Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (7): 2343-2353.doi: 10.13229/j.cnki.jdxbgxb.20231113

Creep properties of concrete under hydrothermal coupling curing

Wei-jing YAO1,2,3( ),Meng-yu BAI1,Hai-bing CAI1,3,Tao LIU1

),Meng-yu BAI1,Hai-bing CAI1,3,Tao LIU1

- 1.School of Civil Engineering and Architecture,Anhui University of Science and Technology,Huainan 232001,China

2.Postdoctoral Science Research Workstation,Wuhu Surveying and Mapping Design Institute Co. ,Ltd. ,Wuhu 241000,China

3.Anhui Key Laboratory of Mining Construction Engineering,Anhui University of Science and Technology,Huainan 232001,China

CLC Number:

- TU528

| [1] | 陈文化. 高温高湿环境下高铁隧道洞口段热湿病害分析[J].铁道工程学报, 2016, 33(11): 102-105, 119. |

| Chen Wen-hua. Analysis of railway tunnel portal section thermal-humidity failure in high temperature and high humidity[J].Journal of Railway Engineering Society, 2016, 33(11): 102-105, 119. | |

| [2] | 王影冲, 王鼎, 郝圣旺. 混凝土蠕变与应力松弛耦合破坏及临界幂律行为[J].工程力学, 2016, 33(): 49-55. |

| Wang Ying-chong, Wang Ding, Hao Sheng-wang. Creep-stress relaxation coupling failure in concrete and its critical power-law behavior[J].Engineering Mechanics, 2016 33(Sup.1): 49-55. | |

| [3] | Gong J, Cao J, Wang Y F. Effects of sulfate attack and dry-wet circulation on creep of fly-ash slag concrete[J].Construction and Building Materials, 2016, 125: 12-20. |

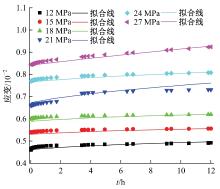

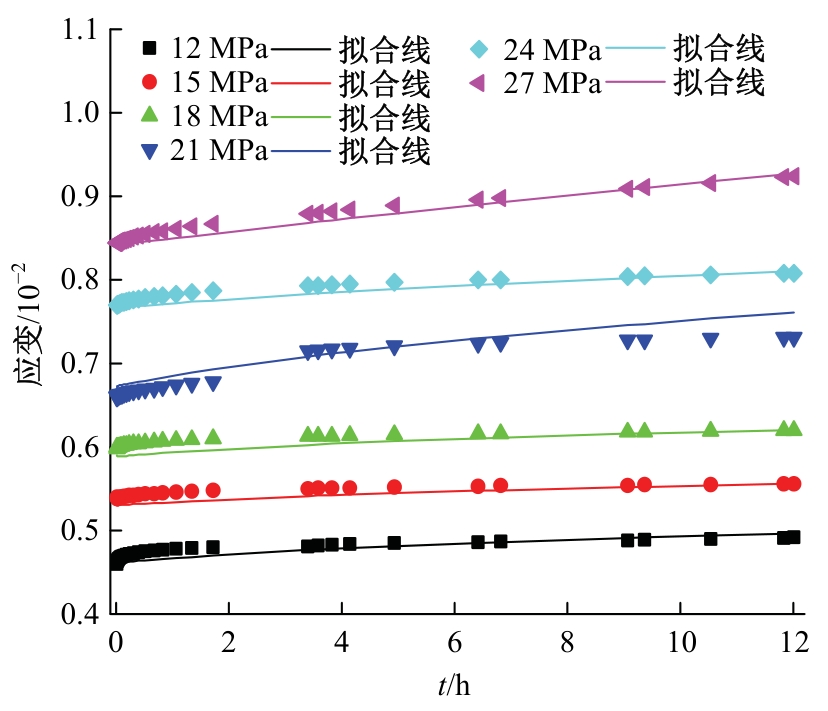

| [4] | Su L, Wang Y F, Mei S Q, et al. Experimental investigation on the fundamental behavior of concrete creep[J].Construction and Building Materials, 2017, 152: 250-258. |

| [5] | 辛亚军, 安定超, 郝海春. 高应力水平区混凝土试件蠕变特性及失稳机制[J].采矿与安全工程学报, 2018, 35(2): 382-390. |

| Xin Ya-jun, An Ding-chao, Hao Hai-chun. Creep characteristics and instability mechanism of concrete specimen in high-stress area[J].Journal of Mining & Safety Engineering, 2018, 35(2): 382-390. | |

| [6] | Zhao Q X, Liu X C, Jiang J Y. Effect of curing temperature on creep behavior of fly ash concrete[J].Construction and Building Materials, 2015, 96: 326-333. |

