Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (1): 99-104.doi: 10.13229/j.cnki.jdxbgxb.20220307

Previous Articles Next Articles

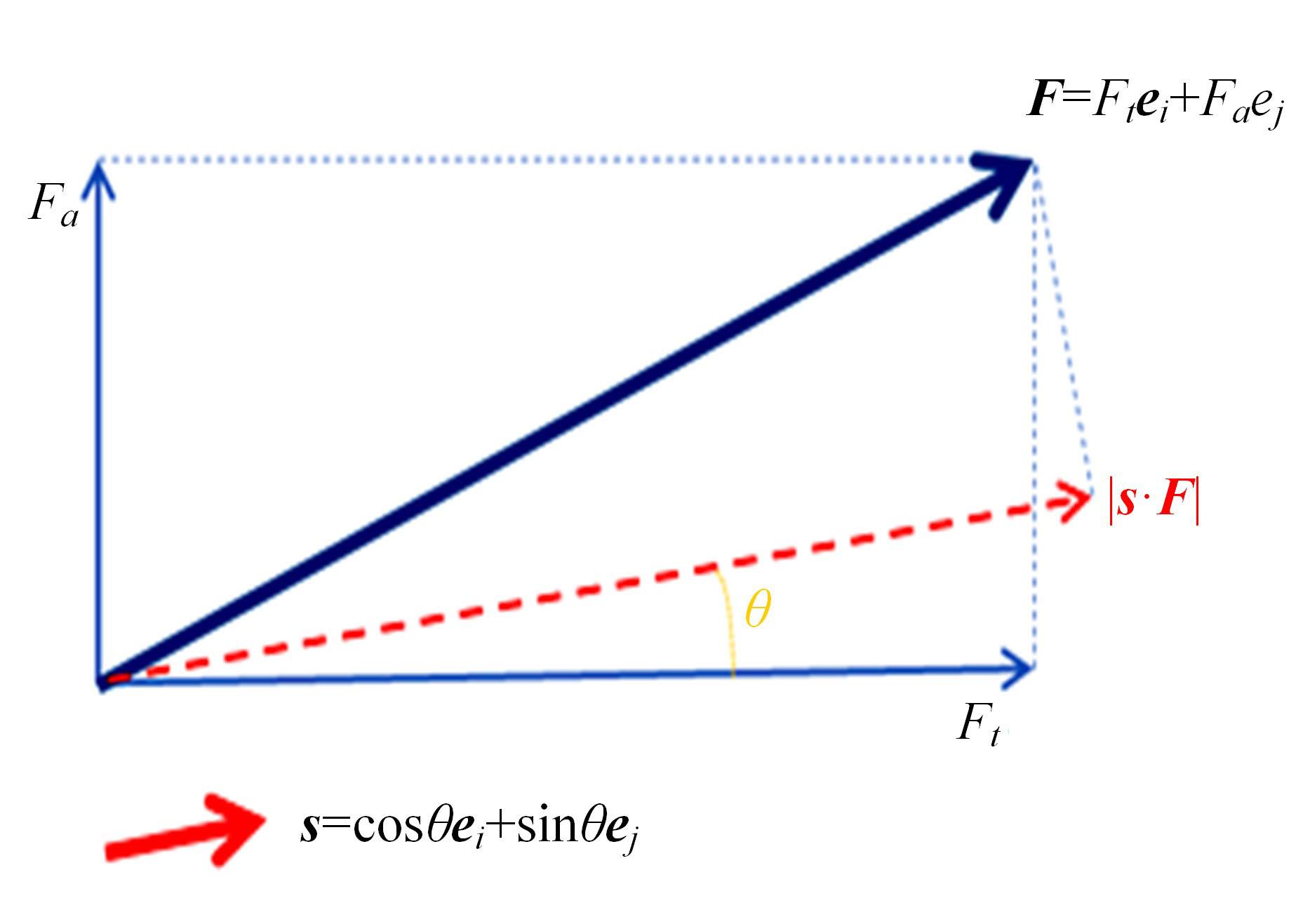

Building biaxial fatigue damage model of wheel rims based on multi-axial loads projection theory

Tie WANG1,2( ),Xu-dong LI3(

),Xu-dong LI3( ),Cheng TIAN3,Hong-wei ZHAO1

),Cheng TIAN3,Hong-wei ZHAO1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.CATARC(Tianjin) Automotive Information Consulting Co. ,Ltd. ,Tianjin 300300,China

3.Chassis Test and Research Department,CATARC Automotive Test Center (Tianjin) Co. ,Ltd. ,Tianjin 300300,China

CLC Number:

