Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (8): 2410-2420.doi: 10.13229/j.cnki.jdxbgxb.20211121

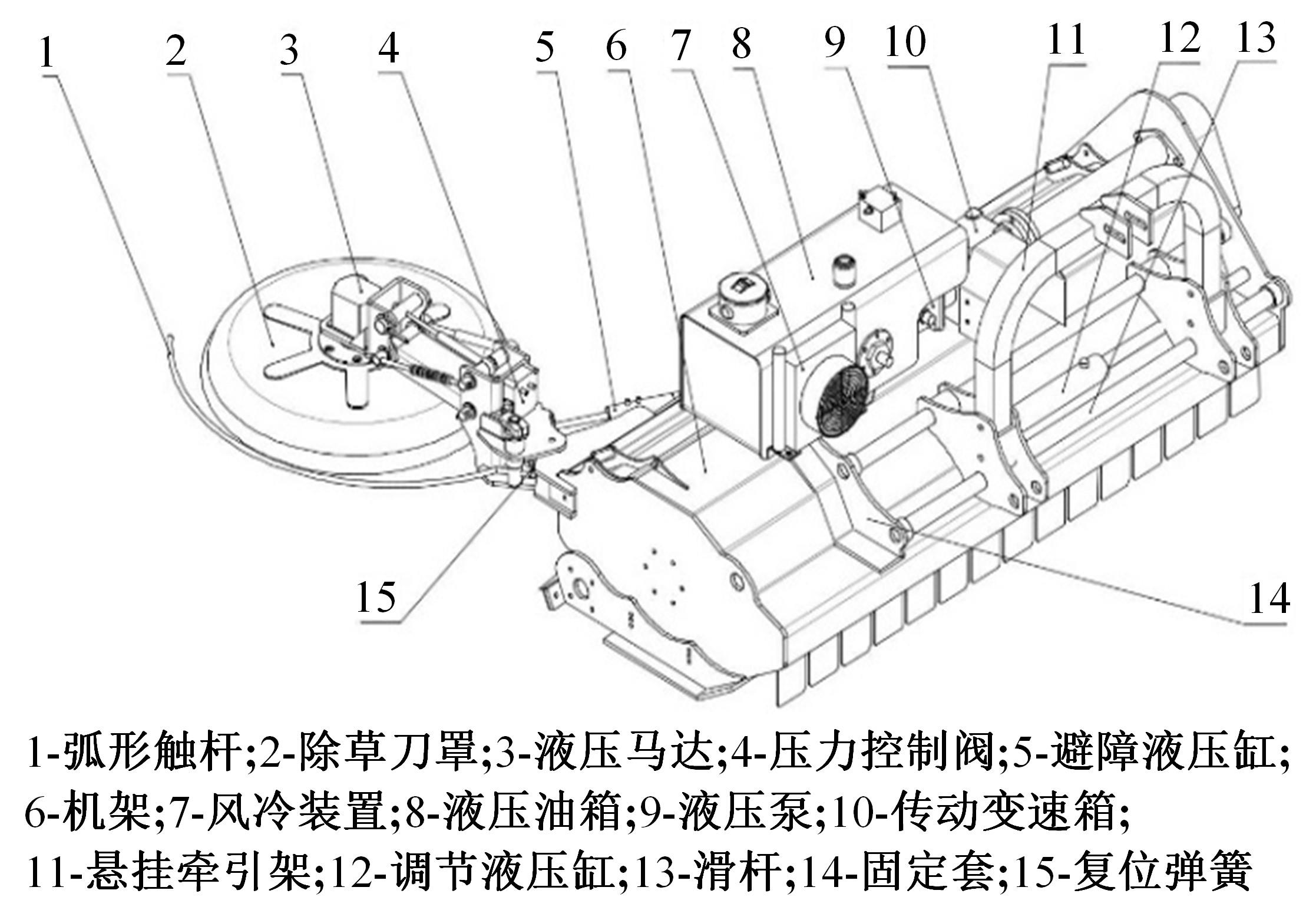

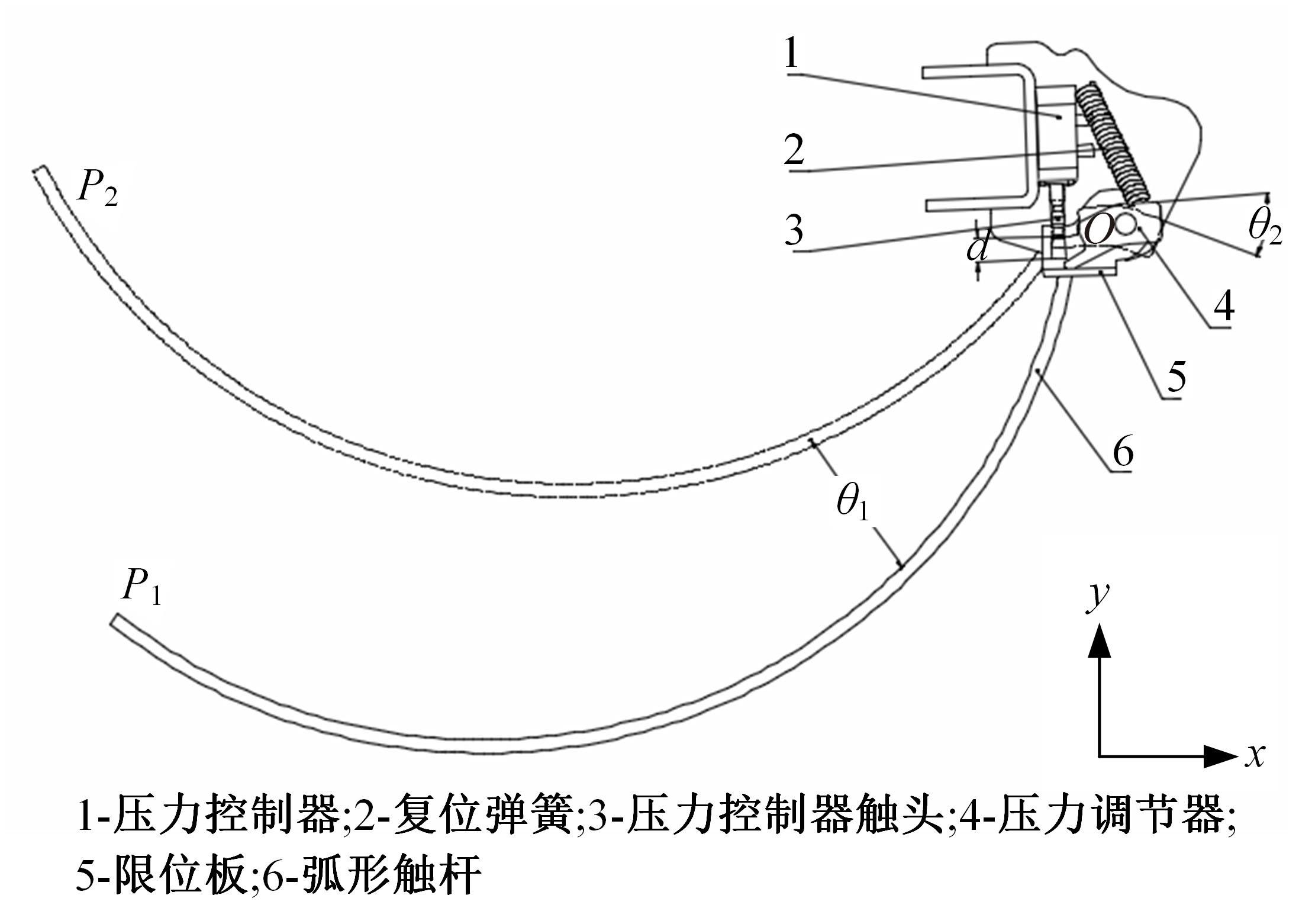

Design and experiment of obstacle avoidance weeding machine for fruit trees

Yong-shuo WANG1( ),Jian-ming KANG1(

),Jian-ming KANG1( ),Qiang-ji PENG1,Ying-kai CHEN2,Hui-min FANG1,Meng-meng NIU1,Shao-wei WANG1

