Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 810-819.doi: 10.13229/j.cnki.jdxbgxb20200070

Previous Articles Next Articles

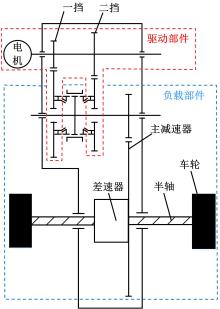

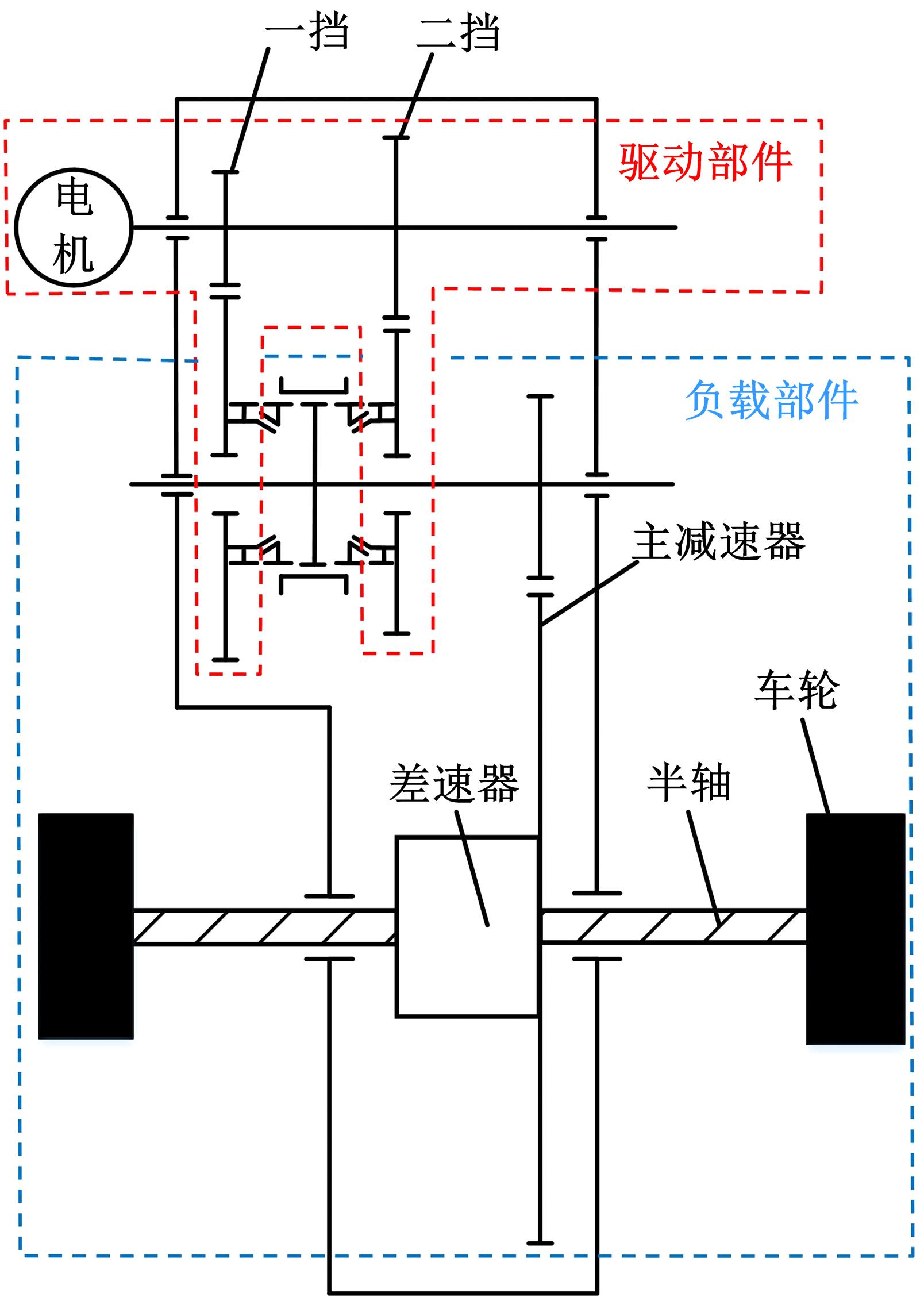

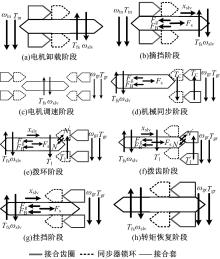

Shift nonlinear modeling and control of automated mechanical transmission in pure electric vehicle

