Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (7): 1892-1901.doi: 10.13229/j.cnki.jdxbgxb.20211038

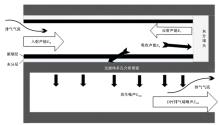

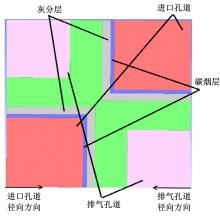

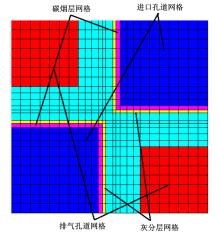

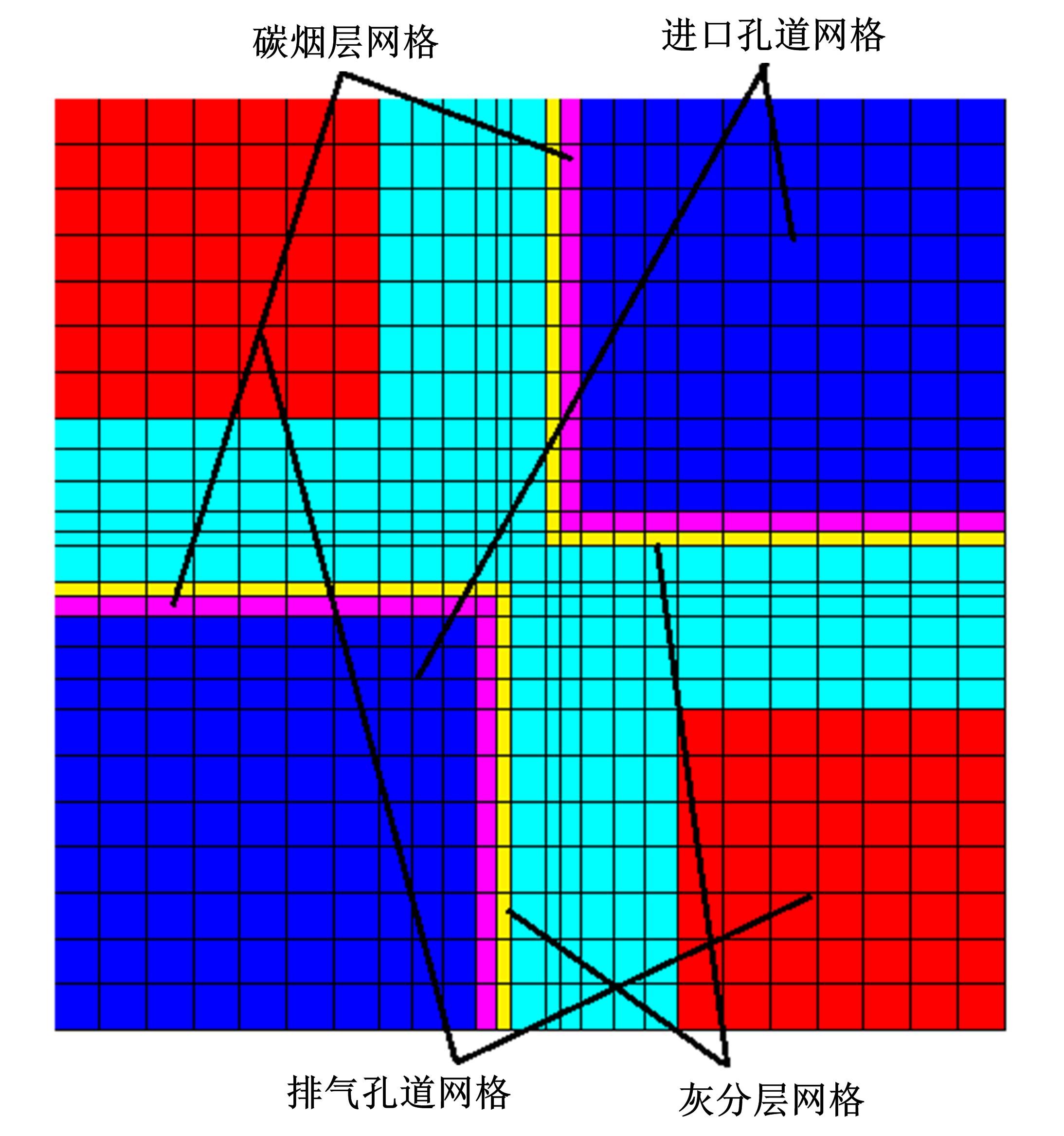

Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment

Gui-sheng CHEN1,2( ),Guo-yan LUO1,2,Liang-xue LI1,2,Zhen HUANG1,2(

),Guo-yan LUO1,2,Liang-xue LI1,2,Zhen HUANG1,2( ),Yi LI3

),Yi LI3

- 1.College of Transportation Engineering,Kunming University of Science and Technology,Kunming 650500,China

