Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (6): 1892-1905.doi: 10.13229/j.cnki.jdxbgxb.20231023

Previous Articles Next Articles

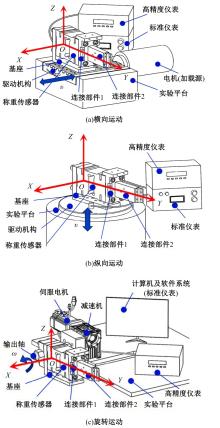

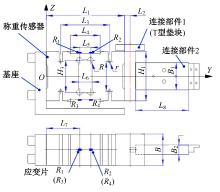

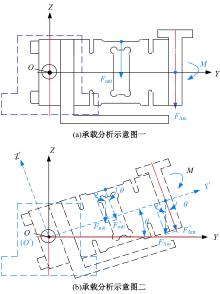

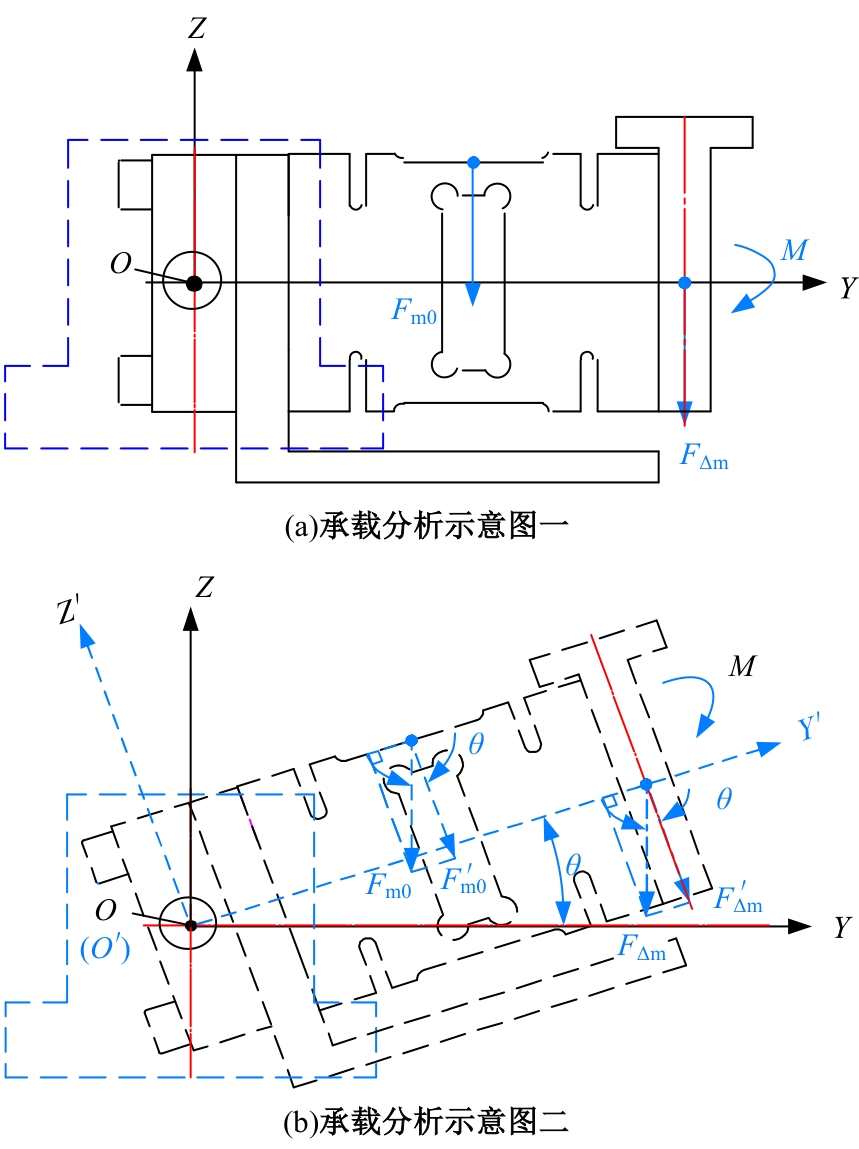

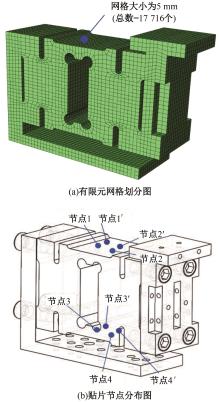

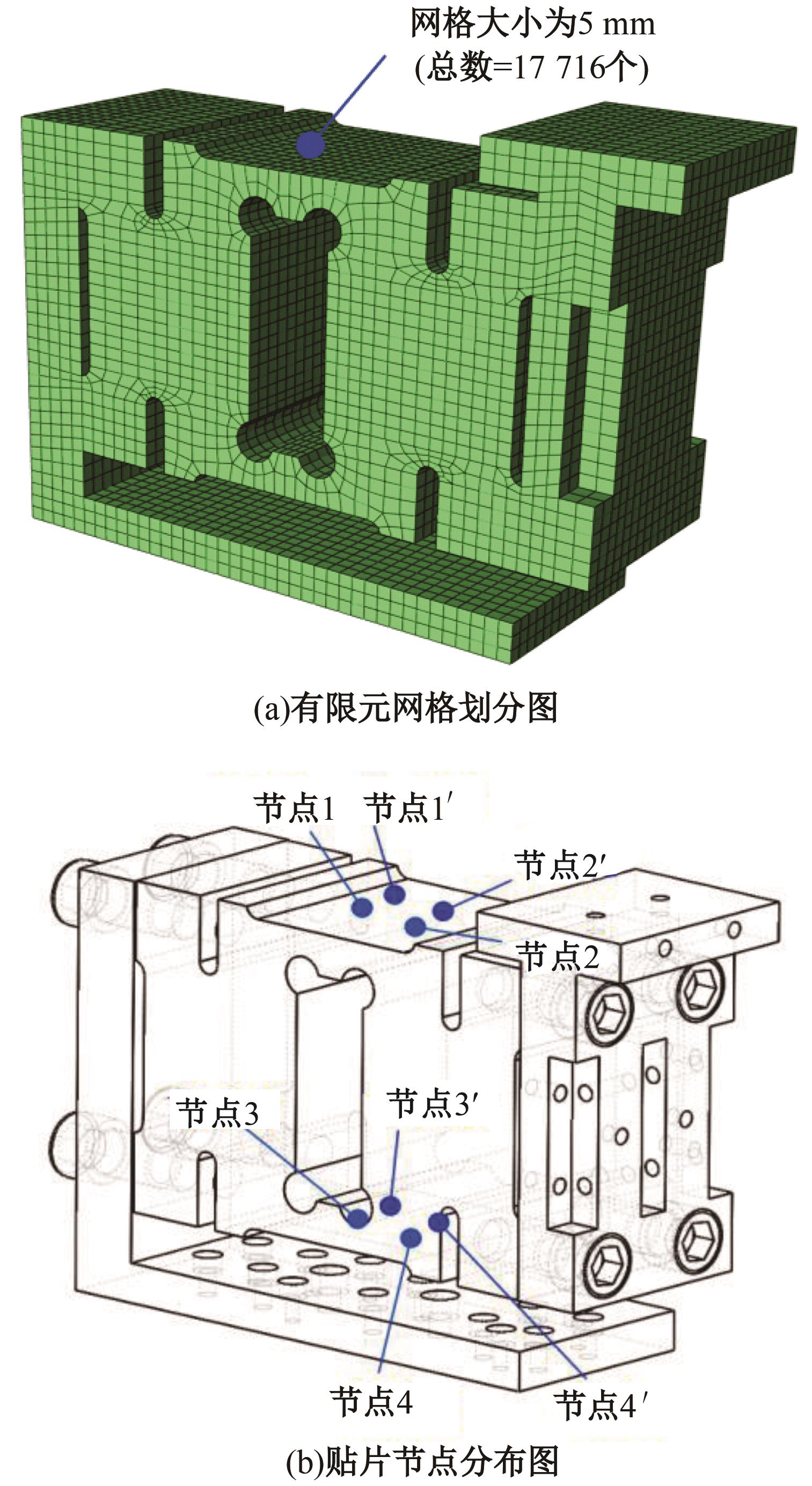

Effect of parasitic load components with multi⁃directional motion on weight⁃sensing outputs

