吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2706-2717.doi: 10.13229/j.cnki.jdxbgxb.20211270

西北寒旱农区胡麻滚勺式精量穴播器的设计及试验

- 甘肃农业大学 机电工程学院,兰州 730070

Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region

- College of Mechanical and Electrical Engineering,Gansu Agricultural University,Lanzhou 730070,China

摘要:

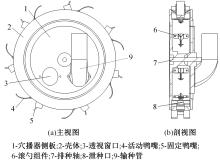

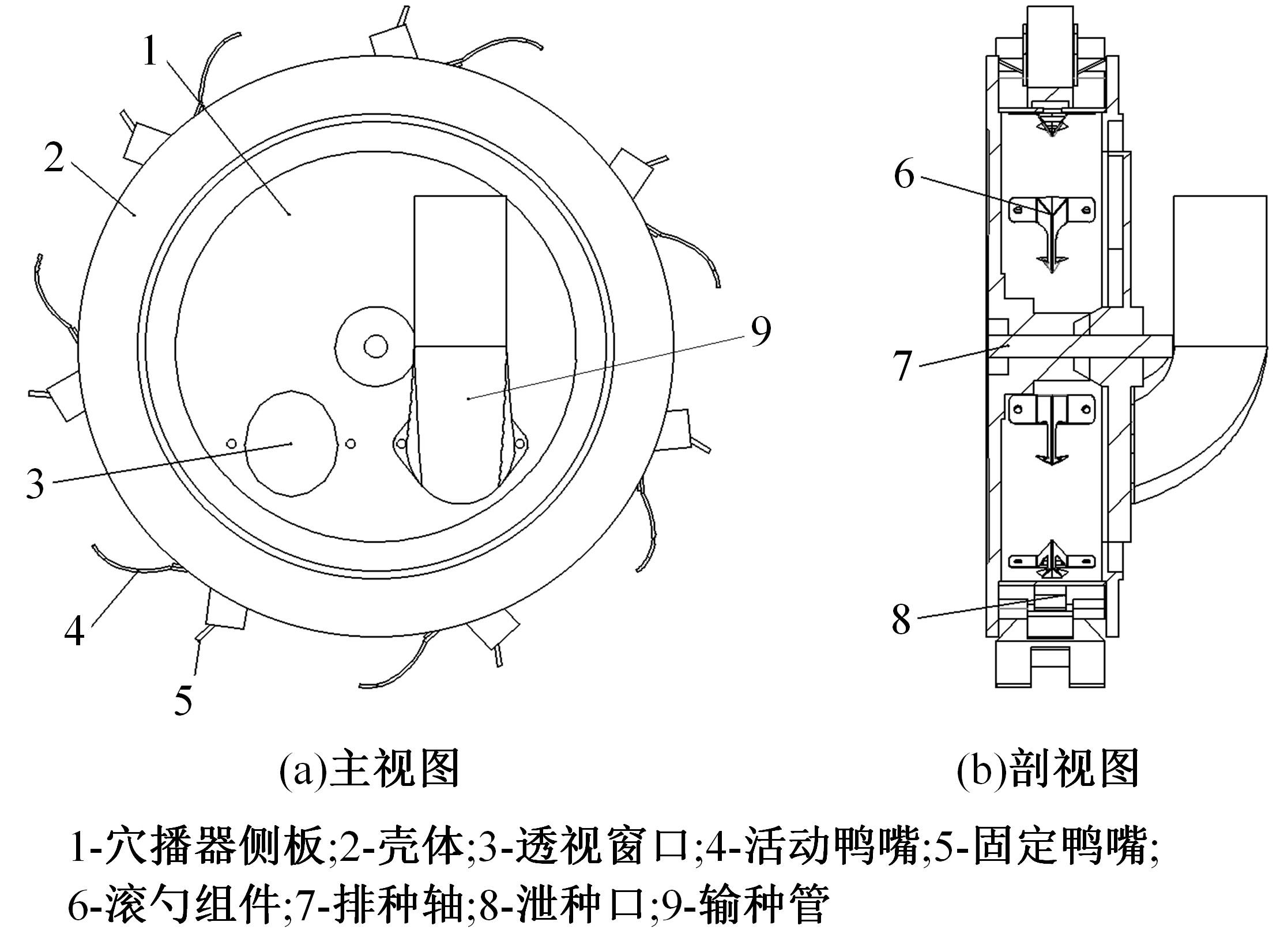

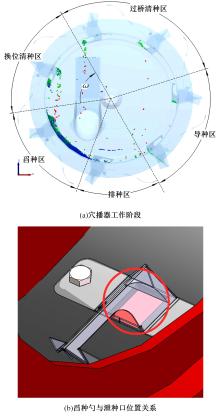