2.Yunnan Key Laboratory of Internal Combustion Engine,Kunming University of Science and Technology,Kunming 650500,China

3.Yunnan Filter Environment Protection Science & Technology Corporation Limited,Kunming 650300,China

CLC Number:

- TK442

| 1 | Lee S H, Kwak J H, Lee S Y, et al. On-road chasing and laboratory measurements of exhaust particle emissions of diesel vehicles equipped with aftertreatment technologies (DPF, urea-SCR) [J]. International Journal of Automotive Technology, 2015, 16(4): 551-559. |

| 2 | Yamamoto K, Sakai T. Simulation of continuously regenerating trap with catalyzed DPF[J]. Catalysis Today, 2015, 242: 357-362. |

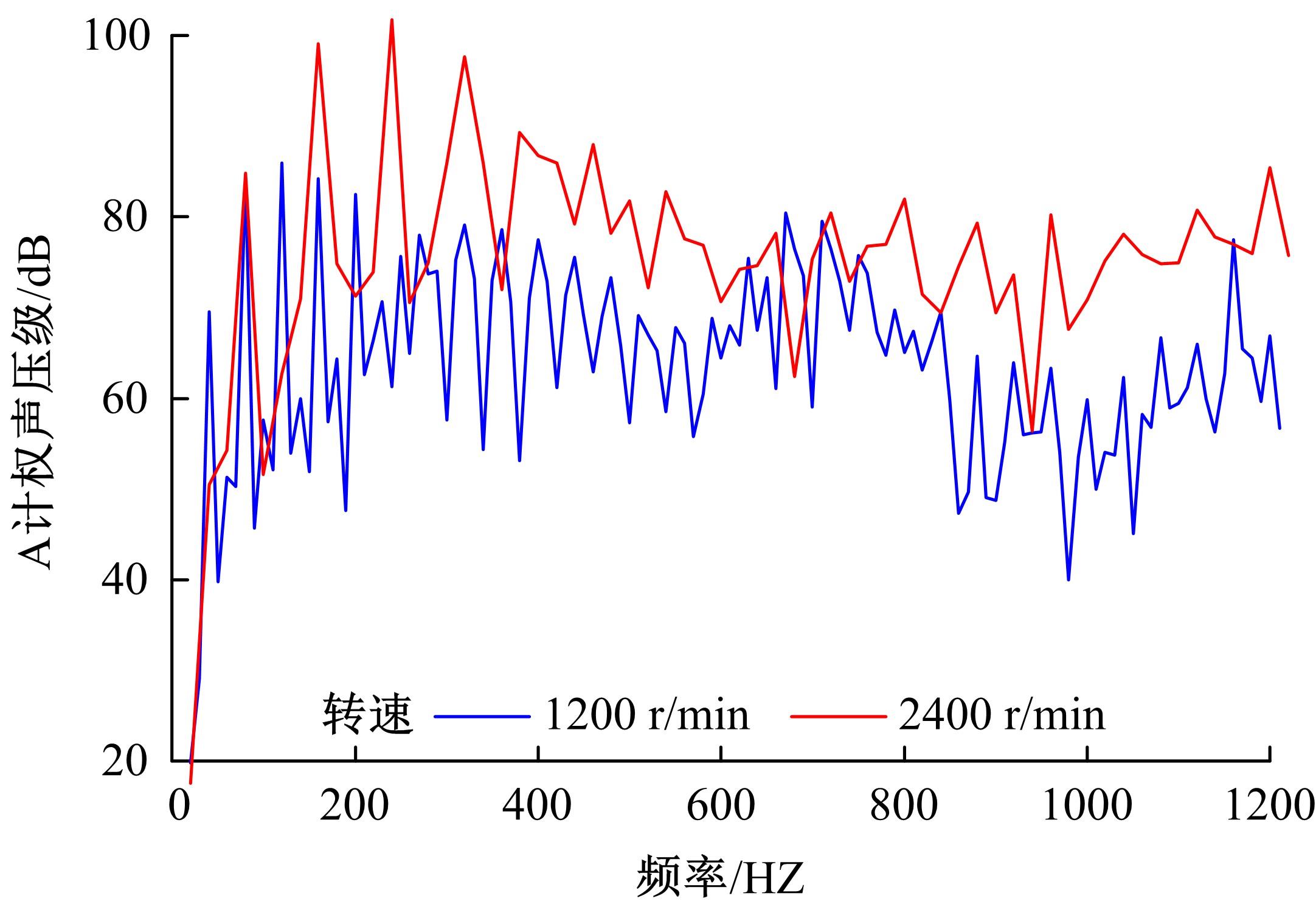

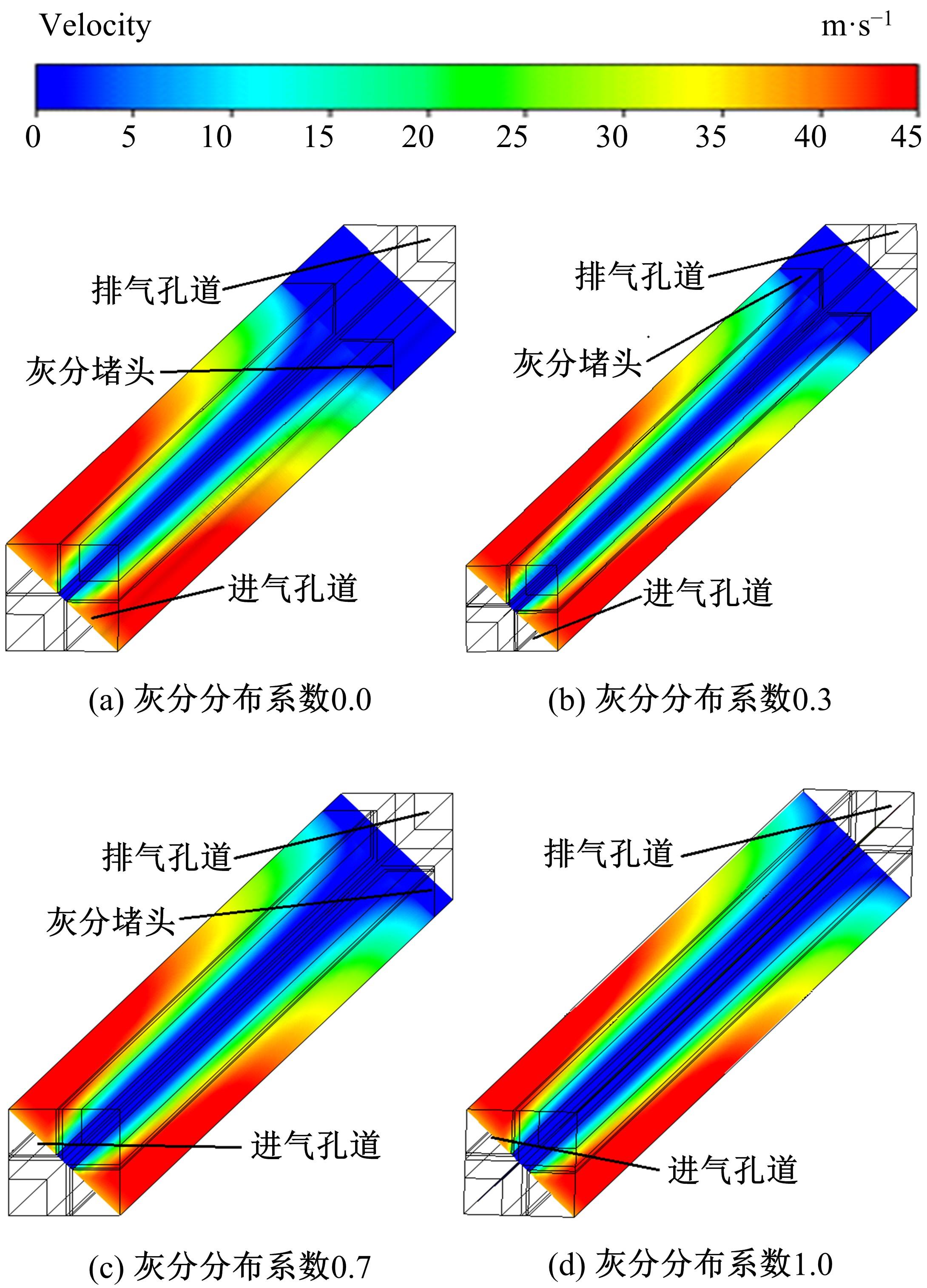

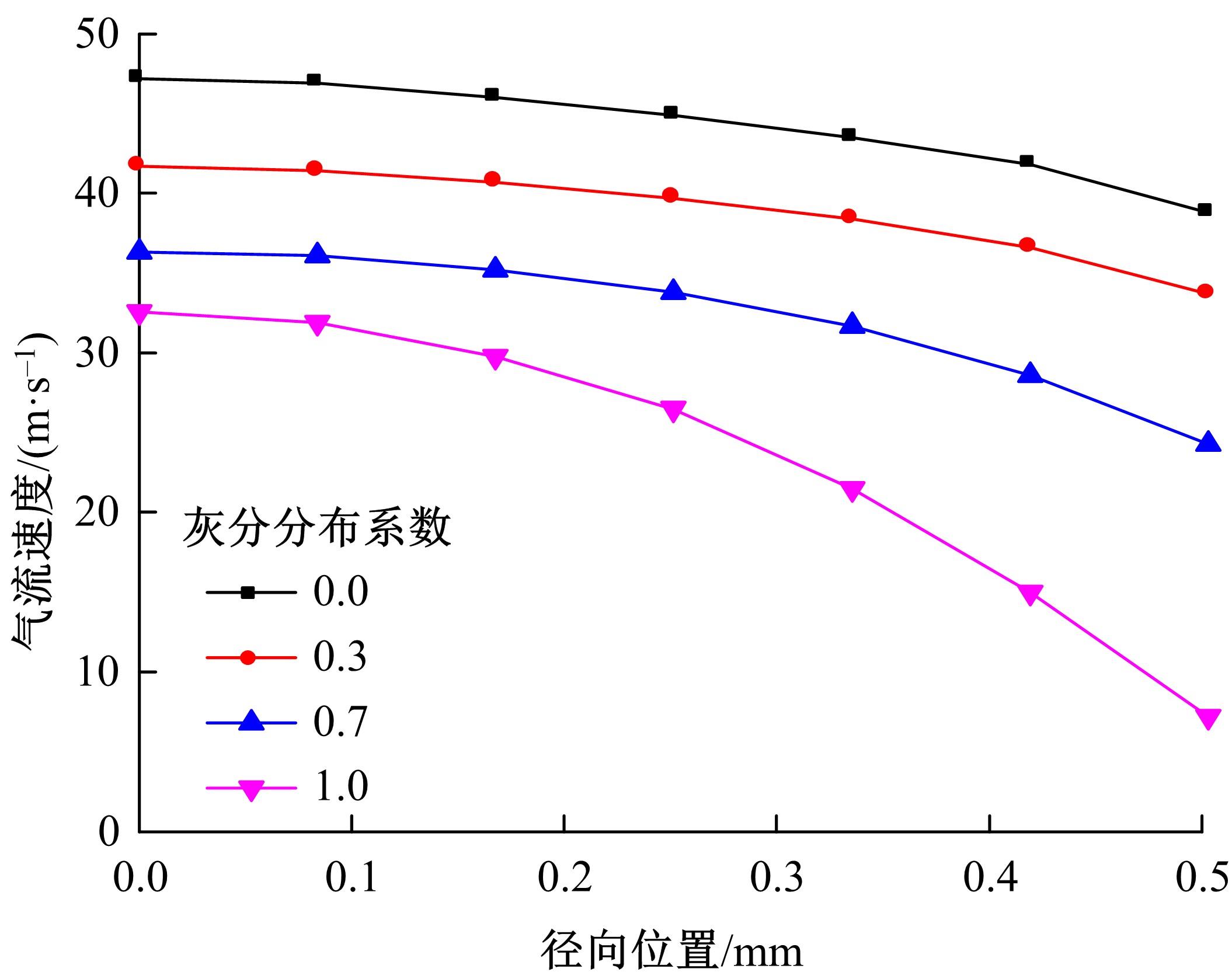

| 3 | 李志军, 侯普辉, 焦鹏昊, 等. DPF孔道内流场及微粒沉积特性的数值模拟[J]. 天津大学学报:自然科学与工程技术版,2015, 48(10): 914-920. |