Gui-yong GUO1,2,3,4,5( ),Jian-feng ZHONG1,2(

),Jian-feng ZHONG1,2( ),Qiu-kun ZHANG1,2,Bao-jie CAI3,4,5

),Qiu-kun ZHANG1,2,Bao-jie CAI3,4,5

- 1.School of Mechanical Engineering and Automation,Fuzhou University,Fuzhou 350108,China

2.Fujian Provincial Key Laboratory of Terahertz Functional Devices and Intelligent Sensing,Fuzhou University,Fuzhou 350108,China

3.Division of Construction and Transportation,Fujian Institute of Metrology,Fuzhou 350003,China

4.Fujian Key Laboratory of Force Measurement,Fuzhou 350100,China

5.Key Laboratory of Force Measurement for State Market Regulation,Fuzhou 350100,China

CLC Number:

- TH715

| [1] | 朱建梅, 黄松和. 平行梁式称重传感器的动态仿真分析[J]. 机械, 2014, 41(11): 31-35, 76. |

| Zhu Jian-mei, Huang Song-he. Dynamic simulation analysis of parallel girder load sensor[J]. Machinery, 2014, 41(11): 31-35, 76. | |

| [2] | 张业兵. 运动速度对动态称重的影响[J]. 山东理工大学学报: 自然科学版, 2007, 21(2): 41-44, 47. |

| Zhang Ye-bin. The influence of vehicle speed on weigh-in-motion[J]. Journal of Shandong University of Technology (Natural Science Edition), 2007, 21(2): 41-44, 47. | |

| [3] | 尹继武, 龙姝明. 应变片倾斜角度对称重传感器偏载误差的影响[J]. 陕西理工学院学报: 自然科学版, 2014, 30(2): 19-23. |

| Yin Ji-wu, Long Shu-ming. Influence of strain gauge tilt angle on eccentric error of load sensor[J].Journal of Shaanxi University of Technology (Natural Science Edition), 2014, 30(2): 19-23. | |

| [4] | 郁有文, 常健, 程继红. 传感器原理及工程应用[M]. 4版. 西安: 西安电子科技大学出版社, 2014. |

| [5] | 赵思宏, 田春艳, 范惠林. 平行梁式称重传感器的有限元分析[J]. 光学精密工程, 2002, 10(2): 209-213. |

| Zhao Si-hong, Tian Chun-yan, Fan Hui-lin. Finite element analysis of the parallel girder load sensor [J]. Optics and Precision Engineering, 2002, 10(2): 209-213. | |

| [6] | 何兆湘, 黄兆祥, 王楠. 传感器原理与检测技术[M]. 武汉: 华中科技大学出版社, 2019. |

| [7] | 郑韬, 俞宁峰, 连昌伟. 应变计式力传感器对高速拉伸载荷振荡的改善[J]. 锻压技术, 2019, 44(8): 124-128, 136. |

| Zheng Tao, Yu Ning-feng, Lian Chang-wei. Improvement of load oscillation in high-speed tension by strain gauge force sensor[J]. Forging & Stamping Technology, 2019, 44(8): 124-128, 136. | |

| [8] | Mocanu S, Panaitescu R, Tonciu O, et al. Influence of the parallel beam load cell installation on the strain/stress field reading error[J].Romanian Journal of Transport Infrastructure, 2023, 12(1): 1-13. |

| [9] | 干方建, 刘正士, 孔凡让, 等. 传感器微分运动引起的机器人运动误差及其在线补偿[J]. 中国机械工程, 2005(23): 2069-2071. |

| Gan Fang-jian, Liu Zheng-shi, Kong Fan-rang, et al. On-line compensation of robot motion errors based on multi-axis force sensor's deformation[J]. China Mechanical Engineering, 2005(23): 2069-2071. | |