| [7] | 李想, 刘传孝, 孟琪, 等. 不同温度下混凝土材料的短时蠕变特性研究[J].矿业研究与开发, 2019, 39(2): 82-86. |

| Li Xiang, Liu Chuan-xiao, Meng Qi, et al. Study on short-term creep characteristics of concrete materials at different temperatures[J].Mining Research and Development, 2019, 39(2): 82-86. | |

| [8] | 刘雨姗, 庞建勇, 姚韦靖. 页岩陶粒轻骨料混凝土高温后蠕变特性[J].建筑材料学报, 2021, 24(5): 1096-1104. |

| Liu Yu-shan, Pang Jian-yong, Yao Wei-jing. Creep behavior of shale ceramsite lightweight aggregate concrete exposed to high temperature[J].Journal of Building Materials, 2021, 24(5): 1096-1104. | |

| [9] | 郭平业, 卜墨华, 张鹏, 等. 高地温隧道灾变机制与灾害防控研究进展[J].岩石力学与工程学报, 2023, 42(7): 1561-1581. |

| Guo Ping-ye, Bu Mo-hua, Zhang Peng, et al. Review on catastrophe mechanism and disaster countermeasure of high geotemperature tunnels[J].Chinese Journal of Rock Mechanics and Engineering, 2023, 42(7): 1561-1581. | |

| [10] | 傅金阳, 徐光阳, 杨曾, 等. 高地温隧道衬砌混凝土早期开裂机理及防控措施[J].铁道学报, 2022, 44(3): 105-114. |

| Fu Jin-yang, Xu Guang-yang, Yang Zeng, et al. Early cracking mechanism and prevention measures for ling concrete in high geotemperature tunnel[J].Journal of the China Railway Society, 2022, 44(3): 105-114. | |

