Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (10): 2761-2772.doi: 10.13229/j.cnki.jdxbgxb.20211350

Previous Articles Next Articles

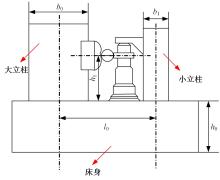

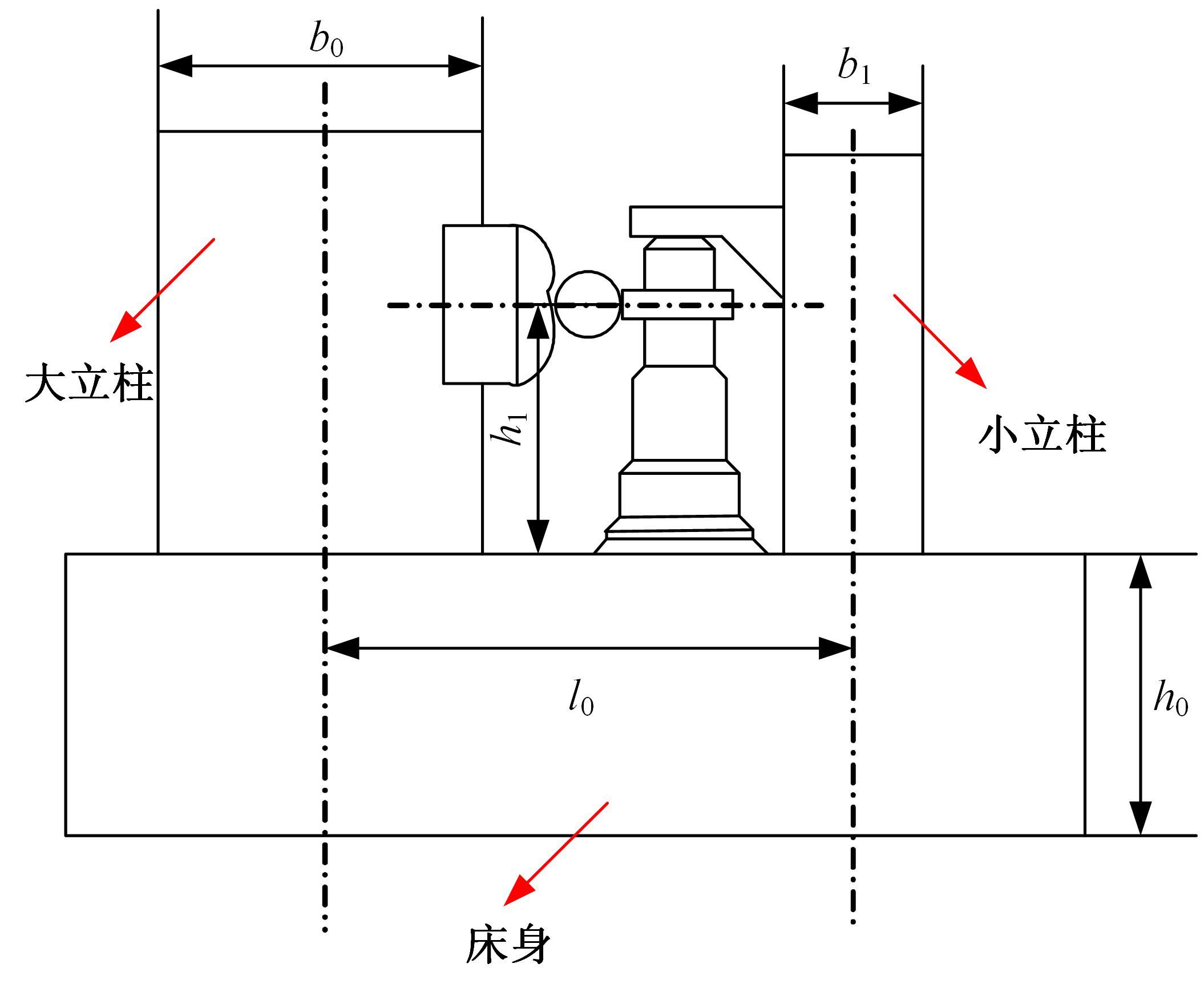

Thermal-force deformation analysis and prediction modeling of CNC gear hobbing machine workbench

Si-bao WANG1,2( ),Zhong-zheng GUO1,2,Chi MA1,2,Shi-long WANG1,2

),Zhong-zheng GUO1,2,Chi MA1,2,Shi-long WANG1,2

- 1.College of Mechanical and Vehicle Engineering,Chongqing University,Chongqing 400044,China

2.State Key Laboratory of Mechanical Transmissions,Chongqing University,Chongqing 400044,China

CLC Number:

- TH161

| 1 | 李国龙, 陶小会, 徐凯, 等. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报: 工学版, 2021, 51(2): 458-467. |

| Li Guo-long, Tao Xiao-hui, Xu Kai,et al. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(2): 458-467. | |

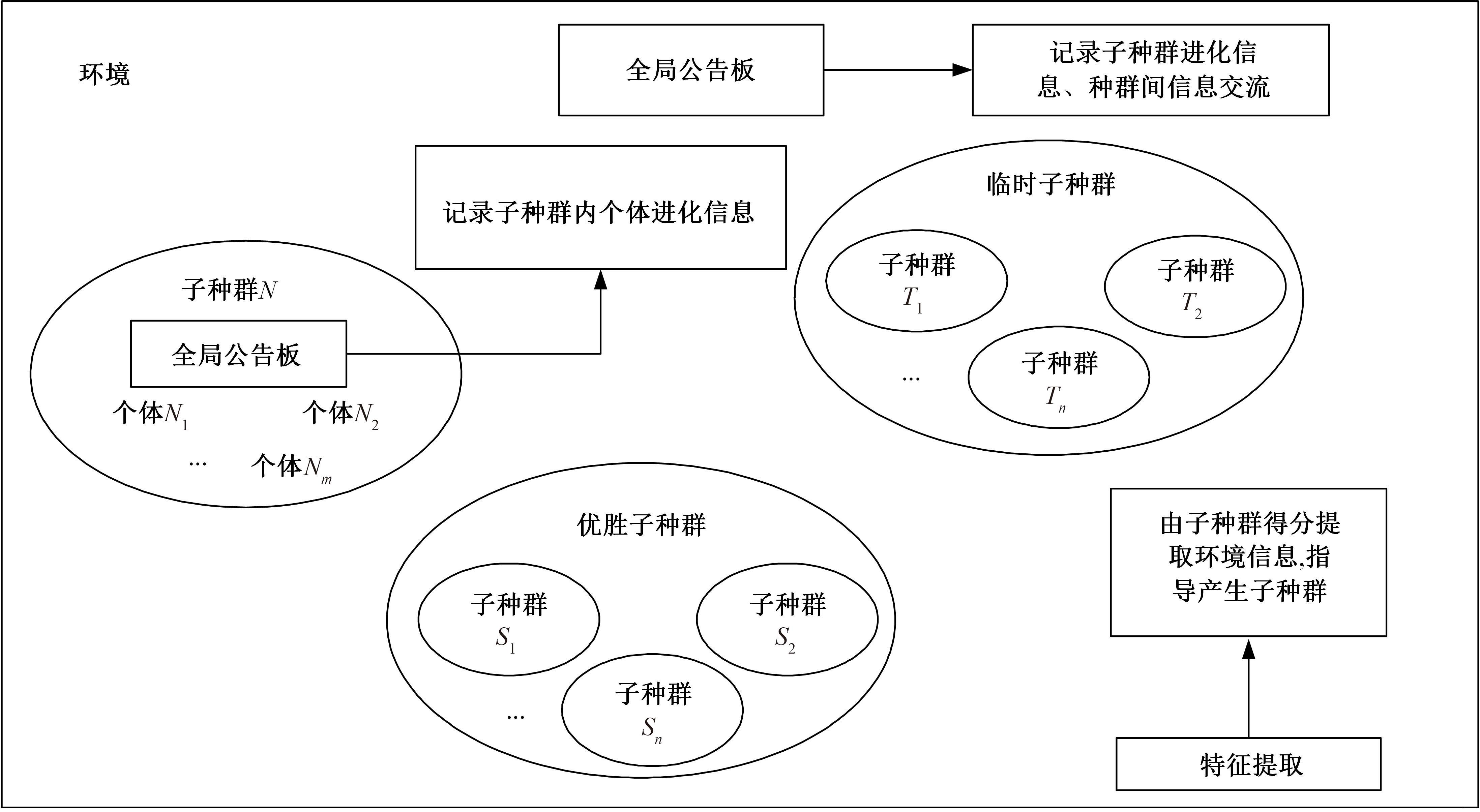

| 2 | 李彬, 张云, 王立平, 等. 基于遗传算法优化小波神经网络数控机床热误差建模[J]. 机械工程学报, 2019, 55(21): 215-220. |

| Li Bin, Zhang Yun, Wang Li-ping,et al. Modeling for CNC machine tool thermal error based on genetic algorithm optimization wavelet neural networks[J]. Journal of Mechanical Engineering, 2019, 55(21): 215-220. | |

| 3 | 郭世杰, 张学炜, 张楠, 等. 机床主轴热关键点选择与典型转速热误差预测[J]. 吉林大学学报: 工学版, 2021, 51(1): 1-10. |

| Guo Shi-jie, Zhang Xue-wei, Zhang Nan, et al. Thermal key point select and error prediction under typical speed of machine tool spindle[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(1): 1-10. | |

