Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (11): 2735-2745.doi: 10.13229/j.cnki.jdxbgxb20210348

Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest

Xing-yu WAN1( ),Qing-xi LIAO1,2,Ya-jun JIANG1,Yi-yin SHAN1,Yu ZHOU1,Yi-tao LIAO1,2(

),Qing-xi LIAO1,2,Ya-jun JIANG1,Yi-yin SHAN1,Yu ZHOU1,Yi-tao LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-Lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

CLC Number:

- S817.11

| 1 | 张哲, 殷艳, 刘芳, 等. 我国油菜多功能开发利用现状及发展对策[J]. 中国油料作物学报, 2018, 40(5): 618-623. |

| Zhang Zhe, Yin Yan, Liu Fang, et al. Current situation and development countermeasures of Chinese rapeseed multifunctional development and utilization[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 618-623. | |

| 2 | 毛鑫,刘桂琼,姜勋平,等. 饲料油菜鲜饲对哺乳母羊和羔羊体质量和血清生化指标的影响[J]. 河南农业科学, 2020, 49(5): 161-167. |

| Mao Xin, Liu Gui-giong, Jiang Xun-ping, et al. Effects of feeding fresh forage rape on body weight and serum parameters of lactating ewes and their lambs[J]. Journal of Henan Agricultural Sciences, 2020, 49(5): 161-167. | |

| 3 | 易四凤, 杨华, 余陵峰, 等. 新鲜饲料油菜对肉牛育肥效果的研究[J]. 中国饲料, 2017(20): 39-43. |

| Yi Si-feng, Yang Hua, Yu Ling-feng, et al. Study on fresh Brassica napus L. on fattening effects in beef cattle[J]. China Feed, 2017(20): 39-43. | |

| 4 | 汪波, 宋丽君, 王宗凯, 等. 我国饲料油菜种植及应用技术研究进展[J]. 中国油料作物学报, 2018, 40(5): 695-701. |

| Wang Bo, Song Li-jun, Wang Zong-kai, et al. Production and feeding technology of fodder rapeseed in china[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 695-701. | |

| 5 | 杨雪海, 张巍, 赵娜, 等. 油菜华油杂62不同生长期氨基酸组成及营养价值评价[J]. 中国油料作物学报, 2017, 39(2): 197-203. |

| Yang Xue-hai, Zhang Wei, Zhao Na, et al. Forage amino acid composition and nutrition of Brassica napus L.cv Huayouza 62 in different growth stages[J]. Chinese Journal of Oil Crop Sciences, 2017, 39(2): 197-203. | |

| 6 | 赵娜,杨雪海,魏金涛,等. 饲用油菜的营养成分分析及其在山羊瘤胃降解特性研究[J]. 草业学报, 2020, 29(5): 50-57. |

| Zhao Na, Yang Xue-hai, Wei Jin-tao, et al. Nutritional composition of forage rape and its rumen degradation characteristics in goats[J]. Acta Prataculturac Sinica, 2020, 29(5): 50-57. | |

