Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (5): 1205-1213.doi: 10.13229/j.cnki.jdxbgxb.20231081

Previous Articles Next Articles

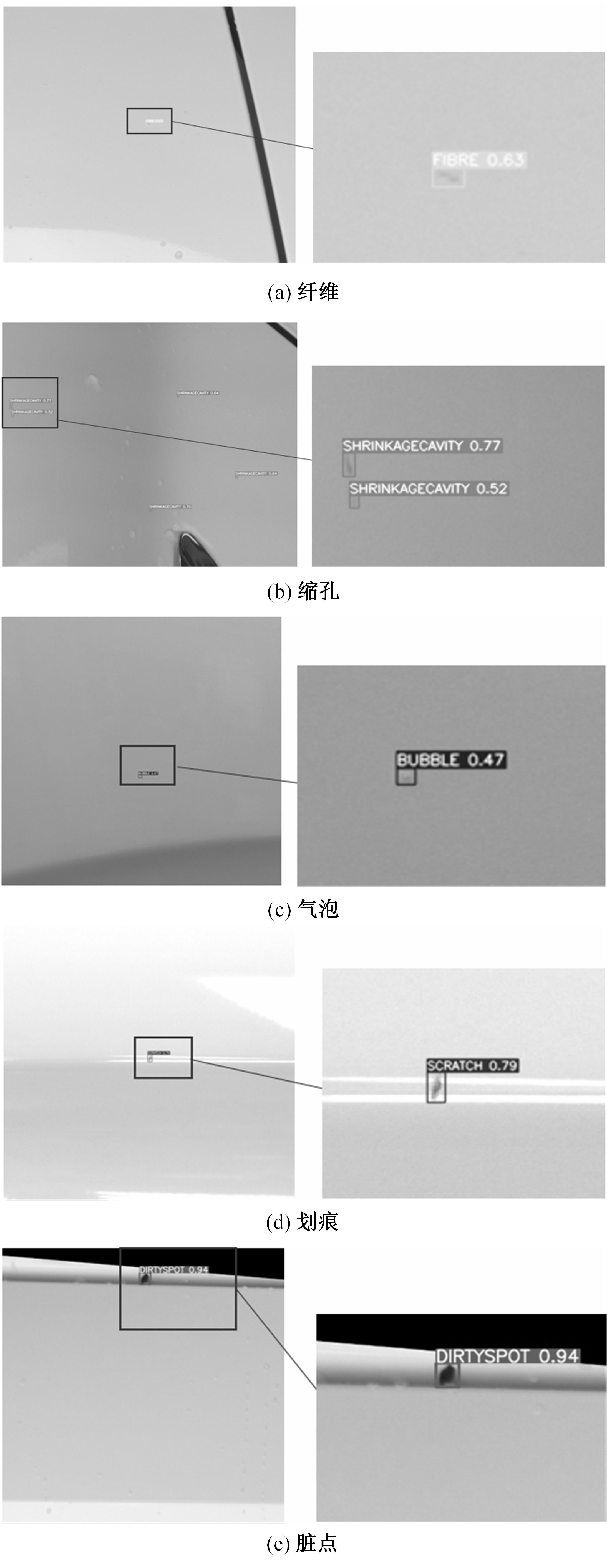

High precision detection system for automotive paint defects

Yu-kai LU1,2( ),Shuai-ke YUAN3,Shu-sheng XIONG1,4(

),Shuai-ke YUAN3,Shu-sheng XIONG1,4( ),Shao-peng ZHU1,Ning ZHANG3

),Shao-peng ZHU1,Ning ZHANG3

- 1.Power Machinery & Vehicular Engineering Institute,Zhejiang University,Hangzhou 310014,China

2.Zhejiang Geely Automobile Co. ,Ltd. ,Hangzhou 310051,China

3.College of Mechanical Engineering,Yanshan University,Qinhuangdao 066004,China

4.Longquan Industrial Innovation Research Institute,Longquan 323700,China

CLC Number:

- TP183

| 1 | Yu J B, Lu X L. Wafer map defect detection and recognition using joint local and nonlocal linear discriminant analysis[J]. IEEE Transactions on Semiconductor Manufacturing,2016,29(1): 33-43. |

| 2 | 刘培勇,董洁,谢罗峰,等. 基于多支路卷积神经网络的磁瓦表面缺陷检测算法[J]. 吉林大学学报: 工学版,2023,53(5): 1449-1457. |

| Liu Pei-yong, Dong Jie, Xie Luo-feng,et al. Surface defect detection algorithm of magnetic tiles based on multi⁃branch convolutional neural network[J]. Journal of Jilin University (Engineering and Technology Edition),2023,53(5): 1449-1457. | |

| 3 | 贺秋伟,王龙山,于忠党,等. 基于图像处理和支持向量机的微型齿轮缺陷检测[J]. 吉林大学学报: 工学版, 2008, 38(3): 565-569. |

| He Qiu-wei, Wang Long-shan, Yu Zhong-dang,et al. Defect detection for microgear based on image processing and support vector machine[J]. Journal of Jilin University (Engineering and Technology Edition),2008, 38(3): 565-569. | |

| 4 | 吴凤和,崔健新,张宁,等. 基于改进YOLOv4算法的轮毂表面缺陷检测[J]. 计量学报,2022,43(11): 1404-1411. |

| Wu Feng-he, Cui Jian-xin, Zhang Ning,et al. Surface defect detection of wheel hub based on improved YOLOv4 algorithm[J]. Acta Metrologica Sinica,2022,43(11): 1404-1411. | |

| 5 | 张飞,单忠德,任永新,等. 缸盖缺陷检测系统线阵相机现场标定方法[J]. 吉林大学学报: 工学版,2017,47(2): 540-545. |

| Zhang Fei, Shan Zhong-de, Ren Yong-xin,et al. Calibration of line array camera for head defect detection system on cylinder cover[J]. Journal of Jilin University (Engineering and Technology Edition),2017,47(2): 540-545. | |

| 6 | Zheng J F, Wu H, Han Z,et al. Insulator-defect detection algorithm based on improved YOLOv7[J]. Sensors,2022,22(22): 22228801. |

| 7 | Sohail A, Adarsh T, Medhat M,et al. A robotics inspection system for detecting defects on semi-specular painted automotive surfaces[C]∥ IEEE International Conference on Robotics and Automation,Paris,France,2020: 8928-8934. |

| 8 | Jing Z, Masaki K, Chao Z,et al. Defect inspection of coated automobile roofs using a single camera[J]. IEEJ Transactions on Electrical and Electronic Engineering,2020,15(4): 616-625. |

| 9 | Jaime M, Solanes J E, Laura A,et al. On the detection of defects on specular car body surfaces[J]. Robotics and Computer-Integrated Manufacturing,2017,48: 263-278. |

| 10 | Edris M Z B, Jawad M S, Zakaria Z. Surface defect detection and neural network recognition of automotive body panels[C]∥ International Conference on Control System,Computing and Engineering,Penang,Malaysia,2015: 117-122. |

| 11 | Yang Y X, Sun Q, Zhang D K,et al. Improved method based on faster R-CNN network optimization for small target surface defects detection of aluminum profile[C]∥ IEEE 15th International Conference on Electronic Measurement & Instruments(ICEMI), Nanjing, China, 2021: 465-470. |

| 12 | Liu M W, Lin Y H, Lo Y C,et al. Defect detection of grinded and polished workpieces using faster R-CNN[C]∥ Advanced Intelligent Mechatronics,Delft,Netherlands,2021: 1290-1296. |

| 13 | Zhang J D, Xu J B, Zhang L Y,et al. An improved mobilenet-ssd algorithm for automatic defect detection on vehicle body paint[J]. Multimedia Tools and Applications,2020,79(31/32): 23367-23385. |

| 14 | Chang F, Liu M, Dong M Y,et al. A mobile vision inspection system for tiny defect detection of smooth car-body surface based on deep ensemble learning[J]. Measurement Science and Technology,2019,30(12): 125905. |

| 15 | Chang F, Dong M Y, Liu M,et al. A lightweight appearance quality assessment system based on parallel deep learning for painted car-body[J]. IEEE Transactions on Instrumentation and Measurement,2020,69(8): 5298-5307. |

| 16 | Xu G, Guo R F, Wang H L. Quality inspection of workpiece camouflage spraying based on improved YOLOv3-tiny[C]∥ IEEE International Conference Computer and Communications,Chengdu,China,2020: 1363-1367. |

