Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 39-48.doi: 10.13229/j.cnki.jdxbgxb20190938

Previous Articles Next Articles

Analysis on particle collision dynamics parameters in diesel exhaust stage

Zhong WANG1( ),You LI1,Mei-juan ZHANG1,2,Shuai LIU1,Rui-na LI1,Huai-bei ZHAO1

),You LI1,Mei-juan ZHANG1,2,Shuai LIU1,Rui-na LI1,Huai-bei ZHAO1

- 1.School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

2.School of Automotive and Traffic,Wuxi Institute of Technology,Wuxi 214121,China

CLC Number:

- TK421

| 1 | 宁智, 资新运, 王宪成. 脉动排气对柴油机微粒凝并作用的研究[J]. 燃烧科学与技术, 2002, 8(6): 503-506. |

| Ning Zhi, Zi Xin-yun, Wang Xian-cheng. Study on the effect of fluctuant exhaust on the aggregation of diesel exhaust particulate[J]. Journal of Combustion Science and Technology, 2002, 8(6): 503-506. | |

| 2 | 王玉明, 林建忠. Brown 凝并中两个不同直径纳米颗粒的碰撞系数[J]. 应用数学和力学, 2011, 32(8): 956-963. |

| Wang Yu-ming, Lin Jian-zhong. Collision efficiency of two nanoparticles with different diameters in the brownian coagulation[J]. Applied Mathematics and Mechanics, 2011, 32(8): 956-963. | |

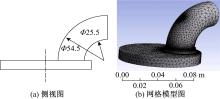

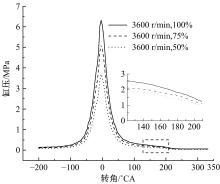

| 3 | 杨芳玲, 王忠, 赵洋, 等. 柴油机等径颗粒平面碰撞过程凝并特征[J]. 科学通报, 2016, 61(12): 1379-1385. |

| Yang Fang-ling, Wang Zhong, Zhao Yang, et al. Coalescence features of planar collision between particulate matters of same diameter from diesel engine[J]. Chinese Science Bulletin, 2016, 61(12): 1379-1385. | |

| 4 | Lennart F, Sergiy A, Stefan H, et al. Collision dynamics in fluidized bed granulators: a DEM-CFD study[J]. Chemical Engineering Science, 2013, 86: 108-123. |

| 5 | Liu W M, Xu J, Liu X D. Numerical study on collision characteristics for non-spherical particles in venturi powder ejector[J]. Vacuum, 2016, 131: 285-292. |

| 6 | 杨芳玲. 柴油机缸内颗粒碰撞与凝并过程研究[D]. 镇江:江苏大学汽车与交通工程学院, 2017. |

| Yang Fang-ling. Study on the collision and coagulation process of particles in diesel engine[D]. Zhenjiang: School of Automotive and Traffic Engineering, Jiangsu University, 2017. | |

| 7 | 赵怀北. 柴油机排气颗粒碰撞过程与团聚特征研究[D]. 镇江:江苏大学能源与动力工程学院,2018. |

| Zhao Huai-bei. Study on the collision process and agglomeration characteristics of particles in diesel engine[D]. Zhenjiang: School of Energy and Power Engineering, Jiangsu University, 2018. | |

| 8 | Matsusaka S, Theerachaisupakij W, Yoshida H, et al. Deposition layers formed by a turbulent aerosol flow of micron and sub-micron particles[J]. Powder Technology, 2001, 118(1/2): 130-135. |

| 9 | 周美立. 汽车系统单元化集成设计中相似性与复杂性[J]. 汽车工程, 2004, 26(6): 735-738. |

| Zhou Mei-li. Similarity and complexity in unitization integrated design for vehicle system[J]. Automotive Engineering, 2004, 26(6): 735-738. | |

| 10 | 刘宏新, 孟永超, 李彦龙, 等. 沼肥采运车储罐动力学数值模拟与相似模型试验[J]. 农业工程学报, 2015, 31(17): 42-49. |

| Liu Hong-xin, Meng Yong-chao, Li Yan-long, et al. Numerical simulation of dynamic and similarity model test of tank in biogas fertilizer transport truck[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(17): 42-49. | |

