吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 147-153.doi: 10.13229/j.cnki.jdxbgxb20191117

• 车辆工程·机械工程 • 上一篇

航空煤油柱塞泵摩擦副涂层材料摩擦性能

- 哈尔滨工业大学 机电工程学院,哈尔滨 150080

Tribological properties of coating materials of tribopairs for aviation kerosene piston pump

Ji-hai JIANG( ),Cun-ran ZHAO,Guan-long ZHANG,Ming-yang CHE

),Cun-ran ZHAO,Guan-long ZHANG,Ming-yang CHE

- School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150080,China

摘要:

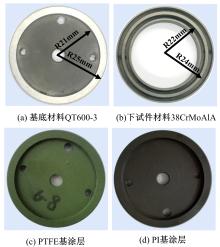

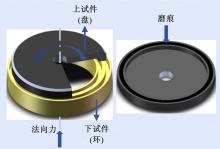

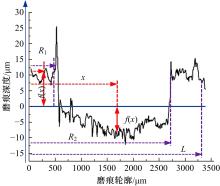

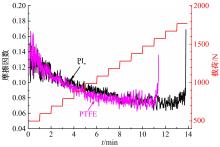

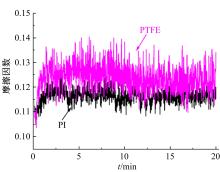

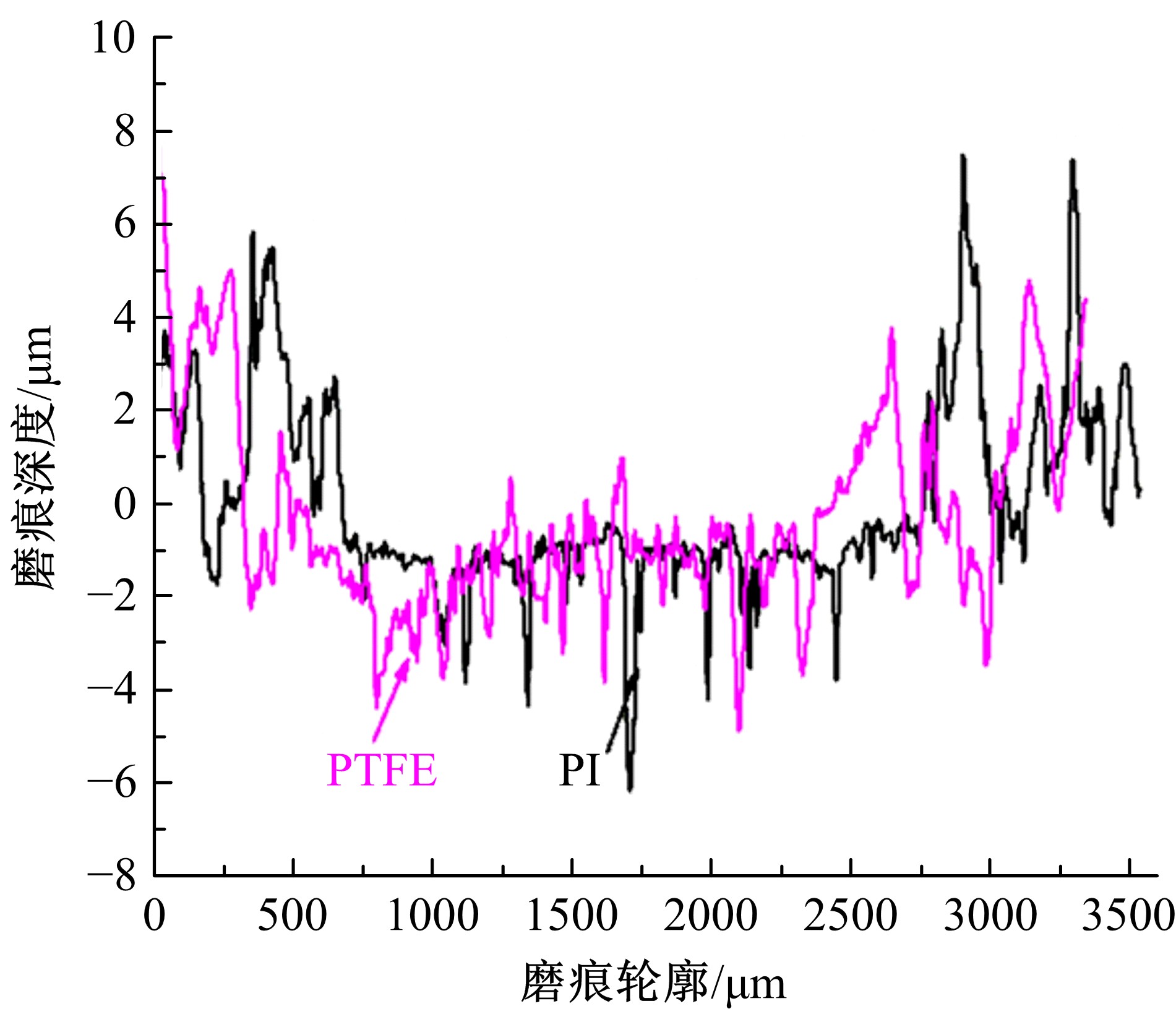

