Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 384-391.doi: 10.13229/j.cnki.jdxbgxb20211089

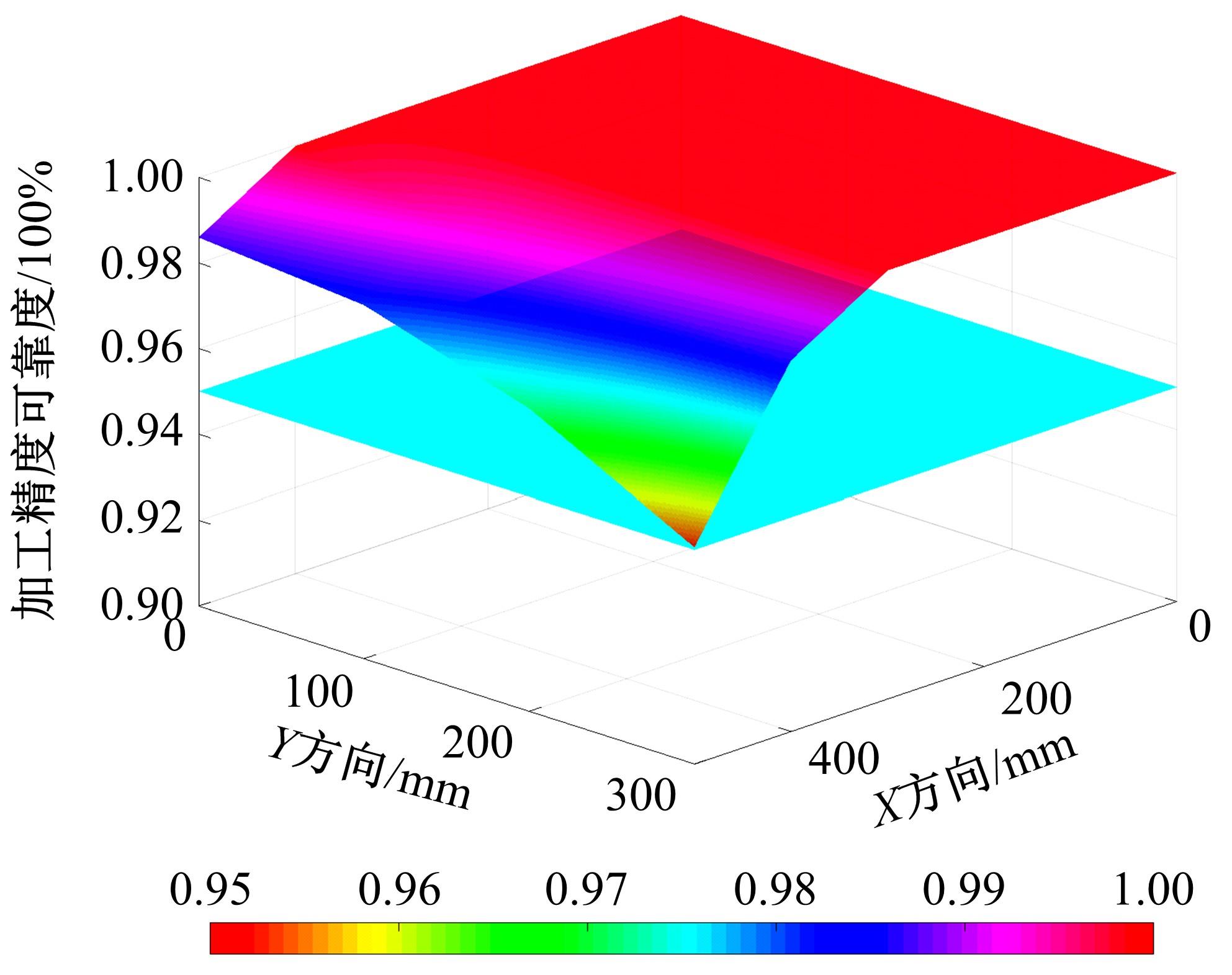

An approach for error allocation of machine tool based on vector projection response surface method

Zi-ling ZHANG1( ),Xiong HU1,Yin QI2,Wei WANG1,Zhi-qiang TAO3,Zhi-feng LIU4,5(

),Xiong HU1,Yin QI2,Wei WANG1,Zhi-qiang TAO3,Zhi-feng LIU4,5( )

)

- 1.Logistics Engineering College,Shanghai Maritime University,Shanghai 201306,China

2.Yingtan Vocational and Technical College,Yingtan,335001,China

3.College of Robotics,Beijing Union University,Beijing 100027,China

4.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

5.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130012,China

CLC Number:

