吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 154-162.doi: 10.13229/j.cnki.Jdxbgxb20200604

• 车辆工程·机械工程 • 上一篇

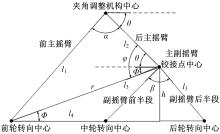

火星车主动悬架设计及蠕动脱困策略

袁宝峰1( ),王成恩1,邹猛2,刘雅芳3,林云成3,贾阳3,陈百超3,金敬福2

),王成恩1,邹猛2,刘雅芳3,林云成3,贾阳3,陈百超3,金敬福2

- 1.上海交通大学 动力与机械学院,上海 200240

2.吉林大学 工程仿生教育部重点实验室,长春 130022

3.北京空间飞行器总体设计部,北京 100094

Design active suspension system and creeping control strategy for mars rover of China

Bao-feng YUAN1( ),Cheng-en WANG1,Meng ZOU2,Ya-fang LIU3,Yun-cheng LIN3,Yang JIA3,Bai-chao CHEN3,Jing-fu JIN2

),Cheng-en WANG1,Meng ZOU2,Ya-fang LIU3,Yun-cheng LIN3,Yang JIA3,Bai-chao CHEN3,Jing-fu JIN2

- 1.School of Mechanical and Power Engineering,Shanghai Jiao Tong University,Shanghai 200240,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.Institute of Spacecraft System Engineering,CAST,Beijing 100094,China

摘要:

在摇臂式悬架的基础上,设计了我国火星车主动悬架结构,制定了大沉陷时蠕动脱困和抬轮脱困控制策略,并进行了4次整车蠕动验证试验。试验结果表明:4次蠕动行驶均使得火星车从沉陷中顺利脱困;蠕动行驶时,整车平均功率为13.5~18.94 W,最大功率为24.8~52.4 W;6个驱动电机平均电流和最大电流比正常行驶时均相应增加,平均电流增加了9.7%~74.8%,最大电流增加了9.6%~34.5%。结果表明,主动悬架配合蠕动脱困策略可以解决摇臂式悬架存在的松软地面沉陷风险,提高我国火星车在松软火星表面的通过性。

中图分类号:

- V416

| 1 | Yingst R A, Cropper K, Gupta S, et al. Characteristics of pebble and cobble-sized clasts along the curiosity rover traverse from sol 100 to 750: terrain types, potential sources, and transport mechanisms[J]. Icarus, 2016, 280: 72-92. |

| 2 | Arvidson R E, Iagnemma K, Maimone M, et al. Mars science laboratory curiosity rover megaripple crossings up to Sol 710 in Gale Crater[J]. Journal of Field Robotics, 2017, 34(3): 495-518. |

| 3 | Blake D F, Morris R V, Kocurek G, et al. Curiosity at gale crater, mars: characterization and analysis of the rocknest sand shadow[J]. Science, 2013, 341: 1239505 |

| 4 | Arvidson R E, Bell J F, Bellutta P, et al. Spirit mars rover mission: overview and selected results from the northern home plate winter haven to the side of scamander crater[J]. Journal of Geophysical Research: Planets, 2010, 115(E7): 633-650. |

| 5 | Squyres S W, Arvidson R E, Bollen D, et al. Overview of the opportunity mars exploration rover mission to meridiani planum: eagle crater to purgatory ripple[J]. Journal of Geophysical Research, 2006, 111(E12): 1-19. |

| 6 | Ellery A. Planetary Rovers: Robotic Exploration of the Solar System[M]. Berlin: Springer, 2015. |

| 7 | 张元勋, 黄靖, 韩亮亮. 星表移动探测机器人研究现状综述[J]. 航空学报, 2020, 8: 1-19. |

| Zhang Yuan-xun, Huang Jing, Han Liang-liang. Review: research status of planetary surface mobile exploration robots[J]. Acta Aeronautica et Astronautica Sinica, 2020, 8: 1-19. | |

| 8 | Arvidson R E, Degrosse P, Grotzinger J P, et al. Relating geologic units and mobility system kinematics contributing to Curiosity wheel damage at Gale Crater, Mars[J]. Journal of Terramechanics, 2017, 73: 73-93. |

| 9 | Ding L, Deng Z Q, Gao H B, et al. Interaction mechanics model for rigid driving wheels of planetary rovers moving on sandy terrain with consideration of multiple physical effects[J]. Journal of Field Robotics, 2014, 32(6): 827-859. |