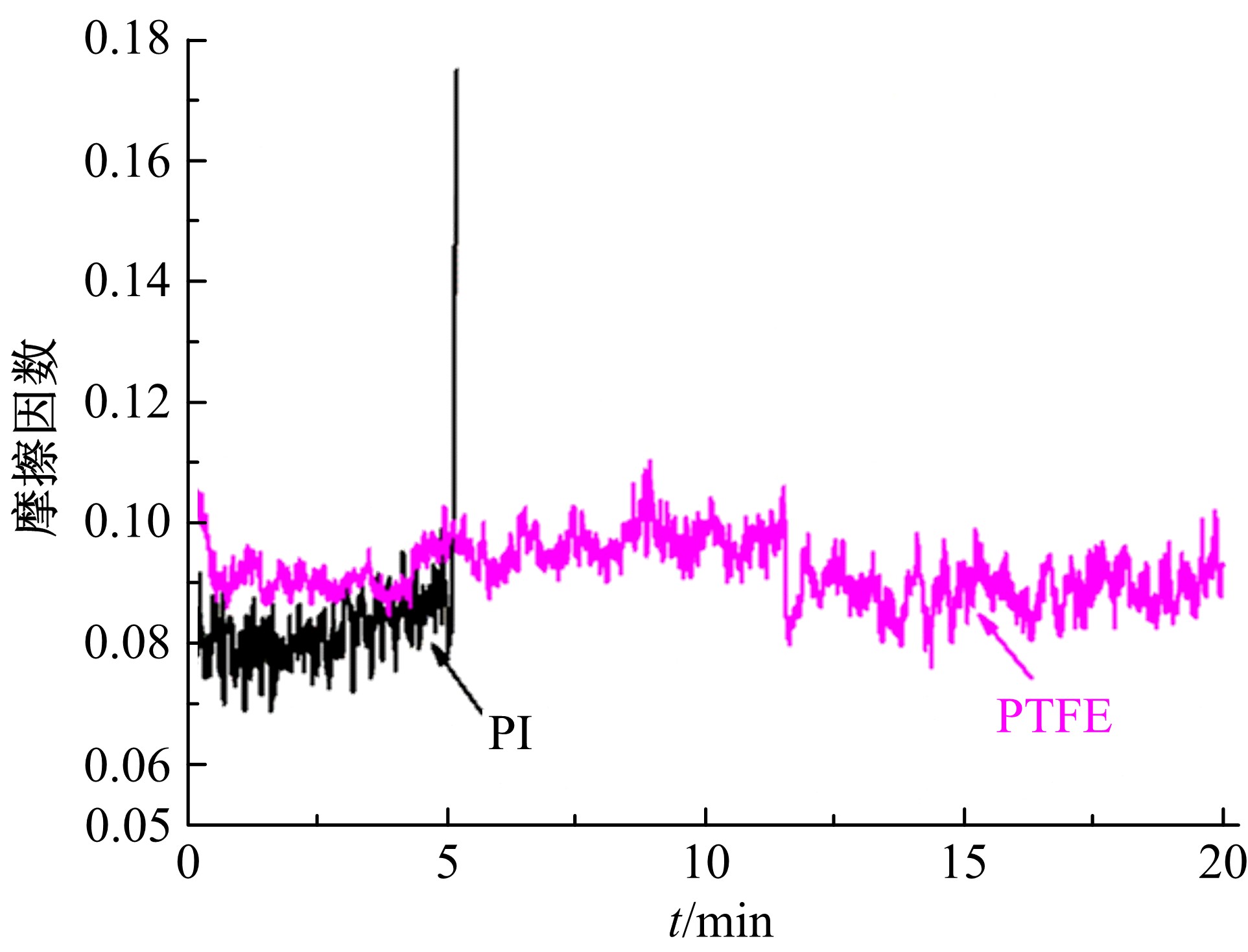

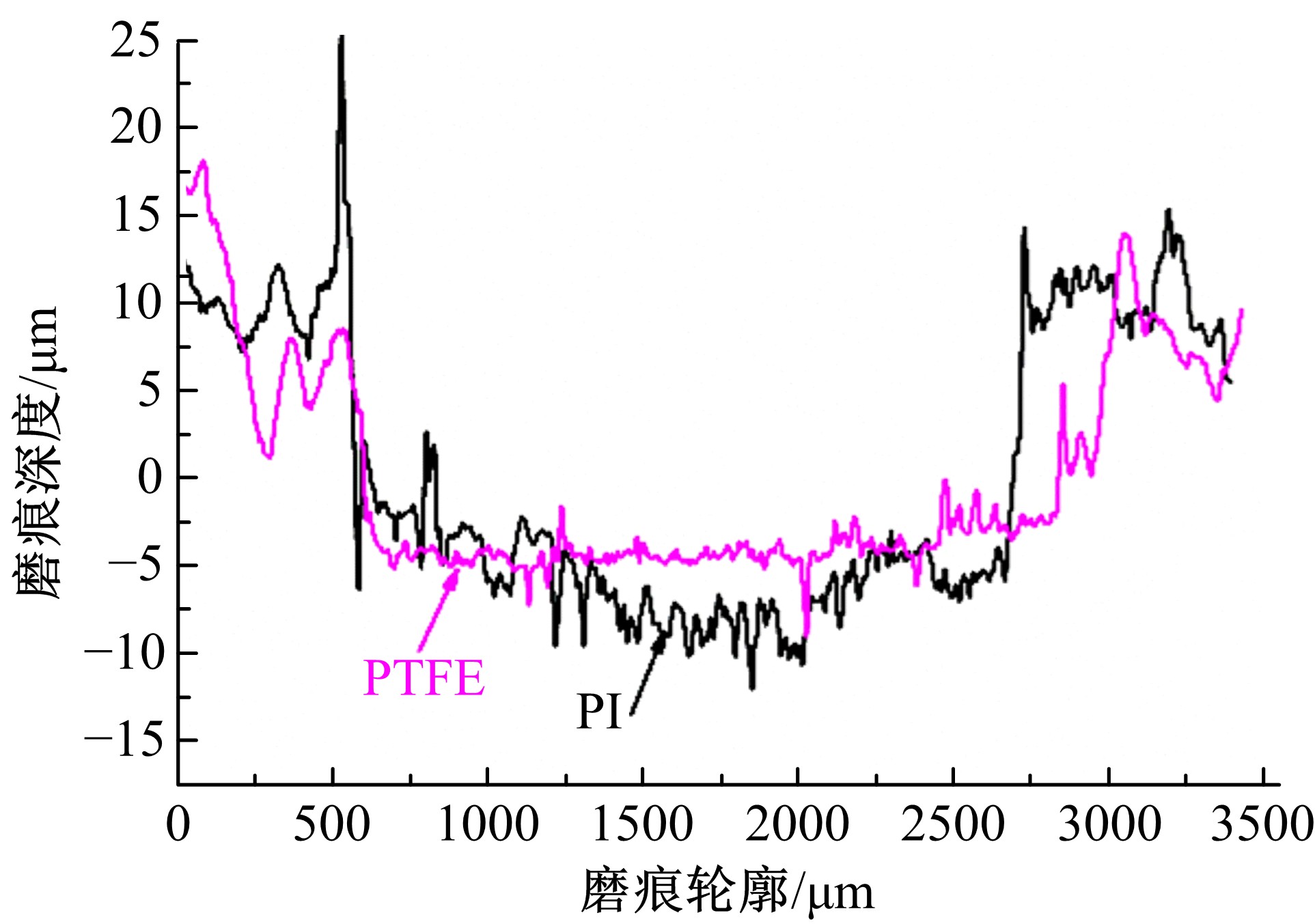

利用盘-环试验台,在70 ℃航空煤油介质中通过改变载荷p和速度v,研究了两种聚酰亚胺(PI)基涂层和聚四氟乙烯(PTFE)基涂层分别与38CrMoAlA滑动摩擦的摩擦学性能。试验讨论了涂层的磨损因子k*、线磨损率Wt、极限pv与加载pv之间的关系,并对涂层磨损表面进行了SEM分析,结果表明,磨损因子k*并非恒定值,而是与涂层的磨损机理有着密切关系,PTFE基涂层与38CrMoAlA滑动摩擦磨损性能更加优异,进而更适合充当航空柱塞泵的摩擦副材料。

中图分类号:

- V257

| 1 | Zhang J H, Chao Q, Xu B. Analysis of the cylinder block tilting inertia moment and its effect on the performance of high-speed electro-hydrostatic actuator pumps of aircraft[J]. Chinese Journal of Aeronautics, 2018, 31(1): 169-177. |

| 2 | Xu B, Chao Q, Zhang J H, et al. Effects of the dimensional and geometrical errors on the cylinder block tilt of a high-speed EHA pump[J]. Meccanica, 2017, 52(10): 2449-2469. |