Qiang SONG1,2( ),Dan-ting SUN1,2,Wei ZHANG1,2

),Dan-ting SUN1,2,Wei ZHANG1,2

- 1.School of Mechanical Engineering,Beijing Institute of Technology,Beijing 100081,China

2.National Engineering Laboratory for Electric Vehicles,Beijing Institute of Technology,Beijing 100081,China

CLC Number:

- U463

| 1 | Kim Y K, Kim H W, Lee I S, et al. A speed control for the reduction of the shift shocks in electric vehicles with a two-speed AMT[J]. Journal of Power Electronics, 2016, 16(4):1355-1366. |

| 2 | Chai B B, Zhang J W, Wu S F. Compound optimal control for shift processes of a two-speed automatic mechanical transmission in electric vehicles[J]. Proceedings of the Institution of Mechanical Engineers, 2019, 233(8):2213-2231. |

| 3 | 黄毅,刘辉,项昌乐,等. 车辆传动系统非线性平移扭转耦合振动响应灵敏度研究[J].振动与冲击,2014,33(23):92-99. |

| Huang Yi, Liu Hui, Xiang Chang-le, et al. Response sensitivity of nonlinear translation-torsional vibration coupled model of a vehicle transmission system[J]. Journal of Vibration and Shock, 2014,33(23):92-99. | |

| 4 | 袁旺,田子龙,杨志坚,等. 乘用车加速工况动力传动系扭振分析与改进[J]. 汽车工程,2018,40(1):91-97, 113. |

| Yuan Wang, Tian Zi-long, Yang Zhi-jian, et al. Analysis and improvement of the torsional vibration of car powertrain under acceleration condition[J]. Automotive Engineering, 2018,40(1):91-97, 113. | |

| 5 | 金红光. 纯电动汽车两挡自动变速器箱体动态特性研究[D]. 长沙:湖南大学机械与运载工程学院,2015. |

| Jin Hong-guang. Dynamic characteristics research of a two-speed automatic transmission housing for pure electric vehicle[D]. Changsha: College of Mechanical and Vehicle Engineering, Hunan University,2015. | |

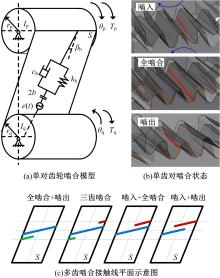

| 6 | Yang Y,Li H,Dai Y P. Nonlinear vibration characteristics of spur gear system subjected to multiple harmonic excitations[J]. Proceedings of the Institution of Mechanical Engineers,2019,233(17):6026-6050. |

| 7 | Yang Y,Cao L Y,Li H,et al. Nonlinear dynamic response of a spur gear pair based on the modeling of periodic mesh stiffness and static transmission error[J]. Applied Mathematical Modelling,2019,72:444-469. |

| 8 | 程功,肖科,王家序,等. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报:工学版,2020,50(2):494-503. |

| Cheng Gong, Xiao Ke, Wang Jia-xu, et al. Gear contact stiffness under mixed lubrication status[J]. Journal of Jilin University (Engineering and Technology Edition),2020,50(2):494-503. | |

| 9 | 林腾蛟,郭松龄,赵子瑞,等.裂纹故障对斜齿轮时变啮合刚度及振动响应的影响分析[J].振动与冲击,2019,38(16):29-36, 63. |

| Lin Teng-jiao, Guo Song-ling, Zhao Zi-rui, et al. Influence of crack faults on time-varying mesh stiffness and vibration response of helical gears[J]. Journal of Vibration and Shock, 2019,38(16):29-36, 63. | |

| 10 | Mo W,Jiao Y,Chen Z. Dynamic analysis of helical gears with sliding friction and gear errors[J]. IEEE Access,2018,6:60467-60477. |

| 11 | Yi Y, Huang K, Xiong Y S,et al. Nonlinear dynamic modelling and analysis for a spur gear system with time-varying pressure angle and gear backlash[J]. Mechanical Systems and Signal Processing,2019,132(1):18-34. |

| 12 | Geng Z,Xiao K,Wang J,et al. Investigation on nonlinear-dynamic characteristics of a new rigid-flexible gear transmission with wear[J]. Journal of Vibration and Acoustics,2019,141(5):051008. |

| 13 | Fang Y,Liang X,Zuo M J. Effects of friction and stochastic load on transient characteristics of a spur gear pair[J]. Nonlinear Dynamics,2018,93(2):599-609. |