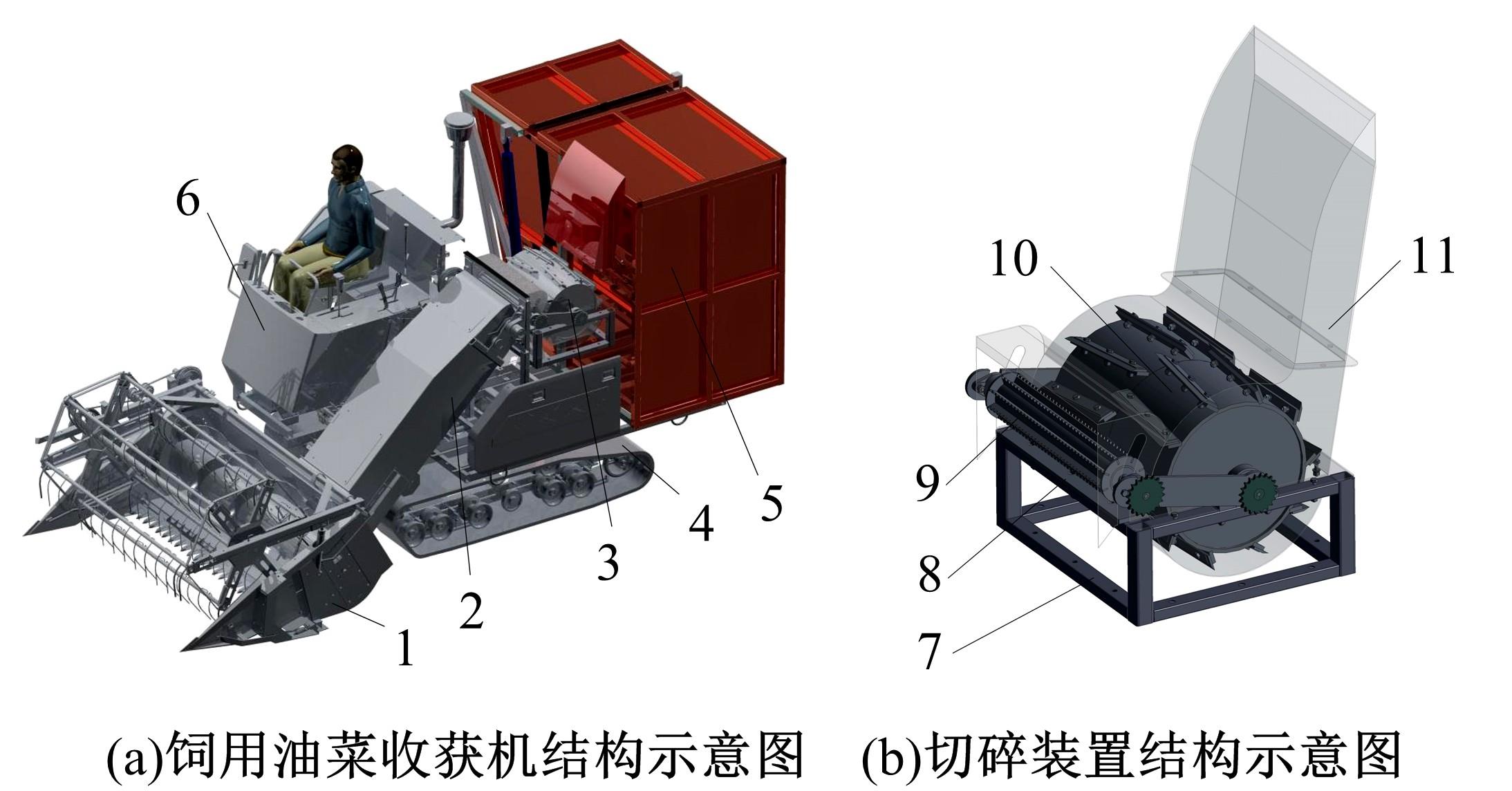

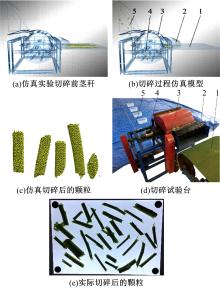

| 7 | 蒋亚军,廖宜涛,廖庆喜. 冬春鲜喂饲用油菜收获机滚刀式切碎装置设计与试验[J]. 农业机械学报, 2019, 50(2): 102-111. |

| Jiang Ya-jun, Liao Yi-tao, Liao Qing-xi. Design and experiment on cylinder-type chopping device of harvester for fodder rapeseed in winter and spring[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2): 102-111. | |

| 8 | 谢方平,吴正阳,王修善,等. 基于无侧限抗压强度试验的土壤离散元参数标定[J]. 农业工程学报, 2020, 36(13): 39-47. |

| Xie Fang-ping, Wu Zheng-yang, Wang Xiu-shan, et al. Calibration of discrete element parameters of soils based on unconfined compressive strength test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(13): 39-47. | |

| 9 | 赵淑红,王加一,陈君执,等. 保护性耕作拟合曲线型深松铲设计与试验[J]. 农业机械学报, 2018, 49(2): 82-92. |

| Zhao Shu-hong, Wang Jia-yi, Chen Jun-zhi, et al. Design and experiment of fitting curve subsoiler of conservation tillage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 82-92. | |

| 10 | Barr J B, Desbiolles J M A, Fielke J M, et al. Development and field evaluation of a high-speed no-till seeding system[J]. Soil and Tillage Research, 2019, 194: 104337. |

