吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (8): 2201-2211.doi: 10.13229/j.cnki.jdxbgxb.20211091

• 车辆工程·机械工程 • 上一篇

赛车俯仰运动下的气动特性

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Aerodynamic characteristics of a racing car in pitching motion

Zhe ZHANG( ),Shi-da SONG,Guo-hua WANG,Ying-chao ZHANG(

),Shi-da SONG,Guo-hua WANG,Ying-chao ZHANG( )

)

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

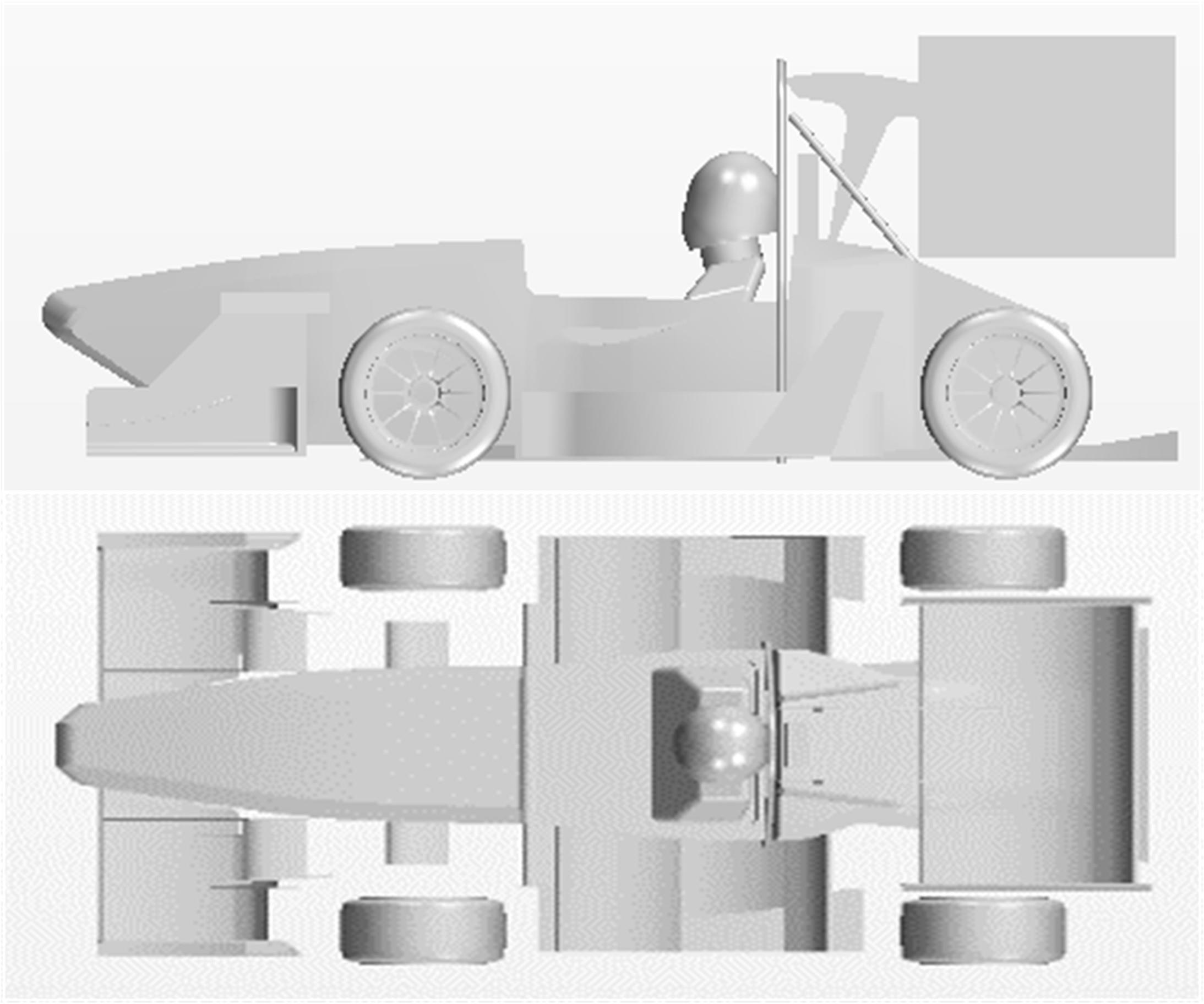

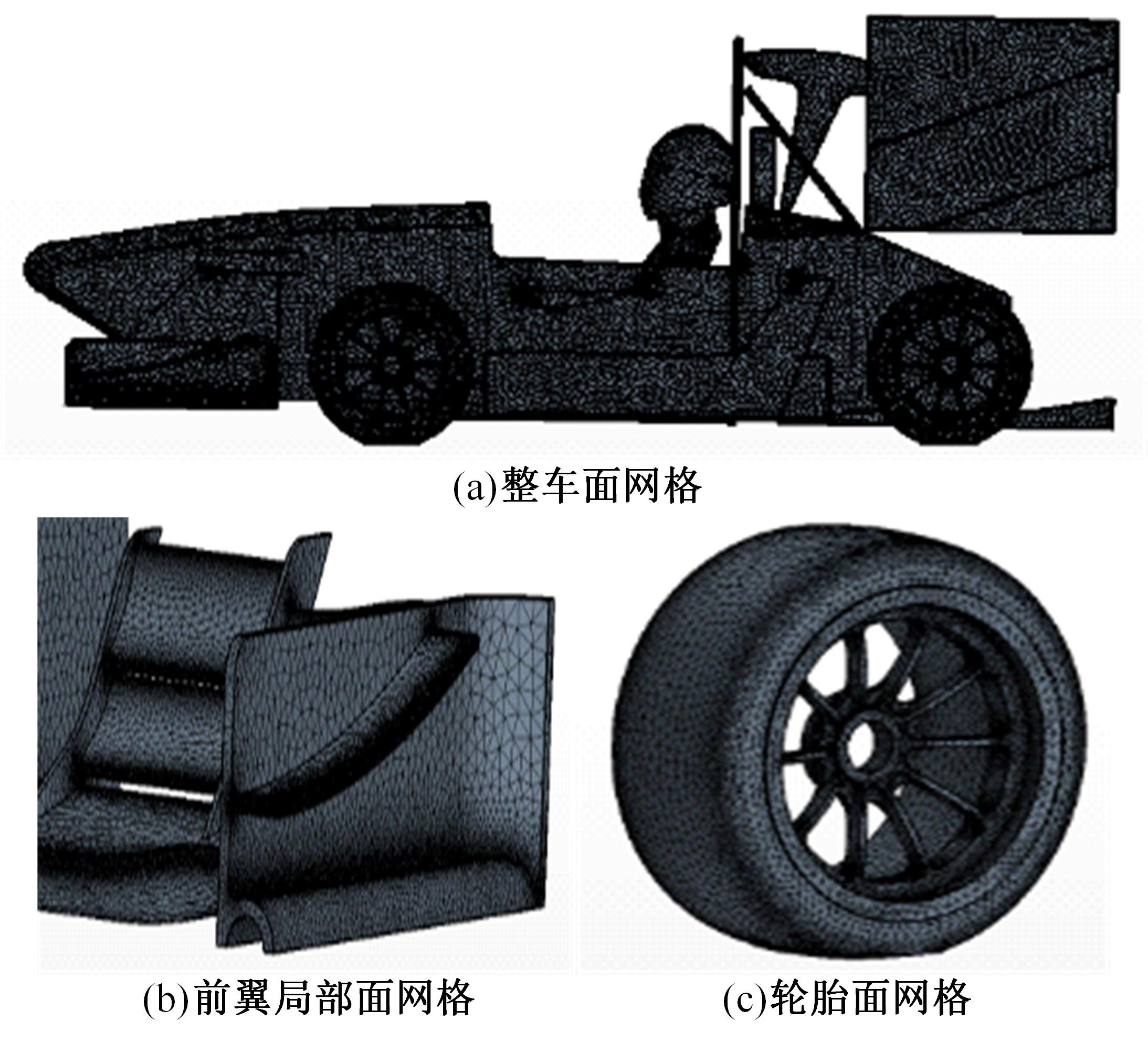

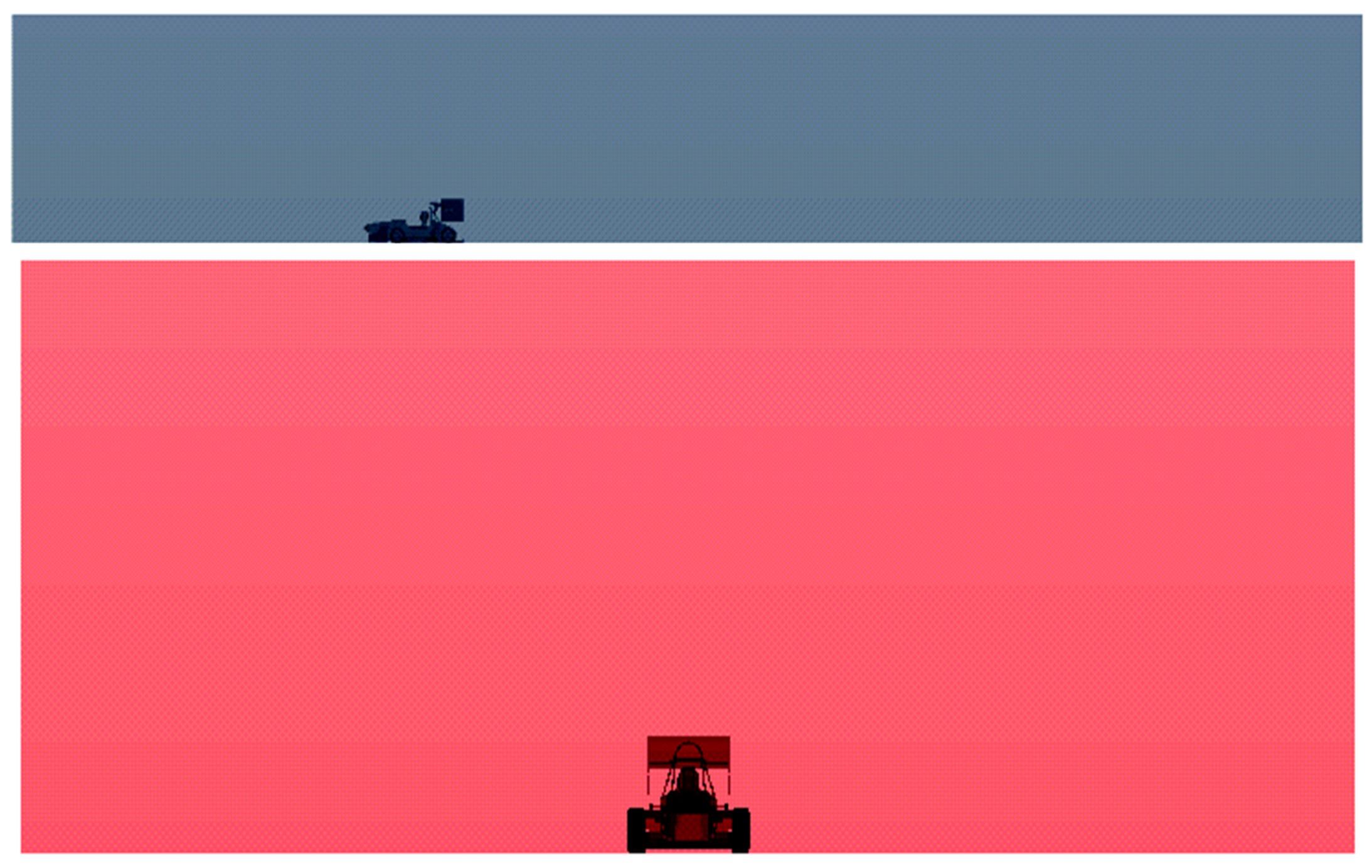

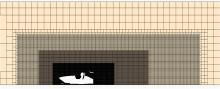

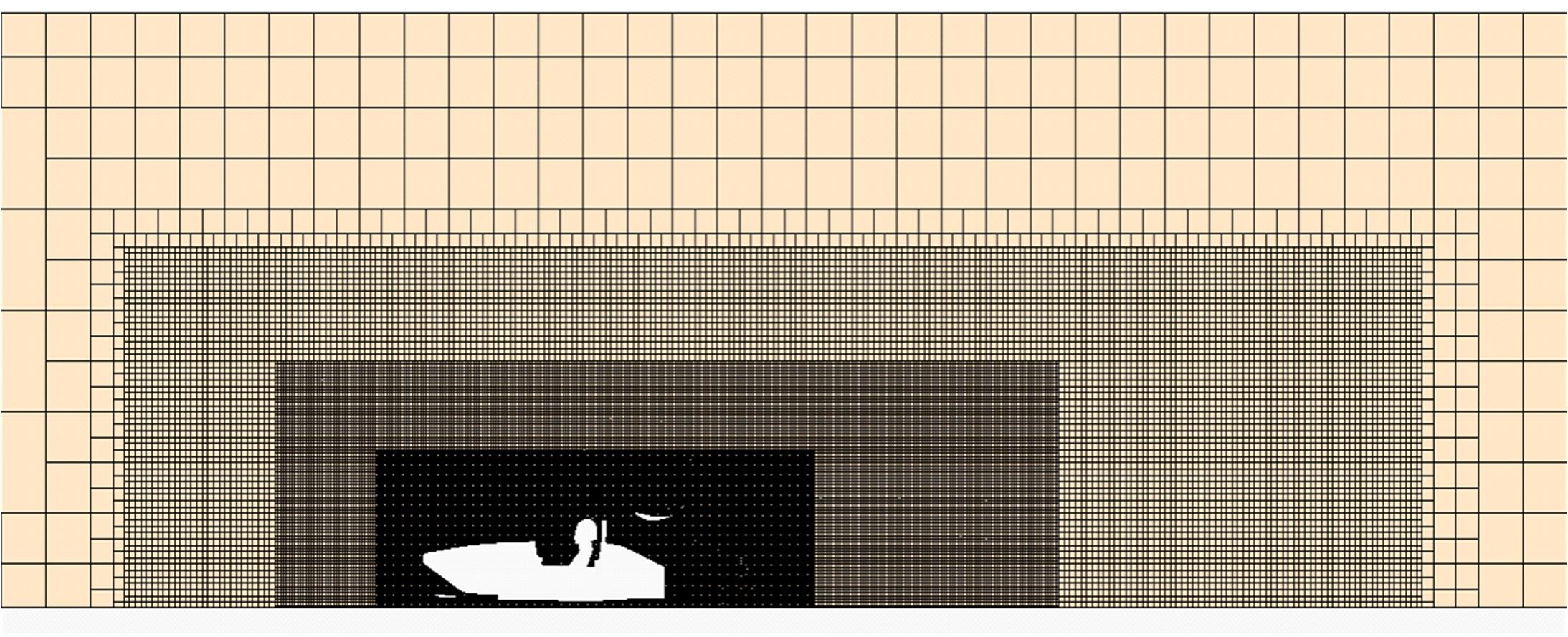

