Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (4): 1198-1203.doi: 10.13229/j.cnki.jdxbgxb20200505

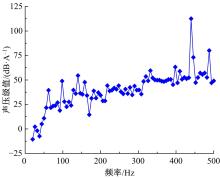

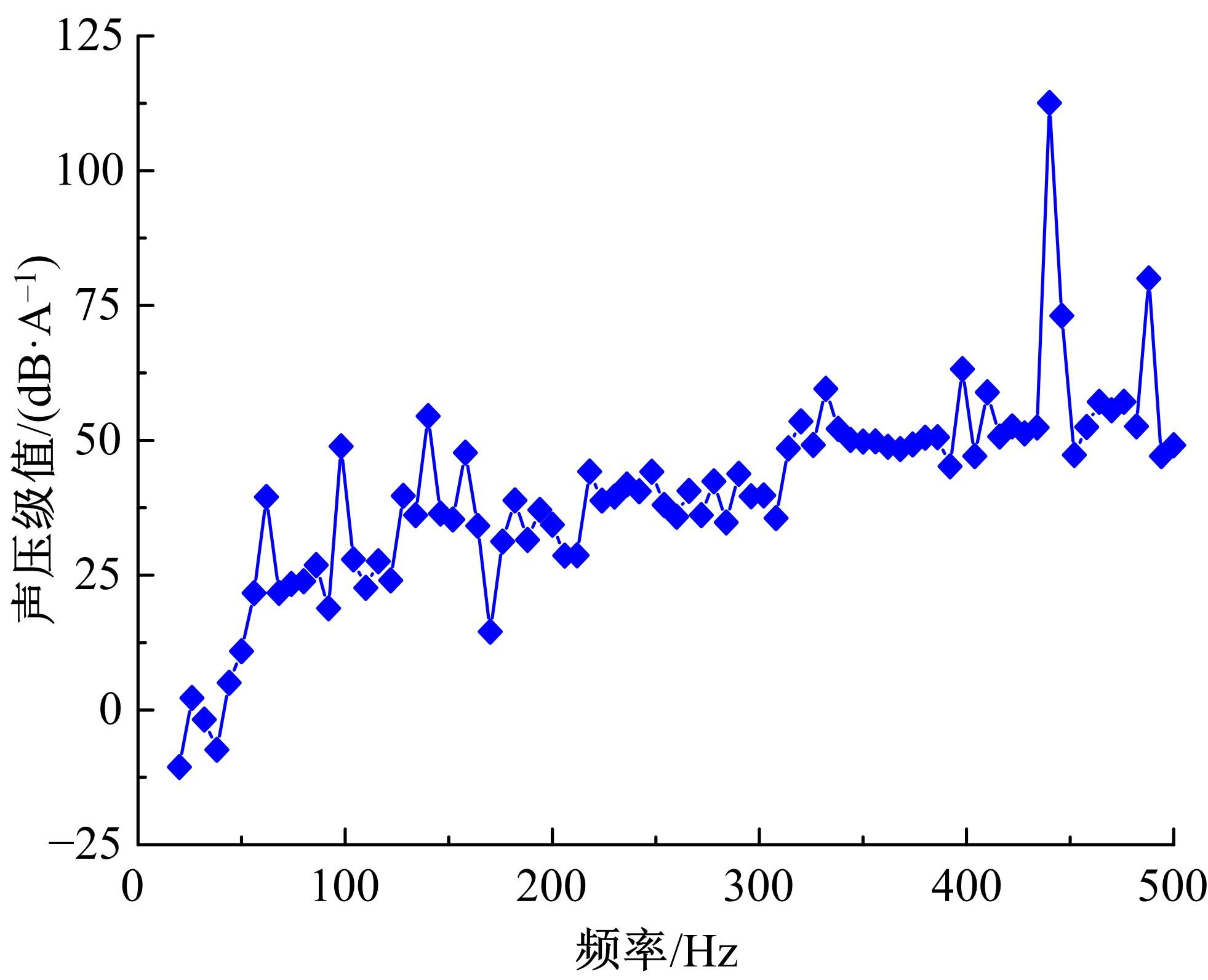

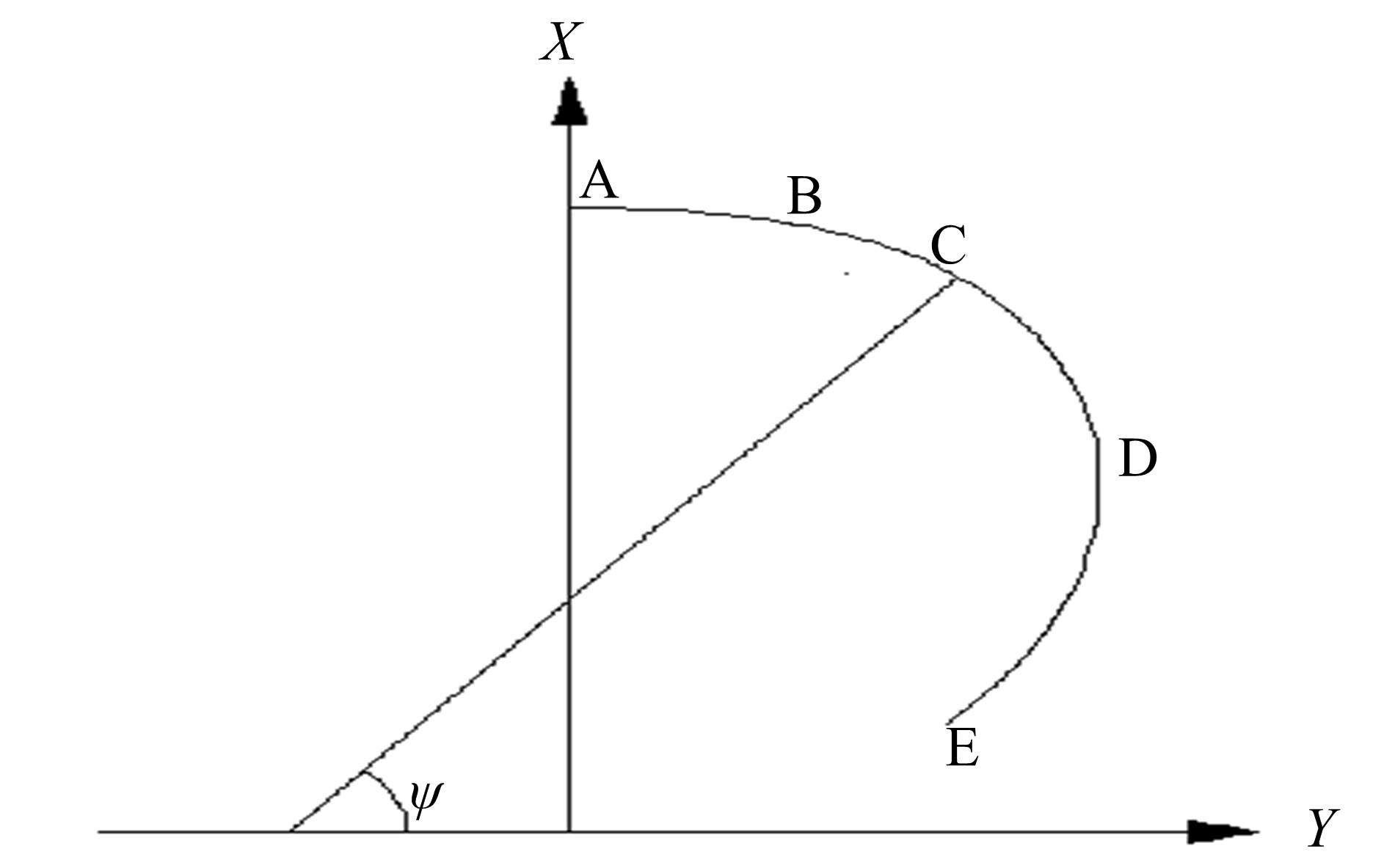