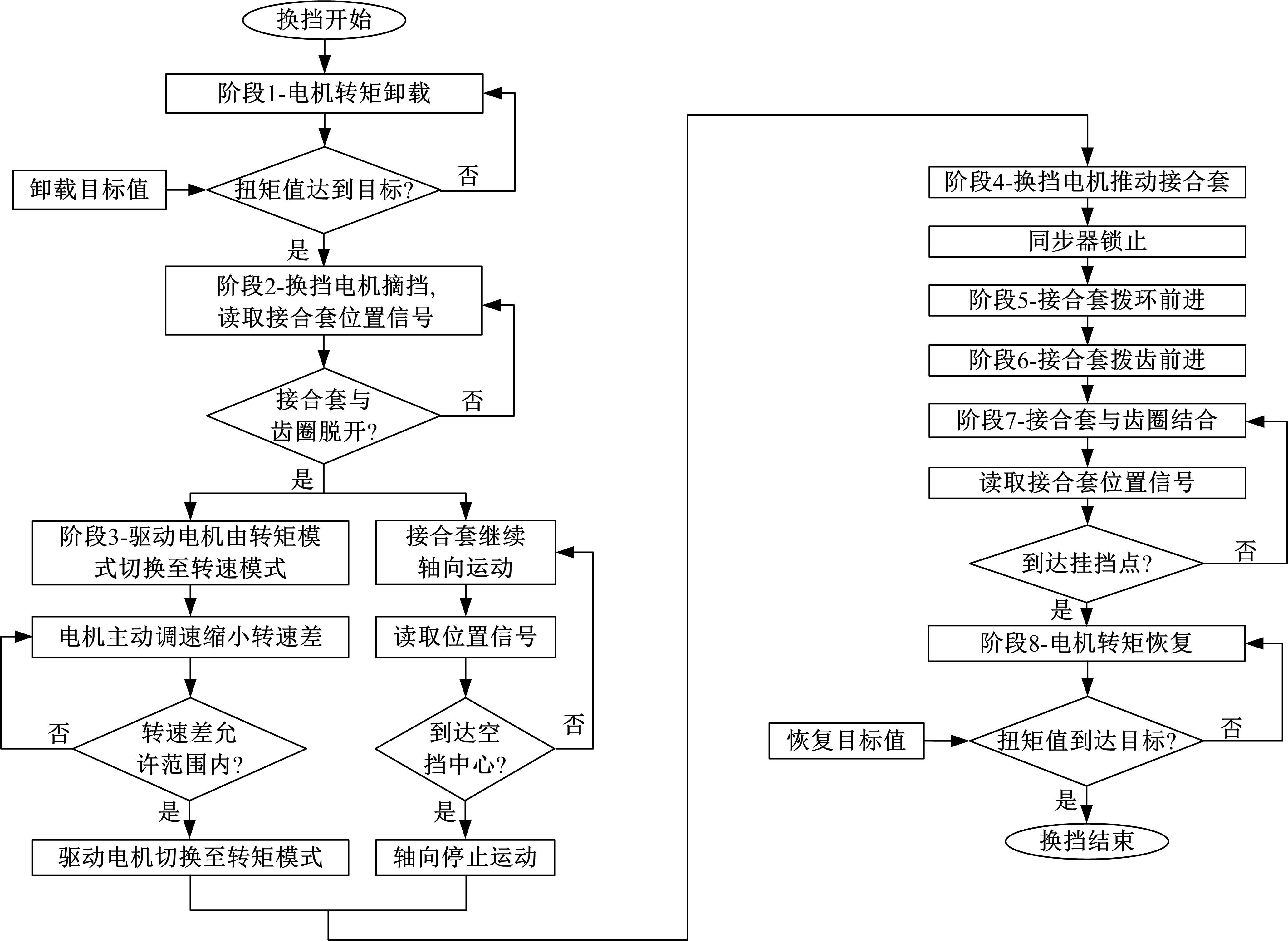

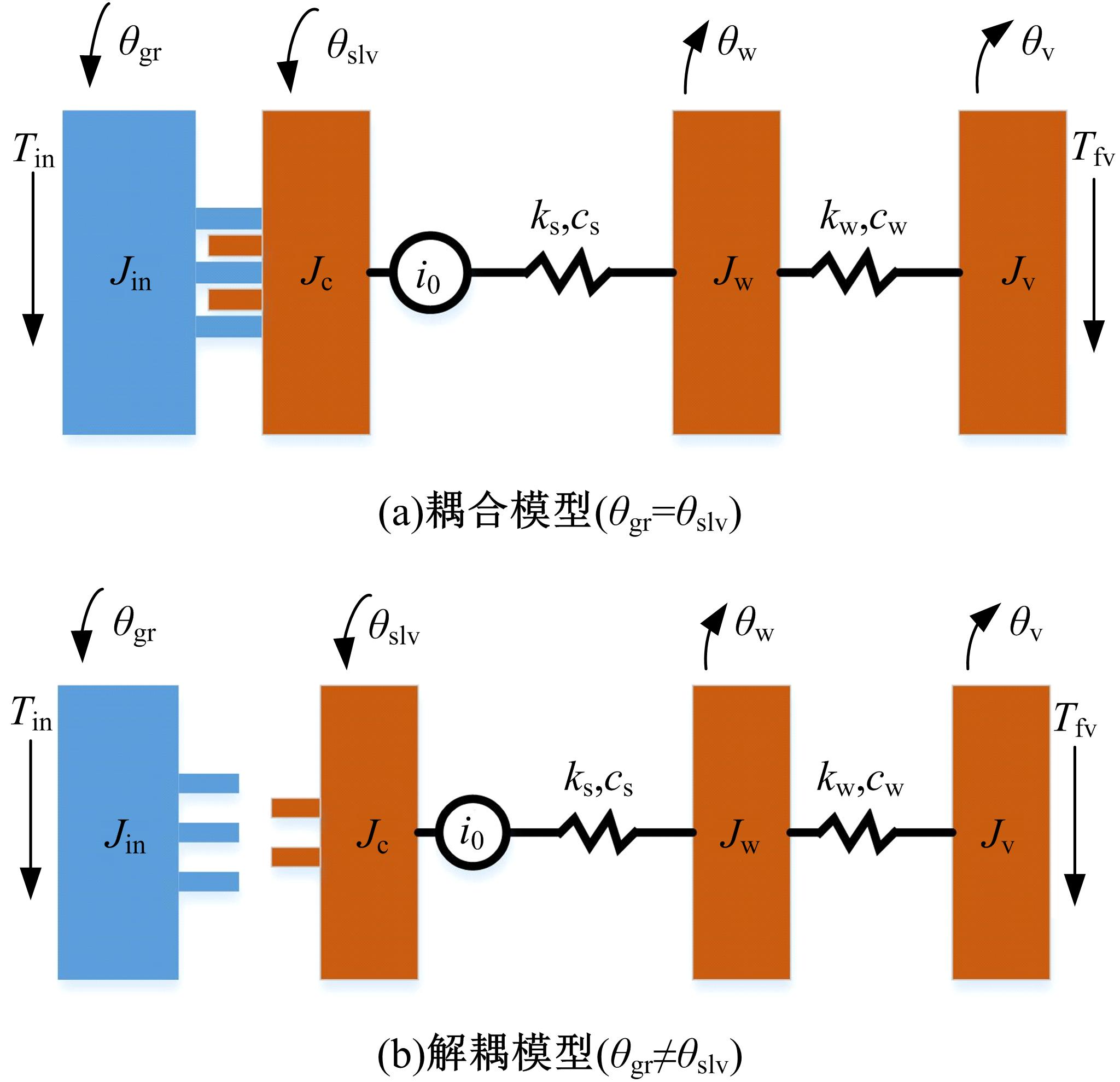

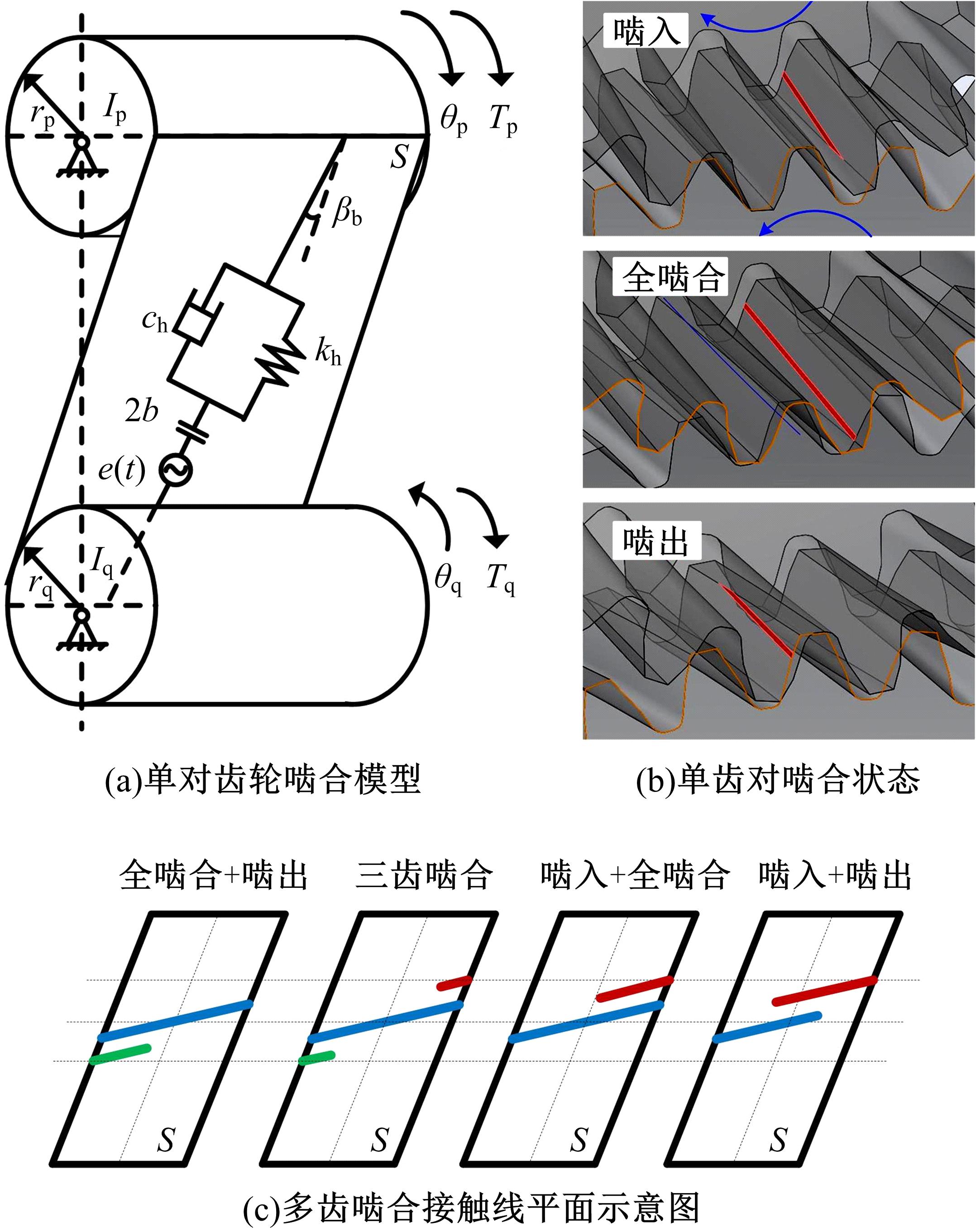

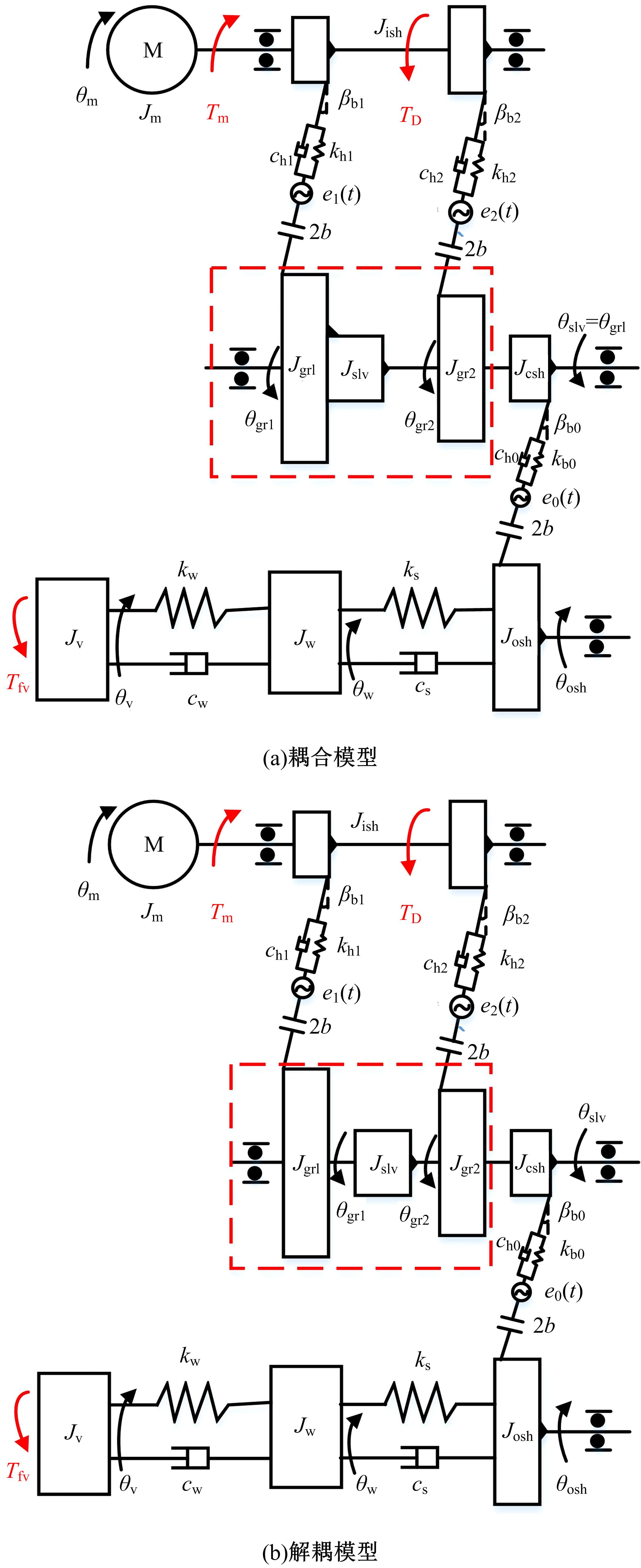

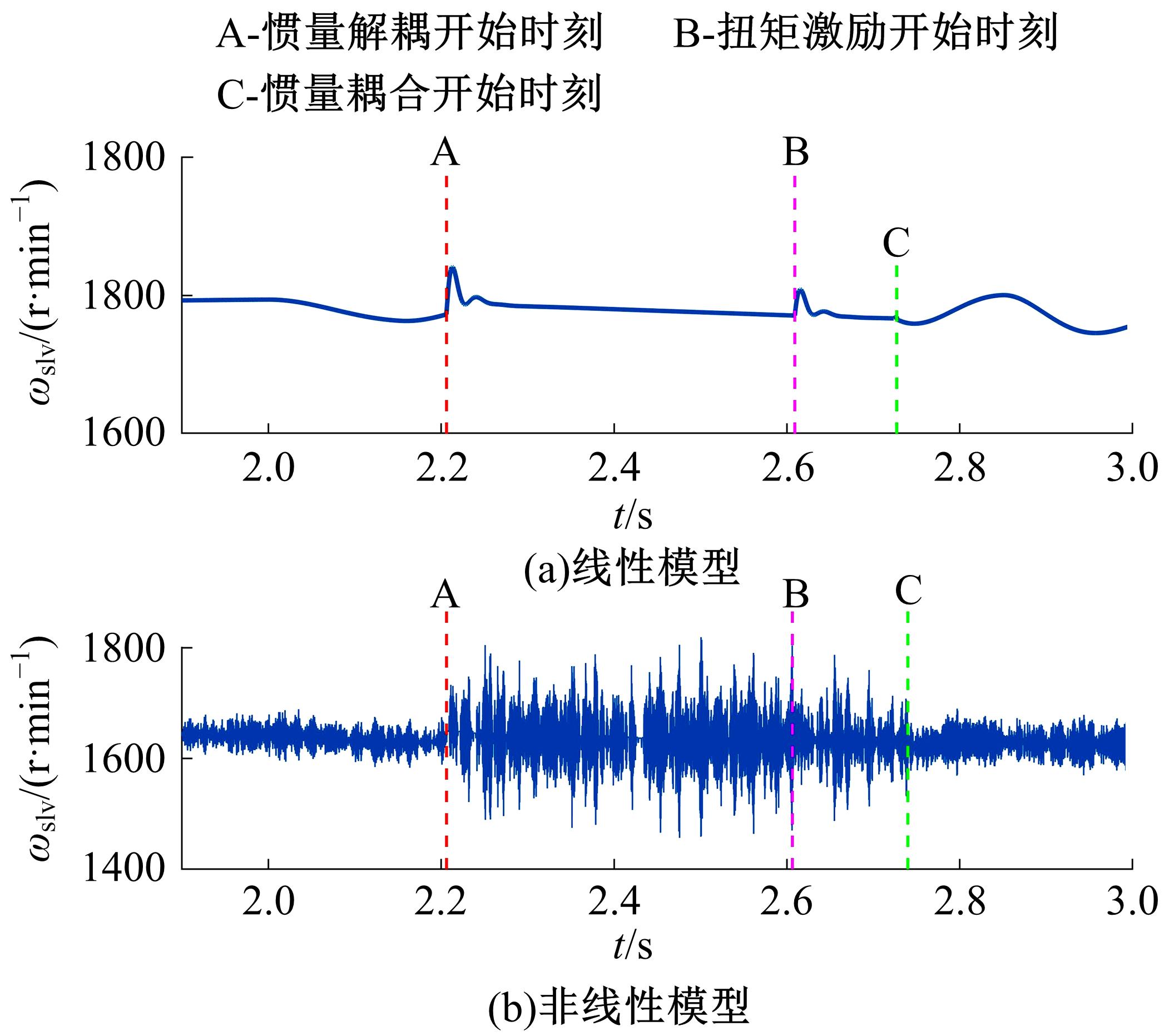

| 14 | 隋立起,田丰,李波,等. 考虑齿轮耦合振动的换挡过程非线性动力学分析[J]. 清华大学学报:自然科学版,2020,60(2):109-116. |