| 3 | 温诗铸, 黄平, 田煜, 等. 摩擦学原理[M]. 北京:清华大学出版社, 2018. |

| 4 | Min C Y, Nie P, Song H J, et al. Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition[J]. Tribology International, 2014, 80: 131-140. |

| 5 | Shi Y J, Mu L W, Feng X, et al. Tribological behavior of carbon nanotube and polytetrafluoroethylene filled polyimide composites under different lubricated conditions[J]. Journal of Applied Polymer Science, 2011, 121(3): 1574-1578. |

| 6 | Chen J S, Jia J H, Zhou H D, et al. Tribological behavior of short-fiber-reinforced polyimide composites under dry-sliding and water-lubricated conditions[J]. Journal of Applied Polymer Science, 2008, 107(2): 788-796. |

| 7 | Ye X Y, Liu X H, Yang Z G, et al. Tribological properties of fluorinated graphene reinforced polyimide composite coatings under different lubricated conditions[J]. Composites Part A:Applied Science and Manufacturing, 2016, 81: 282-288. |

| 8 | Demas N G, Polycarpou A A. Tribological performance of PTFE-based coatings for air-conditioning compressors[J]. Surface & Coatings Technology, 2008, 203(3/4): 307-316. |

| 9 | Friedrich K. Wear of reinforced polymers by different abrasive counterparts[J]. Composite Materials Series, 1986, 1: 233-287. |

| 10 | Furey M J. The formation of polymeric films directly on rubbing surfaces to reduce wear[J]. Wear, 1973, 26(3): 369-392. |