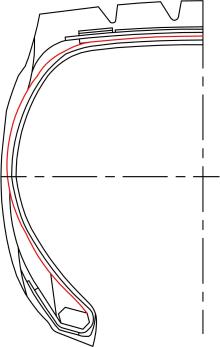

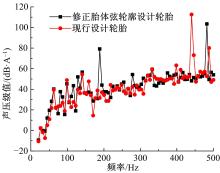

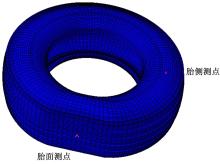

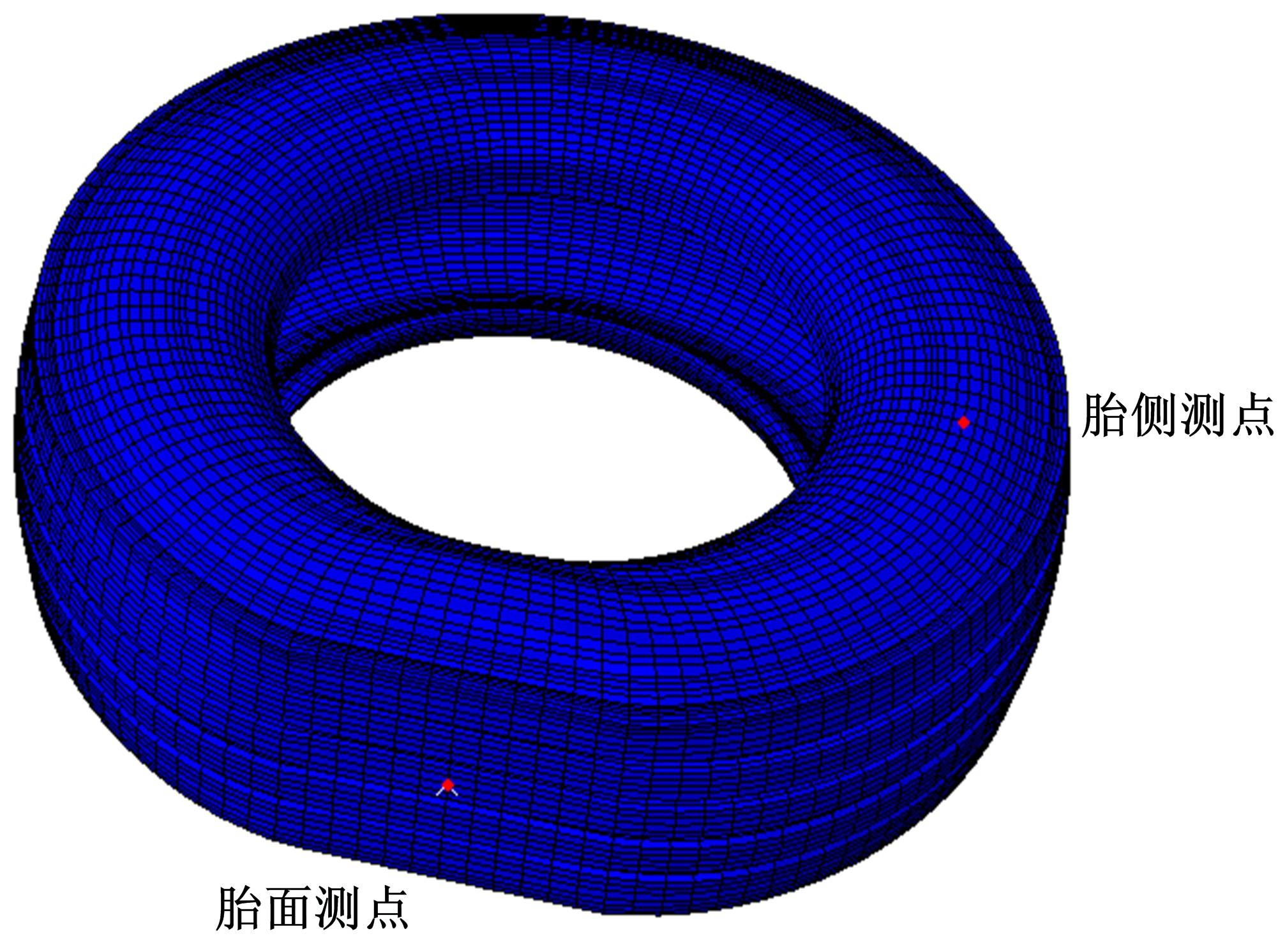

Noise reduction mechanism of truck radial tire based on modified carcass string contour design

Jian YANG( ),Qi XIA,Hai-chao ZHOU,Guo-lin WANG

),Qi XIA,Hai-chao ZHOU,Guo-lin WANG

- School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

CLC Number:

- U463.3

| 1 | Molisani L R, Burdisso R A, Tsihlas D. A coupled tire structure/acoustic cavity model[J]. International Journal of Solids and Structures, 2003, 40(19): 5125-5138. |

| 2 | Kim B S. A study on tire-structure-borne sound[J]. JSME International Journal Series C, 2003, 46(2): 683-691. |

| 3 | 梁晨,赵璠,王国林,等. 基于新非自然平衡轮廓设计的载重子午线轮胎振动辐射噪声的研究[J]. 振动工程学报,2015,28(5):800-808. |

| Liang Chen, Zhao Fan, Wang Guo-lin, et al. Research on radial noise from vibration of load radial tire based on new unnatural balanced contour design[J]. Journal of Vibration Engineering, 2015, 28(5): 800-808. | |

| 4 | 刘占村,李明,刘杰,等. 带束层结构对轿车子午线轮胎接地印痕、径向刚度及噪声的影响[J]. 轮胎工业,2011,31(9):534-536. |

| Liu Zhan-cun, Li Ming, Liu Jie, et al. Influence of belt structure on ground mark, radial stiffness and noise of radial tire [J]. Tire Industry, 2011, 31 (9): 534-536. | |

| 5 | Zhou Hai-chao, Wang Guo-lin, Zhang Ying-wen, et al. Study of the influence of tire belt structure on vibration noise[J]. Recent Patents on Mechanical Engineering, 2017, 10(4): 270-278. |

| 6 | 何敏. 降低胎噪的轮胎消音器[J]. 现代橡胶技术,2012,38(1):33-35. |

| He Min. Tire silencer for reducing tire noise [J]. Advanced Rubber Technology, 2012, 38 (1) : 33-35. | |

| 7 | Mohamed Z, Wang X. A study of tyre cavity resonance and noise reduction using inner trim[J]. Mechanical Systems and Signal Processing, 2015, 50(51): 498-509. |

| 8 | 李牧皛,王瑞乾,温泽峰,等. 喷涂式阻尼车轮振动声辐射特性分析[J]. 噪声与振动控制,2014,34(4):30-34, 38. |

| Li Mu-xiao, Wang Rui-qian, Wen Ze-feng, et al. Analysis on vibration and sound radiation characteristics of sprayed damping wheel[J]. Noise and Vibration Control, 2014, 34(4): 30-34, 38. | |

| 9 | 赵书凯,邓世涛,丁海峰,等. 轮胎噪声影响因素及低噪声轮胎设计方法[J]. 轮胎工业,2014,34(2):76-80. |

| Zhao Shu-kai, Deng Shi-tao, Ding Hai-feng, et al. Influencing factors of tire noise and low noise tire design method [J]. Tire Industry, 2014, 34 (2): 76-80. | |

| 10 | Lafont T, Stelzer R, D'Amico R, et al. Modelling tyre noise in finite element simulations for pass-by noise predictions[J]. Journal of Mechanical Engineering Science, 2019, 233(18): 6398-6408. |

| 11 | Hu Xiao-jun, Liu Xian-dong, Wan Xiao-fei, et al. Experimental analysis of sound field in the tire cavity arising from the acoustic cavity resonance[J]. Applied Acoustics, 2020, 161(1):107172. |

