Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (3): 657-662.doi: 10.13229/j.cnki.jdxbgxb.20220518

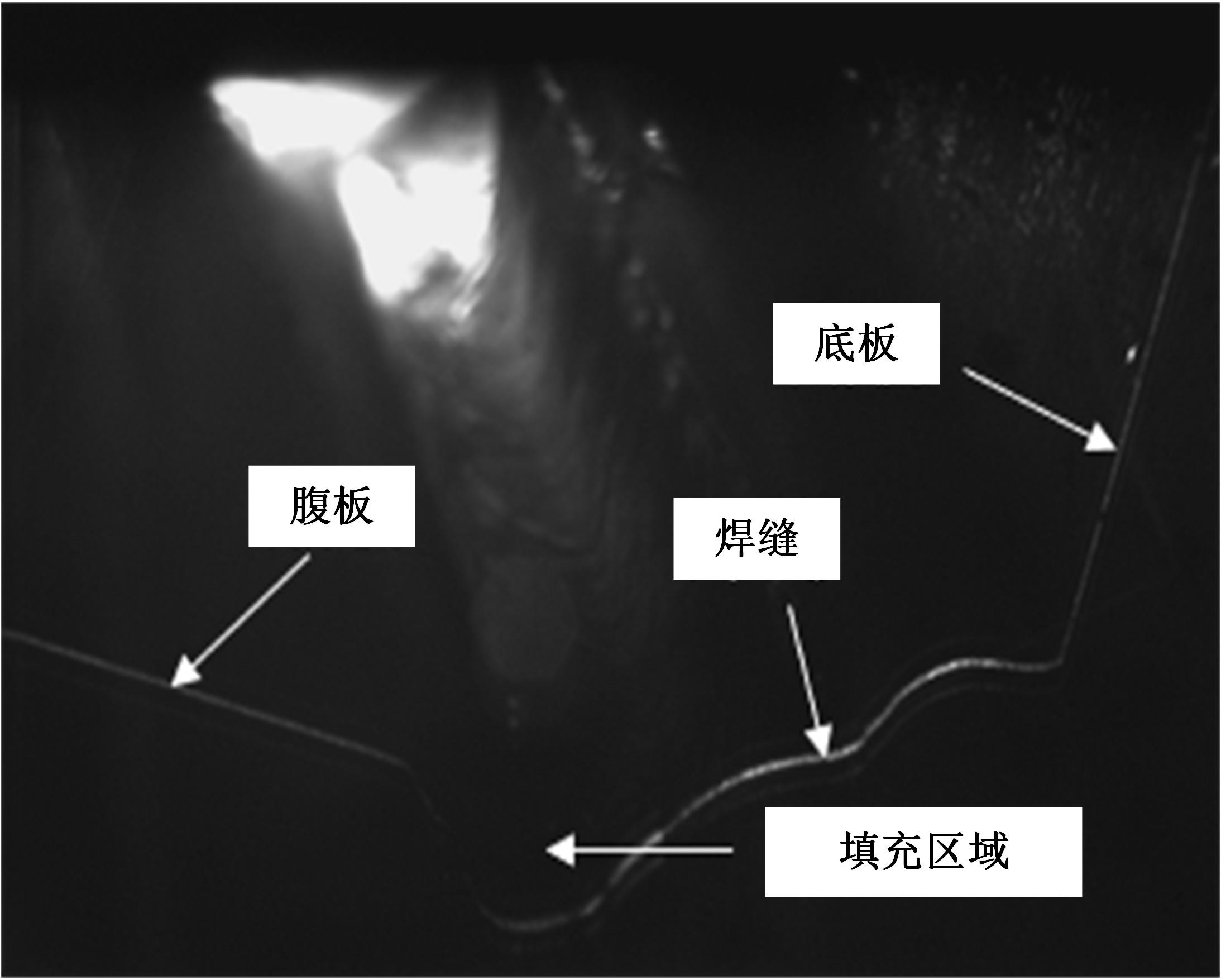

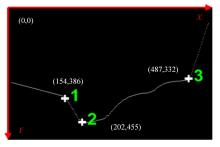

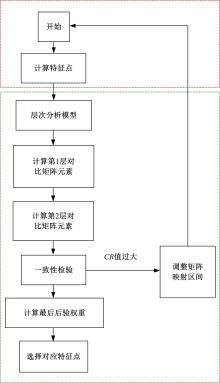

Autonomous decision⁃making of welding positions based on analytic hierarchy process in T⁃joint arc welding

Yin-shui HE1( ),He XIAO1,Cang-hai LUO1,Yu ZHANG1,Zhuo-hua YU2(

),He XIAO1,Cang-hai LUO1,Yu ZHANG1,Zhuo-hua YU2( ),Hai-tao YUAN3

),Hai-tao YUAN3

- 1.School of Resources & Environment,Nanchang University,Nanchang 330031,China

2.School of Intelligent Manufacturing,Nanchang Jiao Tong Institute,Nanchang 330100,China

3.School of Advanced Manufacturing,Nanchang University,Nanchang 330031,China

CLC Number:

- TG409

| 1 | 周晓,梁燚杰,奚中轩,等. 白车身 B 柱焊接变形模拟及预变形控制方法[J]. 吉林大学学报:工学版,2023,53(8): 2212-2218. |

| Zhou Xiao, Liang Yi-jie, Xi Zhong-xuan, et al. Welding deformation and compensation method of B-pillar in body-in-white[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(8): 2212-2218. | |

| 2 | Zhang Chao-hua, Li Suo, Sun Jia-min, et al. Controlling angular distortion in high strength low alloy steel thick-plate T-joints[J]. Journal of Materials Processing Technology, 2019, 267: 257-267. |

| 3 | Liu Yan, Shi Lei, Tian Xin-cheng. Weld seam fitting and welding torch trajectory planning based on NURBS in intersecting curve welding[J]. International Journal of Advanced Manufacturing Technology, 2018, 95(5): 2457-2471. |