| 17 | Venkat A A, Chih H C, Hsu C C,et al. Applying deep learning to defect detection in printed circuit boards via a newest model of you-only-look-once[J]. Mathematical Biosciences and Engineering,2021,18(4): 4411-4428. |

| 18 | Liao D H, Cui Z H, Zhang X,et al. Surface defect detection and classification of Si3N4 turbine blades based on convolutional neural network and YOLOv5[J]. Advances in Mechanical Engineering,2022,14(2): 16878132221081580. |

| 19 | Tu X G, Yuan Z H, Liu B K,et al. An improved YOLOv5 for object detection in visible and thermal infrared images based on contrastive learning[J]. Frontiers in Physics,2023,11: 354-363. |

| 20 | Zhang R, Xie C, Deng L W. A fine-grained object detection model for aerial images based on YOLOv5 deep neural network[J]. Chinese Journal of Electronics,2023,32(1): 51-63. |

| 21 | Wang C Y, Alexey B, Liao H Y. YOLOv7: trainable bag-of-freebies sets new state-of-the-art for real-time object detectors[C]∥ Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition,Vancouver,Canada,2022: 7464-7475. |

| [1] | Ling HUANG,Zuan CUI,Feng YOU,Pei-xin HONG,Hao-chuan ZHONG,Yi-xuan ZENG. Vehicle trajectory prediction model for multi-vehicle interaction scenario [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1188-1195. |

| [2] | Hong-yan GUO,Lian-bing WANG,Xu ZHAO,Qi-kun DAI. Joint estimation of vehicle mass and road slope considering lateral motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1175-1187. |

| [3] | Shao-hua WANG,Qi-rui ZHANG,De-hua SHI,Chun-fang YIN,Chun LI. Analysis of nonlinear vibration response characteristics of hybrid transmission system with dual-planetary gear sets [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 890-901. |

| [4] | Xue-jing DU,Ning WANG,Jie ZHANG,Yu-long PEI. Control strategy of lateral stability of semi-trailer train in dangerous section of cold area [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 996-1006. |

| [5] | Zhen-hai GAO,Rong-gui CAI,Tian-jun SUN,Tong YU,Hao-yuan ZHAO,Hao BAN. Data⁃filtering method for driving behavior based on vehicle shared autonomy [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 589-599. |

| [6] | Xian-yi XIE,Yu-han WANG,Li-sheng JIN,Xin ZHAO,Bai-cang GUO,Ya-ping LIAO,Bin ZHOU,Ke-qiang LI. Intelligent vehicle trajectory tracking control based on adjusting step size of control horizon [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 620-630. |

| [7] | Xiao-lin DENG,Fu-mo YANG,Shan-gan QIN. Comparative analysis on crashworthiness of a novel bamboo⁃like hexagonal gradient hierarchical multicellular tube [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 333-345. |

| [8] | Yi-gang WANG,Yu-peng WANG,Hao ZHANG,Si-an ZHAO. Identification and analysis of aerodynamic noise sources in the bogie area of high⁃speed trains [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 346-355. |

| [9] | Jian-jun NIE,Jun-kai HOU,Xiao-lin XIE,Hong-zhen YAN. Design and obstacle surmounting performance analysis of a novel mobile chassis for inspection robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 356-364. |

| [10] | Guo-jun YANG,Ya-hui QI,Xiu-ming SHI. Review of bridge crack detection based on digital image technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 313-332. |

| [11] | Xiong-fei LI,Zi-xuan SONG,Rui ZHU,Xiao-li ZHANG. Remote sensing change detection model based on multi⁃scale fusion [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 516-523. |

| [12] | Yue-lin CHEN,Zhu-cheng GAO,Xiao-dong CAI. Long text semantic matching model based on BERT and dense composite network [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 232-239. |

| [13] | Tie WANG,Xu-dong LI,Cheng TIAN,Hong-wei ZHAO. Building biaxial fatigue damage model of wheel rims based on multi-axial loads projection theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 99-104. |

| [14] | Xu-dong LI,Xin-yu WANG,Cheng TIAN,Xin-feng ZHANG,Zhi-hui NIU,Zhi-qiang ZHAO. Compiling vehicle durability load spectrum based on customer usage correlation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 66-75. |

| [15] | Zhao-wei CHEN,Qian-hua PU. Suppression characteristics of vehicle⁃bridge coupling vibration of long⁃span cable⁃stayed bridge with resilient wheels [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2519-2532. |

|

||