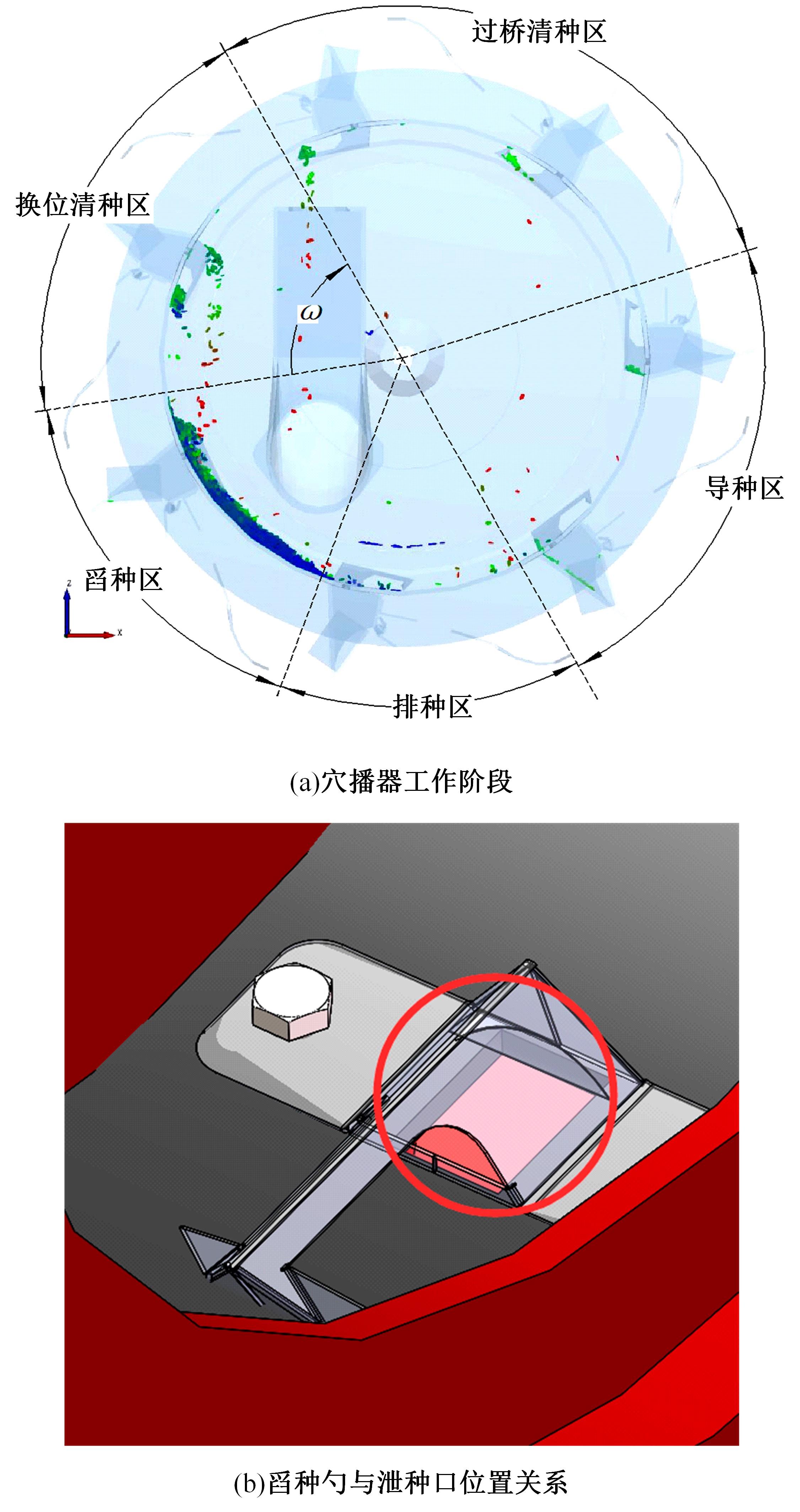

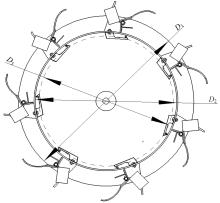

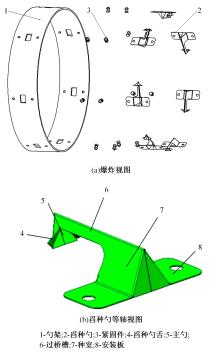

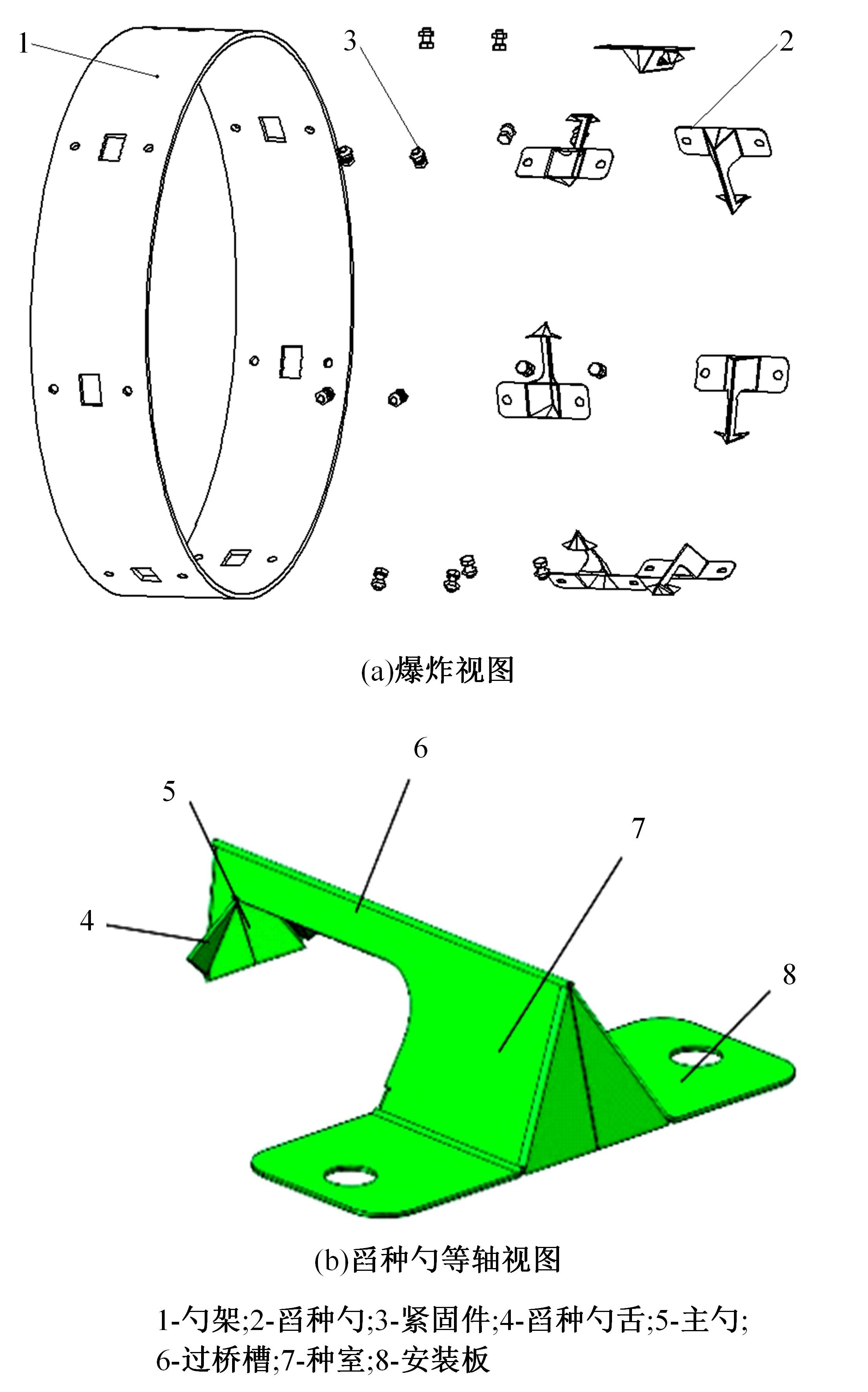

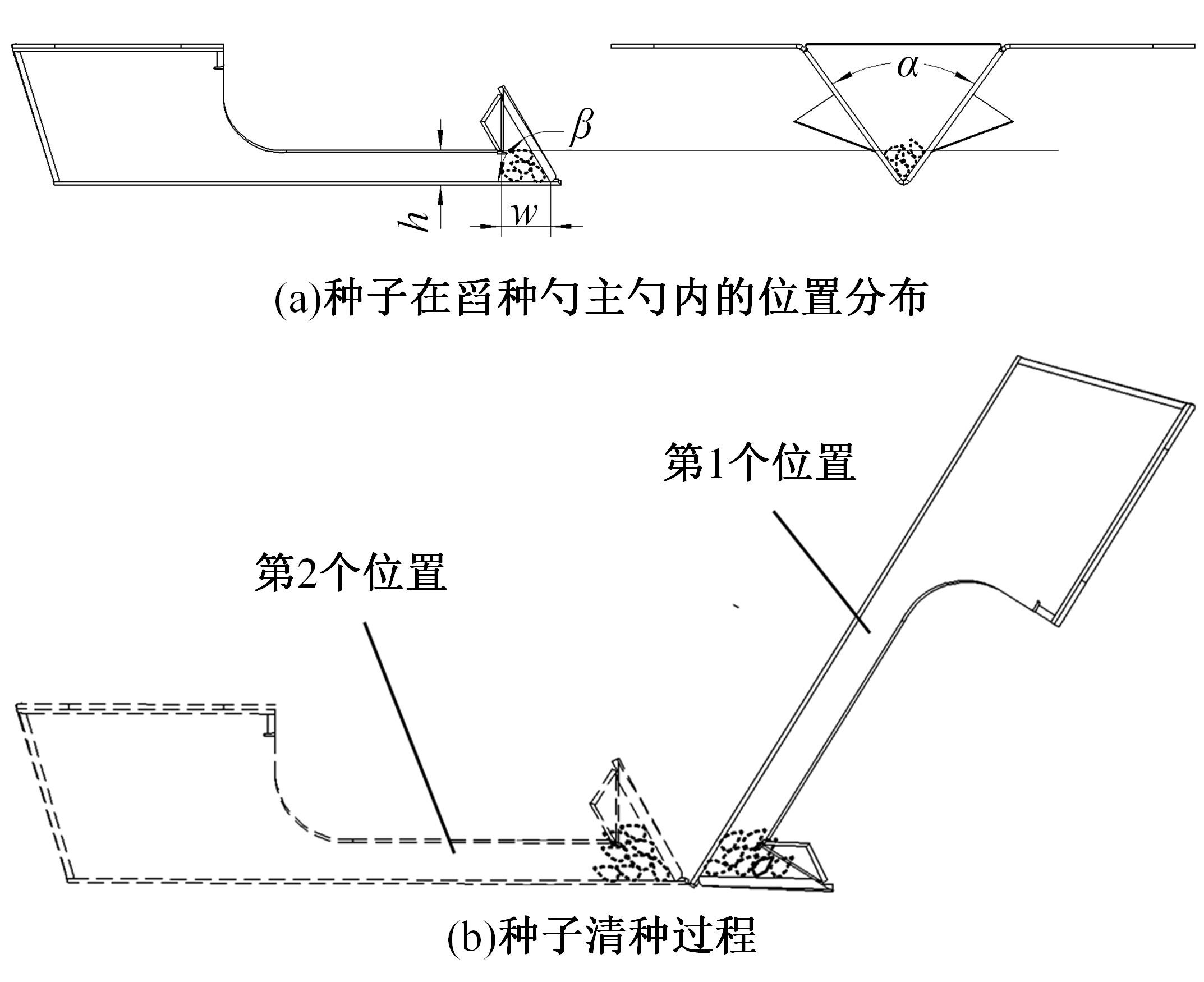

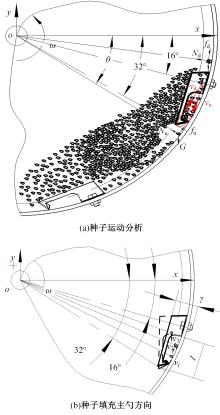

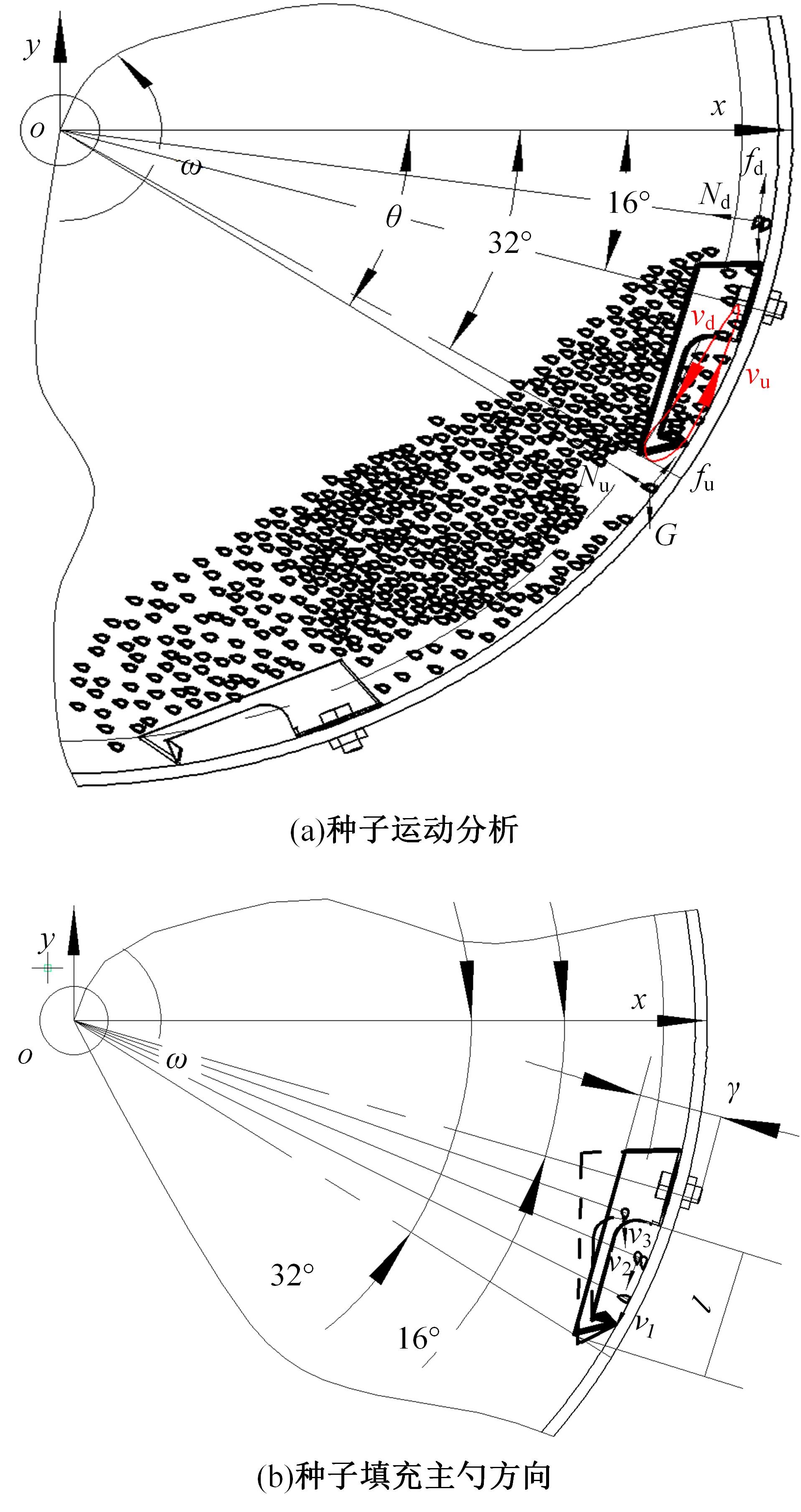

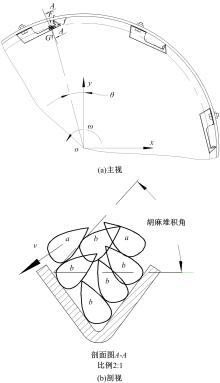

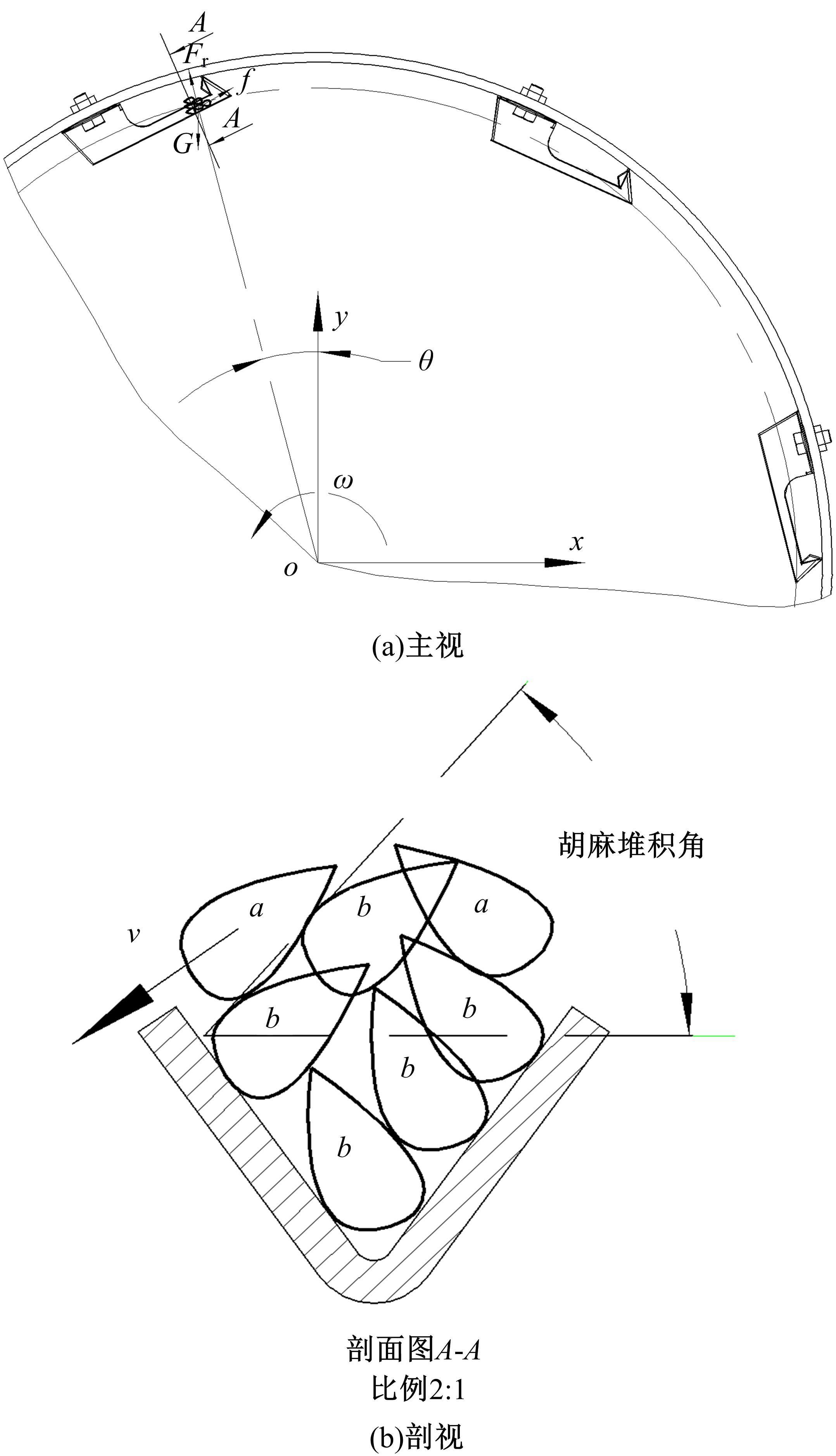

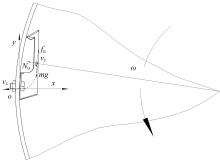