),Qiang-ji PENG1,Ying-kai CHEN2,Hui-min FANG1,Meng-meng NIU1,Shao-wei WANG1

- 1.Shandong Academy of Agricultural Machinery Science,Jinan 250110,China

2.Shandong Academy of Agricultural Sciences,Jinan 250110,China

CLC Number:

- S224.1

| 1 | 于威,韩晓梅. 现代化果园机械除草装备与技术应用现状及发展趋向[J].现代农村科技, 2017(6): 97. |

| Yu Wei, Han Xiao-mei. The application status and development trend of modern orchard mechanical weeding equipment and technology[J]. Modern Rural Science and Technology, 2017(6): 97. | |

| 2 | 王奇,周文琪,唐汉,等. 弧齿往复式稻田株间自动避苗除草装置设计与试验[J].农业机械学报,2021, 52(6): 53-61, 72. |

| Wang Qi, Zhou Wen-qi, Tang Han, et al. Design and experiment of arc-tooth reciprocating motion type seedling avoided weeding control device for intertillage paddy[J]. Transactions of the Chinese Society for Agricaltulal Machinery, 2021, 56(6): 53-61, 72. | |

| 3 | Terpstra R, Kouwenhoven J K. Inter-row and intra-row weed-control with a hoe-ridger[J]. Journal of Agricultural Engineering Research, 1981, 26(2): 127-134. |

| 4 | Melander B. Intelligent versus non-intelligent mechanical intra-row weed control in transplanted onion and cabbage[J]. Crop Protection,2015, 72: 1-8. |

| 5 | Norremark M. The development and assessment of the accuracy of an autonomous GPS-based system for intra-row mechanical weed control in row crops[J]. Biosystems Engineering, 2008, 101(4): 396-410. |

| 6 | Norremark M. Evaluation of an autonomous GPS-based systemfor intra-row weed control by assessing the tilled area[J]. Precision Agriculture, 2012, 13(2): 149-162. |

| 7 | Cordill C, Grift T E. Design and testing of an intra-row mechanical weeding machine for corn[J]. Biosystems Engineering, 2011, 110(3): 247-252. |

| 8 | 陈振歆,王金武,牛春亮,等. 弹齿式苗间除草装置关键部件设计与试验[J]. 农业机械学报,2010,41(6): 81-86. |

| Chen Zhen-xin, Wang Jin-wu, Niu Chun-liang, et al. Design and experiment of key components of trash cultivator's working in paddy rice seeding lines[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(6): 81-86. | |

| 9 | 杨松梅,王金武,刘永军,等. 水田株间立式除草装置的设计[J]. 农机化研究,2014, 36(12): 154-157. |

| Yang Song-mei, Wang Jin-wu, Liu Yong-jun, et al. Design and simulation analysis of vertical weed control device between seedlings in paddy field[J]. Journal of Agricultural Mechanization Research, 2014, 36(12): 154-157. | |

| 10 | 韩豹,申建英,李悦梅. 3ZCF-7700 型多功能中耕除草机设计与试验[J]. 农业工程学报,2011, 27(1): 124-129. |

| Han Bao, Shen Jian-ying, Li Yue-mei. Design and experiment of 3ZCF-7700 multi-functional weeding-cultivating machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(1): 124-129. | |

| 11 | 张朋举,张纹,陈树人,等. 八爪式株间机械除草装置虚拟设计与运动仿真[J]. 农业机械学报,2010,41(4): 56-59. |

| Zhang Peng-ju, Zhang Wen, Chen Shu-ren, et al. Virtual design and kinetic simulation for eight claw intra-row mechanical weeding device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(4): 56-59. | |