| 4 | Fang H C, Ong S K, Nee A Y C. Adaptive pass planning and optimization for robotic welding of complex joints[J]. Advances in Manufacturing, 2017, 5(2): 93-104. |

| 5 | Zhang Yang, Lv Xiao-qing, Xu Lian-yong, et al. A segmentation planning method based on the change rate of cross-sectional area of single V-groove for robotic multi-pass welding in intersecting pipe-pipe joint[J]. International Journal of Advanced Manufacturing Technology, 2019, 101(1): 23-38. |

| 6 | Liu Yan, Ren Li-juan, Tian Xin-cheng. A robot welding approach for the sphere-pipe joints with swing and multi-layer planning[J]. International Journal of Advanced Manufacturing Technology, 2019, 105(1): 265-278. |

| 7 | 刘成文, 彭安华, 杜爱民. 基于级别优序关系和层次分析法的铝合金焊接方法决策[J]. 数学的实践与认识, 2018, 48(11): 150-157. |

| Liu Cheng-wen, Peng An-hua, Du Ai-min. Decision-making of aluminum alloys welding method based on hierarchy and analytic hierarchy process[J]. Practice and Understanding of Mathematics, 2018, 48(11): 150-157. | |

| 8 | Bhattacharya A, Singla S. Dissimilar GTAW between AISI 304 and AISI 4340 steel: multi-response optimization by analytic hierarchy process[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2017, 231(4): 824-835. |

| 9 | 沈鸿源, 陈华斌, 林涛,等. 应用于铝合金焊接中的被动视觉获取[J]. 上海交通大学学报, 2015, 49(3):341-343. |

| Shen Hong-yuan, Chen Hua-bin, Lin Tao, et al. Passive visual technology in aluminum alloy welding[J]. Journal of Shanghai Jiaotong University, 2015, 49(3): 341-343. | |