| 11 | Batchelor G K. The application of the similarity theory of turbulence to atmospheric diffusion[J]. Quarterly Journal of the Royal Meteorological Society, 2010, 76(328): 133-146. |

| 12 | 李瑞霞,柳朝晖,贺铸,等. 各向同性湍流内颗粒碰撞率的直接模拟研究[J]. 力学学报,2006,38(1):25-32. |

| Li Rui-xia,Liu Zhao-hui,He Zhu,et al. Direct numerical simulation of inertial particle collisions in isotropic turbulence[J]. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(1): 25-32. | |

| 13 | Wang L, Chen S, Xie H. Numerical simulation of the growth of nanoparticles in a flame CVD process[J]. Chinese Particuology, 2004, 2(5): 215-221. |

| 14 | Seinfeld J H, Pandis S N, Noone K. Atmospheric chemistry and physics: from air pollution to climate change[J]. Environment Science and Policy for Sustainable Development, 1998, 40(7): 26-29. |

| 15 | 韩健, 东明, 李素芬, 等. 飞灰颗粒与平板表面撞击过程的实验研究[J]. 化工学报, 2013, 64(9): 3161-3167. |

| Han Jian, Dong Ming, Li Su-fen, et al. Experimental research on fly ash particles impacting planar surface[J]. CIESC Journal, 2013, 64(9): 3161-3167. | |

| 16 | 周美立. 相似性科学[M]. 北京: 科学出版社, 2004. |

| 17 | 王忠, 孙波, 赵洋, 等. 小型非道路柴油机排气管内颗粒的粒径分布与氧化特性[J]. 农业工程学报, 2016, 32(10): 41-46. |

| Wang Zhong, Sun Bo, Zhao Yang, et al. Characteristics of particle coagulation and oxidation in exhaust pipe of diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(10): 41-46. | |

| 18 | Streets D G, Gupta S, Waldhoff S T, et al. Black carbon emissions in China: Asia[J]. Atmospheric Environment, 2001, 35(25): 4281-4296. |

| 19 | Huang Y, Lee C, Choi Y, et al. Effect of the size and morphology of particles dispersed in nano-oil on friction performance between rotating discs[J]. Journal of Mechanical Science & Technology, 2011, 25(11): 2853-2857. |

| 20 | Marshall J S. Viscous damping force during head-on collision of two spherical particles[J]. Physics of Fluids, 2011, 23(1): 5382-5393. |

| 21 | 黄立沛. 基于离散元素法的动态配料模型预测控制算法研究[D]. 重庆:重庆大学自动化学院, 2017. |

| Huang Li-pei. Research on model predictive control algorithm of dynamic batching process based on discrete element method[D]. Chongqing:School of Automation, Chongqing University, 2017. | |

| 22 | Kittelson D B. Engines and nanoparticles: a review[J]. Journal of Aerosol Science, 1998, 29(5/6): 575-588. |

| 23 | Park D, Choi N K, Lee S G, et al. Real-time measurement of the size distribution of diesel exhaust particles using a portable 4-stage electrical low pressure impactor[J]. Particle & Particle Systems Characterization, 2010, 26(4): 179-186. |

| 24 | Cashdollar K L, Zlochower I A. Explosion temperatures and pressures of metals and other elemental dust clouds[J]. Journal of Loss Prevention in the Process Industries, 2006, 20(4-6): 337-348. |

| 25 | Hauert F, Vogl A, Radandt S. Dust cloud characterization and its influence on the pressure-time-history in silos[J]. Process Safety Progress, 1996, 15(3): 178-184. |

| 26 | Stessel R I, Peirce J J. Pulsed-flow air classification for waste-to-energy[J]. Journal of Energy Engineering, 1983, 109(2): 60-73. |

| 27 | Tukmakov A L. Numerical model of the electro-gas-dynamics of a gas-particle system based on the equations of motion of a two-velocity two-temperature gas-particle mixture[J]. Journal of Applied Mechanics & Technical Physics, 2015, 56(4): 636-643. |