| 12 | 陈树人,张朋举,尹东富,等. 基于LabVIEW的八爪式机械株间除草装置控制系统[J]. 农工程学报,2010, 26(): 234-237. |

| Chen Shu-ren, Zhang Peng-ju, Yin Dong-fu, et al. Control system of eight claw intra-row mechanical weeding device based on LabVIEW[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(Sup.2): 234-237. | |

| 13 | 胡炼,罗锡文,张智刚,等. 株间除草装置横向偏移量识别与作物行跟踪控制[J]. 农业工程学报,2013,29(14): 8-14. |

| Hu Lian, Luo Xi-wen, Zhang Zhi-gang, et al. Side-shift offset identification and control of crop row tracking for intra-row mechanical weeding[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(14): 8-14. | |

| 14 | 陈子文,李南,孙哲,等. 行星刷式株间锄草机械手优化与试验[J]. 农业机械学报,2015, 46(9): 94-99. |

| Chen Zi-wen, Li Nan, Sun Zhe, et al. Optimization and experiment of intra-row brush weeding manipulator based on planetary gear train[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(9): 94-99. | |

| 15 | 余涛,蔡晓华,赵德春,等. 智能苗间锄草平台设计[J].农机化研究,2013, 35(11): 30-34. |

| Yu Tao, Cai Xiao-hua, Zhao De-chun, et al. Design of intelligent weeding platform between seedlings[J]. Journal of Agricultural Mechanization Research, 2013, 35(11): 30-34. | |

| 16 | 丛茜,徐金,马博帅,等.基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J].吉林大学学报:工学版,2021, 51(2): 754-760. |

| Cong Qian, Xu Jin, Ma Bo-shuai, et al. Design and test of tractor hydraulic suspension system testing device based on virtual simulation[J]. Journal of Jilin University (Engineering and Technology Edition),2021, 51(2): 754-760. | |

| 17 | 王新彦,江泉,吕峰,等.基于参数化模型的零转弯半径割草机侧翻稳定性[J].吉林大学学报:工学版,2021, 51(5): 1908-1918. |

| Wang Xin-yan, Jiang Quan, Lv Feng, et al. Rollover stability of zero turning radius lawn mower based on parametric model[J]. Journal of Jilin University (Engineering and Technology Edition),2021, 51(5): 1908-1918. | |

| 18 | 于畅畅,徐丽明,王庆杰,等. 篱架式栽培葡萄双边作业株间自动避障除草机设计与试验[J].农业工程学报,2019, 35(5): 1-9. |

| Yu Chang-chang, Xu Li-ming, Wang Qing-jie, et al. Design and experiment of bilateral operation intra-row auto obstacle avoidance weeder for trellis cultivated grape[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(5): 1-9. | |

| 19 | 张圣,骆艳洁. 液压系统节能设计[J]. 机床与液压,2007(1): 151-152, 108. |

| Zhang Sheng, Luo Yan-jie. Energy-saving design of hydraulic system[J]. Machine Tool and Hydraulics, 2007(1): 151-152, 108. | |

| 20 | 长广仁藏.旋耕拖拉机基本设计理论[M].北京:机械工业出版社,1978. |

| 21 | 胡友民,杜润生,杨叔子. 液压系统运行状态监测[J]. 液压与气动, 2002(8): 35-37. |

| Hu You-min, Du Run-sheng, Yang Shu-zi. Operation status monitoring of hydraulic system[J]. Hydraulics and Pneumatics, 2002(8): 35-37. | |