- TH161

| 1 | Zhang Zi-ling, Liu Zhi-feng, Cai Li-gang, et al. An accuracy design approach for a multi-axis NC machine tool based on reliability theory[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(5-8): 1547-1566. |

| 2 | Zhang Zi-ling, Qi Yin, Cheng Qiang, et al. Machining accuracy reliability during the peripheral milling process of thin-walled components[J]. Robotics and Computer Integrated Manufacturing, 2019, 59: 222-234. |

| 3 | 刘志峰, 刘广博, 程强, 等. 基于多体系统理论的精密立式加工中心精度建模与预测[J]. 吉林大学学报: 工学版, 2012, 42(2): 388-391. |

| Liu Zhi-feng, Liu Guang-bo, Cheng Qiang, et al. Precision modeling and prediction of precise vertical machining center based on theory of multi-body system[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(2): 388-391. | |

| 4 | Cai Li-gang, Zhang Zi-ling, Cheng Qiang, et al. A geometric accuracy design method of multi-axis NC machine tool for improving machining accuracy reliability[J]. Eksploatacja I Niezawodnosc-Maintenance and Reliability, 2015, 17(1): 143-155. |

| 5 | Cai Li-gang, Zhang Zi-ling, Cheng Qiang, et al. An approach to optimize the machining accuracy retainability of multi-axis NC machine tool based on robust design[J]. Precision Engineering-Journal of the International Societies for Precision Engineering and Nanotechnology, 2016, 43: 370-386. |

| 6 | 曲兴田, 赵永兵, 刘海忠, 等. 基串并混联机床几何误差建模与实验[J]. 吉林大学学报: 工学版, 2017, 47(1): 137-144. |

| Qu Xing-tian, Zhao Yong-bing, Liu Hai-zhong, et al. Modeling and experiment of spatial geometric errors of hybrid serial parallel machine tool[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 137-144. | |

| 7 | 李国龙, 陶小会, 徐凯, 等. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报: 工学版, 2021, 51(2): 458-467. |

| Li Guo-long, Tao Xiao-hui, Xu Kai, et al. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 458-467. | |

| 8 | 李圣一, 戴一帆, 尹自强, 等. 精密和超精密机床精度建模技术[M]. 长沙: 国防科技大学出版社, 2007. |

| 9 | Helton J C, Johnson J D, Sallaberry C J, et al. Survey of sampling-based methods for uncertainty and sensitivity analysis[J]. Reliability Engineering & System Safety, 2006, 91(10/11): 1175-1209. |

| 10 | 吕震宙, 宋述芳, 李洪双, 等. 结构机构可靠性及可靠性灵敏度分析[M]. 北京: 科学出版社, 2009. |

| 11 | 郑财, 黄贤振, 胡明伟, 等. 三轴数控机床加工精度可靠性分析[J]. 机床与液压, 2017, 45(15): 180-183, 160. |

| Zheng Cai, Huang Xian-zhen, Hu Ming-wei, et al. Three axis NC machine tool machining accuracy reliability analysis[J]. Machine Tool & Hydraulics, 2017, 45(15): 180-183, 160. | |

| 12 | Zhang Zi-ling, Cai Li-gang, Cheng Qiang, et al. A geometric error budget method to improve machining accuracy reliability of multi-axis machine tools[J]. Journal of Intelligent Manufacturing, 2019, 30(2): 495-519. |

| 13 | 余治民, 刘子建, 艾彦迪, 等. 大型数控龙门导轨磨床几何误差建模与基于可靠性理论的精度分配[J]. 机械工程学报, 2013, 17: 142-151. |

| Yu Zhi-min, Liu Zi-jian, Ai Yan-di, et al. Geometric error model and precision distribution based on reliability theory for large CNC gantry guideway grinder[J]. Journal of Mechanical Engineering, 2013, 17: 142-151. | |

| 14 | 孙志礼,张义民,何雪浤,等. 数控机床性能分析及可靠性设计技术[M]. 北京: 机械工业出版社, 2011. |

| 15 | Cheng Qiang, Zhao Hong-wei, Zhao Yong-sheng, et al. Machining accuracy reliability analysis of multi-axis machine tool based on Monte Carlo simulation[J]. Journal of Intelligent Manufacturing, 2018, 29(1): 191-209. |

| 16 | Zhang Zi-ling, Cheng Qiang, Qi Bao-bao, et al. A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and monte carlo method[J]. Journal of Manufacturing Systems, 2021, 60: 553-568. |