- U467

| 1 | 王霄锋,王波,赵震伟,等. 汽车车轮结构强度分析. 机械强度[J],2002,24(1):66-69. |

| Wang Xiao-feng, Wang Bo, Zhao Zhen-wei, et al. Structure strength analysis of automotive wheels[J]. Journal of Mechanical Strength, 2002, 24(1): 66-69. | |

| 2 | 杨占春,崔胜民,赵桂范. 用改进的史密斯公式预测汽车车轮疲劳寿命[J]. 哈尔滨工业大学学报,2000,32(6):100-102. |

| Yang Zhan-chun, Cui Sheng-min, Zhao Gui-fan. Prediction of automobile wheel fatigue life with improved smith equation[J]. Journal of Harbin Institute of Technology, 2000, 32(6): 100-102. | |

| 3 | 崔胜民,杨占春. 汽车车轮疲劳寿命预测方法的研究[J]. 机械强度,2002,24(4):617-619. |

| Cui Sheng-min, Yang Zhan-chun. Research on the fatigue life prediction method of automobile wheel[J]. Journal of Mechanical Strength, 2002, 24(4): 617-619. | |

| 4 | 董赟,冯瑞成,剡昌锋,等. 一种计算轮辋疲劳损伤的数值模拟新算法[J]. 中国机械工程,2015,26(23):3178-3183. |

| Dong Yun, Feng Rui-cheng, Yan Chang-feng, et. al . A new numerical simulation method for calculating fatigue damage of wheels[J]. Chinese Mechanical Engineering, 2015, 26(23): 3178-3183. | |

| 5 | 王悦东,盛杰琼. 单轴和多轴疲劳准则下的车轮疲劳强度分析[J]. 大连交通大学学报,2016,37(2):47-52. |

| Wang Yue-dong, Sheng Jie-qiong. Analysis of wheel fatigue strength under uni-axial and multi-axis fatigue criterions[J]. Journal of Dalian Jiaotong Unitversity, 2016, 37(2): 47-52. | |

| 6 | 闫胜昝,童水光,张响,等. 汽车车轮弯曲疲劳试验分析研究[J]. 机械强度,2008,30(4):687-691. |

| Yan Sheng-zan, Tong Shui-guang, Zhang Xiang, et al. Analysis study on bending fatigue test of automobile wheels[J]. Journal of Mechanical Strength, 2008, 30(4): 687-691. | |

| 7 | Wan X F, Shan Y C, Liu X D, et al. Simulation of biaxial wheel test and fatigue life estimation considering the influence of tire and wheel camber[J]. Advances in Engineering Software, 2016, 92: 57-64. |

| 8 | Fabio M S, Riccardo M, Ivo K, et al. Simulation of the scenario of the biaxial wheel fatigue test[J]. Advances in Engineering Software, 2017,114 : 1-11. |

| 9 | 姚卫星. 结构疲劳寿命分析[M]. 北京:科学出版社,2018. |

| 10 | Johannesson P, Speckert M. Euide to Load Analysis for Durability in Vehicle Engineering[M]. London:John Wiley & Sons Ltd, 2014. |

| [1] | Xu-dong LI,Xin-yu WANG,Cheng TIAN,Xin-feng ZHANG,Zhi-hui NIU,Zhi-qiang ZHAO. Compiling vehicle durability load spectrum based on customer usage correlation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 66-75. |

| [2] | Zhao-wei CHEN,Qian-hua PU. Suppression characteristics of vehicle⁃bridge coupling vibration of long⁃span cable⁃stayed bridge with resilient wheels [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2519-2532. |

| [3] | Ping-yi LIU,Xiao-ting LI,Ruo-lin GAO,Hai-tao LI,Wen-jun WEI,Ya WANG. Design and experiment of tilt-driving mechanism for the vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2185-2192. |

| [4] | Xue-jin HUANG,Jin-xing ZHONG,Jing-yu LU,Ji ZHAO,Wei XIAO,Xin-mei YUAN. Electric vehicle charging load forecasting method based on user portrait [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2193-2200. |

| [5] | Shu-pei ZHANG,Ming-yue XIA,Wei ZHANG,Zhao CHEN,Yi-xiang CHEN. Impact dynamic modeling and simulation for ball joint with clearance considering nonlinear stiffness [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2227-2235. |

| [6] | Hui CHEN,Ya-jun SHAO. Measurement method of pavement surface spectrum with multi⁃sensor coupling based on inertial benchmark [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2254-2262. |

| [7] | Lei CHEN,Yang WANG,Zhi-sheng DONG,Ya-qi SONG. A vehicle agility control strategy based on steering intent [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1257-1263. |

| [8] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [9] | Yong ZHANG,Feng-zhao MAO,Shui-chang LIU,Qing-yu WANG,Shen-gong PAN,Guang-sheng ZENG. Optimization on distortion grid of vehicle external flow field based on Laplacian Algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1289-1296. |

| [10] | Shao-hua WANG,Kun CHU,De-hua SHI,Chun-fang YIN,Chun LI. Robust compound coordinated control of HEV based on finite⁃time extended state observation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1272-1281. |

| [11] | Yan-li YIN,Xue-jiang HUANG,Xiao-liang PAN,Li-tuan WANG,Sen ZHAN,Xin-xin ZHANG. Hierarchical control of hybrid electric vehicle platooning based on PID and Q⁃Learning algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1481-1489. |

| [12] | Gui-shen YU,Xin CHEN,Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG. Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1338-1344. |

| [13] | Yan-tao TIAN,Xing HUANG,Hui-qiu LU,Kai-ge WANG,Fu-qiang XU. Multi⁃mode behavior trajectory prediction of surrounding vehicle based on attention and depth interaction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1474-1480. |

| [14] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1007-1018. |

| [15] | Li-juan YU,Yang AN,Jia-long HE,Guo-fa LI,Sheng-xu WANG. Research progress and development trend of extrapolation method in electromechanical equipment load spectrum [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 941-953. |

|

||