| 28 | Tong Z, Zhong W, Yu A, et al. CFD-DEM investigation of the effect of agglomerate-agglomerate collision on dry powder aerosolisation[J]. Journal of Aerosol Science, 2016, 92(10): 109-121. |

| 29 | 李新令, 黄震, 王嘉松, 等. 柴油机排气颗粒浓度和粒径分布特征试验研究[J]. 内燃机学报, 2007, 25(2): 113-117. |

| Li Xin-ling, Huang Zhen, Wang Jia-song, et al. Investigation on concentrations and size distribution characteristic of particles from diesel engine[J]. Transactions of CSICE, 2007, 25(2): 113-117. | |

| 30 | 朴香兰, 王国强, 张占强, 等. 水平转弯颗粒流的离散元模拟[J]. 吉林大学学报:工学版, 2010, 40(1): 98-102. |

| Xiang-lan Piao, Wang Guo-qiang, Zhang Zhan-qiang, et al. Discrete element method simulation of granular flow on horizontalturn[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(1): 98-102. | |

| 31 | 王晓燕, 李芳, 葛蕴珊, 等. 甲醇柴油与生物柴油微粒排放粒径分布特[J]. 农业机械学报, 2009, 40(8): 7-12. |

| Wang Xiao-yan, Li Fang, Ge Yun-shan, et al. Particle size distribution of particulate matter emission from the diesel engine burning methanol-diesel fuel and biodiesel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(8): 7-12. | |

| 32 | 黄军. 扭曲管内流态化粒子对壁面的磨蚀及碰撞动力学研究[D]. 湖南:湘潭大学机械工程学院, 2015. |

| Huang Jun. Study on the wall erosion and collision dynamics of fluidized particles in twisted tube[D]. Hunan:School of Mechanical Engineering, Xiangtan University, 2015. | |