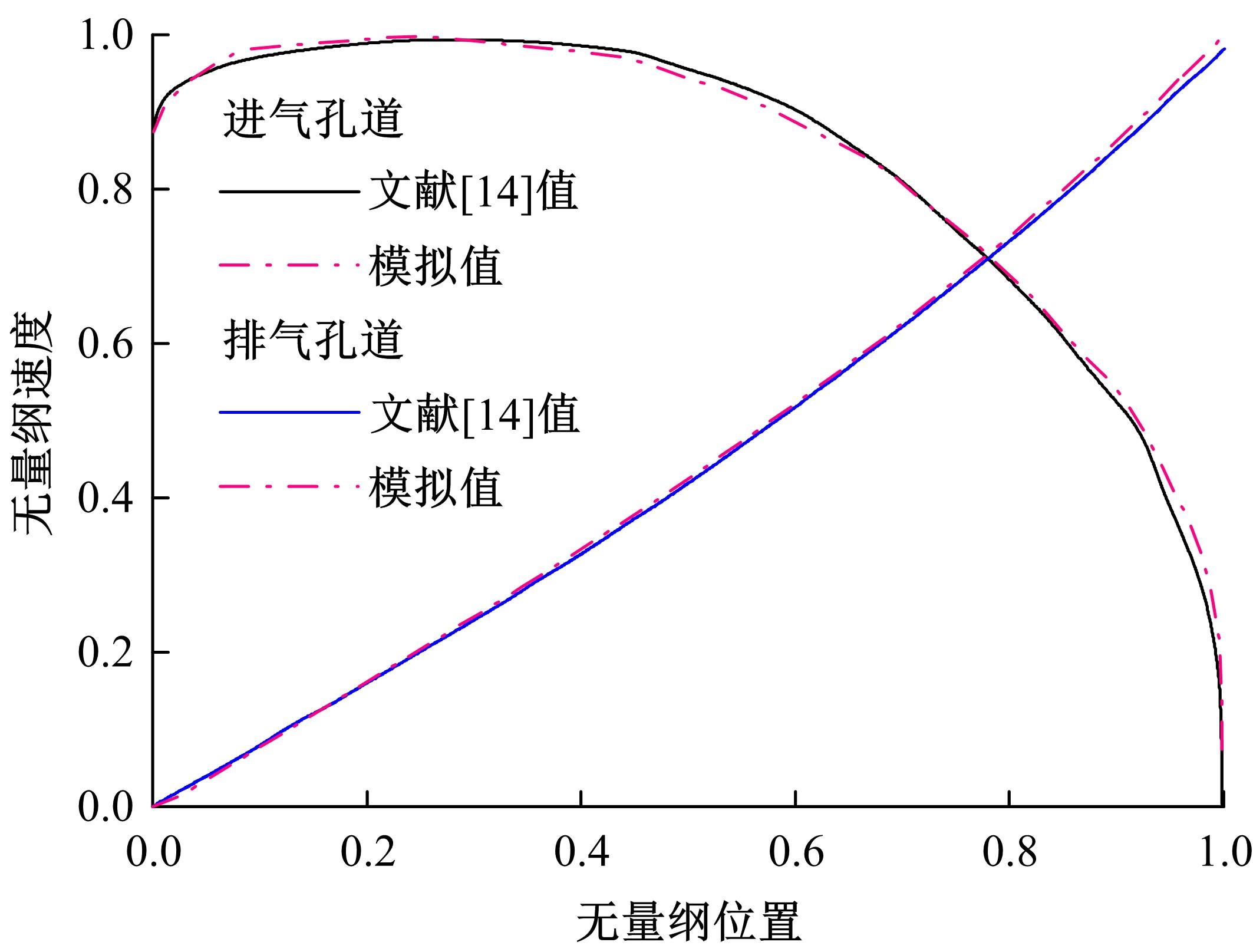

| Li Zhi-jun, Hou Pu-hui, Jiao Peng-hao, et al. Numerical Simulation for Flow and Soot A- ccumulation in the Channels of Diesel Particulate Filter[J] Journal of Tianjin University(Science and Technology), 2015, 48(10): 914-920. | |

| 4 | 李志军, 王楠, 张立强, 等.柴油机微粒捕集器非对称孔道内流场和压降特性模拟[J]. 吉林大学学报:工学版, 2016, 46(6): 1892-1899. |

| Li Zhi-jun, Wang Nan, Zhang Li-qiang, et al. Numerical simulation for flow and pressure drop characteristics in asymmetrical channels of diesel particulate filter[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(6): 1892-1899. | |

