Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (6): 2007-2012.doi: 10.13229/j.cnki.jdxbgxb20200627

Phase transformation and magnetic properties of MnBi alloys by sintered and quenched

Yuan-long E( ),Hong-sheng JIA(

),Hong-sheng JIA( ),Xin-xuan YANG,Dong-fei LI,Mei LIU,Hai-bo LI

),Xin-xuan YANG,Dong-fei LI,Mei LIU,Hai-bo LI

- Key Laboratory of Functional Materials Physics and Chemistry,Ministry of Education,Jilin Normal University,Siping 136000,China

CLC Number:

- TM273

| 1 | 李海波,张玉梅,刘梅,等. FePt/Ag薄膜的结构和磁性[J]. 吉林大学学报:工学版,2010, 40(6):1572-1576. |

| Li Hai-bo, Zhang Yu-mei, Liu Mei, et al. Structure and magnetic properties of FePt/Ag thin film[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(6):1572-1576. | |

| 2 | Nguyen T X, Vuong O K T, Nguyen H T, et al. Preparation and magnetic properties of MnBi/Co nanocomposite magnets[J]. Journal of Electronic Materials, 2017, 46(6):3359-3366. |

| 3 | Ito M, Tanaka Y, Satoh T, et al. Magnetic properties and structure of low temperature phase MnBi with island structure[J]. AIP Advances, 2017, 7(5):No.056226. |

| 4 | Kim S, Moon H, Jung H, et al. Magnetic properties of large-scaled MnBi bulk magnets[J]. Journal of Alloys and Compounds, 2017, 708:1245-1249. |

| 5 | Cao S, Yue M, Yang Y X, et al. Magnetic properties and thermal stability of MnBi/NdFeB hybrid bonded magnets[J]. Journal of Applied Physics, 2011, 109(7): No.07A740. |

| 6 | Jensen B A, Tang W, Liu X B, et al. Optimizing composition in MnBi permanent magnet alloys[J]. Acta Materialia, 2019, 181:595-602. |