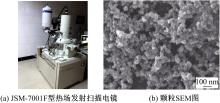

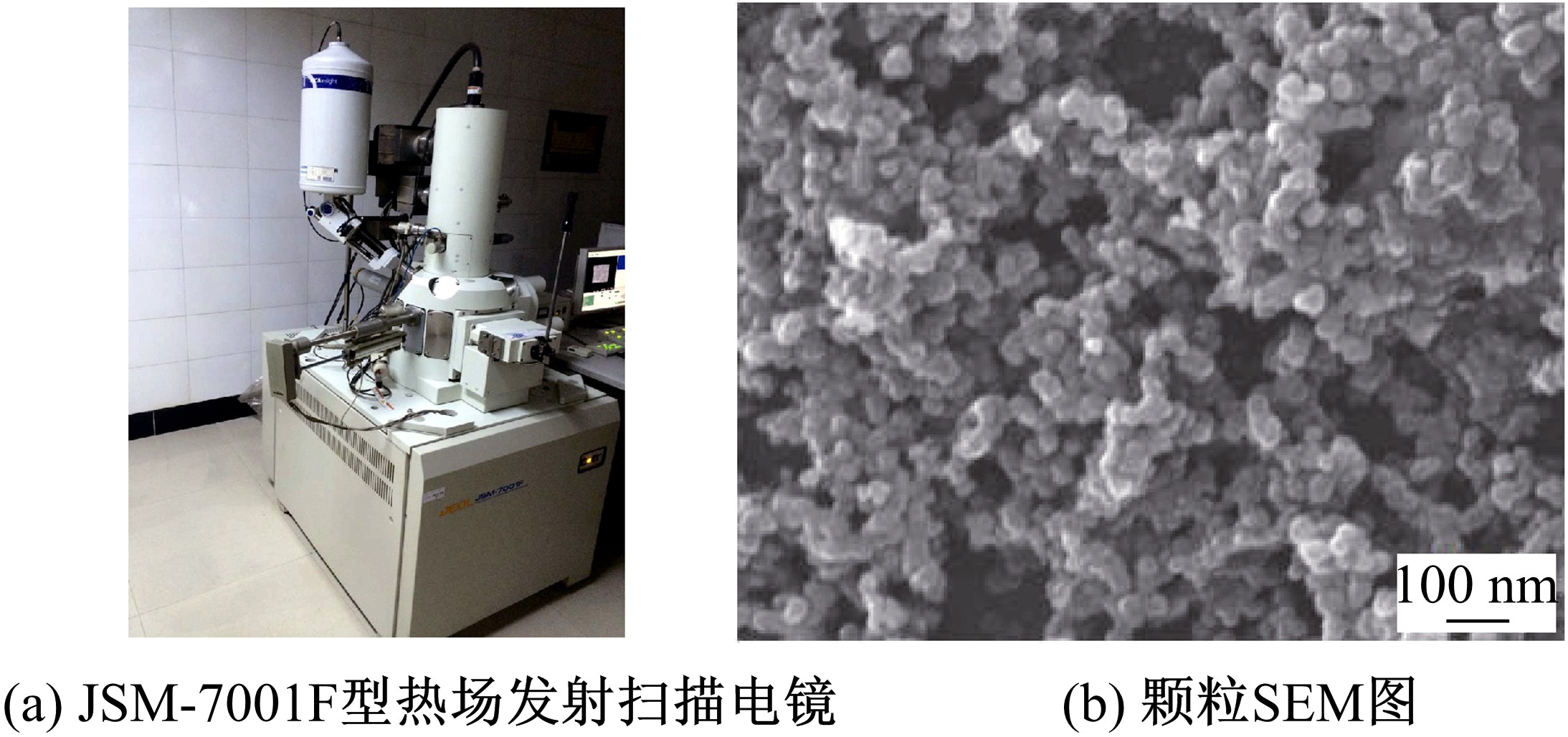

| 33 | 赵怀北, 王忠, 刘帅, 等. 柴油机排气颗粒的力学特征与形貌分析[J]. 科学通报, 2017, 62(30): 3498-3505. |

| Zhao Huai-bei, Wang Zhong, Liu Shuai, et al. Analysis on the morphology and mechanical characteristics of agglomerated particles emitted from the diesel exhaust process[J]. China Science Bulletin, 2017, 62(30): 3498-3505. |

| [1] | Fang-wu MA,Hong-yu LIANG,Qiang WANG,Yong-feng PU. In-plane dynamic crushing of dual-material structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 114-121. |

| [2] | Chang SU,Ying HAN,Ying-chao ZHANG,Zhen-hua MIAO. Influence performance with wheel spoke design parameters of vehicle aerodynamic [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 107-113. |

| [3] | Zhi-gang YANG,Ya-jun FAN,Chao XIA,Shi-jun CHU,Xi-zhuang SHAN. Drag reduction of a square⁃back Ahmed model based on bi⁃stable wake [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1635-1644. |

| [4] | Wei LAN,Jiang LIU,Li XIN,Jing-xi LI,Xing-jun HU,Jing-yu WANG,Tao SANG. Influence of rearview mirror styling on water phase distribution on side windows [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1590-1599. |

| [5] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [6] | Chang-qing DU,Xi-liang CAO,Biao HE,Wei-qun REN. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1556-1564. |

| [7] | Xue-ping FAN,Guang QU,Yue-fei LIU. Bridge extreme stress prediction based on new data assimilation algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 572-580. |

| [8] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [9] | Xiang-jun YU,Yuan-hui HUAI,Xue-fei LI,De-wu WANG,An YU. Shoveling trajectory planning method for wheel loader based on kriging and particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 437-444. |

| [10] | Shun-fu JIN,Xiu-chen QIE,Hai-xing WU,Zhan-qiang HUO. Clustered virtual machine allocation strategy in cloud computing based on new type of sleep-mode and performance optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 237-246. |

| [11] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [12] | Li XIN,Wei LAN,Jiang LIU,Qin-lin WAN,Peng GUO,Xing-jun HU,Yang XIAO. Simulation and control of pollution on automobile body surface during wading [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1786-1794. |

| [13] | Xin CHEN,Xin-jian RUAN,Ming LI,Ning WANG,Jia-ning WANG,Kai-xuan PAN. Application of modified discrete scheme based onlarge eddy simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1756-1763. |

| [14] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [15] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

|

||