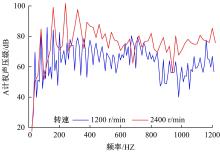

| 5 | 李冰, 李靓雪, 陈贵升, 等. 柴油机DPF孔道气相流场及噪声特性分析[J]. 内燃机学报, 2021, 39(3): 265-272. |

| Li Bing, Li Liang-xue, Chen Gui-sheng, et al. Analysis of gas phase flow in channels and its noise characteristics for a diesel engine DPF[J]. Transactions of CSICE, 2021, 39(3): 265-272. | |

| 6 | Hua X, Herrin D W, Wu T W, et al. Simulation of diesel particulate filters in large exhaust systems[J]. Applied Acoustics, 2013, 74(12): 1326-1332. |

| 7 | Gao W, Feng L. FEM analysis on acoustic performance of wall flow diesel particulate filters[J]. Chinese Journal of Mechanical Engineering, 2011, 24(4): 701-706. |

| 8 | Montenegro G, Onorati A, Torre D, et al. The 3D cell approach for the acoustic modeling of after-treatment devices[J]. SAE International Journal of Engines, 2011, 4(2): 2519-2530. |

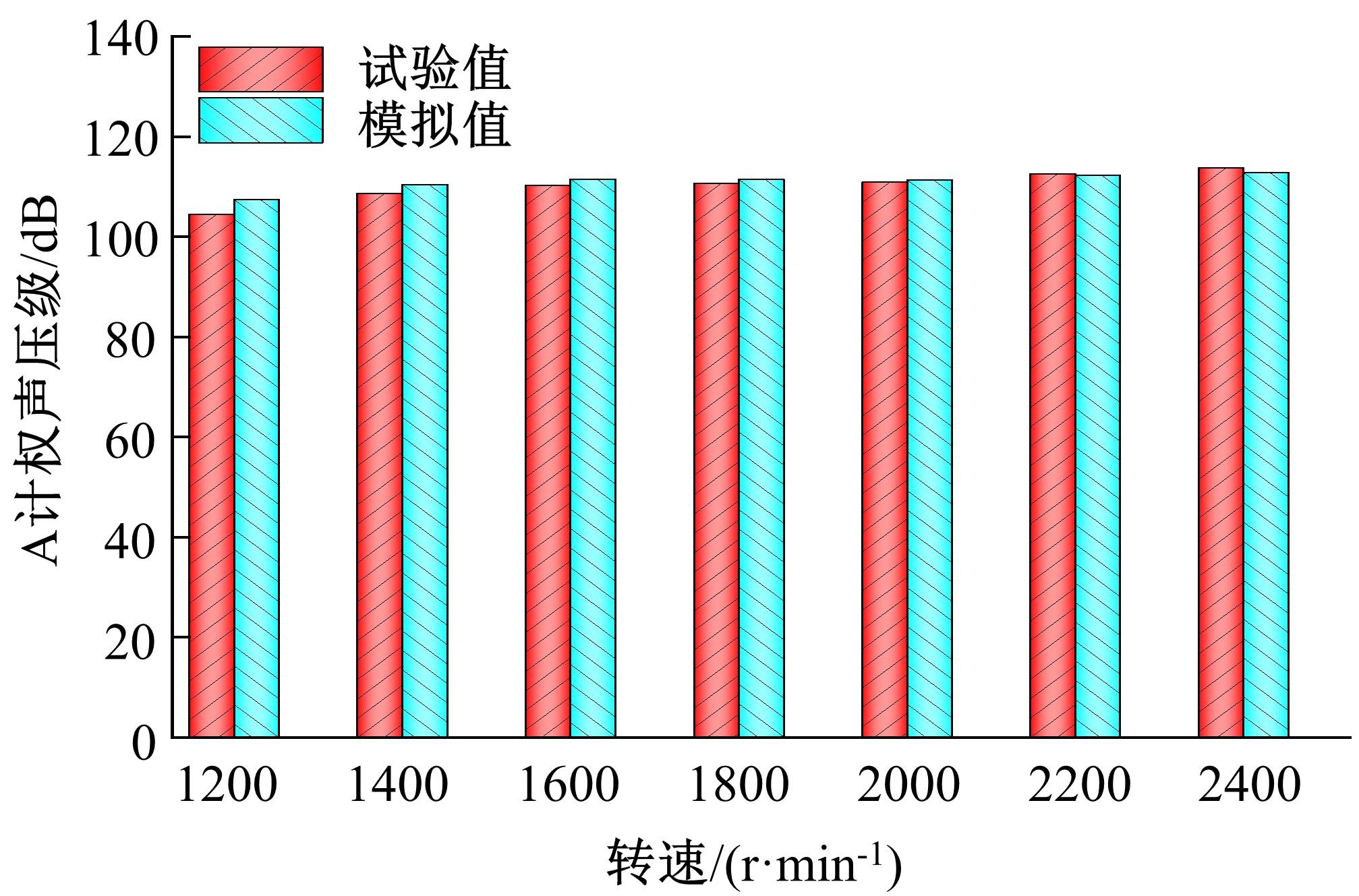

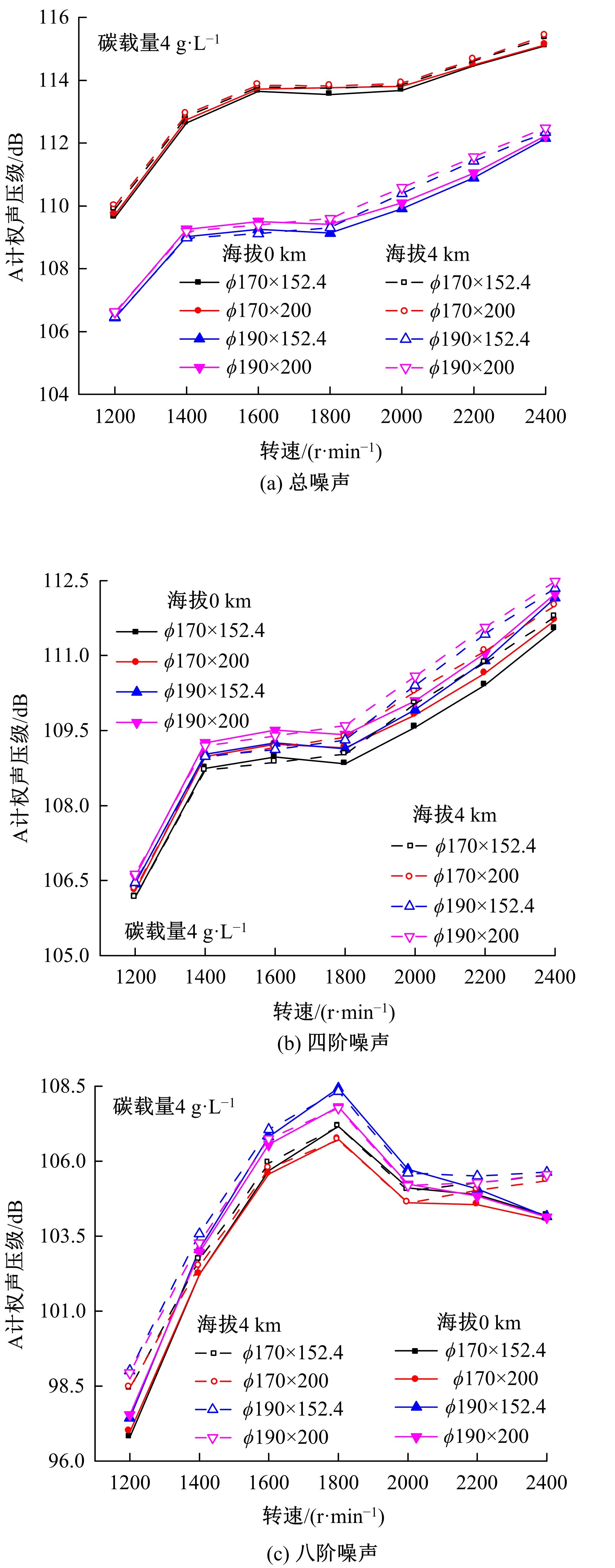

| 9 | 陈贵升, 周群林, 马龙杰, 等. 柴油机DPF压降及噪声特性分析[J]. 汽车工程, 2020, 42(7): 874-881. |

| Chen Gui-sheng, Zhou Qun-lin, Ma Long-jie, et al. Analysis of DPF pressure drop and noise characteristics of diesel engine[J]. Automotive Engineering, 2020, 42(7): 874-881. | |