| Li-qi Sui, Tian Feng, Li Bo, et al. Nonlinear dynamics analyses of gear shifting with gear vibrations[J]. Journal of Tsinghua University(Science and Technology),2020,60(2):109-116. | |

| 15 | 马辉,王奇斌,黄婧,等. 不同自由度耦合斜齿轮转子系统的振动特性[J].振动·测试与诊断,2014,34(4):650-657, 775. |

| Ma Hui, Wang Qi-bin, Huang Jing, et al. Vibration characteristics analysis of a helical gear rotor system considering different degrees of freedom coupling[J]. Journal of Vibration, Measurement & Diagnosis, 2014,34(4):650-657, 775. | |

| 16 | 张义民,何永慧,朱丽莎,等. 多平行轴齿轮耦合转子系统的振动响应[J]. 振动、测试与诊断,2012,32(4):527-531, 684. |

| Zhang Yi-min, He Yong-hui, Zhu Li-sha, et al. Vibration response of multi-shaft rotor system with coupled gear mesh[J]. Journal of Vibration, Measurement & Diagnosis, 2012,32(4):527-531, 684. | |

| 17 | Wang J G, Zhang J,Yuan Z, et al. Nonlinear characteristics of a multi-degree-of-freedom spur gear system with bending-torsional coupling vibration[J]. Mechanical Systems and Signal Processing,2019,121:810-827. |

| 18 | 符升平,项昌乐,姚寿文, 等. 基于刚柔耦合动力学的齿轮传动系统动态特性[J]. 吉林大学学报:工学版, 2011, 41(2): 382-386. |

| Fu Sheng-ping, Xiang Chang-le, Yao Shou-wen, et al. Dynamic characteristic of gear transmission system based on rigid and flexible coupled dynamics[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(2):382-386. | |

