Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (10): 2795-2806.doi: 10.13229/j.cnki.jdxbgxb.20211384

Previous Articles Next Articles

Sprocket size measurement method based on machine vision

Hao-jing BAO1( ),Si-yuan LIU1(

),Si-yuan LIU1( ),Zhen REN2,Yun-hui ZHANG1,Zheng-yi HU3,4,Yu-peng GE1

),Zhen REN2,Yun-hui ZHANG1,Zheng-yi HU3,4,Yu-peng GE1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.School of Mechanical Engineering,Changchun University,Changchun 130022,China

3.School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510641,China

4.Production and Education Integration Development Center,Changchun Automobile Industry College,Changchun 130010,China

CLC Number:

- TH164

| 1 | 孟繁忠. 链条链轮产品设计与检验[M]. 北京:机械工业出版社, 1996. |

| 2 | 谭庆昌, 赵洪志. 机械设计[M]. 北京:高等教育出版社, 2008. |

| 3 | 张国雄. 三坐标测量机[M]. 天津:天津大学出版社,1999. |

| 4 | 郑国伟.《中国制造2025》简介与相关情况[J].中国仪器仪表,2018(10):25-28. |

| Zheng Guo-wei. Brief Introduction of made in China 2025 and related information[J]. China Instrumentation, 2018(10): 25-28. | |

| 5 | Liu Si-yuan, Tan Qing-chang, Zhang Ya-chao. Shaft diameter measurement of using the structured light vision[J]. Sensors, 2015, 15(8): 19750-19767. |

| 6 | Gu Peng, Zhu Chuan-min, Yu Yi-qing,et al. Evaluation and prediction of drilling wear based on machine vision[J]. International Journal of Advanced Manufacturing Technology, 2021, 114(7/8): 2055-2074. |

| 7 | Sun Chuan-zhi, Wang Bao-sheng, Liu Yong-meng, et al. Design of high accuracy cylindrical profile measurement model for low-pressure turbine shaft of aero engine[J]. Aerospace Science and Technology, 2019, 95: No.105442. |

| 8 | Song Li-mei, Ru Yuan, Yang Yan-gang, et al. Full-view three-dimensional measurement of complex surfaces[J]. Optical Engineering, 2018, 57(10): No.104106. |

| 9 | 田峰. 链轮毛刺检测方法与几何参数测量技术研究[D]. 扬州:扬州大学机械工程学院,2021. |

| Tian Feng. Research on spocket burr detection method and geometric parameter measurement technology[D]. Yangzhou: School of Mechnical Engineering,Yangzhou University,2021. | |

| 10 | Ma Yu-zhen, Yu Yong-xin, Wang Xin-hua. Diameter measuring technique based on capacitive probe for deep hole or oblique hole monitoring[J]. Measurement, 2014, 47: 42-44. |

| 11 | Md H A, Syuhei K, Kensuke U. Application of machine vision in improving safety and reliability for gear profile measurement[J]. Machine Vision and Applications, 2014(25):1549-1559. |

| 12 | Miao Jian-wei, Tan Qing-chang, Liu Si-yuan, et al. Vision measuring method for the involute profile of a gear shaft[J]. Applied Optics, 2020, 59(13): 4183-4190. |

| 13 | Kou Ying, Zhang Long-fei, Liu Si-yuan, et al. Aperture measurement based on a conic invariant[J]. Applied Optics, 2022, 61(6): 99-106. |

| 14 | Liu Zhen, Wei Xin-guo, Zhang Guang-jun. External parameter calibration of widely distributed vision sensors with non-overlapping fields of view[J]. Optics and Lasers in Engineering, 2013, 51(6): 643-650. |

| 15 | Lu R S, Li Y F. A global calibration method for large-scale multi-sensor visual measurement systems[J]. Sensors and Actuators A-Physical, 2004, 116(3): 384-393. |

| 16 | Liu Zhen, Zhang Guang-jun, Wei Zhen-zhong,et al. Novel calibration method for non-overlapping multiple vision sensors based on 1D target[J]. Optics and Lasers in Engineering, 2011, 49(4): 570-577. |

| 17 | Bao Hao-jing, Tan Qing-chang, Liu Si-yuan, et al. Computervision measurement of pointer meter readings based on inverse perspective mapping[J]. Applied Sciences-Basel, 2019, 9(18): No.9183729. |

| 18 | 顾国华, 王佳节, 陈钱, 等. 二维旋转平台下的相机参数标定[J]. 光学精密工程, 2017, 25(7): 1890-1899. |

| Gu Guo-hua, Wang Jia-jie, Chen Qian, et al. Camera parameter calibration based on two-dimensional rotating platform[J]. Optics and Precision Engineering, 2017, 25(7): 1890-1899. | |