| 10 | 饶均. 汽车排气系统流动特性与声学特性研究[D]. 重庆: 重庆交通大学航运与船舶工程学院, 2016. |

| Rao Jun. Study on flow performance and acoustic performance of automobile exhaust system[D]. Chongqing: College of Shipping and Marine Engineering,Chongqing Jiaotong University, 2016. | |

| 11 | 邓兆祥, 赵海军, 赵世举, 等. 穿孔管消声单元气流再生噪声产生机理[J]. 内燃机学报, 2009, 27(5):452-457. |

| Deng Zhao-xiang, Zhao Hai-jun, Zhao Shi-ju, et al. Producing mechanism of flow noise generation from perforated duct muffler element[J]. Transactions of CSICE, 2009, 27(5): 452-457. | |

| 12 | 陈贵升, 吕誉, 沈颖刚, 等. 高原环境下增压柴油机耦合DPF的性能仿真[J]. 内燃机学报, 2019, 37(6): 505-513. |

| Chen Gui-sheng, Lv Yu, Shen Ying-gang, et al. Simulation study of performances in plateau environment on a turbocharged diesel engine coupled with DPF[J]. Transactions of CSICE, 2019, 37(6): 505-513. | |

| 13 | Morsi S A, Alexander A J. An investigation of particle trajectories in two-phase flow systems[J]. Journal of Fluid Mechanics, 1972, 55(2): 193-208. |

| 14 | Zhang X G, Tennison P, Ruona W. 3D numerical study of pressure Loss characteristics and filtration efficiency through a frontal unplugged DPF[J]. SAE International Journal of Fuels & Lubricants, 2010, 3(1): 177-193. |

| [1] | Yan ZHANG,Wei LIU,Shu-yong ZHANG,Yi-qiang PEI,Meng-meng DONG,Jing QIN. Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 504-514. |

| [2] | Wen-zhi GAO,Yan-jun WANG,Xin-wei WANG,Pan ZHANG,Yong LI,Yang DONG. Real⁃time diagnosis for misfire fault of diesel engine based on convolutional neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 417-424. |

| [3] | Zhong-hua GU,Pei-gang YAN,Pan-hong LIU,Xiang-feng WANG. Applying data driven algorithm to promote prediction accuracy of separation boundary simulation with eddy viscosity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2532-2541. |

| [4] | Dong TANG,Yu-bin HAN,Lun HUA,Jin-chong PAN,Sheng LIU. Effect of lubricating oil ash on performance of gasoline particle filter in direct injection gasoline engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2501-2507. |

| [5] | Wen-bo ZHAO,Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU. Needle motion and its influence on in-nozzle flow and spray jet characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2234-2243. |

| [6] | Zhi-jun LI,Hao LIU,Li-peng ZHANG,Zhen-guo LI,Yuan-kai SHAO,Zhi-yang LI. Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 422-434. |

| [7] | Zhong WANG,You LI,Mei-juan ZHANG,Shuai LIU,Rui-na LI,Huai-bei ZHAO. Analysis on particle collision dynamics parameters in diesel exhaust stage [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 39-48. |

| [8] | Yun-feng HU,Yi-tong DING,Zhi-xin ZHAO,Bing-jing JIANG,Jin-wu GAO. Data-driven modeling and receding optimization control of diesel engine combustion process [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 49-62. |

| [9] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [10] | Chang-qing SONG,Wen-miao CHEN,Jun LI,Da-wei QU,Hao CUI. Effects of single and dual ignition on combustion characteristics of natural gas under different equivalence ratios [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1929-1935. |

| [11] | Yi-xiao ZHU,Xiao-min HE,Yi JIN. Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1936-1944. |

| [12] | Xin CHEN,Xin-jian RUAN,Ming LI,Ning WANG,Jia-ning WANG,Kai-xuan PAN. Application of modified discrete scheme based onlarge eddy simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1756-1763. |

| [13] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [14] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [15] | Xiao-yu HU,Guo-xiang LI,Shu-zhan BAI,Ke SUN,Si-yuan LI. Modified boiling heat transfer model considering roughness and material of heating surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1945-1950. |

|

||