| 11 | 廖庆喜,张朋玲,廖宜涛,等. 基于EDEM的离心式排种器排种性能数值模拟[J]. 农业机械学报, 2014, 45(2): 109-114. |

| Liao Qing-xi, Zhang Peng-ling, Liao Yi-tao, et al. Numerical simulation on seeding performance of centrifugal rape-seed metering device based on EDEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 109-114. | |

| 12 | 刘彩玲,王亚丽,都鑫,等. 摩擦复充种型孔带式水稻精量排种器充种性能分析与验证[J]. 农业工程学报, 2019, 35(4): 29-36. |

| Liu Cai-ling, Wang Ya-li, Du Xin, et al. Performance analysis and verification of cell-belt rice precision seed-metering based on friction and repeated filling principle[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(4): 29-36. | |

| 13 | 钱震杰,金诚谦,袁文胜,等. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报: 工学版, 2021, 51(3): 1121-1130. |

| Qian Zhen-jie, Jin Cheng-qian, Yuan Wen-sheng, et al. Frictional impact dynamics of threshing process between flexible teeth and grains[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1121-1130. | |

| 14 | 马彦华,宋春东,宣传忠,等. 苜蓿秸秆压缩仿真离散元模型参数标定[J]. 农业工程学报, 2020, 36(11): 22-30. |

| Ma Yan-hua, Song Chun-dong, Xuan Chuan-zhong, et al. Parameters calibration of discrete element model for alfalfa straw compression simulation[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(11): 22-30. | |

| 15 | 耿端阳,孙延成,牟孝栋,等. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 693-702. |

| Geng Duan-yang, Sun Yan-cheng, Mou Xiao-dong, et al. Simulation test and optimization of grain breakage of silage maize based on differential roller[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 693-702. | |

| 16 | 王扬,吕凤妍,徐天月,等. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报: 工学版, 2018, 48(2): 507-517. |

| Wang Yang, Feng-yan Lyu, Xu Tian-yue, et al. Shape and size analysis of soybean kernel and modeling[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(2): 507-517. | |

| 17 | Su Z, Li Y, Dong Y, et al. Simulation of rice threshing performance with concentric and non-concentric threshing gaps[J]. Biosystems Engineering, 2020, 197: 270-284. |

| 18 | 付宏,吕游,李艳双,等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报: 工学版, 2012, 42(4): 997-1002. |

| Fu Hong, You Lyu, Li Yan-shuang, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(4): 997-1002. | |

| 19 | Mao H, Wang Q, Li Q. Modelling and simulation of the straw-grain separation process based on a discrete element model with flexible hollow cylindrical bonds[J]. Computers and Electronics in Agriculture, 2020, 170: 105229. |

| 20 | 王宪良,胡红,王庆杰,等. 基于离散元的土壤模型参数标定方法[J]. 农业机械学报, 2017, 48(12): 78-85. |

| Wang Xian-liang, Hu Hong, Wang Qing-jie, et al. Calibration method of soil contact characteristic parameters based on DEM theory[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 78-85. | |

| 21 | 丁启朔,任骏,Belal Eisa Adam,等. 湿粘水稻土深松过程离散元分析[J]. 农业机械学报, 2017, 48(3): 38-48. |

| Ding Qi-shuo, Ren Jun, Belal Eisa Adam, et al. DEM analysis of subsoiling process in wet clayey paddy soil[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 38-48. | |

| 22 | 李建桥,黄晗,王颖,等. 松软地面机器系统研究进展[J]. 农业机械学报, 2015, 46(5): 306-320. |

| Li Jian-qiao, Huang Han, Wang Ying, et al. Development on research of soft-terrain machine systems[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 306-320. | |

| 23 | 王笑丹,王洪美,韩云秀,等. 基于离散元法的牛肉咀嚼破碎模型构建[J]. 农业工程学报, 2016, 32(4): 228-234. |

| Wang Xiao-dan, Wang Hong-mei, Han Yun-xiu, et al. Structure of beef chewing model based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(4): 228-234. | |

| 24 | 张锋伟,宋学锋,张雪坤,等. 玉米秸秆揉丝破碎过程力学特性仿真与试验[J]. 农业工程学报, 2019, 35(9): 58-65. |

| Zhang Feng-wei, Song Xue-feng, Zhang Xue-kun, et al. Simulation and experiment on mechanical characteristics of kneading and crushing process of corn straw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(9): 58-65. | |

| 25 | Horabik J, Molenda M. Parameters and contact models for DEM simulations of agricultural granular materials: a review[J]. Biosystems Engineering, 2016,147: 206-225. |