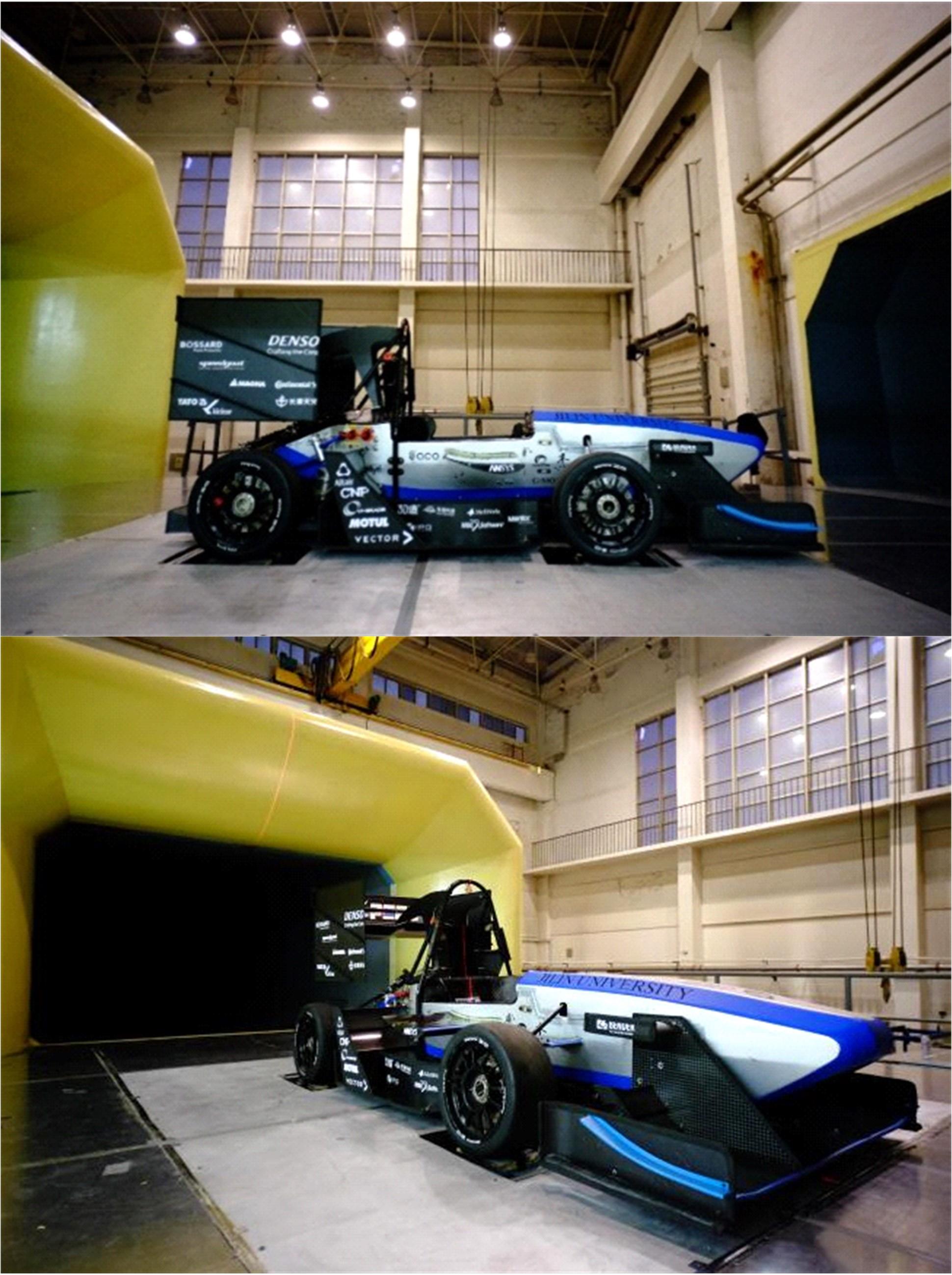

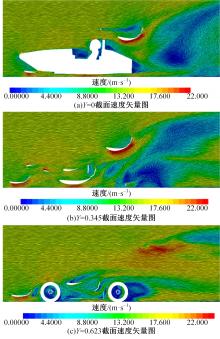

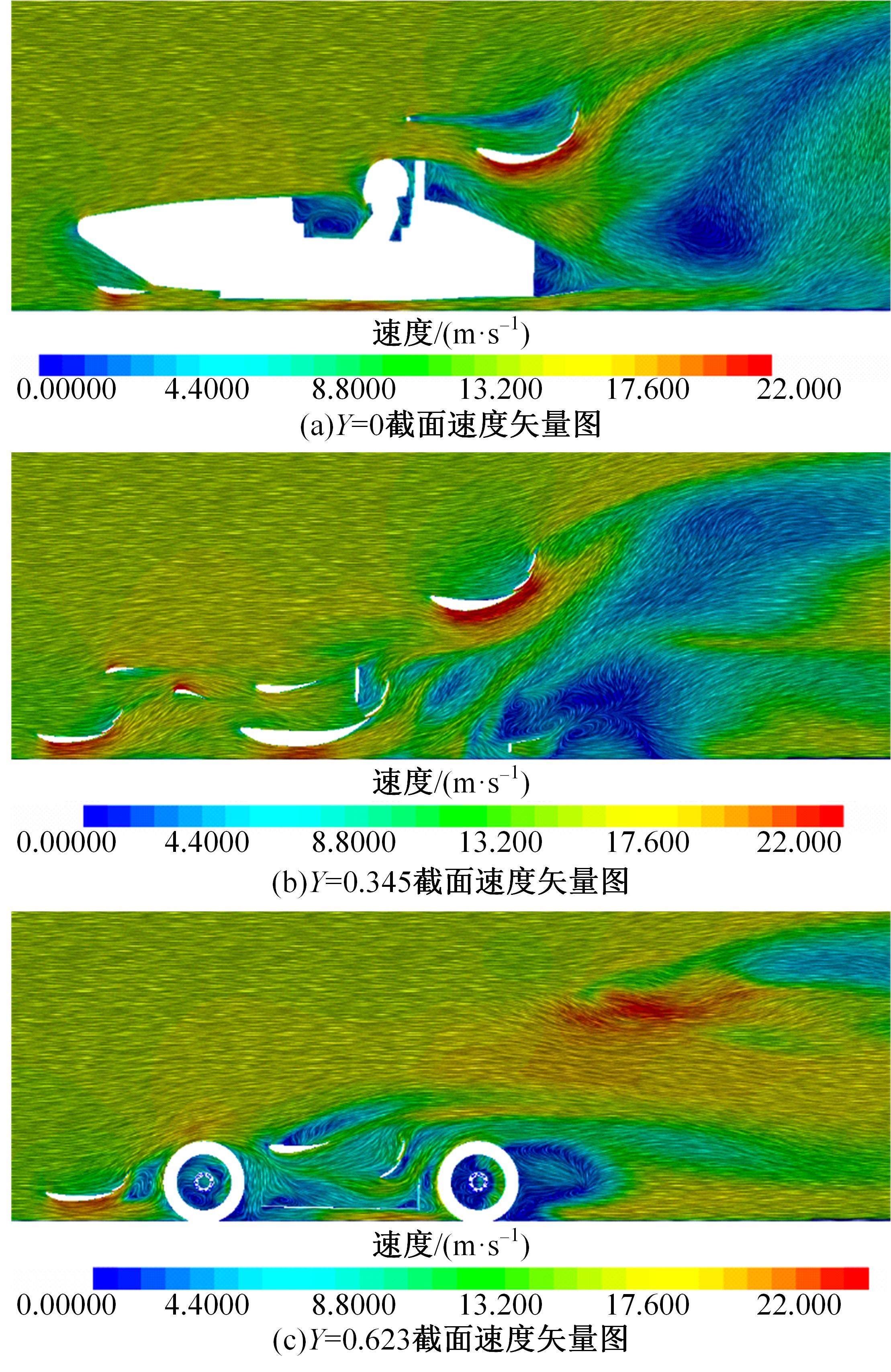

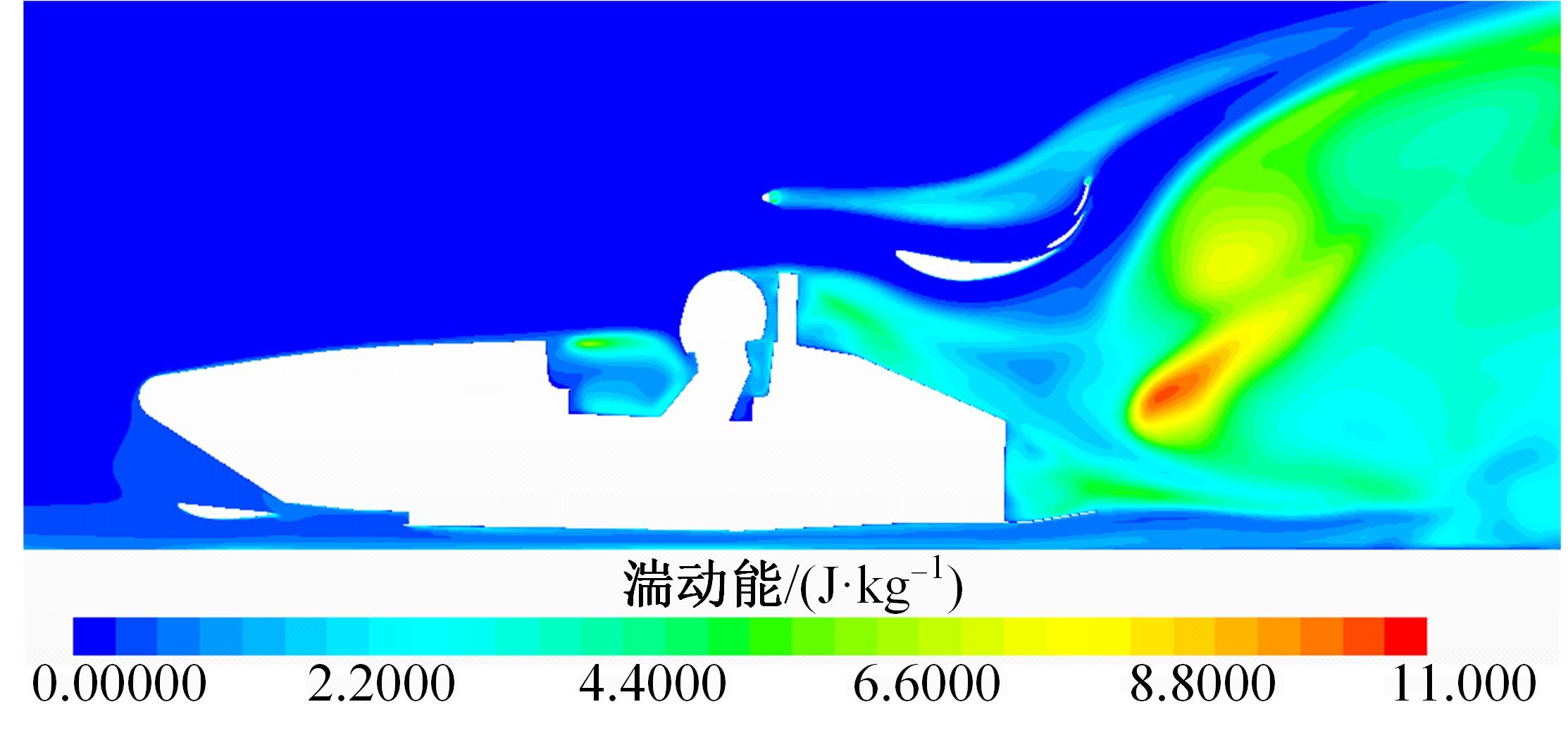

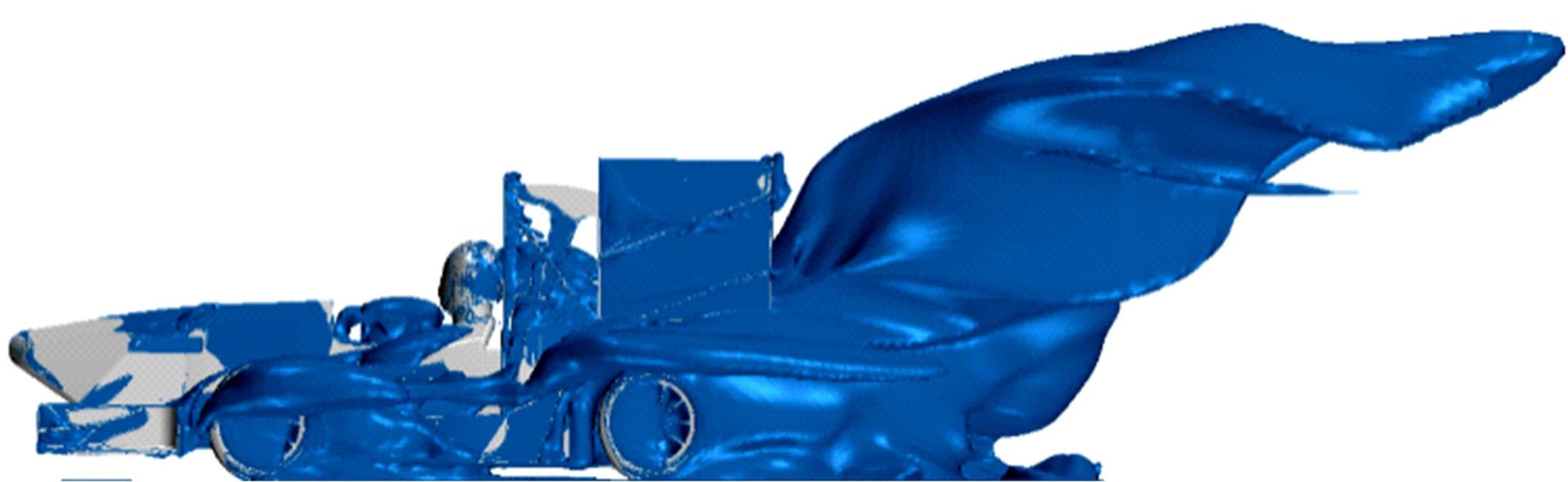