| 4 | Liang Y, Su H, Lu L, et al. Thermal optimization of an ultra-precision machine tool by the thermal displacement decomposition and counteraction method[J]. International Journal of Advanced Manufacturing Technology, 2015, 76(1-4): 635-645. |

| 5 | Grama S N, Mathur A, Aralaguppi R, et al. Optimization of high speed machine tool spindle to minimize thermal distortion[J]. Procedia CIRP, 2017, 58:457-462. |

| 6 | 谢杰, 黄筱调, 方成刚, 等. 磨齿机电主轴热特性及热误差建模[J]. 浙江大学学报: 工学版, 2018, 52(2): 247-254. |

| Xie Jie, Huang Xiao-diao, Fang Cheng-gang, et al. Thermal characteristics and thermal error modeling analysis for motorized spindle of gear grinding machine tool[J]. Journal of Zhejiang University(Engineering Science), 2018, 52(2): 247-254. | |

| 7 | Liu Y, Wang X F, Zhu X G, et al. Thermal error prediction of motorized spindle for five-axis machining center based on analytical modeling and BP neural network[J]. Journal of Mechanical Science and Technology, 2021, 35(1): 281-292. |

| 8 | Miao E-M, Gong Y-Y, Niu P-C, et al. Robustness of thermal error compensation modeling models of CNC machine tools[J]. International Journal of Advanced Manufacturing Technology, 2013, 69(9-12): 2593-2603. |

| 9 | Lei M, Jiang G, Yang J, et al. Thermal error modeling with dirty and small training sample for the motorized spindle of a precision boring machine[J]. International Journal of Advanced Manufacturing Technology, 2017, 93(1-4): 571-586. |

| 10 | Xiang S, Yang J. Error map construction and compensation of a NC lathe under thermal and load effects[J]. International Journal of Advanced Manufacturing Technology, 2015, 79(1-4): 645-655. |

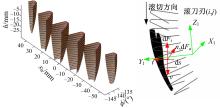

| 11 | Tang Xian-kang, Zhao Jun, Zhang Zi-jian. Model of cutting forces prediction for gear milling considering the three-dimensional undeformed chip thickness, penetration curve and working angles[J]. The International Journal of Advanced Manufacturing Technology, 2022, 118(5/6): 1659-1671. |

| 12 | Umasai K, Venkata M, Pbgsn M. Mechanistic models for prediction of cutting forces and power consumption considering chip geometry[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2020, 235(2): 479-488. |

| 13 | 陈永鹏. 高速干切滚齿多刃断续切削空间成形模型及其基础应用研究[D]. 重庆: 重庆大学机械与运载学院, 2015. |

| Chen Yong-peng. Spatial forming model of high-sppeed dry hobbong by interrupted cutting with multiple-cutting-edge and its application[D]. Chongqing: College of Mechanical and Vehicle Engineering, Chongqing University, 2015. | |

| 14 | Sabkhi N, Pelaingre C, Barlier C, et al. Characterization of the cutting forces generated during the gear hobbing process: spur gear[J]. Procedia CIRP, 2015, 31: 411-416. |

| 15 | Jomaa W, Songmene V, Bocher P. Predictive analytical modeling of cutting forces generated by high-speed machining of ductile and hard metals[J]. Machining Science and Technology, 2017, 21(3): 335-361. |

| 16 | 黄颖旭, 李波, 田锡天. 基于主轴电流的铣削力间接监测方法[J]. 计算机集成制造系统, 2022, 28(1): 93-101. |

| Huang Ying-xu, Li Bo, Tian Xi-tian. Indirect monitoring method of milling force based on spindle current[J]. Computer Integrated Manufacturing Systems, 2022, 28(1): 93-101. | |

| 17 | Mostaghimi H, Park C I, Kang G, et al. Reconstruction of cutting forces through fusion of accelerometer and spindle current signals[J]. Journal of Manufacturing Processes, 2021, 68: 990-1003. |

| 18 | Panagiotis S, Harry B, Thanassis S, et al. A method for cutting force estimation through joint current signals in robotic machining[J]. Procedia Manufacturing, 2021, 55: 124-131. |

| 19 | Yamada Y, Kakinuma Y. Mode decoupled cutting force monitoring by applying multi encoder based disturbance observer[J]. Procedia CIRP, 2016, 57:643-648. |

| 20 | 王国权. 数控滚齿机动态误差补偿技术研究[D]. 合肥:合肥工业大学机械工程学院, 2015. |

| Wang Guo-quan.The Dynamic Error Compensating Technology Research of CNC Gear Hobbing Machine[D]. Hefei: College of Mechanical Engineering,Hefei University of Technology, 2015. | |