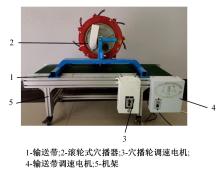

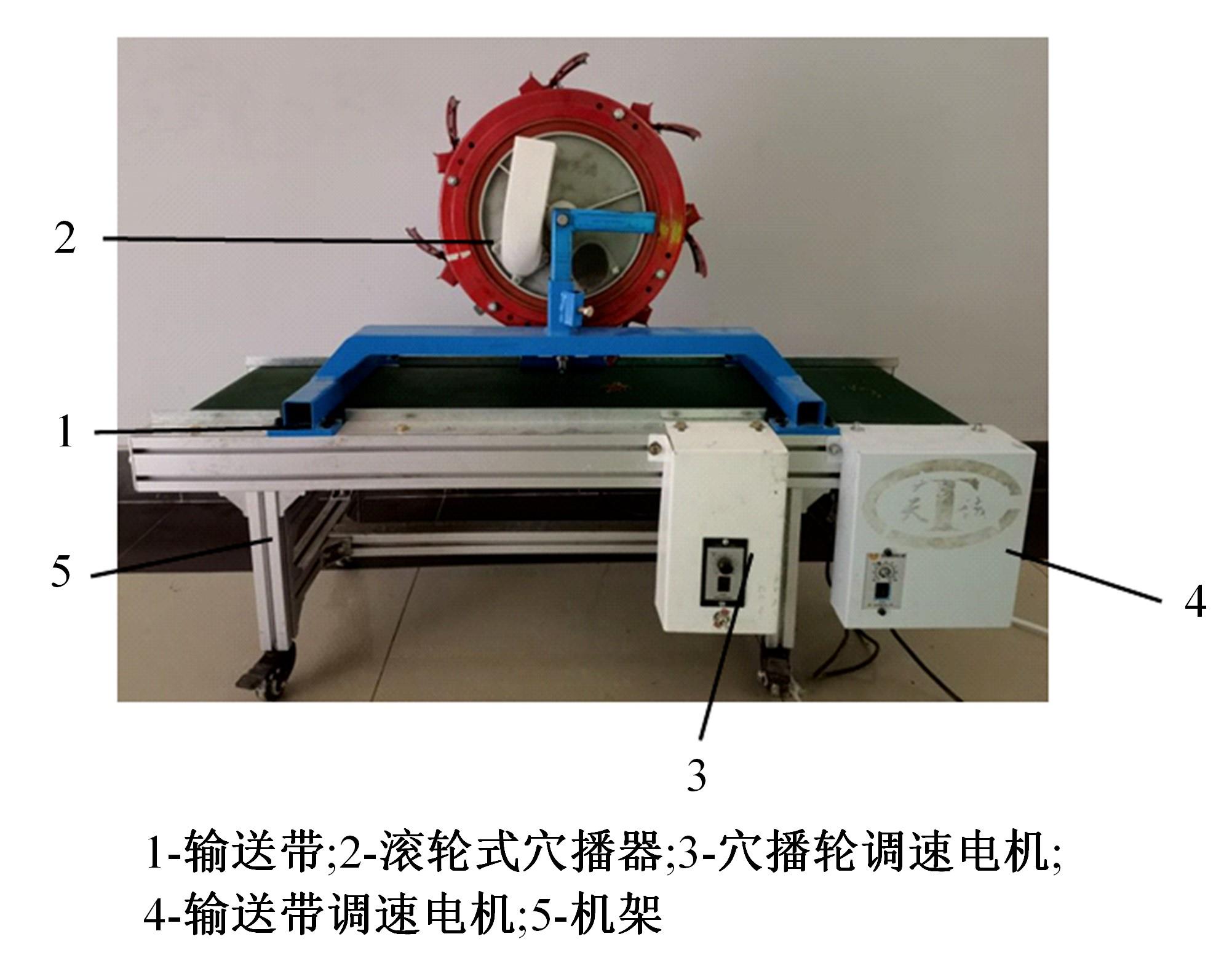

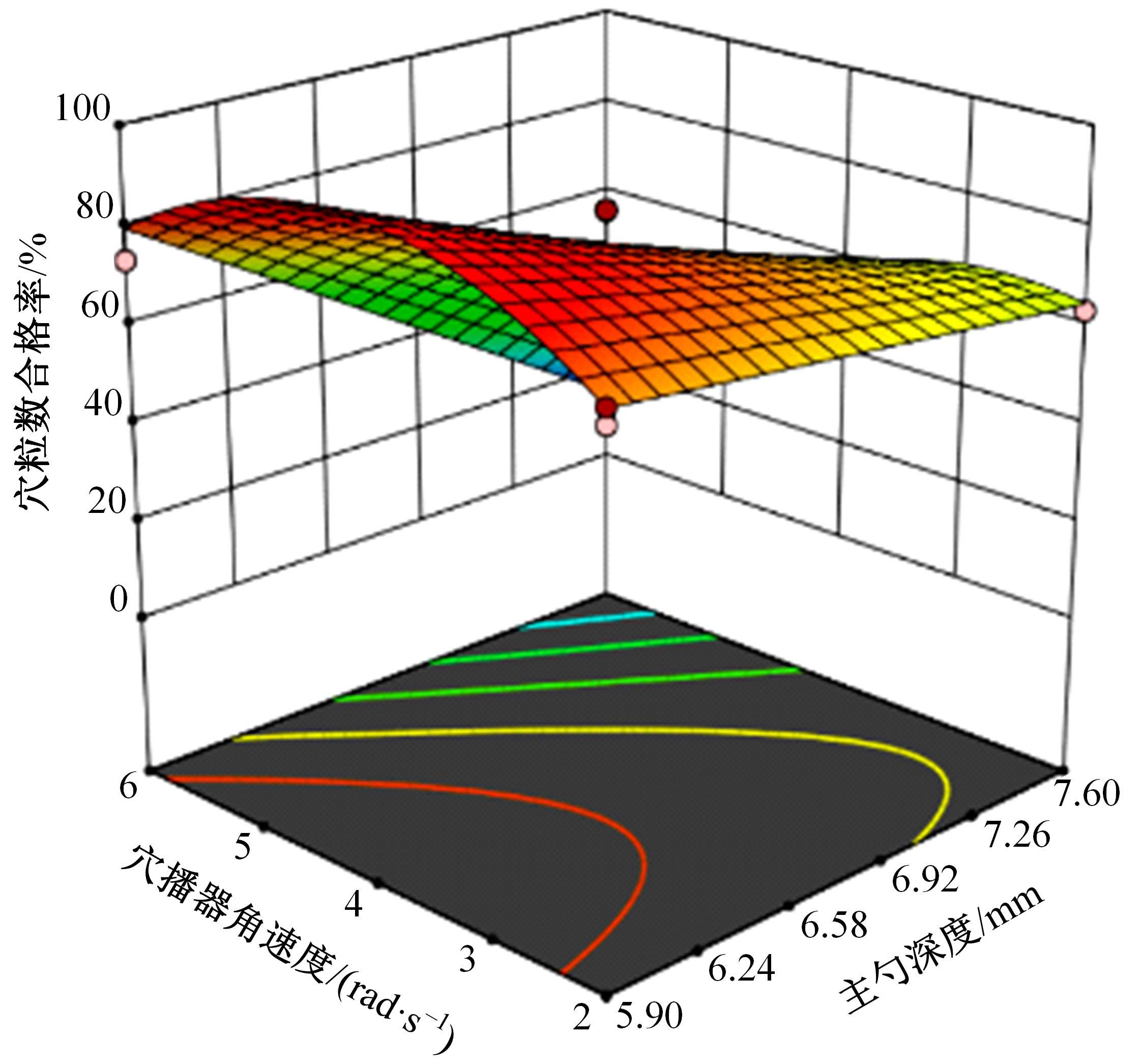

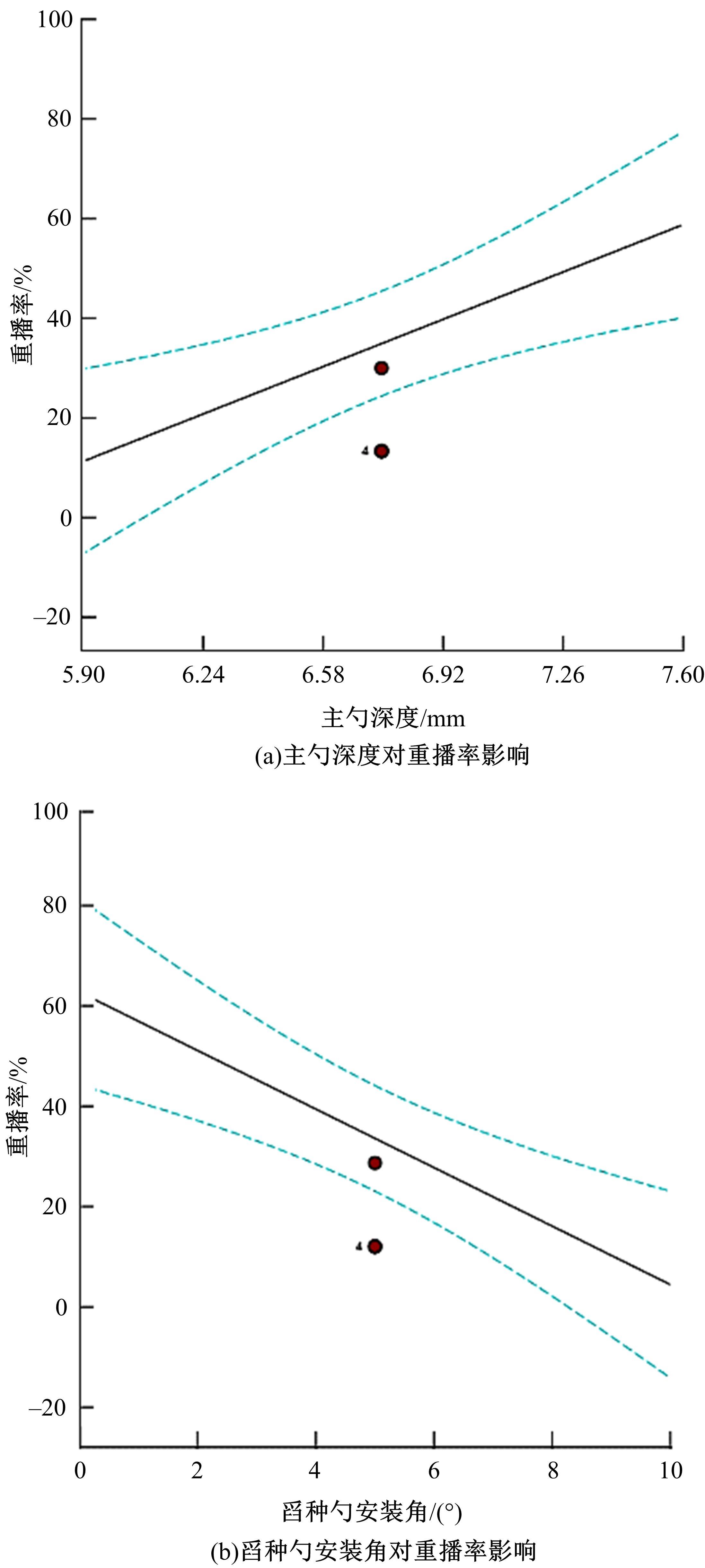

针对胡麻穴播器用种量大、穴粒数变异系数大、穴孔缺种等实际问题,结合甘肃覆膜种植环境,设计了一种带舀种勺舌的滚勺式精量穴播器。通过分析穴播器的作业原理和排种过程,确定了滚勺组件组成及舀种勺尺寸、安装数量、安装角等主要参数,并采用响应曲面法分析了主勺深度、舀种勺安装角和穴播器角速度对穴播器排种性能的影响。结果表明:当主勺深度为6.68 mm、舀种勺安装角为7.62°、穴播器角速度为3.22 rad/s时,穴粒数合格率为92.5%,漏播率为2.54%,重播率为4.96%。本文研究结果可为胡麻精量穴播排种装置设计提供参考。

中图分类号:

- S223.2