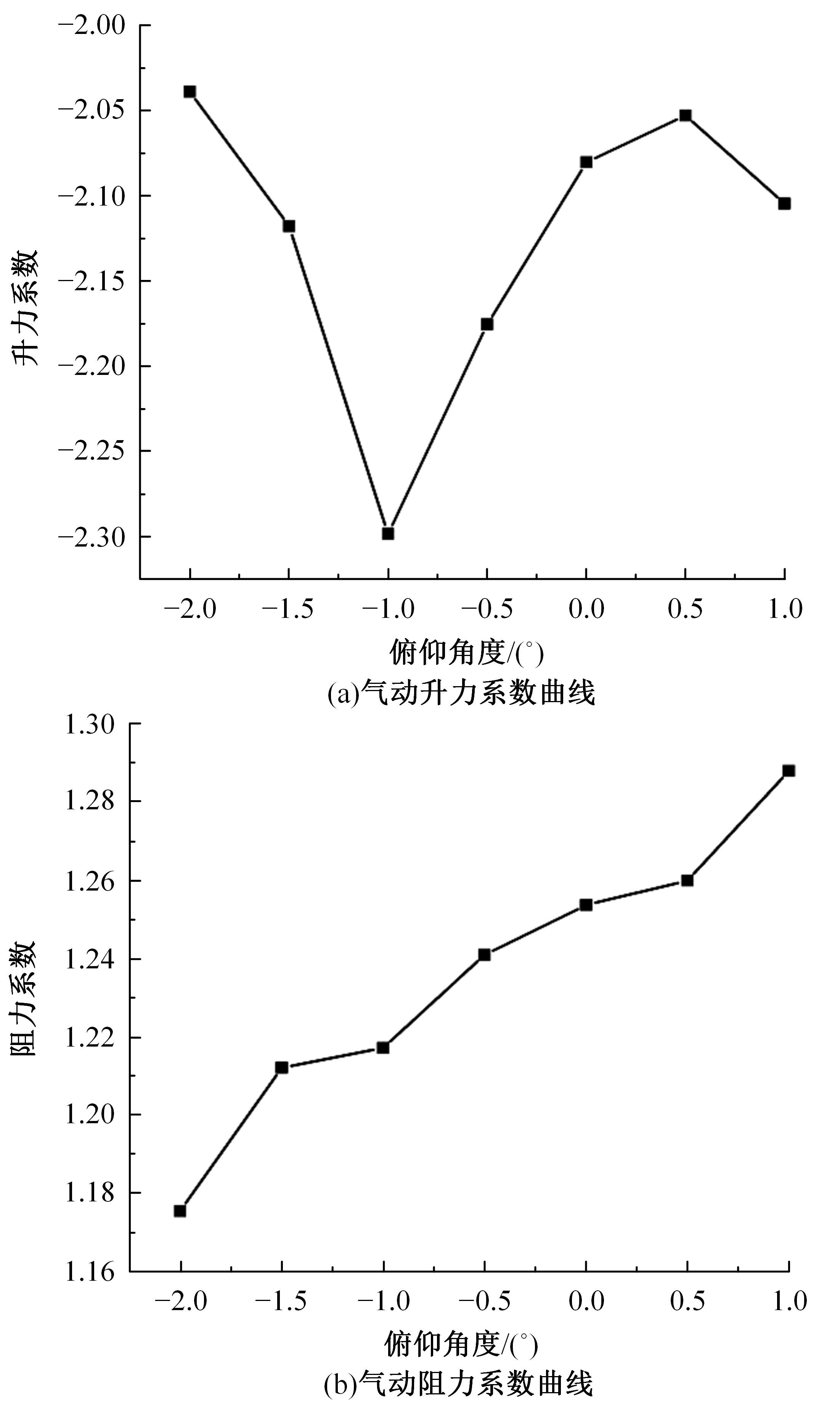

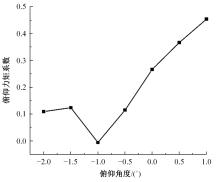

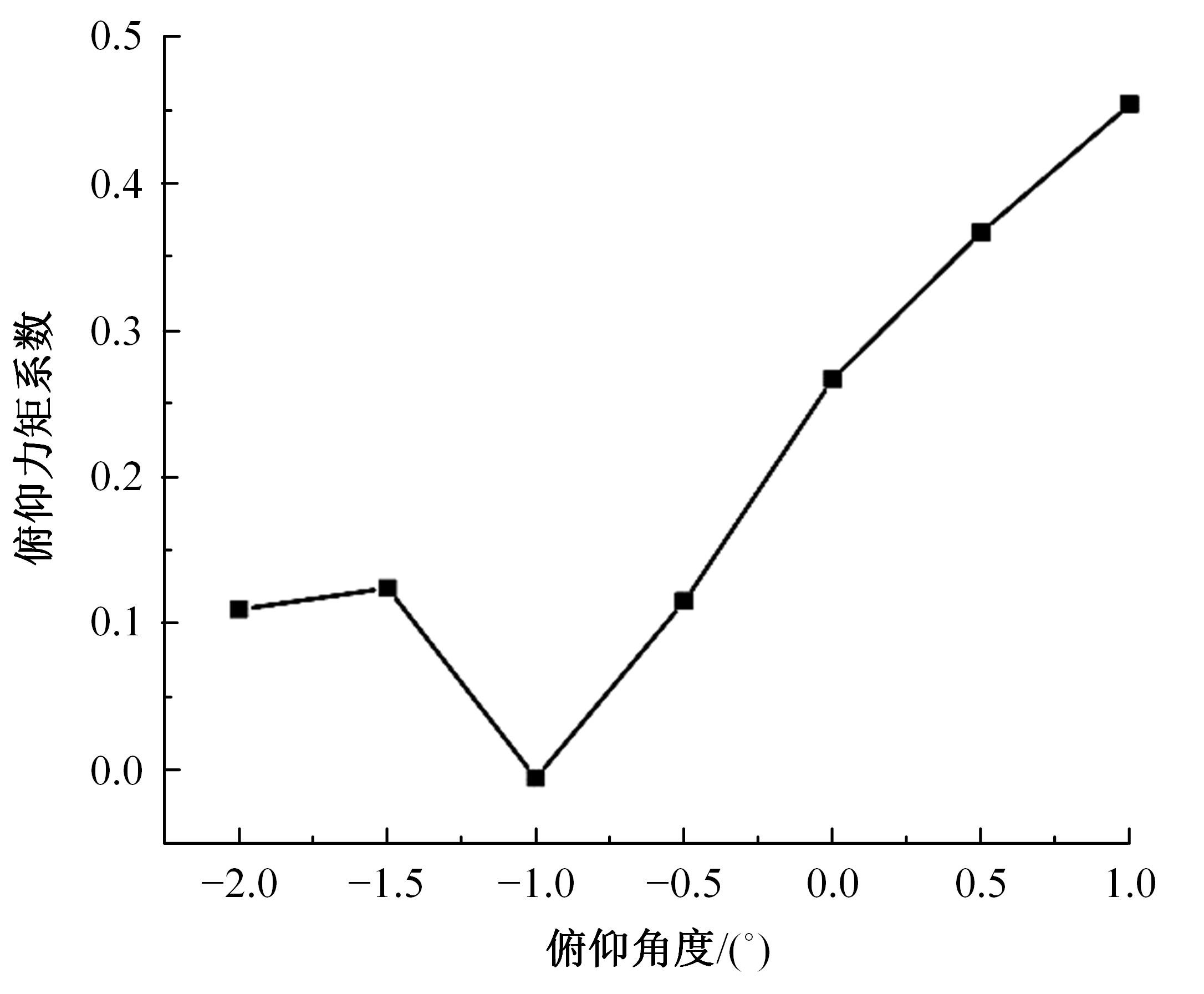

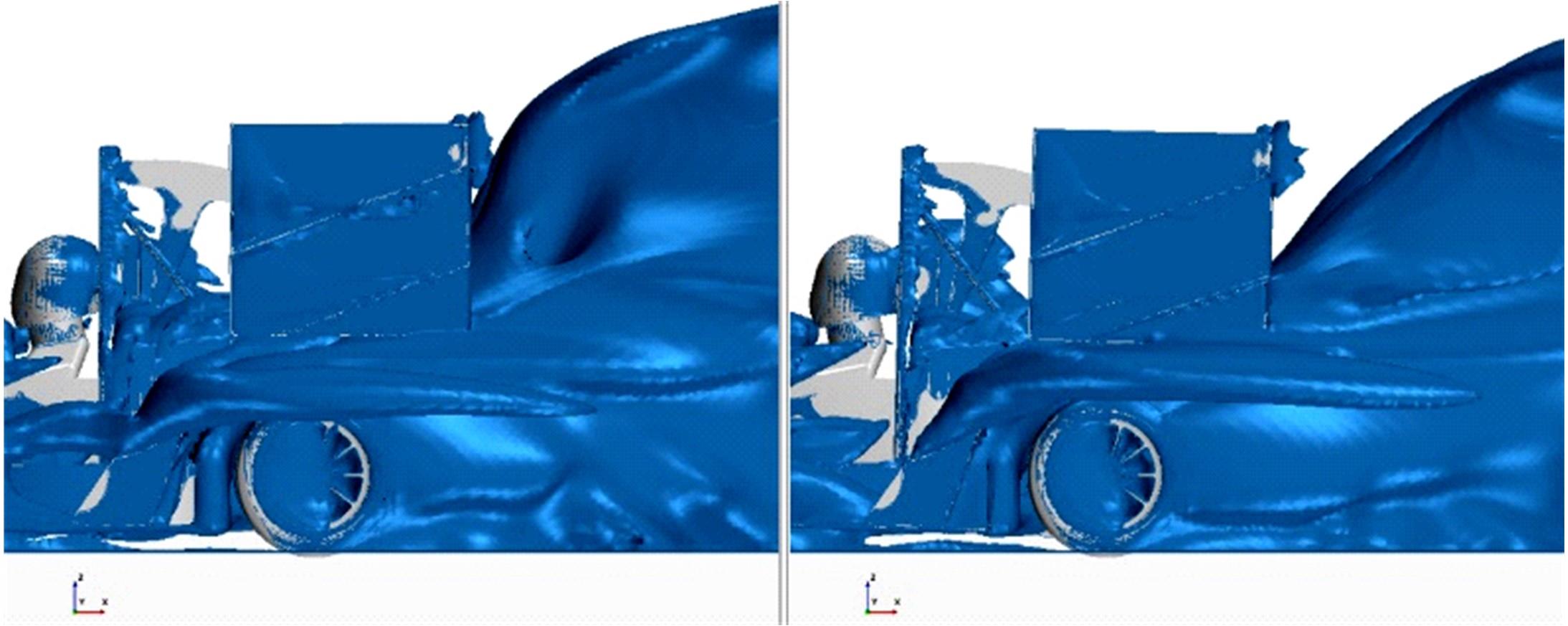

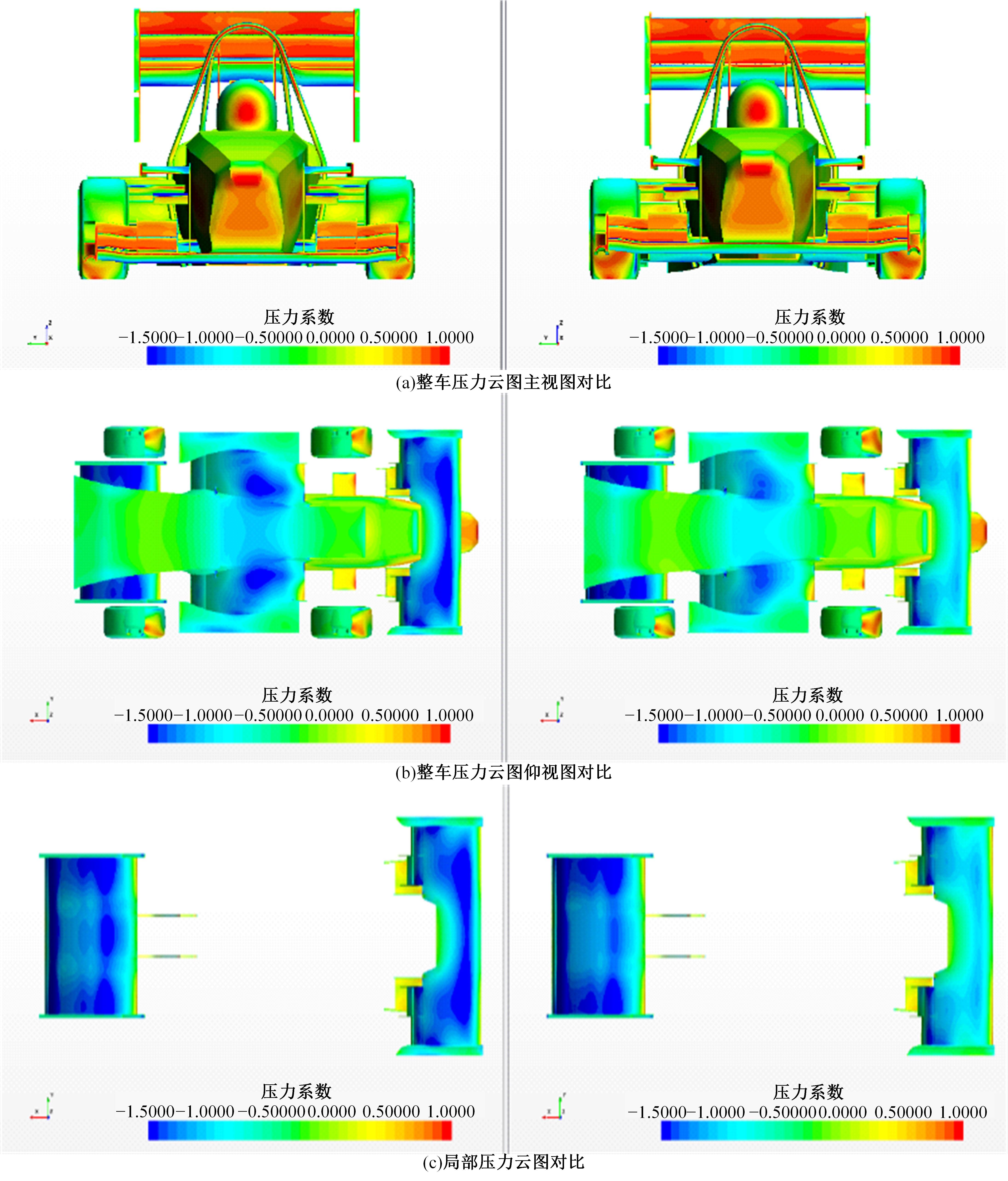