| 11 | Bahadur S. The development of transfer layers and their role in polymer tribology[J]. Wear, 2000, 245(1/2): 92-99. |

| 12 | Dascalescu D, Polychronopoulou K, Polycarpou A A. The significance of tribochemistry on the performance of PTFE-based coatings in CO2 refrigerant environment[J]. Surface & Coatings Technology, 2009, 204(3): 319-329. |

| 13 | Dowson D, Higginson G R. A numerical solution to the elasto-hydrodynamic problem(reprinted from vol 1, 1959)[J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 2009, 223(1): 54-63. |

| [1] | 庄蔚敏,王鹏跃,解东旋,陈延红. 基于连续损伤力学的铝车身涂层抗划伤能力[J]. 吉林大学学报(工学版), 2019, 49(3): 829-835. |

| [2] | 金敬福, 李杨, 陈廷坤, 丛茜, 齐迎春. 涂层弹性模量对结冰附着强度的影响[J]. 吉林大学学报(工学版), 2017, 47(5): 1548-1553. |

| [3] | 孙伟, 李健, 贾师. 硬涂层复合结构非线性刚度及阻尼辨识[J]. 吉林大学学报(工学版), 2016, 46(4): 1156-1162. |

| [4] | 赵存然, 刘伟, 姜继海, 邵辉, 田勇. 斜盘式轴向柱塞泵加速模型[J]. 吉林大学学报(工学版), 2016, 46(4): 1124-1129. |

| [5] | 邓海顺, 黄坤, 王传礼, 李永梅. 平衡式两排轴向柱塞泵缸体倾覆力矩[J]. 吉林大学学报(工学版), 2015, 45(5): 1468-1473. |

| [6] | 刘昌盛, 何清华, 张大庆, 李铁辉, 龚俊, 赵喻明. 混合动力挖掘机势能回收系统参数优化与试验[J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

| [7] | 龚俊, 何清华, 张大庆, 张云龙, 刘昌盛, 唐中勇. 混合动力叉车节能效果评价及能量回收系统试验[J]. 吉林大学学报(工学版), 2014, 44(01): 29-34. |

| [8] | 庄蔚敏, 陈延红. 基于连续损伤力学的表面涂层损伤模拟[J]. , 2012, 42(04): 857-862. |

| [9] | 戴晟, 左敦稳, 黎向锋, 程虎, 方志刚, 王珉, 缪宏. 2738模具钢表面激光熔覆Ni基WC复合涂层的摩擦磨损性能[J]. , 2012, 42(04): 924-929. |

| [10] | 王国磊, 陈恳, 陈雁, 朱丽, 王力强, 颜华. 变参数下的空气喷枪涂层厚度分布建模[J]. 吉林大学学报(工学版), 2012, 42(01): 188-192. |

| [11] | 韩耀武, 孙大千, 谷小燕, 王文权, 宣兆志. 等离子喷涂参数对镍基合金涂层组织及冲蚀磨损性能的影响[J]. 吉林大学学报(工学版), 2010, 40(02): 461-0466. |

| [12] | 姚国凤,丁艳霞,王敏 . 界面形貌对残余应力的影响[J]. 吉林大学学报(工学版), 2009, 39(03): 704-0707. |

| [13] | 崔学军,程平,张海涛,金为群,王洪艳 . 涂层与基体界面结合强度测定模型的有限元模拟[J]. 吉林大学学报(工学版), 2007, 37(02): 357-0361. |

| [14] | 杨晓红, 刘勇兵,张明喆,周宏,梁涛,王军 . 压铸铝合金AlSi9Cu3的铁金属间化合物对高速钢刀具钻削磨损特性的影响[J]. 吉林大学学报(工学版), 2006, 36(增刊2): 6-10. |

| [15] | 张国祥,,,陈光南,张坤,罗耕星,李怀学,. 基体界面屈服强度和残余应力失配对界面裂纹扩展的影响[J]. 吉林大学学报(工学版), 2006, 36(03): 294-0297. |

|

||