| 1 | 邓欣,陈信波, 邱财生, 等. 我国亚麻种质资源研究与利用概述[J]. 中国麻业科学, 2015, 37(6): 322-329. |

| Deng Xin, Chen Xin-bo, Qiu Cai-sheng, et al. Review on research and utilization of flax (linum usitatissimum L.) germplasm resources[J]. Plant Fiber Sciences in China, 2015, 37(6): 322-329. | |

| 2 | 金晓蕾, 张辉, 贾霄云, 等. 我国胡麻品质育种现状及展望[J]. 内蒙古农业科技, 2014, 42(1): 117-119. |

| Jin Xiao-lei, Zhang Hui, Jia Xiao-yun, et al. Present situation and prospects of linseed quality breeding in our country[J]. Journal of Northern Agriculture, 2014, 42(1): 117-119. | |

| 3 | 张运晖, 赵瑛, 罗俊杰. 甘肃胡麻产业发展浅议[J]. 甘肃农业科技,2013(7):54-55. |

| Zhang Yun-hui, Zhao Ying, Luo Jun-jie. The development of hops industry in Gansu province[J]. Gansu Agricultural Science and Technology, 2013(7): 54-55. | |

| 4 | 周刚, 石林榕, 赵武云, 等. 旱地胡麻起垄覆膜播种联合作业机工作参数优化与性能试验[J]. 中国农业大学学报, 2019, 24(6): 147-156. |