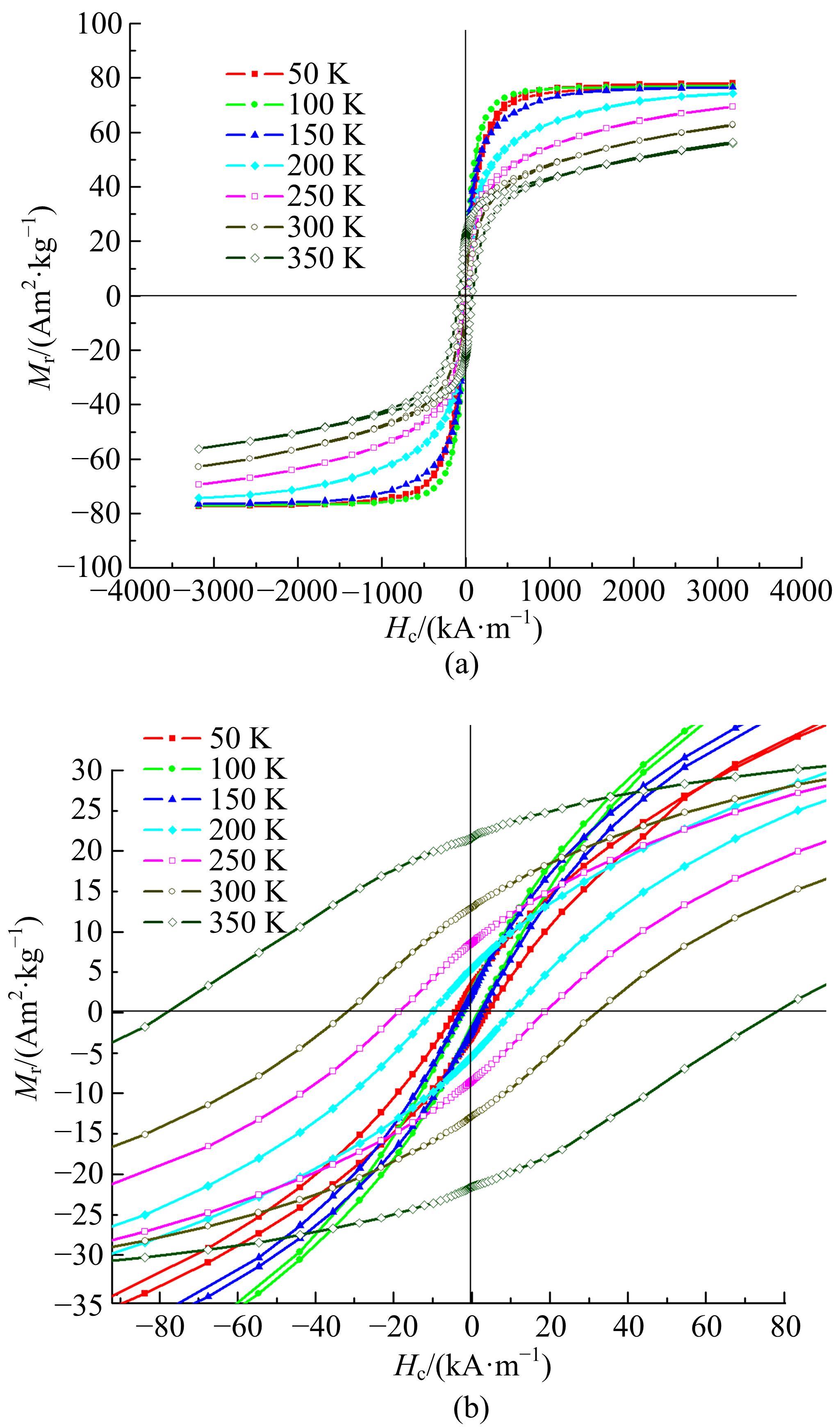

| 7 | Huang Y L, Shi Z Q, Hou Y H, et al. Microstructure, improved magnetic properties, and recoil loops characteristics for MnBi alloys[J]. Journal of Magnetism and Magnetic Materials, 2019, 485:157-164. |

| 8 | Nguyen T X, Nguyen V V. Fabrication of MnBi alloys with high ferromagnetic phase content: effects of heat treatment regimes and dopants[J]. Journal of Materials Science: Materials in Electronics, 2019, 30: 6888-6894. |

| 9 | Cao J, Huang Y L, Hou Y H, et al. Microstructure and magnetic properties of MnBi alloys with high coercivity and significant anisotropy prepared by surfactant assisted ball milling[J]. Journal of Magnetism and Magnetic Materials, 2019, 473: 505-510. |

| 10 | Xiang Z, Wang T L, Ma S J, et al. Microstructural evolution and phase transformation kinetics of MnBi alloys[J], Journal of Alloys and Compounds, 2018, 741: 951-956. |

| 11 | 曹俊,黄有林,闫小童,等. MnBi合金的磁性能与回复曲线研究[J]. 功能材料,2018,49(6):6119-6123. |

| Cao Jun, Huang You-lin, Yan Xiao-tong, et al. Magnetic performance and recoil loops characteristics of MnBi alloy[J]. Journal of Functional Materials, 2018, 49(6): 6119-6123. | |

| 12 | 刘泽民,张素银,邵诚,等. 无稀土MnBi永磁合金的研究进展[J]. 科技咨询,2016,14(34):80-84. |

| Liu Ze-min, Zhang Su-yin, Shao Cheng, et al. The research progress of rare-earth free permanent magnetic alloy in MnBi[J]. Science & Technology Information, 2016,14(34): 80-84. | |

| 13 | 张素银,刘泽民,邵成,等. 稀土元素Gd对MnBi合金的微结构与磁性能的影响[J]. 功能材料,2017,48(1):1221-1224, 1229. |

| Zhang Su-yin, Liu Ze-min, Shao Cheng, et al. Effect of rare earth elements Gd doping on microstructure and magnetic properties of MnBi alloy[J]. Journal of Functional Materials, 2017, 48(1): 1221-1224, 1229. | |

| 14 | Kang K, Moodenbaugh A R, Lewis L H. MnBi nanostructures: size dependence of magnetostructural transition and matrix templating[J].Applied Physics Letters, 2007, 90(15):No.153112. |

| 15 | Yang J B, Kamarju K, Yelon W B, et al. Magnetic properties of the MnBi intermetallic compound[J]. Applied Physics Letters, 2001, 79(12): 1846-1848. |

| 16 | Yang J B, Yang Y B, Chen X G, et al. Anisotropic nanocrystalline MnBi with high coercivity at high temperature[J]. Applied Physics Letters, 2011, 99(8):No.082505. |