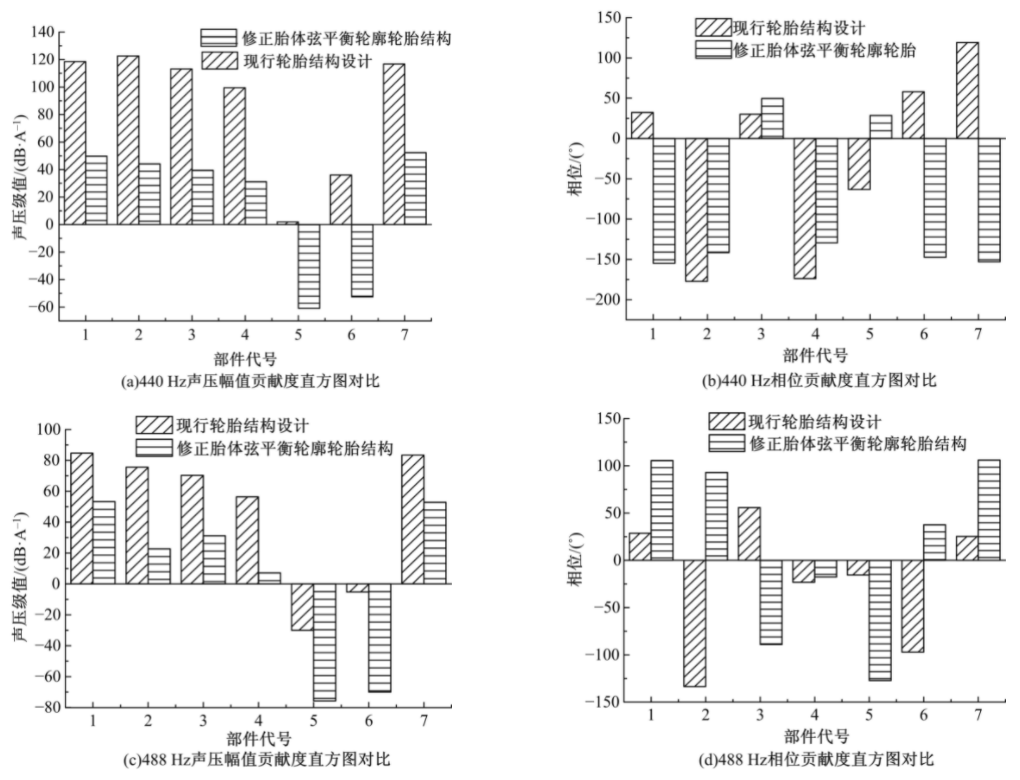

| 12 | 王国林,裴晓朋,周海超,等. 轮胎结构振动声学贡献度分析及降噪方法研究[J]. 振动与冲击,2015, 34(24):53-58. |

| Wang Guo-lin, Pei Xiao-peng, Zhou Hai-chao, et al.Acoustic contribution of tire structure vibration and method for noise reduction [J]. Journal of Vibration and Shock, 2015,34(24):53-58. | |

| 13 | 王国林,任洁雨,杨建,等. 轮胎胎体轮廓设计对侧偏刚度的影响研究[J].机械工程学报, 2015, 51(14): 131-137. |

| Wang Guo-lin, Ren Jie-yu, Yang Jian, et al. Effect study of radial tire contour design to cornering stiffness[J]. Journal of Mechanical Engineering, 2015, 51(14):131-137. |

| [1] | Xin CHEN,Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG. Equivalent modeling of tensile-shear behavior for friction stir spot welding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1190-1197. |

| [2] | Da-feng SONG,Li-li YANG,Xiao-hua ZENG,Xing-qi WANG,Wei-zhi LIANG,Nan-nan YANG. Battery life optimization of hybrid electric vehicle based on driving cycle construction [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 781-791. |

| [3] | Jia-xu ZHANG,Xin-zhi WANG,Jian ZHAO,Zheng-tang SHI. Path planning and discrete sliding mode tracking control for high⁃speed lane changing collision avoidance of vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1081-1090. |

| [4] | Ren HE,Xiao-cong ZHAO,Yi-bin YANG,Jian-qiang WANG. Man⁃machine shared driving model using risk⁃response mechanism of human driver [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 799-809. |

| [5] | Qiang SONG,Dan-ting SUN,Wei ZHANG. Shift nonlinear modeling and control of automated mechanical transmission in pure electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 810-819. |

| [6] | Bo WANG,Yang-yang HE,Bing-bing NIE,Shu-cai XU,Jin-huan ZHANG. Abdominal injury of vehicle occupant in underbody blast events [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 792-798. |

| [7] | Wei-min ZHUANG,Peng-yue WANG,Rui-juan GAO,Dong-xuan XIE. Effect of hot forming on static mechanical properties of AA5754 aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 847-854. |

| [8] | Shou-tao LI,Rui WANG,Jing-chun XU,De-jun WANG,Yan-tao TIAN,Ding-li YU. A vehicle collision avoidance control method based on model predictive composite control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 738-746. |

| [9] | Wei-da WANG,Yan-jie WU,Jia-lei SHI,Liang LI. Electronic hydraulic brake power system control strategy based on driver intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 406-413. |

| [10] | Guo-ying CHEN,Jun YAO,Peng WANG,Qi-kun XIA. Stability control strategy for rear in⁃wheel motor drive vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 397-405. |

| [11] | Fang-wu MA,Hong-yu LIANG,Qiang WANG,Yong-feng PU. In-plane dynamic crushing of dual-material structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 114-121. |

| [12] | Dao WU,Li-bin ZHANG,Yun-xiang ZHANG,Hong-ying SHAN,Hong-mei SHAN. Visual detection method for vehicle braking time sequence based on slip rate identification [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 206-216. |

| [13] | En-hui ZHANG,Ren HE,Wei-dong SU. Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 83-95. |

| [14] | Lu XIONG,Yan-chao WEI,Le-tian GAO. Inertial measurement unit/wheel speed sensor integrated zero-speed detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 134-138. |

| [15] | Ji-qing CHEN,Qing-sheng LAN,Feng-chong LAN,Zhao-lin LIU. Trajectory tracking control based on tire force prediction and fitting [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1565-1573. |

|

||