. Journal of Mechanical Engineering, 2009(5): 177-183. | |

| 11 | 郑建新,任元超. 7050铝合金二维超声滚压加工表面完整性综合评价[J]. 中国机械工程, 2018, 29(13): 1622-1626. |

| Zheng Jian-xin, Ren Yuan-chao. Comprehensive assessment of surface integrity in two dimensional Ultrasonic rolling 7050 aluminum alloys[J]. Chinese Mechanical Engineering, 2018, 29(13): 1622-1626. | |

| 12 | Wang P, Guo H, Wang D F, et al. Microstructure and tribological performances of M50 bearing steel processed by ultrasonic surface rolling[J]. Tribology International, 2022, 175: No.107818. |

| 13 | Xie J W, Zhang S Q, Sun Y G, et al. Microstructure and mechanical properties of high entropy CrMnFeCoNi alloy processed by electopulsing-assisted ultrasonic surface rolling[J]. Materials Science & Engineering A, 2020, 795: No.140004. |

| 14 | 王磊,黄秉汉,丛家慧,等.超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报:工学版, 2022, 52(11): 2542-2548. |

| Wang Lei, Huang Bing-han, Cong Jia-hui, et al. Effect of ultrasonic impact on fatigue performance of friction stir weld[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2542-2548. | |

| 15 | Yu Y Y, Sun W G, Tong D H. Effect of loading frequency on corrosion fatigue crack growth rate of 7N01 aluminum alloy[J]. Materials Science and Engineering C, 2020, 768: No.022060. |

| 16 | Zhao W D, Liu D X, Zhang X H, et al. Improving the fretting and corrosion fatigue performance of 300M ultra-high strength steel using the ultrasonic surface rolling process[J]. International Journal of Fatigue, 2019, 121: 30-38. |

| 17 | Shen F H, Wang B, Yi D Q, et al. Effects of heating rate during solid-solution treatment on microstructure and fatigue properties of AA2524 T3 Al–Cu–Mg sheet[J]. Materials and Design, 2016, 104: 116-125. |

| 18 | Ye C, Suslov S, Fei X, et al. Bimodal nanocrystallization of NiTi shape memory alloy by laser shock peening and post-deformation annealing[J]. Acta Materialia, 2011, 59(19): 7219-7227. |

| 19 | Kim H K, Kim W J. Microstructural instability and strength of an AZ31 Mg alloy after severe plastic deformation [J]. Materials science and Engineering A, 2004, 385: 300-308. |

| 20 | 鲁金忠, 季仕杰, 吴刘军,等. 激光冲击⁃超声滚压复合工艺对AZ91D镁合金力学性能的影响[J].吉林大学学报:工学版, 2020, 50(4): 1301-1309. |

| Lu Jin-zhong, Ji Shi-jie, Wu Liu-jun, et al. Effect of laser shock peening and ultrasound surface rolling combined processes on mechanical properties of AZ91D Mg alloy[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1301-1309. | |

| 21 | Chen B, Huang B, Liu H, et al. Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 6061 aluminum alloy[J]. Journal of Materials Research, 2014, 29(24): 3002-3010. |

| 22 | Lu J Z, Wu L J, Sun G F, et al. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts[J]. Acta Materialia, 2017, 127: 252-266. |

| 23 | Li L, Li Y, Wang F H. Electrochemical corrosion behavior of nanocrystalline materials—a review[J]. Journal of Materials Science and Technology, 2010, 1(26): 1-14. |

| 24 | Valiev R Z, Enikeev N A, Murashkin M Y, et al. On the origin of extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation[J]. Scripta Materialia, 2010, 63(9): 949-952. |

| [1] | Lei SHANG,Ping YANG,Xiang-guo YANG,Jian-xin PAN,Jun YANG,Meng-ru ZHANG. Temperature control of proton exchange membrane fuel cell thermal management system based on APSO-BP-PID control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2401-2413. |

| [2] | Lin JIANG,Guo-long LI,Shi-long WANG,Kai XU,Zhe-yu LI. Thermal expansion error modeling of feed axis based on principal component regression [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2149-2155. |

| [3] | Ya-ning CUI,Chun-di SI,Tao-tao FAN,Fei WANG. Analysis on crack propagation of asphalt bridge deck pavement under water-force coupling action [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1988-1996. |

| [4] | Ze-qiang ZHANG,Can WANG,Jun-qi LIU,Dan JI,Si-lu LIU. Parallel row ordering problem based on improved sparrow search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1851-1861. |

| [5] | Cai-xia SHU,Jia YANG,Qing-xi LIAO,Xing-yu WAN,Jia-cheng YUAN. Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1807-1820. |

| [6] | Lei WANG,Dong-xia LI,Song ZHOU,Li HUI,Zhen-xin SHEN. Fatigue crack propagation behavior and life prediction of 2024-O aluminum alloy FSW joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1563-1569. |

| [7] | Li HUI,Lei JIN,Wan-wan SONG,Song ZHOU,Jin-lan AN. Crack growth rate of SMA490BW steel in different welding areas for bogie [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 650-656. |

| [8] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [9] | Yun-tong LI,Xing-yu WAN,Qing-xi LIAO,Yin-lei LIU,Qing-song ZHANG,Yi-tao LIAO. Design and experiment of wide folding rape windrower based on crawler type power chassis [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3740-3754. |

| [10] | Wei-jun WU,Jiang-bo WU,Jia-le ZHANG,Qiang ZHOU,Qiao-hong YANG,Xun-peng QIN. Stability analysis and scale synthesis of new multifunctional aerial work platform [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(12): 3450-3459. |

| [11] | Huan-lin ZHOU,Xin GUO,Xuan WANG,Li-xue FANG,Kai LONG. Topology optimization design of multiphase porous structures considering geometric nonlinearity [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2754-2763. |

| [12] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [13] | Bo-sen CHAI,Guang-yi WANG,Dong YAN,Guo-ren ZHU,Jin ZHANG,Heng-sheng LYU. Numerical simulation of cavitation in torque converter and analysis of its influence on performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2236-2244. |

| [14] | Guo-hui CHEN,Ye-yin XU,Ying-hou JIAO. Meshing stiffness calculation and vibration analysis of helical gear considering deflection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1902-1910. |

| [15] | Sheng LI,Jia ZHU,De-hui HUANG,Cun-fu CHEN,Hong-qing FEI,Wei FENG,Xing-jun HU. Structural parameters optimization of louver fins of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 998-1006. |

|