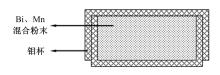

| 17 | 黄潇,李传健,李卫. 粉末混合烧结法制备MnBi永磁合金的研究[J]. 金属功能材料,2006,13(2):14-16. |

| Huang Xiao, Li Chuan-jian, Li Wei. Preparation of MnBi permanent alloy using powder technique[J]. Metallic Functional Materials, 2016, 13(2): 14-16. | |

| 18 | 蒋欢畅,张朋越,葛洪亮,等. 熔淬法制备MnxBi100-x永磁合金的成相过程和磁性能[J]. 磁性材料及器件,2014,45(2):6-8. |

| Jiang Huan-chang, Zhang Peng-yue, Ge Hong-liang, et al. Phase formation behavior and magnetic properties of MnxBi100-x permanent magnetic alloys prepared by melt-spinning[J]. Journal of Magnetic Materials and Devices, 2014, 45(2): 6-8. | |

| 19 | 钟文定,杨正. 锰铋合金在不同热处理后的磁性研究[J]. 物理学报,1962,18(4):188-193. |

| Zhong Wen-ding, Yang Zheng. Magnetic properties of MnBi alloys after different heat treatments[J]. Acta Physica Sinica, 1962, 18(4):188-193. |

| [1] | Fan YANG,Xu-dong ZHANG,Meng ZHAO,Bo SHE,Jun-kai DENG. Deformation behavior of shape memory alloy-metallic glass matrix composites based on finite element calculations [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 172-180. |

| [2] | Chun-zheng DUAN,Fang-yuan ZHANG,Wen-neng KOU,Bin WEI. Martensitic transformation of surface white layer in high speed hard cutting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1575-1583. |

| [3] | YANG Yue, LI Xue, XU Xiao-dan. Microstructure and properties of sintered Ti-B-C-N power [J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

| [4] | JIN Jing-fu, HAN Li-man, CAO Min, LI Yang, QI Ying-chun, CONG Qian. Volume expansion rule of water droplets during freezing process [J]. 吉林大学学报(工学版), 2016, 46(5): 1546-1551. |

| [5] | MA Yun-hai, SHANG Wen-bo, FAN Xue-ying, GAO Zhi-hui, TONG Jin, YAN Zhi-feng, CHANG Zhi-yong. Preparation and degradation of porous β-tricalcium phosphate bioceramic for bone imitaion [J]. 吉林大学学报(工学版), 2015, 45(4): 1367-1374. |

| [6] | ZHUANG Wei-min, XIE Dong-xuan, YU Tian-ming, YU Wan-dong. Numerical simulation of hot forming of high-strength steel based on damage-phase transformation constitutive model [J]. 吉林大学学报(工学版), 2015, 45(4): 1206-1212. |

| [7] | LU Guang-lin, QIU Xiao-ming, BAI Yang, LUN Xin-jie|DENG Bao-qing,REN Lu-qu. Microstructure and performance of c-BN bionic wearresistant composites [J]. 吉林大学学报(工学版), 2011, 41(01): 73-0077. |

| [8] | WANG Yingwei, JIANG Yinshan, HOU Tianyi, ZHANG Jun, ZHANG Yanjun, SUN Shenmei. Effects of Different Milling Manners on TiO2 Powders [J]. 吉林大学学报(工学版), 2005, 35(04): 348-352. |

| [9] | GUO Zuo-xing, LI Guang-yu, GUAN Zhen-zhong, LI Yu-tian . Study on Laser Reactive Sintering of Fe-Al Powder Compacts [J]. 吉林大学学报(工学版), 2003, (1): 28-32. |

|

||