| 10 | Zhang Chao-hua, Li Suo, Hu Long, et al. Effects of pass arrangement on angular distortion, residual stresses and lamellar tearing tendency in thick-plate T-joints of low alloy steel[J]. Journal of Materials Processing Technology, 2019, 274: No. 116293. |

| 11 | He Yin-shui, Ma Guo-hong, Chen Shan-ben. Autonomous decision-making of welding position during multipass GMAW with T-Joints: a Bayesian network approach[J]. IEEE Transactions on Industrial Electronics, 2021, 69(4): 3909-3917. |

| [1] | Li-jie ZHANG,Xi-ta A,Xiao TIAN,Wen LI. Multi⁃objective optimization design of accelerated degradation test based on Gamma process [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 361-367. |

| [2] | Wei-zhi DONG,Shuang ZHANG,Fu ZHU. Evaluation of pavement performance of asphalt mixture based on extension analytic hierarchy process [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2137-2143. |

| [3] | De-lei YANG,Le-wei TONG. Calculation formula of SCF for CHS⁃CFSHS welded T⁃joints with brace under axial tension [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1891-1899. |

| [4] | WANG Zhi-yuan, LI Guo-dong, WANG Yong-hua. Optimization decision model for bridge design based on AHP-TOPSIS [J]. 吉林大学学报(工学版), 2017, 47(2): 478-482. |

| [5] | ZHAO Ding-xuan, WANG Qian, ZHANG Zhu-xin. Extenics theory for reliability assessment of carrier helicopter based on analytic hierarchy process [J]. 吉林大学学报(工学版), 2016, 46(5): 1528-1531. |

| [6] | LI Xian-sheng, LI Ming-ming, REN You, YAN Jia-hui, CHEN Xiao-xia. Driver's fixation characteristics in different urban road alignments [J]. 吉林大学学报(工学版), 2016, 46(5): 1447-1452. |

| [7] | LI Huan-li, GUO LI-hong, WANG Xin-zui, LI Xiao-ming, DONG Yue-fang, FANG Yan-chao. Iris recognition based on weighted Gabor filter [J]. 吉林大学学报(工学版), 2014, 44(01): 196-202. |

| [8] | YAN Qing-dong, LIU Shu-cheng, WEI Wei, YANG Hui-bin. Evaluation for matching between hydrodynamic torque converter and engine based on improved radar chart method [J]. 吉林大学学报(工学版), 2013, 43(06): 1510-1516. |

| [9] | CHI Xue-fen, WU Di, LIU Dan. IBP+MMBP/Geo/1/K vacation queuing system with threshold [J]. 吉林大学学报(工学版), 2013, 43(03): 781-787. |

| [10] | LIU Ren-yun, YU Fan-hua. Robust optimal design for reliability based on analytic hierarchy process-particle swarm method [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 139-142. |

| [11] | HAO Qing-bo, YANG Zhao-jun, CHEN Chuan-hai, CHEN Fei, LI Guo-fa. Reliability prediction for NC machine tool based on interval AHP [J]. , 2012, 42(04): 845-850. |

| [12] | YU Fan-hua, LIU Ren-yun. Multi-objective reliability based on robust optimization design for vehicle leaf spring [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 226-230. |

| [13] | SHEN Gui-xiang, SHAO Na, ZHANG Ying-zhi, HE Yu, WANG Xiao-feng. Customer satisfaction evaluation for numerically-controlled machine tools based on extension theory [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 164-167. |

| [14] | CHEN Yong, CHEN Xiao-kai, LIN Yi. Application of improved radar chart evaluation method on evaluation of automobile comprehensive performances [J]. 吉林大学学报(工学版), 2011, 41(6): 1522-1526. |

| [15] |

.

Reliability evaluation of numerically -controlled machine tool based on extenics theory [J]. 吉林大学学报(工学版), 2011, 41(01): 106-0109. |

|

||