| [10] | 陈浩文, 李坚, 王兵, 等 . 机器人交互作业中六维力传感器重力补偿研究[J]. 组合机床与自动化加工技术, 2021(10): 47-51. |

| Chen Hao-wen, Li Jian, Wang Bing, et al. Research on gravity compensation of six-axis force sensor in robot interactive operation[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2021(10):47-51. | |

| [11] | Li J, Guan Y, Chen H, et al. A high-bandwidth end-effector with active force control for robotic pol‐ishing[J]. IEEE Access, 2020, 8: 169122-169135. |

| [12] | Taeyong K, Marco V A, Jaehong S, et al. Development of a differential load cell negating inertial force[J]. Measurement, 2023, 223: No.113789. |

| [13] | 马涛, 马源, 黄晓明 . 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报: 工学版,2023, 53(7): 2067-2077. |

| Ma Tao, Ma Yuan, Huang Xiao-ming. Optimal combination of key parameters of intelligent compaction based on multiple nonlinear regression[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(7): 2067-2077. |

| [1] | Yi TANG,Bing-chuan LU,Hong-chen YI,Cheng YU,Bin NAN. Multi spectral image fusion algorithm for unmanned aerial vehicles based on gradient consistency constraint [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 2076-2081. |

| [2] | Yong ZHAO,Wen-ming JIN,Qi-feng ZHENG,Shu-qing KOU. Influence of cracking groove depth on cracking performance of bearing seat of reducer housing [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1552-1558. |

| [3] | An-shun ZHANG,Wei FU,Jun-hui ZHANG,Feng GAO. Shear properties and stress-strain relationships characterization of Changsha compacted clay [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1604-1616. |

| [4] | Ling LI,Hui-tao TIAN,Dong-hao MIAO,Miao-xia XIE,Fu-an CHENG. Analysis of relaxation characteristics of multi-bolted connections under the transverse cyclic load [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1525-1535. |

| [5] | Ming-feng SU,Guo-jun WANG,Cong ZHOU,Tian WANG. A heuristic task offloading approach with delay and energy constraints for edge-cloud collaboration [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1648-1663. |

| [6] | Xin-chen YE,Hai-long ZHANG,Jie WANG,Da-lei LI,Meng ZHANG,Ya-zhou ZHANG,Xu DU,Jia LI,Wan-qiong WANG. EMD-LSTM-based group prediction algorithm of container resource load in preprocessing molecular spectral line data [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1374-1383. |

| [7] | Yong-jun ZHOU,Feng-rui MU,Cheng CAI,Fan YANG. Influence factors of preload loss in cable clamp bolt of suspension bridge based on orthogonal experiment method [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1188-1196. |

| [8] | Yun-feng HU,Jia-min LI,Zhi-guo TANG. Solving method on inverse kinematics of mobile loading missile manipulator by multi-population grey wolf optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(4): 1443-1452. |

| [9] | Jian-huang YAN,Zhi-yong WANG,En-hong TANG,Xue HAN,Hai-feng LI,Zi-qin JIANG. Mechanical properties of austenitic stainless steels under monotonic and cyclic loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 912-924. |

| [10] | Dang LU,Xiao-fan WANG,Hai-dong WU. Analysis of uniform distribution characteristics of contact pressure of TWEEL tires [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 811-819. |

| [11] | Liang-liang ZHANG,Hua CHENG,Xiao-jian WANG. Energy evolution law and failure criterion of high strength concrete under conventional triaxial compression [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 974-985. |

| [12] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

| [13] | Guo-wei FAN,Yu GAO,Quan-zhi LIU,Yang XIAO,Xue-ying LYU,Le ZHANG,Liu ZHANG. Attitude maneuvering planning method of remote sensing satellite based on improved adaptive pseudo-spectrum method [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 355-365. |

| [14] | Han-ying HUANG,Peng-fei LI. Method and experiments on edge computing resource allocation in smart fishery [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 316-324. |

| [15] | Yu-xin XUE,Yong-jun ZHOU,Ye-lu WANG,Kai-xiang FAN,Yu ZHAO. Application of dynamic load allowance test method of simply supported girder bridge based on suspension hammer system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2557-2567. |

|