| [11] | .普通混凝土配合比设计规程 [S]. |

| [12] | . 普通混凝土长期性能和耐久性能试验方法标准 [S]. |

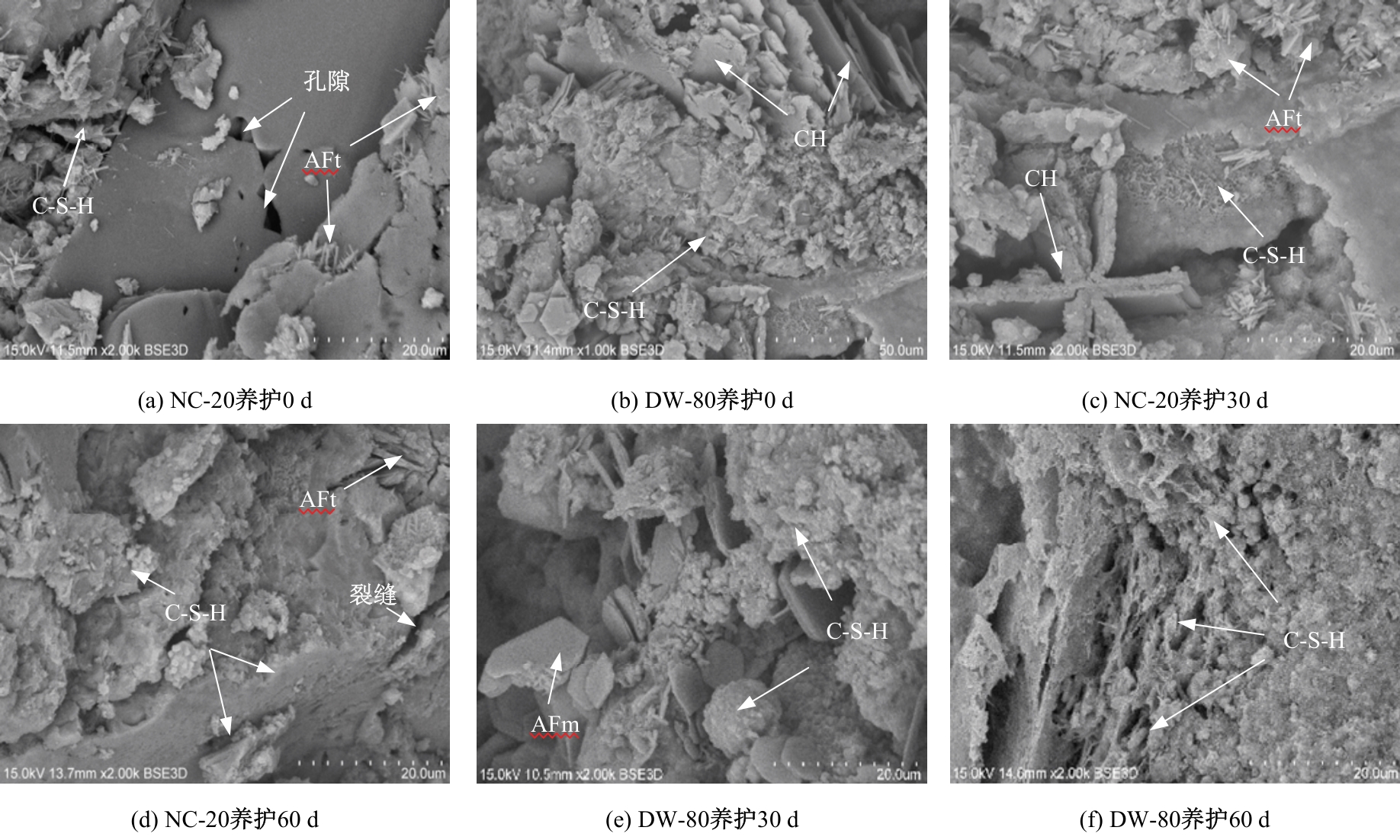

| [13] | 邵化建, 李宗利, 肖帅鹏, 等. 干湿循环作用下混凝土力学性能及微观结构研究[J].硅酸盐通报, 2021, 40(9): 2948-2955. |

| Shao Hua-jian, Li Zong-li, Xiao Shuai-peng, et al. Mechanical properties and microstructure of concrete under drying-wetting cycles[J].Bulletin of the Chinese Ceramic Society, 2021, 40(9): 2948-2955. | |

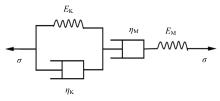

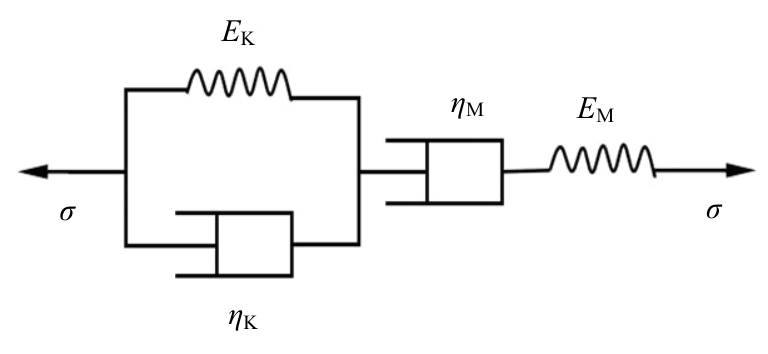

| [14] | 周瑞鹤, 程桦, 蔡海兵, 等. 三轴压缩分级卸荷条件下粉砂岩蠕变特性及蠕变模型[J].岩石力学与工程学报, 2022, 41(6): 1136-1147. |

| Zhou Rui-he, Cheng Hua, Cai Hai-bing, et al. Creep characteristics and creep model of siltstone under triaxial compression and graded unloading[J].Chinese Journal of Rock Mechanics and Engineering, 2022, 41(6): 1136-1147. | |

| [15] | 张俊文, 霍英昊. 深部砂岩分级增量加卸载蠕变特性[J].煤炭学报, 2021, 46(): 661-669. |

| Zhang Jun-wen, Huo Ying-hao. Creep behavior of deep sandstones under stepwise incremental loading and unloading conditions[J].Journal of China Coal Society, 2021, 46(Sup.2): 661-669. | |

| [16] | Vidal T, Sellier A, Ladaoui W, et al. Effect of temperature on the basic creep of high-performance concretes heated between 20 and 80 ℃[J].Journal of Materials in Civil Engineering Archive, 2015, 27(7): No.B4014002. |

| [17] | 马芹永, 郁培阳, 袁璞. 干湿循环对深部粉砂岩蠕变特性影响的试验研究[J].岩石力学与工程学报, 2018, 37(3): 593-600. |

| Ma Qin-yong, Yu Pei-yang, Yuan Pu. Experimental study on creep properties of deep siltstone under cyclic wetting and drying[J].Chinese Journal of Rock Mechanics and Engineering, 2018, 37(3): 593-600. | |

| [18] | 谌文武, 原鹏博, 刘小伟. 分级加载条件下红层软岩蠕变特性试验研究[J].岩石力学与工程学报, 2009, 28(): 3076-3081. |

| Chen Wen-wu, Yuan Peng-bo, Liu Xiao-wei. Study on creep properties of red-bed soft rock under step load[J].Chinese Journal of Rock Mechanics and Engineering, 2009, 28(Sup.1): 3076-3081. | |

| [19] | 于本田, 刘通, 王焕, 等. 花岗斑岩石粉含量对混凝土性能及微观结构的影响[J].吉林大学学报:工学版, 2022, 52(5): 1052-1062. |

| Yu Ben-tian, Liu Tong, Wang Huan, et al. Influence of granite porphyry stone powder content on properties and microstructure of concrete[J].Journal of Jilin University(Engineering and Technology Edition), 2022, 52(5): 1052-1062. | |