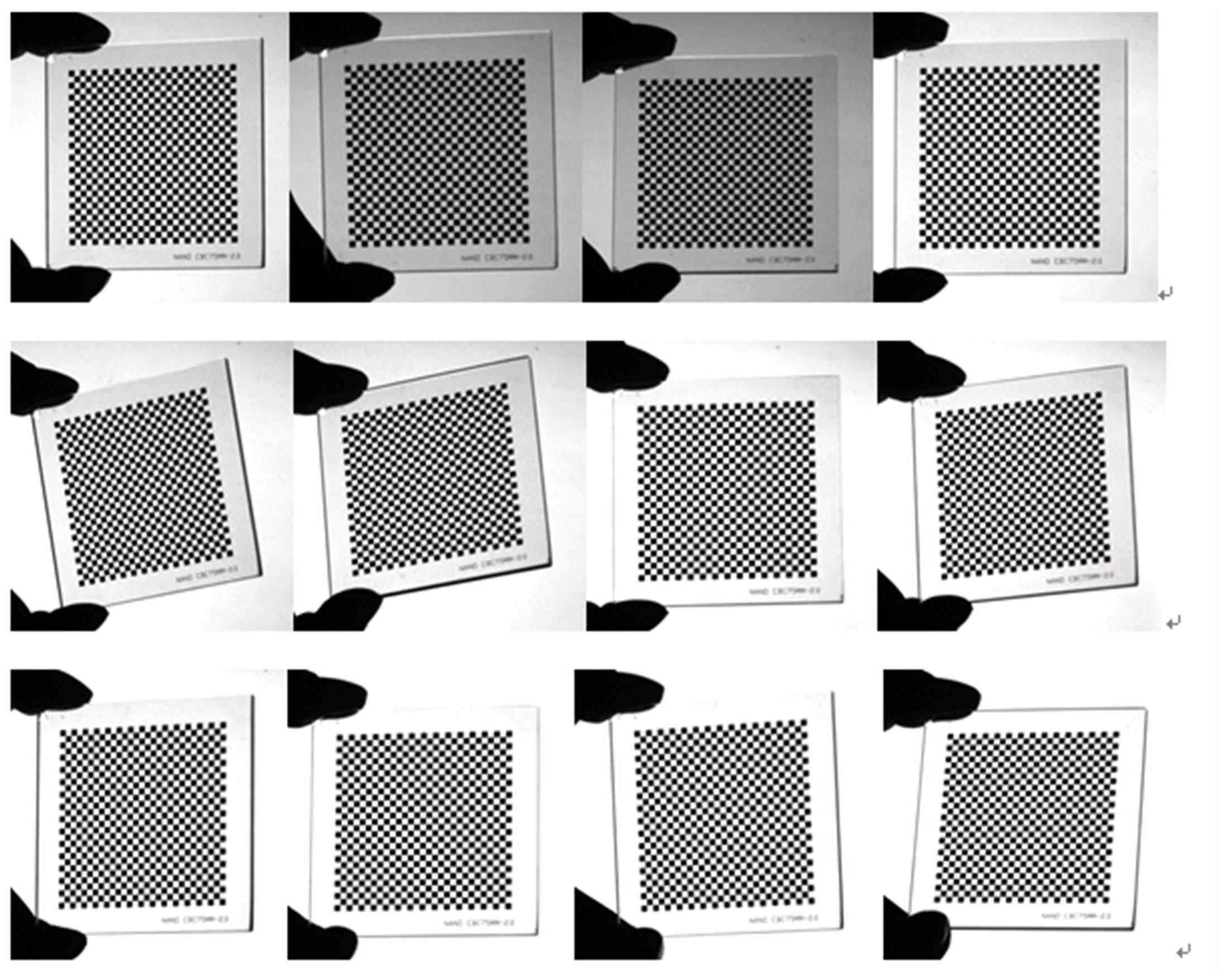

| 19 | Zhang Z. A flexible new technique for camera calibration[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2000, 22(11): 1330-1334. |