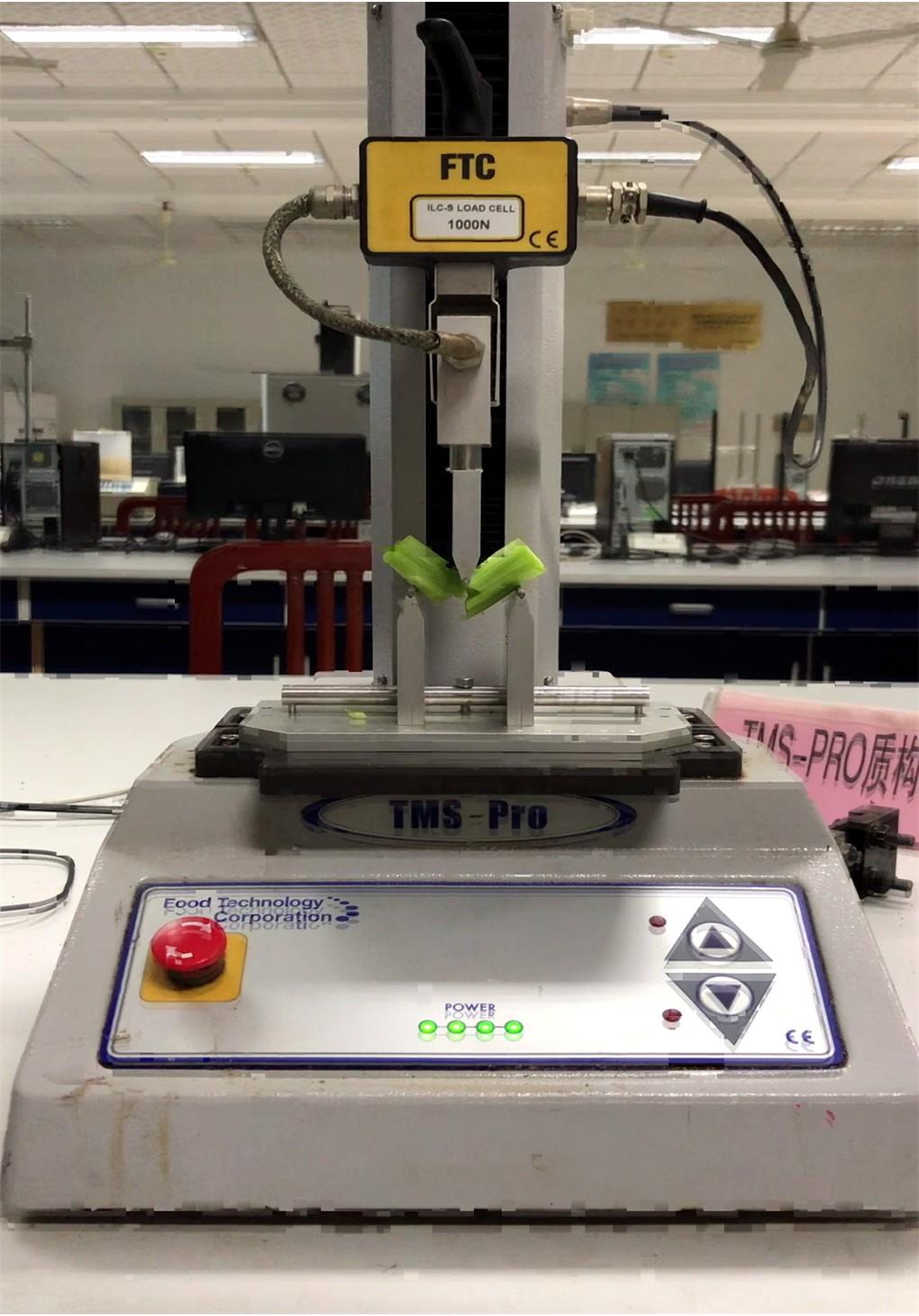

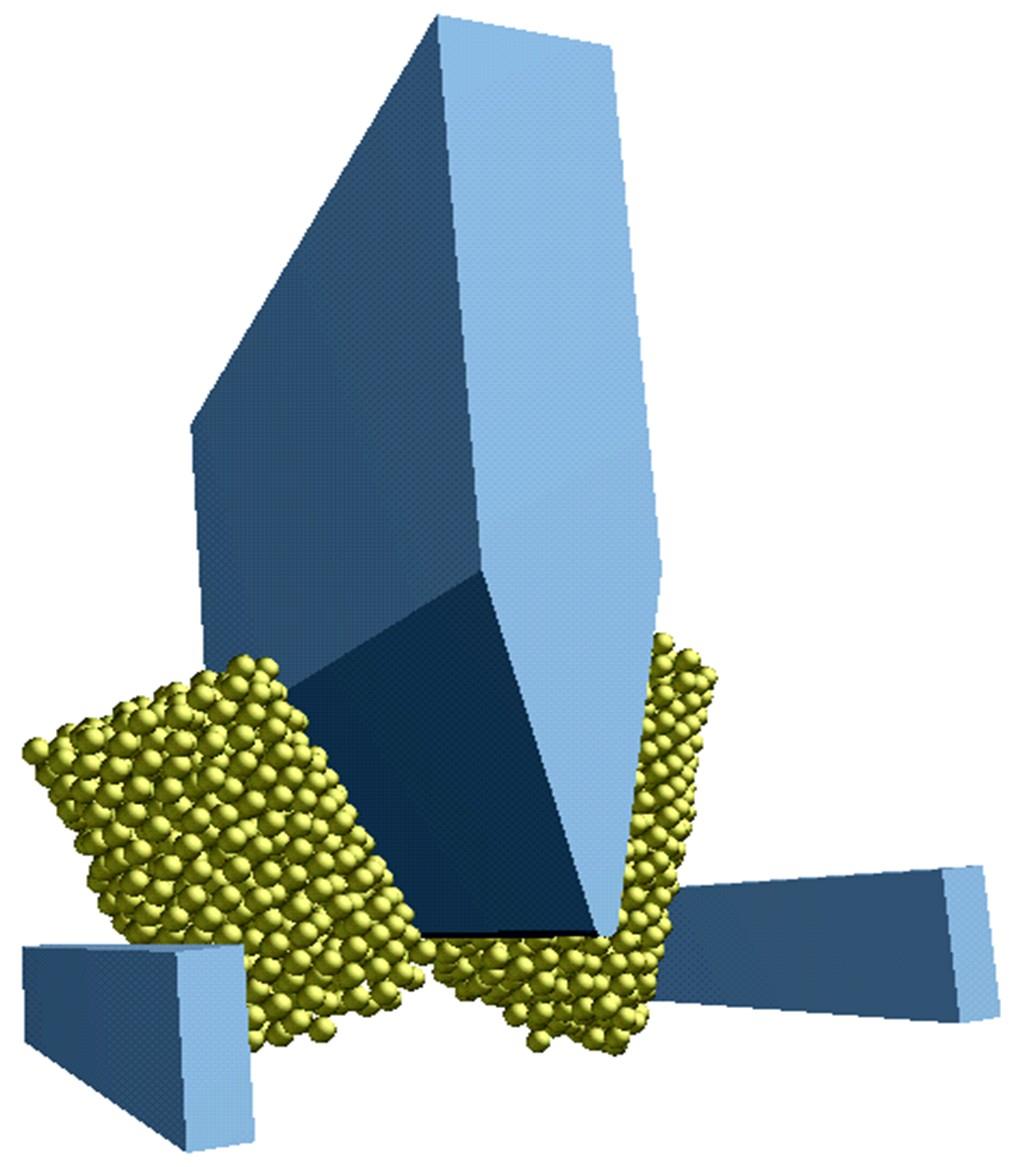

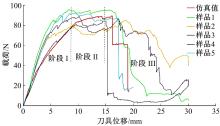

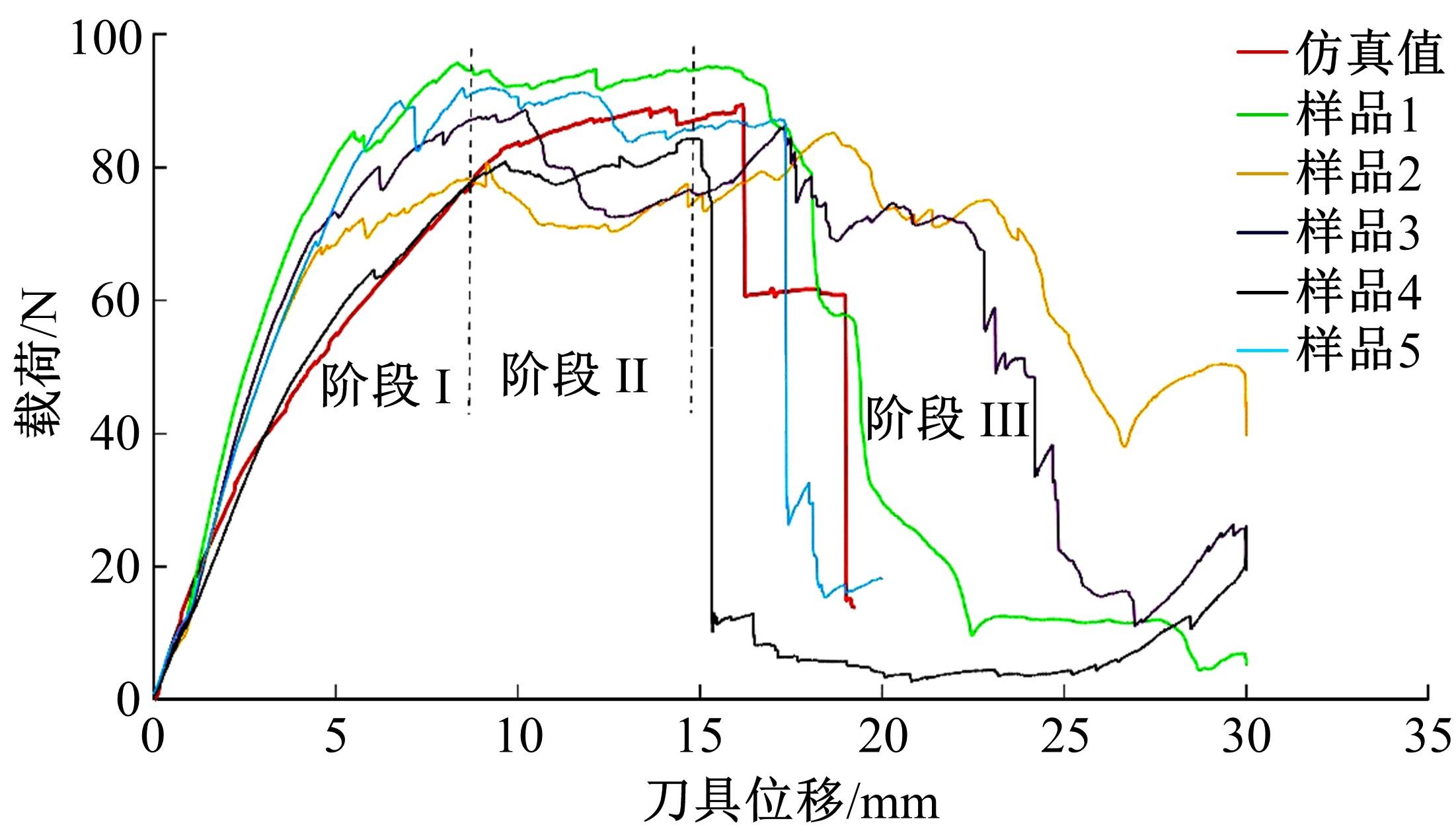

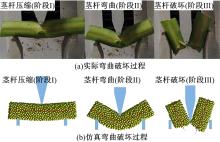

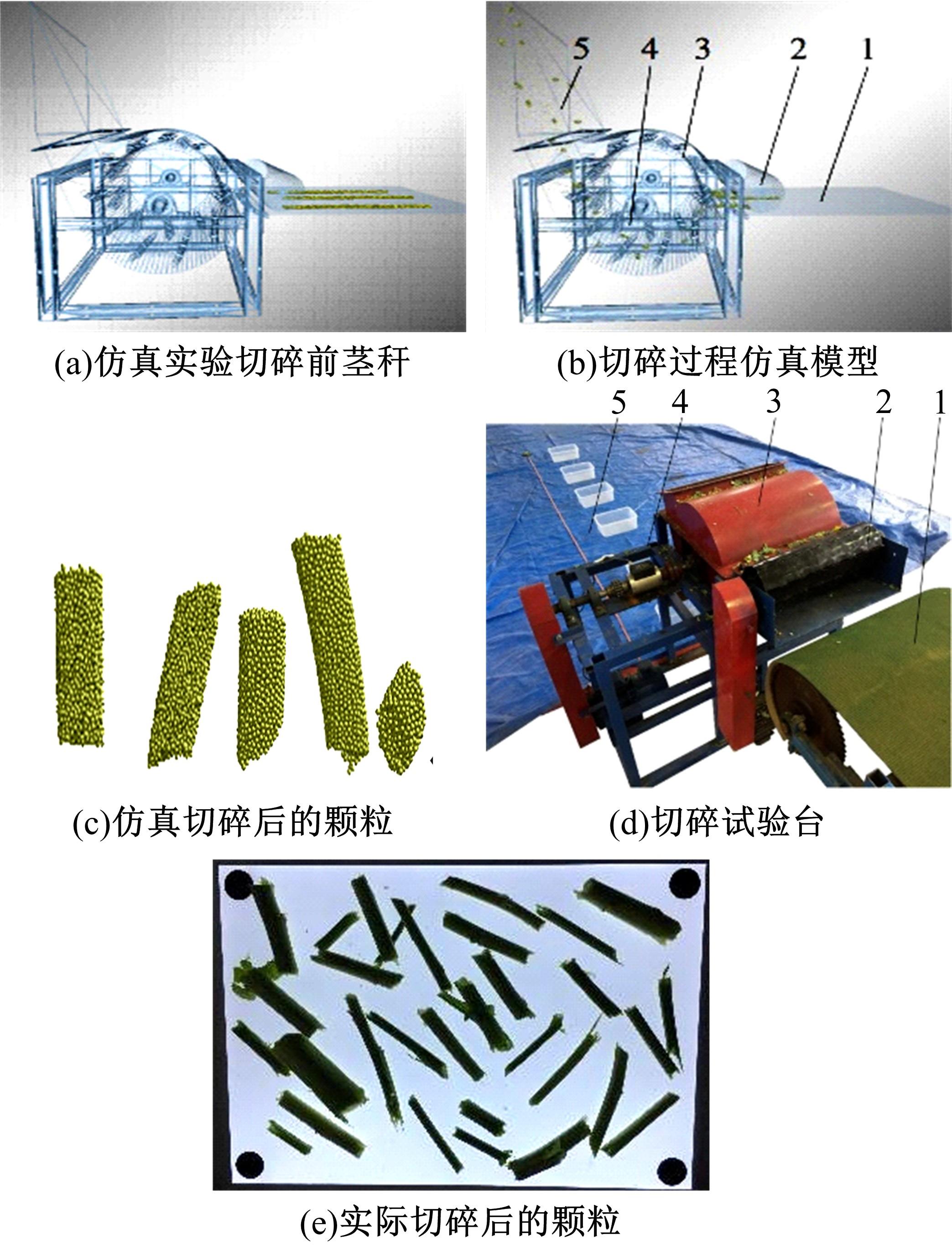

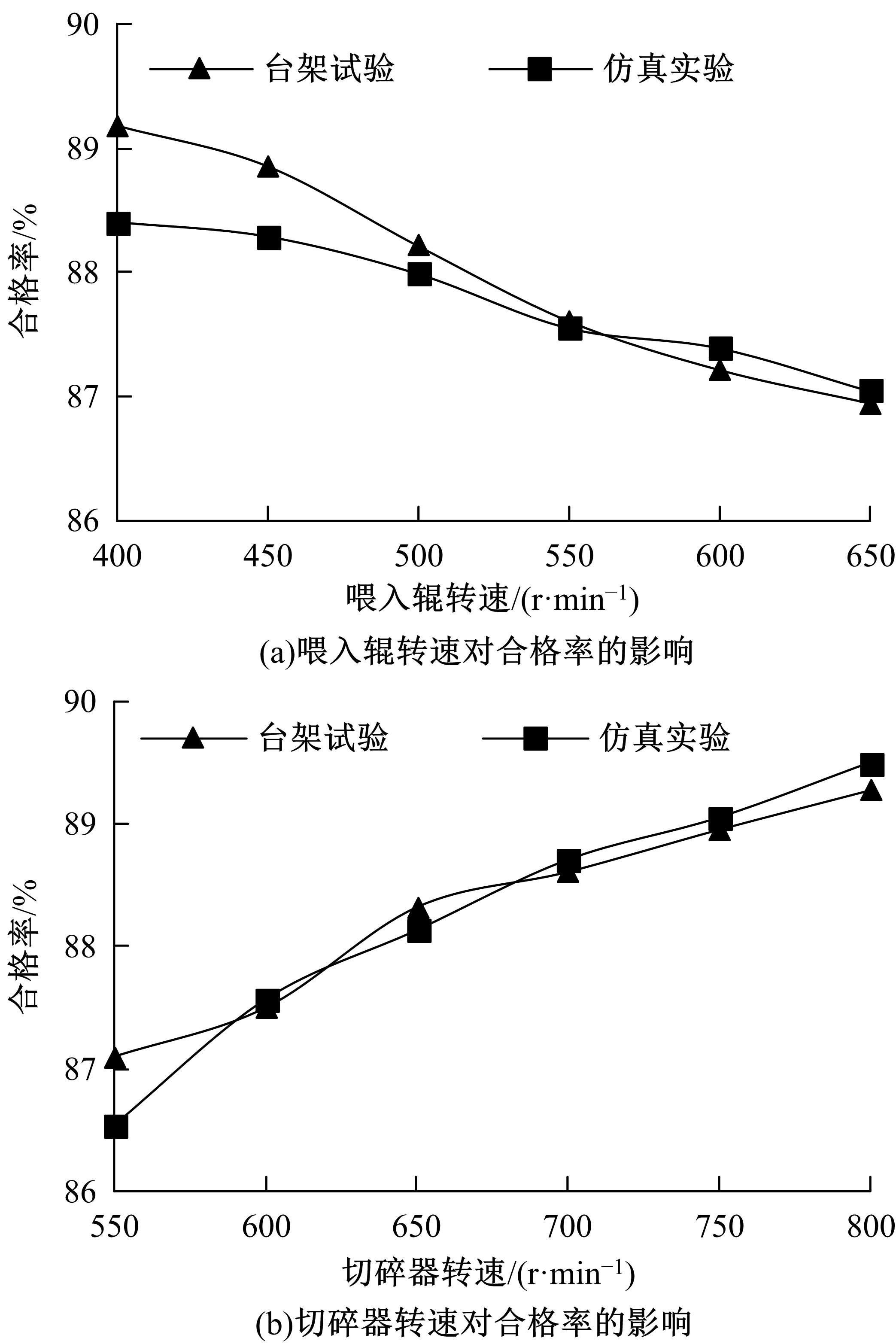

| 26 | 廖宜涛,廖庆喜,周宇,等. 饲料油菜薹期收获茎秆破碎离散元仿真参数标定[J]. 农业机械学报, 2020, 51(6): 73-82. |