| 10 | 薛龙, 党兆龙, 陈百超, 等. 地面力学在火星壤力学参数估计研究中的进展与展望[J]. 宇航学报, 2020, 41(2): 136-146. |

| Xue Long, Dang Zhao-long, Chen Bai-Chao, et al. Advances and prospects of martian soil parameter identification based on terramechanics[J]. Journal of Astronautics, 2020, 41(2): 136-146. | |

| 11 | Yang J, Dong M M, Ye J T. A literature review of the rocker-bogie suspension for the planetary rover[C]∥ Proceedings of the International Seminar on Artificial Intelligence, Networking and Information Technology,Thailand, 2017:137-142. |

| 12 | Patel N, Slade R, Clemmet J, et al. The ExoMars rover locomotion subsystem[J]. Journal of Terramechanics, 2010, 47(4): 227-242. |

| 13 | Heverly M, Matthews J, Lin J, et al. Traverse performance characterization for the mars science laboratory rover[J]. Journal of Field Robotics, 2013, 30(6): 835-846. |

| 14 | Ono M, Fuchs T J, Steffy A, et al. Risk-aware planetary rover operation: autonomous terrain classification and path planning[C]∥IEEE Aerospace Conference Proceedings, Bigs Sky,USA,2015: 1-10. |

| 15 | 薛龙, 党兆龙, 陈百超, 等.面向火星着陆器缓冲试验的模拟火星壤力学特性分析[J]. 吉林大学学报:工学版, 2019, 49(1): 176-186. |

| Xue Long, Dang Zhao-long, Chen Bai-chao, et al. Terra-mechanics of Mars soil simulant for Martian Lander's landing tests[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(1): 176-186. | |

| 16 | Zhou F, Arvidson R E, Bennett K, et al. Simulations of mars rover traverses[J]. Journal of Field Robotics, 2014, 31(1): 141-160. |

| 17 | John L C. Mars Exploration Rover Spirit end of mission report[R]. Los Angeles: California Inst of Tech, Pasadena Jet Propulsion Lab, 2015:1-34. |

| 18 | 李建桥, 薛龙, 邹猛, 等. 已有模拟火壤力学性质分析及新火星壤研制[J]. 吉林大学学报:工学版, 2016, 46(1): 172-178. |

| Li Jian-qiao, Xue Long, Zou Meng, et al. Terra-mechanics characters and development of Martian simulant regolith [J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(1): 172-178. |

| [1] | 王军年, 叶涛, 孙文, 王庆年. 可变刚度和阻尼的半主动馈能悬架隔振性能[J]. 吉林大学学报(工学版), 2017, 47(3): 701-708. |

| [2] | 李静, 张家旭. 基于鲁棒L2-L∞/H∞的车辆底盘集成控制[J]. 吉林大学学报(工学版), 2016, 46(6): 1757-1764. |

| [3] | 李静1, 王子涵1, 秦民2, 禚帅帅1, 曹振1. 基于SimScape的半主动悬架垂直速度处理电路设计[J]. 吉林大学学报(工学版), 2014, 44(4): 912-917. |

| [4] | 陈双, 宗长富, 张立军, 尹刚. 主动悬架平顺性和侧倾姿态综合控制策略[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 59-64. |

| [5] | 刘伟,史文库,郭福祥,沈志宏,方德广. 基于转向稳定性的汽车悬架协调优化[J]. 吉林大学学报(工学版), 2011, 41(03): 602-607. |

| [6] | 李静, 余春贤, 宋大凤, 赵健, 周宇. 汽车半主动悬架阻尼可调减振器[J]. 吉林大学学报(工学版), 2010, 40(增刊): 13-0016. |

| [7] | 刘顺安, 于显利, 姚永明, 陈延礼. 俯仰角优化下车辆主动悬架最优—智能集成控制系统[J]. 吉林大学学报(工学版), 2010, 40(增刊): 17-0023. |

| [8] | 于树友,陈虹 . 基于滚动优化的H∞/广义H2主动悬架控制[J]. 吉林大学学报(工学版), 2007, 37(05): 1164-1169. |

| [9] | 李幼德, 宋大凤, 李静, 初亮, 王东科. 汽车可调阻尼半主动悬架控制器[J]. 吉林大学学报(工学版), 2004, (1): 71-74. |

|

||