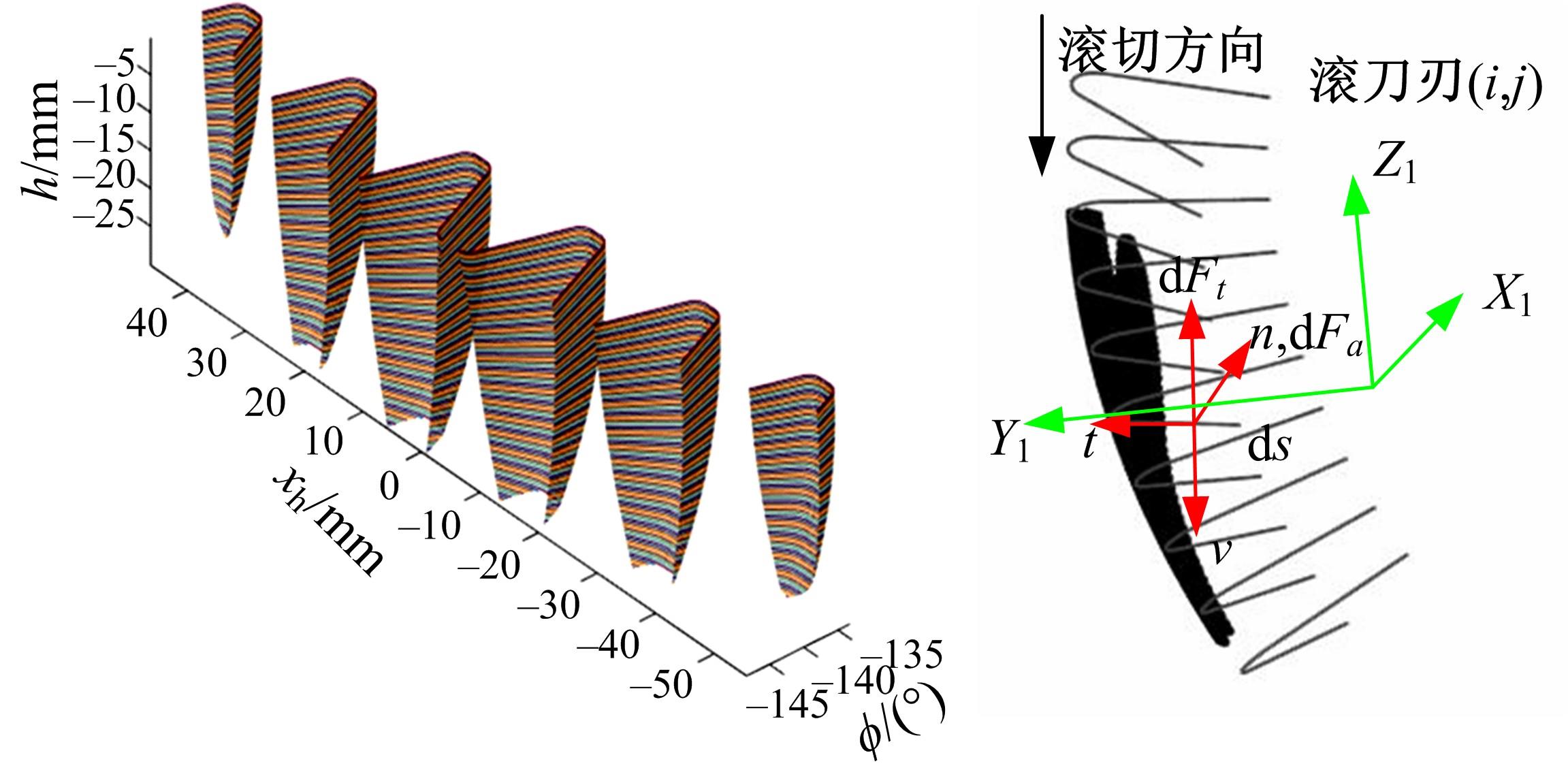

| 21 | 李根, 李文辉. 基于思维进化算法的人脸特征点跟踪[J]. 吉林大学学报:工学版, 2015, 45(2): 606-612. |

| Li Gen, Li Wen-hui. Facial feature tracking on mind evolutionary algorithm[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(2): 606-612. |

| [1] | Shi-jie GUO,Xue-wei ZHANG,Nan ZHANG,Guan QIAO,Shu-feng TANG. Thermal key point select and error prediction under typical speed of machine tool spindle [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 72-81. |

| [2] | LYU Feng, YANG Yin-sheng, GUO Chang-qing. New approach of criticality analysis of equipment based on improved fuzzy matter-element model [J]. 吉林大学学报(工学版), 2014, 44(01): 111-116. |

| [3] | YAN Zhan-hui, YU Jun-yi . The Survey of Thermal Deformation for Machine Tools [J]. 吉林大学学报(工学版), 2001, (3): 95-97. |

|

||