| 17 | Zhang Zi-ling, Liu Zhi-feng, Cheng Qiang, et al. An approach of comprehensive error modeling and accuracy allocation for the improvement of reliability and optimization of cost of multi-axis NC machine tool[J]. The International Journal of Advanced Manufacturing Technology, 2016, 89(1): 561-579. |

| 18 | 张明. 结构可靠度分析: 方法与程序[M]. 北京: 科学出版社, 2009. |

| 19 | Cheng Qiang, Wu Can, Gu Pei-hua, et al. An analysis methodology for stochastic characteristic of volumetric error in multiaxis CNC machine tool[J]. Mathematical Problems in Engineering, 2013(11): 863283. |

| 20 | Abdul W K. Calibration of 5-axis machine tools[D]. Beijing: School of Mechanical Engineering and Automation, Beihang University, 2010. |

| 21 | 陈传海, 姚国祥, 金桐彤, 等. 基于响应面与遗传算法的主轴系统动力学建模及参数修正[J/OL]. [2021-08-10]. . |

| [1] | Chuan-hai CHEN,Cheng-gong WANG,Zhao-jun YANG,Zhi-feng LIU,Hai-long TIAN. Research status and development trend analysis of reliability modeling of CNC machine tools [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. |

| [2] | Yu-xuan WEI,Ming ZHANG,Jia LIU,Shuo LIU,Ming-yu LU,Hong-yu WANG. Buckling performance of variable stiffness composite cylindrical shells based on mode imperfections [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 91-100. |

| [3] | Xue-zhi YAN,Zi-ting WANG,Xin WANG. Analysis of relationship between baseline length and error transfer in ultrasonic 3D positioning system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1461-1469. |

| [4] | Min-da REN,Lin CONG,Si-lin SUN,Han-qing FENG. Experiment of performance evolution of asphalt mixtures under multiple pore water pressure cycles [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1277-1286. |

| [5] | Kai MA,Bang-hui LI,Kun YANG,Qiao-ling LIU. First and second⁃order sensitivity method of structure static displacement [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 472-477. |

| [6] | Guo-long LI,Xiao-hui TAO,Kai XU,Zhe-yu LI. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 458-467. |

| [7] | Yi JIA,Ren-da ZHAO,Yong-bao WANG,Fu-hai LI. Sensitivity analysis of viscous damper parameters for multi⁃span and long⁃unit continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1871-1883. |

| [8] | CHEN Dong-hui, LYU Jian-hua, LONG Gang, ZHANG Yu-chen, CHANG Zhi-yong. Static rollover stability of semi-mounted agricultural machinery based on ADAMS [J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [9] | LIU Yun, KANG Bing, HOU Tao, WANG Ke, LIU Fu. Optimal initialization-based C-means method [J]. 吉林大学学报(工学版), 2018, 48(1): 306-311. |

| [10] | LUO Shi-dong, BA Xiao-hui, WANG Yun, CHEN Jie. Joint strategy for high sensitivity Galileo E1B/C signal acquisition [J]. 吉林大学学报(工学版), 2017, 47(5): 1617-1624. |

| [11] | YAN Guang, ZHUANG Wei, LIU Feng, ZHU Lian-qing. Preload package and characteristics of a sensitizing effect sensor based Fiber Bragg Grating (FBG) [J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [12] | ZHANG Ze-xing, CHEN Guo-ying, ZONG Chang-fu. Objective evaluation indices of steering performance for EPS based on sensitivity analysis [J]. 吉林大学学报(工学版), 2015, 45(4): 1043-1048. |

| [13] | KE Jun, CHENG Zhi-yong, SHI Wen-ku, SHI Teng, ZHANG Yi-jing, GUO Fu-xiang. Modal analysis and structure optimization of bus floor based on floor vibration control [J]. 吉林大学学报(工学版), 2015, 45(3): 719-725. |

| [14] | GAO Yin-han, AN Zhan-yang, WANG Ju-xian, WANG Tian-hao, LIU Chang-ying, ZHANG Jun-dong. Application of equivalent cable bundle method in time domain radiation sensitivity of automotive cable harness [J]. 吉林大学学报(工学版), 2015, 45(3): 946-952. |

| [15] | CHEN Shu-ming, PENG Deng-zhi, WANG Deng-feng, LIANG Jie. Structural-acoustic coupling and optimal experimental design for automotive interior low frequency noise [J]. 吉林大学学报(工学版), 2014, 44(6): 1550-1556. |

|

||