| 20 | Grimson W E, Hildreth E C. Digital step edges from zero crossing of second directional derivatives[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1985, 7(1): 121-127. |

| 21 | 崔家礼, 宫贺, 王一丁, 等. 基于代数距离的椭圆拟合的优化及应用研究[J]. 计算机科学, 2014(2): 88-90. |

| Cui Jia-li, Gong He, Wang Yi-ding, et al. Optimization and research on ellipse fitting and application based on algebraic distance[J]. Computer Science, 2014(2): 88-90. | |

| 22 | Walter Gander, Gene H, Golub Rolf Strebel. Least-squares fitting of circles and ellipses[J]. BIT Numerical Mathematics, 1994, 43: 558-578. |

| [1] | Jing-bin LI,Yu-kun YANG,Bao-qin WEN,Za KAN,Wen SUN,Shuo YANG. Method of extraction of navigation path of post-autumn residual film recovery based on stubble detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1528-1539. |

| [2] | LIU En-ze,WU Wen-fu. Agricultural surface multiple feature decision fusion disease judgment algorithm based on machine vision [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1873-1878. |

| [3] | LIN Jin-hua, WANG Yan-jie, WANG Lu, YAO Yu. Real-time surface reconstruction based global camera pose optimization [J]. 吉林大学学报(工学版), 2018, 48(3): 909-918. |

| [4] | ZHANG Fei, SHAN Zhong-de, REN Yong-xin, NIE Jun-gang, LIU Feng. Calibration of line array camera for head defect detection system on cylinder cover [J]. 吉林大学学报(工学版), 2017, 47(2): 540-545. |

| [5] | ZHOU Xiao-dong, ZHANG Ya-chao, TAN Qing-chang, ZHANG Wei-jun. New method of cylindricity measurement based on structured light vision technology [J]. 吉林大学学报(工学版), 2017, 47(2): 524-529. |

| [6] | ZHANG Bo, WANG Wen-jun, WEE Minkooc, CHENG Bo. Detection handheld phone use by driver based on machine vision [J]. 吉林大学学报(工学版), 2015, 45(5): 1688-1695. |

| [7] | LIU Chang-ying, CAI Wen-jing, WANG Tian-hao, LI Ji-zhi, JIA Yan-mei, SONG Yu-he. Vision inspection technology of fracture splitting notch of auto connecting rod [J]. 吉林大学学报(工学版), 2014, 44(4): 1076-1080. |

| [8] | WAN Chuan, TIAN Yan-tao, LIU Shuai-shi, CHEN Hong-wei. Face tracking and facial expression recognition system based on active machine vision [J]. 吉林大学学报(工学版), 2013, 43(02): 459-465. |

| [9] | WANG Dian-hai, TAO Peng-fei, JIN Sheng, MA Dong-fang. Method of calibrating and validating car-following model [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 59-65. |

| [10] | LI Zhi-long, HUANG Cheng-jie, LI Li-guang, WU Zhi-jun. Simultaneous measurement of particle field and size distribution by two digital cameras [J]. 吉林大学学报(工学版), 2011, 41(05): 1503-1506. |

| [11] | ZHAO Ding-Xuan, CUI Yu-Xin, GONG Jie, NI Tao, HOU Jing-Wei, ZHAO Ying, WANG Chao-Fei. Method of tracking and measuring moving object based on machine vision [J]. 吉林大学学报(工学版), 2010, 40(增刊): 257-0261. |

| [12] | HUANG Cheng-jie,WU Zhi-jun,LI Zhi-long,LI Li-guang. Fundamentals of particle velocity and size measurement in same field and its experimental validation [J]. 吉林大学学报(工学版), 2010, 40(04): 1106-1111. |

| [13] | MENG Xiang-Yan, SUN Yong-Hai, WANG Xiao-Dan, LI Zhi, HU Tie-Jun, HE Bing. Methods of extraction and analysis of grading features of ribeye section of beef carcass [J]. 吉林大学学报(工学版), 2010, 40(02): 485-0490. |

| [14] | YIN Yong-guang,DING Yun. Rapid method for enumeration of Escherichia coli in food based on computer vision [J]. 吉林大学学报(工学版), 2009, 39(增刊2): 344-0348. |

| [15] | WANG Hong-Rui, TIAN Yan-Chao, GU Qing. Adaptive tuning methods for digital camera parameters under variou illuminations [J]. 吉林大学学报(工学版), 2009, 39(05): 1262-1267. |

|

||