| [20] | Xu Y D, He T S, Ma X D, et al. The influence of calcium sulphoaluminate cement on the hydration process of cement paste mixed with alkali free liquid accelerator[J].Materials Today Communications, 2022, 33:No. 104622. |

| [21] | Cui S A, Liu P, Su J, et al. Experimental study on mechanical and microstructural properties of cement-based paste for shotcrete use in high-temperature geothermal environment[J].Construction and Building Materials, 2018, 174: 603-612. |

| [22] | 关博文, 邸文锦, 王发平, 等. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J].吉林大学学报:工学版, 2023, 53(4): 1112-1121. |

| Guan Bo-wen, Di Wen-jin, Wang Fa-ping, et al. Damage of concrete subjected to sulfate corrosion under dry-wet cycles and alternating loads[J].Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1112-1121. | |

| [23] | 钱觉时, 余金城, 孙化强, 等. 钙矾石的形成与作用[J].硅酸盐学报, 2017, 45(11): 1569-1581. |

| Qian Jue-shi, Yu Jin-cheng, Sun Hua-qiang, et al. Formation and function of ettringite in cement hydrates[J].Journal of the Chinese Ceramic Society, 2017, 45(11): 1569-1581. |

| [1] | Qiong FENG,Xiao-yang XIE,Peng-hui WANG,Hong-xia QIAO,Yun-xia MA. Prediction of reinforced concrete durability based on whale optimization algorithm-back propagation neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2276-2285. |

| [2] | Kang YAO,Qiao DONG,Xue-qin CHEN,Bin SHI,Shi-ao YAN,Xiang WANG. Mixed⁃mode mesoscale fracture behavior of concrete based on a phase field regularized cohesive zone model [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(7): 2286-2297. |

| [3] | Wen-yuan XU,Wei LI,Da-yang WANG,Yong-cheng JI. Damage mechanism of FRP reinforced concrete under alkali freezing coupling effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(6): 2050-2062. |

| [4] | Sheng-qi MEI,Xiao-dong LIU,Xing-ju WANG,Xu-feng LI,Teng WU,Xiang-xu CHENG. Prediction of high strength concrete creep based on parametric MIC analysis and machine learning algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(5): 1595-1603. |

| [5] | Zi-ming HE,Ai-qin SHEN,Lu-sheng WANG,Yin-chuan GUO,Jiang-fei HE. Review on strengthening technology of recycled concrete aggregate and its effect on performance of recycled aggregate concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 790-810. |

| [6] | Liang-liang ZHANG,Hua CHENG,Xiao-jian WANG. Energy evolution law and failure criterion of high strength concrete under conventional triaxial compression [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 974-985. |

| [7] | Jie YUAN,Jun-bo WANG,Xin CHEN,Xin HUANG,Ao-xiang ZHANG,An-qi CUI. Research progress on application of artificial intelligence in ultra⁃high performance concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(3): 771-789. |

| [8] | Guang-lei QU,Zong-wei YAN,Mu-lian ZHENG,Hong LIU,Yue-ming YUAN. Performance prediction of porous concrete based on neural network and regression analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 269-282. |

| [9] | Huai-xin LI,Chang-gen YAN,Bin LIN,Yu-ling SHI. Strength and statistical damage model in whole process of clay-concrete combined body [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 245-255. |

| [10] | Fang-fang WEI,Li-ping LI,Qing-peng XU,You-zheng ZHAO,Jing-jing YANG. Experiment on seismic behavior of fire-fired composite shear wall with double steel plates and infill concrete after reinforcement [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 230-244. |

| [11] | Wei-guo YANG,Ying-nan SU,Jian-qiang ZOU,Ruo-chen MA,Qing-liang ZHANG. Experiment and finite element analysis on new type of flange connection for precast concrete-filled steel tube core column [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 283-296. |

| [12] | Fu-cheng WANG,Xin-rong ZHAO,Jia-bing TIAN,Guo-liang XIE,Li-ming ZHOU. Influence of rice straw ash on compressive properties and microstructure of concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2620-2630. |

| [13] | Hai-feng LIU,Ren-guang TAO,Jia-ling CHE,Wei-wu YANG,Li-chen ZHU. Influence of loading and high temperature on uniaxial compressive properties of desert sand concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2609-2619. |

| [14] | Jin-song ZHU,Xin-yao TONG,Xiao-xu LIU. Flexural behavior of ultra-high performance concrete joint without formwork in prefabricated small box girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2568-2580. |

| [15] | Yong-xin SUN,Peng-zhen LIN,Zi-jiang YANG,Wei JI. Calculation method for crack width of UHPC beams considering bond slip effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2600-2608. |

|

||