Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (6): 1883-1891.doi: 10.13229/j.cnki.jdxbgxb.20231047

Previous Articles Next Articles

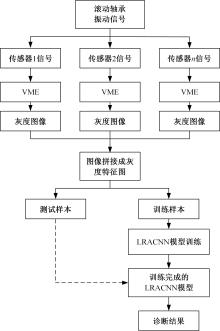

Rolling bearing fault diagnosis based on variational mode extraction and lightweight network

Zhi-gang FENG( ),Shou-qi WANG,Ming-yue YU

),Shou-qi WANG,Ming-yue YU

- College of Automation,Shenyang Aerospace University,Shenyang 110136,China

CLC Number:

- TH17

| [1] | Yang D, Karimi H R, Sun K. Residual wide-kernel deep convolutional auto-encoder for intelligent rotating machinery fault diagnosis with limited samples[J]. Neural Networks, 2021, 14: 133-144. |

| [2] | 陈晓雷, 孙永峰, 李策, 等. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报: 工学版, 2022, 52(2): 296-309. |

| Chen Xiao-lei, Sun Yong-feng, Li Ce, et al. Stable anti⁃noise fault diagnosis of rolling bearing based on CNN⁃BiLSTM[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 296-309. | |

| [3] | Gu J, Peng Y, Lu H, et al. A novel fault diagnosis method of rotating machinery via VMD, CWT and improved CNN[J]. Measurement, 2022, 200: No.111635. |

| [4] | Yao D, Liu H, Yang J, et al. A lightweight neural network with strong robustness for bearing fault diagnosis[J]. Measurement, 2020, 159: No.107756. |

| [5] | Bai R, Xu Q, Meng Z, et al. Rolling bearing fault diagnosis based on multi-channel convolution neural network and multi-scale clipping fusion data augmentation[J]. Measurement, 2021, 184: No.109885. |

| [6] | Zhong H, Lv Y, Yuan R, et al. Bearing fault diagnosis using transfer learning and self-attention ensemble lightweight convolutional neural network[J]. Neurocomputing, 2022, 501: 765-777. |

| [7] | Wang S, Feng Z. Multi-sensor fusion rolling bearing intelligent fault diagnosis based on VMD and ultra-lightweight GoogLeNet in industrial environments[J]. Digital Signal Processing, 2024, 145: No.104306. |

| [8] | 王军, 张维通, 闫正兵, 等. 基于迁移QCNN的孪生网络轴承故障诊断方法[J]. 计算机测量与控制, 2024, 32(4): 6-12. |

| Wang Jun, Zhang Wei-tong, Yan Zheng-bing, et al. Twin network-based bearing fault diagnosis method with transfer QCNN[J]. Computer Measurement & Control, 2024, 32(4): 6-12. | |

| [9] | Nazari M, Sakhaei S M. Variational mode extraction: A new efficient method to derive respiratory signals from ECG[J]. IEEE Journal of Biomedical and Health Informatics, 2018, 22(4): 1059-1067. |

| [10] | Saini R, Jha N K, Das B, et al. ULSAM: Ultra-ightweight ubspace ttention odule for ompact onvolutional eural etworks[C]∥2020 IEEE Winter Conference on Applications of Computer Vision (WACV), Snowmass, CO, USA, 2020: 1616-1625. |

| [11] | Ye M, Yan X, Chen N, et al. Intelligent fault diagnosis of rolling bearing using variational mode extraction and improved one-dimensional convolutional neural network[J]. Applied Acoustics, 2023, 202: No.109143. |

| [12] | Smith W A, Randall R B. Rolling element bearing diagnostics using the case western reserve university data: a benchmark study[J]. Mechanical Systems and Signal Processing, 2015, 64-65: 100-131. |

| [13] | Wang Y, Yan J, Sun Q, et al. Bearing intelligent fault diagnosis in the industrial internet of things context: a lightweight convolutional neural network[J]. IEEE Access, 2020, 8: 87329-87340. |

| [14] | Ling L, Wu Q, Huang K, et al. A lightweight bearing fault diagnosis method based on multi-channel depthwise separable convolutional neural network[J]. Electronics, 2022, 11(24): No.4110. |

| [15] | Xu Z, Mei X, Wang X, et al. Fault diagnosis of wind turbine bearing using a multi-scale convolutional neural network with bidirectional long short term memory and weighted majority voting for multi-sensors[J]. Renewable Energy, 2022, 182: 615-626. |

| [1] | Rui-shan DU,Zi-shan WANG. Multi perspective facial expression recognition algorithm based on spatiotemporal attention [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 2097-2102. |

| [2] | Ya-li XUE,Tong-an YU,Shan CUI,Li-zun ZHOU. Infrared small target detection based on cascaded nested U-Net [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1714-1721. |

| [3] | Hua CAI,Yu-yao WANG,Qiang FU,Zhi-yong MA,Wei-gang WANG,Chen-jie ZHANG. Semantic segmentation network based on attention mechanism and feature fusion [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1384-1395. |

| [4] | He-shan ZHANG,Meng-wei FAN,Xin TAN,Zhan-ji ZHENG,Li-ming KOU,Jin XU. Dense small object vehicle detection in UAV aerial images using improved YOLOX [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1307-1318. |

| [5] | De-qiang CHENG,Gui LIU,Qi-qi KOU,Jian-ying ZHANG,He JIANG. Lightweight image super⁃resolution network based on adaptive large kernel attention fusion [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 1015-1027. |

| [6] | Yang LI,Xian-guo LI,Chang-yun MIAO,Sheng XU. Low⁃light image enhancement algorithm based on dual branch channel prior and Retinex [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 1028-1036. |

| [7] | Na WANG,Yue-lei CUI,Yang LI,Zi-cong WANG. Rolling bearing fault diagnosis method via wavelet packet logarithmic-energy map [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 494-502. |

| [8] | Hua-song DONG,Yuan-feng LIAN. Lightweight detection algorithm for lossless transcoding and heavy compression of massive digital media videos [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 741-747. |

| [9] | Xiao-ran GUO,Tie-jun WANG,Yue YAN. Entity relationship extraction method based on local attention and local remote supervision [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 307-315. |

| [10] | Hao WANG,Bin ZHAO,Guo-hua LIU. Temporal and motion enhancement for video action recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 339-346. |

| [11] | Lu Li,Jun-qi Song,Ming Zhu,He-qun Tan,Yu-fan Zhou,Chao-qi Sun,Cheng-yu Zhou. Object extraction of yellow catfish based on RGHS image enhancement and improved YOLOv5 network [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2638-2645. |

| [12] | Ping YU,Kang ZHAO,Jie CAO. Rolling bearing fault diagnosis based on optimized A-BiLSTM [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2156-2166. |

| [13] | Sheng-jie ZHU,Xuan WANG,Fang XU,Jia-qi PENG,Yuan-chao WANG. Multi-scale normalized detection method for airborne wide-area remote sensing images [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2329-2337. |

| [14] | Yun-zuo ZHANG,Yu-xin ZHENG,Cun-yu WU,Tian ZHANG. Accurate lane detection of complex environment based on double feature extraction network [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1894-1902. |

| [15] | Chang-jian WANG,Jiu-ming LIU,Jin-zhou ZHANG,Bin LI. Laser sequence pulse diagnosis method of planetary reducer fault based on high-speed photography technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1869-1875. |

|