| Zhou Gang, Shi Lin-rong, Zhao Wu-yun, et al. Optimization of the working parameters and performance experiment of flax ridging and covering film combined seeder in dry-land[J]. Journal of China Agricultural University, 2019, 24(6): 147-156. | |

| 5 | 杜佳伟, 杨学军, 刘立晶, 等. 小粒种子精量播种机研究现状及发展趋势[J]. 农业工程, 2017, 7(6): 9-13. |

| Du Jia-wei, Yang Xue-jun, Liu Li-jing, et al. Research status and development trend of precision seeder for small seeds[J]. Agricultural Engineering, 2017, 7(6): 9-13. | |

| 6 | 李来祥, 刘广才, 杨祁峰, 等. 甘肃省旱地全膜双垄沟播技术研究与应用进展[J]. 干旱地区农业研究, 2009, 27(1): 114-118. |

| Li Lai-xiang, Liu Guang-cai, Yang Qi-feng, et al. Research and application development for the techniques of whole plastic-film mulching on double ridges and planting in catchment furrows in dry land[J]. Agricultural Research in the Arid Areas, 2009, 27(1): 114-118. | |

| 7 | 杨祁峰, 刘广才, 熊春蓉, 等. 旱地玉米全膜双垄沟播技术的水分高效利用机理研究[J]. 农业现代化研究, 2010, 31(1):113-116. |