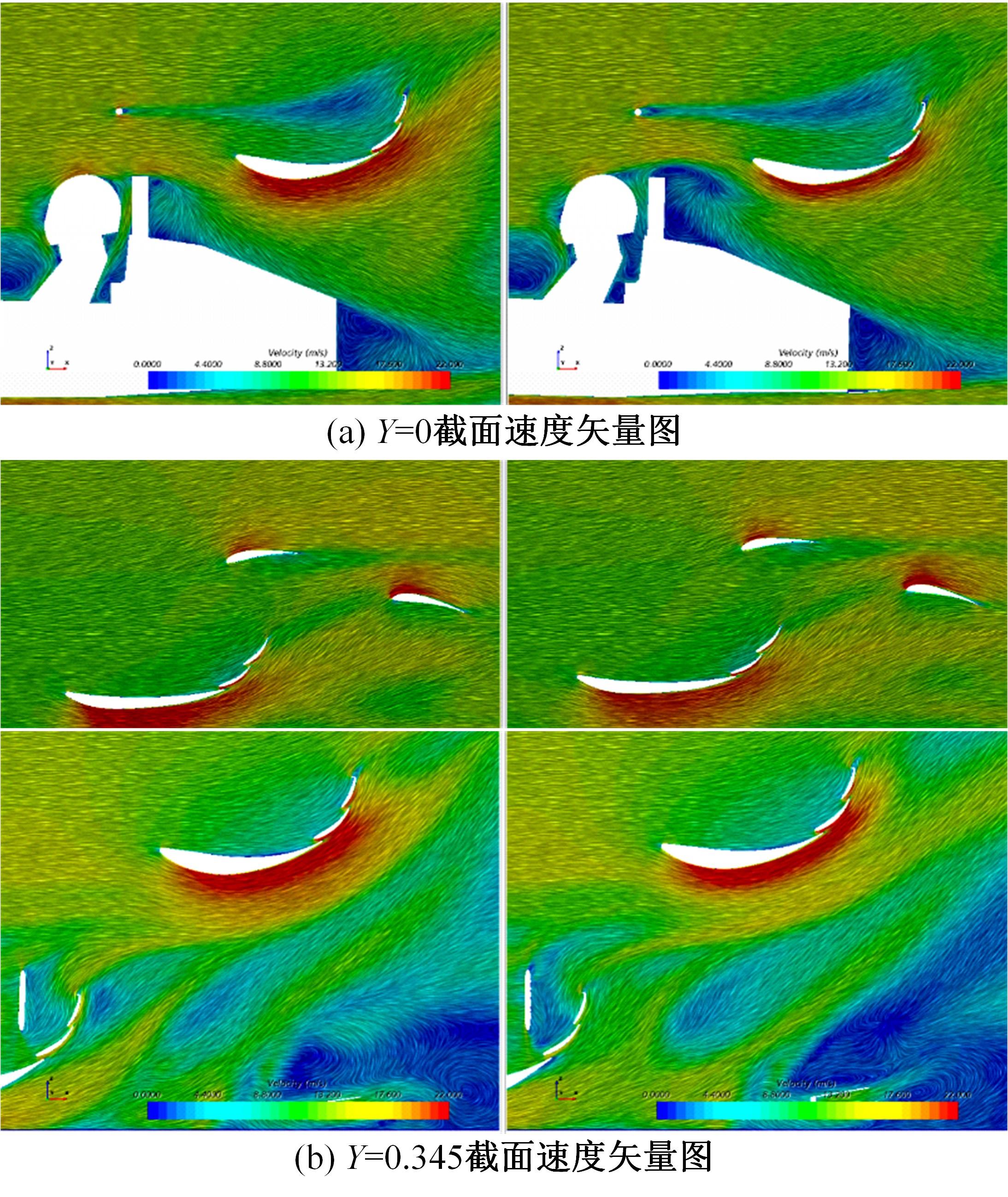

确定了俯仰姿态的仿真工况并对赛车进行各工况下的整车外流场仿真分析。探究了各俯仰工况下的气动特性及各气动部件之间的相互影响,通过分析车身周围的流场变化得到了各工况之间气动数据差别的原因。通过分析仿真结果可知,所有工况下赛车的气动负升力主要由车身、前翼和尾翼提供,而前、后车轮主要提供气动升力。赛车的气动阻力主要由车身和尾翼产生,两者之和占比超总阻力75%,前、后车轮的气动阻力之和所占比例仅为10%左右。当赛车身姿态发生俯仰变化时,前翼、尾翼、离地间隙的变化和各气动部件间的交互作用导致整车气动特性发生改变。结果表明:在俯仰角度为-1.0°工况下,整车气动升阻比最大,在各俯仰工况中赛车气动效率最高,总气动负升力的绝对值最大,总气动阻力相对较小,气动俯仰力矩最小,此工况下赛车的综合性能较好。

中图分类号:

- U461.1

| 1 | 约瑟夫·卡茨, 张英朝.赛车空气动力学[M].北京:机械工业出版社出版, 2019. |

| 2 | Brammer H. Aerodynamics of a race car[D]. Queensland: School of Engineering, University of Queensland, 2002. |

| 3 | Stapleford W R, Carr G W. Aerodynamics Characteristics of Exposed Rotating Wheels[M]. Motor Industry Research Association, 1969. |

| 4 | Kellar P S. Formula 1 car wheel aerodynamics[J]. Sports Engineering, 1999, 2(4):203-212. |

| 5 | Al Muharrami M S, Almousa S M, Almutairi A F M, et al. Study of open and closed wheels aerodynamics of racing cars in wind tunnels with movable ground at different car speeds[C]∥ 18th Australasion Fluid Mechanics Conference Launceston, Australia, 2012. |

| 6 | Ehirim O. Optimal diffuser design for formula sae race car using an innovative geometry buildup and CFD simulation setup with on-track testing correlation[C]∥ SAE Technical Papers, 2012-01-1169. |

| 7 | Lu X. Research on the flow field around a formula SAE car[C]∥ Sae Technical Papers, 2015-26-0208. |

| 8 | Kalinowski M, Szczepanik M. Aerodynamic shape optimization of racing car front wing[J]. IOP Conference Series: Materials Science and Engineering, 2021(1):012058. |

| 9 | Ma J, Chen X, Duan Y, et al. FSAE race car dynamics and trajectory optimization considering aerodynamic effects[C]∥ SAE Technical Paper, 2018-01-0821. |

| 10 | Hetawal Sneh. Aerodynamic study of formula SAE car[J]. Procedia Engineering, 2014, 97: 1198-1207. |

| 11 | Rehnberg S, Lucas B, Svensson R, et al. Race car aerodynamics-the design process of an aerodynamic package for the 2012 chalmers formula SAE car[C]∥ SAE Technical Paper, 2013-01-0797. |

| 12 | Craig C, Passmore M A. Methodology for the design of an aerodynamic package for a formula SAE Vehicle[J]. SAE International Journal of Passengen Cars-Mechanical Systems, 2014, 7(2): 575-585. |

| 13 | 潘小卫. 赛车CFD仿真及风洞试验研究[D].长沙:湖南大学机械与运载工程学院, 2009. |

| Pan Xiao-wei. Research on CFD simulation and wind tunnel test of racing car[D]. Changsha: School of Mechanical and Vehicle Engineering, Hunan University, 2009. | |

| 14 | 牛贺功. 基于CFD的FSAE赛车外流场数值模拟及优化[D]. 青岛: 青岛理工大学汽车与交通学院, 2014. |

| Niu He-gong. Numerical simulation and optimization of FSAE racing car based on CFD[D]. Qingdao: College of Automotive and Transportation, Qingdao Technological University, 2014. | |

| 15 | 张璇. 基于CFD技术的FSC赛车外流场分析及优化[D].锦州: 辽宁工业大学汽车与交通工程学院,2017. |

| Zhang Xuan. Analysis and optimization of external flow field of FSC racing car based on CFD technology [D].Jinzhou: School of Automotive and Traffic Engineering, Liaoning University of Technology, 2017. | |

| 16 | 孙文. 基于CFD的低速赛车前后翼设计[D]. 长沙:湖南大学机械与运载工程学院, 2016. |

| Sun Wen. Design of front and rear wings of low-speed racing car based on CFD[D]. Changsha: School of Mechanical and Vehicle Engineering, Hunan University, 2016. | |

| 17 | 曹惠南. 考虑侧风影响的平头商用车气动减阻优化[D]. 长春: 吉林大学汽车工程学院, 2020. |

| Cao Hui-nan. Aerodynamic drag reduction optimization of flat headed commercial vehicles considering the influence of crosswind[D].Changchun: College of Automotive Engineering, Jilin University, 2020. | |

| 18 | Jessing C, Stoll D, Kuthada T, et al. New horizons of vehicle aerodynamics[J]. Proceedings of Institution of Mechanical Engineers, 2017, 231(9): 1-13. |

| [1] | 辛俐,兰巍,刘江,万沁林,郭鹏,胡兴军,肖阳. 汽车涉水车身表面污染仿真及控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1786-1794. |

| [2] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [3] | 王靖宇, 于旭涛, 胡兴军, 郭鹏, 辛俐, 郭峰, 张扬辉. 汽车外后视镜流致振特性及其流动机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1669-1676. |

| [4] | 董超, 成凯, 胡康乐, 胡文强. 全地形铰接式履带车辆俯仰运动性能[J]. 吉林大学学报(工学版), 2017, 47(3): 827-836. |

| [5] | 袁哲, 周茜茜, 刘春宝, 马文星, 徐志轩. 基于BEM理论的兆瓦级风力机叶片设计及其气动性能[J]. 吉林大学学报(工学版), 2016, 46(4): 1142-1148. |

| [6] | 田为军, 王骥月, 李明, 陈思远, 刘方圆, 丛茜. 小型水平轴风力机叶片仿生设计[J]. 吉林大学学报(工学版), 2015, 45(5): 1495-1501. |

| [7] | 王军年, 张煦, 康丹, 王庆年, 唐德隆, 张君彦. 轮毂电机驱动太阳能赛车参数匹配及巡航控制[J]. 吉林大学学报(工学版), 2015, 45(3): 689-695. |

| [8] | 王靖宇,王泽伟,顾庆童,胡兴军,王保玉. 弯道行驶车辆瞬态气动特性的数值模拟[J]. 吉林大学学报(工学版), 2015, 45(1): 44-48. |

| [9] | 刘顺安, 贺兴柱, 陈延礼, 杨璐鸿, 李万林. 非对称布局形式的涵道尾桨气动特性[J]. 吉林大学学报(工学版), 2014, 44(5): 1353-1359. |

| [10] | 胡兴军, 丁鹏宇, 秦鹏, 郭鹏, 罗文斌, 杨博. 侧风影响下桥上行驶的重型货车气动特性模拟 [J]. , 2012, (03): 534-538. |

| [11] | 丛茜, 刘玉荣, 马毅, 金敬福. 家燕翅展翼型的气动特性[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 231-235. |

| [12] | 王靖宇,胡兴军,李庆臣,王景晟. 面包车尾部造型对其气动特性的影响[J]. 吉林大学学报(工学版), 2011, 41(03): 618-622. |

| [13] | 金敬福, 马毅, 刘玉荣, 丛茜. 长耳鸮翼型组的气动特性分析[J]. 吉林大学学报(工学版), 2010, 40(增刊): 278-0281. |

| [14] | 张英朝,张喆,李杰,韦甘,罗双虎. 基于空气动力学数值模拟的汽车造型设计[J]. 吉林大学学报(工学版), 2009, 39(增刊2): 260-0263. |

| [15] | 胡兴军;张英朝;李胜;林有志;王加雪;杨永柏 . 基于微分雷诺应力湍流模型的车辆气动特性的数值模拟[J]. 吉林大学学报(工学版), 2008, 38(03): 504-0507. |

|

||