| 19 | 程潇骁. 电机变速器耦合系统换挡过程动力学建模与控制策略研究[D]. 北京:清华大学汽车工程系,2014. |

| Cheng Xiao-xiao. Dynamics modeling and control strategy for the shifting process of coupled motor-transmission system[D]. Beijing: Department of Automotive Engineering, Tsinghua University, 2014. | |

| 20 | 隋平阳. 电动车辆齿轮传动系统非线性动力学特性研究[D]. 北京:北京理工大学机械与车辆学院,2016. |

| Ping-yang Sui. Study on nonlinear dynamic characteristics of gear system for electric vehicle's transmission[D]. Beijing:School of Mechanical Engineering, Beijing Institute of Technology,2016. | |

| 21 | Song Q, Sui P Y. Nonlinear dynamics coupling analysis on gear system of automated mechanical transmission[C]∥The 3rd International Conference on Material Engineering and Application, Shanghai, China, 2016:518-523. |

| 22 | 柴本本. 电驱动两挡机械式自动变速器换挡过程控制研究[D]. 上海:上海交通大学机械与动力工程学院,2019. |

| Chai Ben-ben. Study on shifting process control for two-speed automatic mechanical transmissions on electric vehicles[D]. Shanghai:School of Mechanical Engineering,Shanghai Jiao Tong University, 2019. |

| [1] | Da-feng SONG,Li-li YANG,Xiao-hua ZENG,Xing-qi WANG,Wei-zhi LIANG,Nan-nan YANG. Battery life optimization of hybrid electric vehicle based on driving cycle construction [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 781-791. |

| [2] | Jia-xu ZHANG,Xin-zhi WANG,Jian ZHAO,Zheng-tang SHI. Path planning and discrete sliding mode tracking control for high⁃speed lane changing collision avoidance of vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1081-1090. |

| [3] | Ren HE,Xiao-cong ZHAO,Yi-bin YANG,Jian-qiang WANG. Man⁃machine shared driving model using risk⁃response mechanism of human driver [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 799-809. |

| [4] | Bo WANG,Yang-yang HE,Bing-bing NIE,Shu-cai XU,Jin-huan ZHANG. Abdominal injury of vehicle occupant in underbody blast events [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 792-798. |

| [5] | Shou-tao LI,Rui WANG,Jing-chun XU,De-jun WANG,Yan-tao TIAN,Ding-li YU. A vehicle collision avoidance control method based on model predictive composite control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 738-746. |

| [6] | Wei-da WANG,Yan-jie WU,Jia-lei SHI,Liang LI. Electronic hydraulic brake power system control strategy based on driver intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 406-413. |

| [7] | Guo-ying CHEN,Jun YAO,Peng WANG,Qi-kun XIA. Stability control strategy for rear in⁃wheel motor drive vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 397-405. |

| [8] | Fang-wu MA,Hong-yu LIANG,Qiang WANG,Yong-feng PU. In-plane dynamic crushing of dual-material structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 114-121. |

| [9] | Dao WU,Li-bin ZHANG,Yun-xiang ZHANG,Hong-ying SHAN,Hong-mei SHAN. Visual detection method for vehicle braking time sequence based on slip rate identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 206-216. |

| [10] | En-hui ZHANG,Ren HE,Wei-dong SU. Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 83-95. |

| [11] | Lu XIONG,Yan-chao WEI,Le-tian GAO. Inertial measurement unit/wheel speed sensor integrated zero-speed detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 134-138. |

| [12] | Ji-qing CHEN,Qing-sheng LAN,Feng-chong LAN,Zhao-lin LIU. Trajectory tracking control based on tire force prediction and fitting [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1565-1573. |

| [13] | Zhi-gang YANG,Ya-jun FAN,Chao XIA,Shi-jun CHU,Xi-zhuang SHAN. Drag reduction of a square⁃back Ahmed model based on bi⁃stable wake [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1635-1644. |

| [14] | Zhe SHEN,Yi-gang WANG,Zhi-gang YANG,Yin-zhi HE. Drift error correction of unknown sound source in wind tunnel using approximation method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1584-1589. |

| [15] | Zhao LIU,Jiang-lin CHENG,Yu-tian ZHU,Li-hui ZHENG. Vertical vibration modeling and motion correlation analysis of rail vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1600-1607. |

|

||