| Liao Yi-tao, Liao Qing-xi, Zhou Yu, et al. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 73-82. | |

| 27 | Liao Y, Wang Z, Liao Q, et al. Calibration of discrete element parameters of fodder rape crop stem at flowering stage[C/OL]. [2020-05-18]. |

| 28 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京: 中国农业科学技术出版社, 2007. |

| 29 | Wan X Y, Liao Q X, Jiang Y J, et al. Cattle feeding experiment and chopping device parameter determination for mechanized harvesting of forage rape crop[J]. Transactions of the ASABE, 2021, 64(2): 715-725. |

| 30 | 郭茜,张西良,徐云峰,等. 基于EDEM的番茄秸秆切割性能仿真及试验研究[J]. 排灌机械工程学报, 2018, 36(10): 1017-1022. |

| Guo Qian, Zhang Xi-liang, Xu Yun-feng, et al. EDEM-based simulation and experiment on tomato cane straw cutting performance[J]. Journal of Drainage and Irrigation Machinery Engineering, 2018, 36(10): 1017-1022. |

| [1] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [2] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [3] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [4] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [5] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [6] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [7] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [8] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [9] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [10] | FU Jun,QIAN Zhi-hui,YIN Wei,WANG Jia-jia,REN Lu-quan. Experimental study of friction and tensile properties of wheat [J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

|

||