| 22 | 郭卫东,李守忠,马璐. ADAMS2013应用实例精解教程[M]. 北京:机械工业出版社,2010. |

| 23 | 李增刚. ADAMS 入门详解与实例[M]. 北京:国防工业出版社,2006. |

| 24 | 康建明,彭强吉,王士国,等. 弹齿式残膜回收机捡拾装置改进设计与试验[J].农业机械学报,2018,49(): 295-303. |

| Kang Jian-ming, Peng Qiang-ji, Wang Shi-guo, et al. Design and experiment on pickup unit of spring-tooth residual plastic film collector[J].Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1): 295-303. | |

| 25 | 彭强吉,李成松,康建明,等. 气力式圆筒筛膜杂分离机改进设计与试验[J].农业机械学报,2020, 51(8):126-135. |

| Peng Qiang-ji, Li Cheng-song, Kang Jian-ming, et al. Improved design and test on pneumatic cylinder sieve film hybrid separator[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(8): 126-135. |

| [1] | Feng LYU,Nian LI,Zhuang-zhuang FENG,Yang-hang ZHANG. Method of collaborative filtering recommendation of personalized product-service system based on user [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1935-1942. |

| [2] | Bin WANG,Bing-hui HE,Na LIN,Wei WANG,Tian-yang LI. Tea plantation remote sensing extraction based on random forest feature selection [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1719-1732. |

| [3] | Duan-yang GENG,Yan-cheng SUN,Xiao-dong MU,Guo-dong ZHANG,Hui-xin JIANG,Jun-ke ZHU. Simulation test and optimization of grain breakage of silage maize based on differential roller [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 693-702. |

| [4] | Chang-kai WEN,Bin XIE,Zheng-he SONG,Jian-gang HAN,Qian-wen YANG. Design method of tractor durability accelerated structure test [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 703-715. |

| [5] | Guo-wei WANG,Qing-hui ZHU,Hai-ye YU,Dong-yan HUANG. Silage traceability system based on digital agricultural machinery equipment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 242-252. |

| [6] | Fang LIANG,De-cheng WANG,Yong YOU,Guang-hui WANG,Yu-bing WANG,Xiao-ming ZHANG,Jin-kui FENG. Design and experiment of root-cutter with fertilization and reseeding compound remediation machine for grassland [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 231-241. |

| [7] | Xin-yan WANG,Quan JIANG,Feng LYU,Zheng-yang YI. Rollover stability of zero turning radius lawn mower based on parametric model [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1908-1918. |

| [8] | Qian CONG,Jin XU,Bo-shuai MA,Xiao-chao ZHANG,Ting-kun CHEN. Design and test of tractor hydraulic suspension system testing device based on virtual simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 754-760. |

| [9] | Chao CHENG,Jun FU,Zhi CHEN,Lu-quan REN. Sieve blocking laws and stripping test of corn grain harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. |

| [10] | Xue-shen CHEN,Zhu-jian HUANG,Xu MA,Long QI,Gui-jin FANG. Design and test of control system for rice mechanical weeding and seedling-avoiding control [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 386-396. |

| [11] | En-ze LIU,Wen-fu WU. Monochrome fruit growth detection internet architecture based oncomprehensive indicator quality evaluation algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2019-2026. |

| [12] | Jia⁃hao QIN,Zhen LI,Muneshi MITSUOKA,Eiji INOUE,Zheng⁃he SONG,Zhong⁃xiang ZHU. Significance variation of factorial effects on tractor stability employing scale⁃model⁃based experimental approach [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1236-1245. |

| [13] | Fang LIANG,Yong YOU,De‑cheng WANG,Guang‑hui WANG,Chang‑bin HE,Shuai LI. Effect of dynamic parameters on relationship between root‑cutting blade and soil in grassland [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 903-911. |

| [14] | WANG Yang, WANG Xiao-mei, CHEN Ze-ren, YU Jian-qun. Modeling method of maize kernels based on discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [15] | CHEN Dong-hui, LYU Jian-hua, LONG Gang, ZHANG Yu-chen, CHANG Zhi-yong. Static rollover stability of semi-mounted agricultural machinery based on ADAMS [J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

|

||