| Yang Qi-feng, Liu Guang-cai, Xiong Chun-rong, et al. Study on highly efficient water utilizing mechanisms on techniques of whole plastic-film mulching on double ridges and planting in catchment furrows of dry-land maize[J]. Research of Agricultural Modernization, 2010, 31(1): 113-116. | |

| 8 | 贾晶霞, 杨德秋, 李建东, 等. 马铃薯栽培农艺与机械化生产技术调研综述[J]. 农机化研究, 2010, 32(11): 1-6. |

| Jia Jing-xia, Yang De-qiu, Li Jian-dong, et al. Investigation summary about potato planting agriculture and mechanical production technique[J]. Journal of Agricultural Mechanization Research, 2010, 32(11): 1-6. | |

| 9 | 曹海峰, 高立辉, 胡科全, 等. 我国亚麻生产机械化及产业发展建议[J]. 中国农机化, 2009(3): 22-25. |

| Cao Hai-feng, Gao Li-hui, Hu Ke-quan, et al. Suggestions on mechanization and development of flax production in China[J]. Journal of Chinese Agricultural Mechanization, 2009(3): 22-25. | |

| 10 | 郑立, 杨作范. 我国西北地区胡麻产业发展的必要性及对策[J]. 现代农业科技, 2012(15): 55-57. |

| Zheng Li, Yang Zuo-fan. Development necessity and countermeasures of flax industry in northwest of China[J]. Modern Agricultural Science and Technology, 2012(15): 55-57. | |

| 11 | 周刚, 石林榕, 赵武云, 等. 旱地垄作膜面胡麻精量播种机设计和仿真[J]. 干旱地区农业研究, 2019, 37(2): 245-252. |

| Zhou Gang, Shi Lin-rong, Zhao Wu-yun, et al. Design and simulation of precision seeder for flax in dryland ridge with plastic-film mulching[J]. Agricultural Research in the Arid Areas, 2019, 37(2): 245-252. | |

| 12 | 宗平, 吴海鹏, 姜忠旭,等. 水稻机穴播种植模式探析[J]. 现代农业科技, 2018(10): 38-39. |

| Zong Ping, Wu Hai-peng, Jiang Zhong-xu, et al. Exploration of rice machine hole-sowing planting pattern[J]. Modern Agricultural Science and Technology, 2018(10): 38-39. | |

| 13 | 石林榕, 马周泰, 赵武云,等. 胡麻籽粒离散元仿真参数标定与排种试验验证[J]. 农业工程学报, 2019, 35(20): 25-33. |

| Shi Lin-rong, Ma Zhou-tai, Zhao Wu-yun, et al. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(20): 25-33. | |

| 14 | 张青松, 余琦, 王磊, 等. 油菜勺式精量穴播穴播器设计与试验[J]. 农业机械学报, 2020, 51(6): 47-54, 64. |

| Zhang Qing-song, Yu Qi, Wang Lei, et al. Design and experiment of scoop-type precision hole metering device for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 47-54, 64. | |

| 15 | 衣淑娟, 陈涛, 李衣菲, 等. 正负气压-型孔轮组合式谷子穴播穴播器设计与试验[J]. 农业机械学报, 2021, 52(6): 83-94. |

| Yi Shu-juan, Chen Tao, Li Yi-fei, et al. Design and test of millet hill-drop seed-metering device with combination of positive-negative pressure and hole wheel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(6): 83-94. | |

| 16 | 张顺, 李勇, 王浩宇, 等. U型腔道式水稻精量穴播穴播器设计与试验[J]. 农业机械学报, 2020,51(10):98-108. |

| Zhang Shun, Li Yong, Wang Hao-yu,et al. Design and experiment of U-shaped cavity type precision hill-drop seed-metering device for rice[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 98-108. | |

| 17 | 张国忠, 张沙沙,杨文平,等. 双腔侧充种式水稻精量穴播穴播器的设计与试验[J]. 农业工程学报,2016, 32(8): 9-17. |

| Zhang Guo-zhong, Zhang Sha-sha, Yang Wen-ping, et al. Design and experiment of double cavity side-filled precision hole seed metering device for rice[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(8): 9-17. | |

| 18 | 刘俊, 朱德泉, 于从羊, 等. 舀勺型孔轮式水稻精量穴播器设计与试验[J]. 浙江农业学报, 2021, 33(4): 739 -752. |

| Liu Jun, Zhu De-quan, Yu Cong-yang, et al. Design and experiment on scoop hole-wheel precision seed-metering device for rice[J]. Acta Agriculturae Zhejiangensis, 2021, 33(4): 739-752. | |

| 19 | 周刚, 石林榕, 赵武云, 等. 旱地胡麻起垄覆膜播种联合作业机工作参数优化与性能试验[J]. 中国农业大学学报, 2019, 24(6): 147-156. |

| Zhou Gang, Shi Lin-rong, Zhao Wu-yun, et al. Optimization of the working parameters and performance experiment of flax ridging and covering film combined seeder in dry-land[J]. Journal of China Agricultural University, 2019, 24(6): 147-156. | |

| 20 | 赵匀. 农业机械分析与综合[M]. 北京:机械工业出版社, 2009. |

| 21 | 王立军, 张志恒, 刘天华, 等. 玉米收获机割台砍劈式茎秆粉碎装置设计与试验[J].农业机械学报, 2020, 51(7): 109-117. |

| Wang Li-jun, Zhang Zhi-heng, Liu Tian-hua, et al. Design and experiment of device for chopping stalk of header of maize harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 109-117. | |

| 22 | 石林榕, 孙步功, 赵武云, 等. 弹性气吸嘴式玉米滚轮穴播器排种性能参数优化与试验[J]. 农业机械学报, 2019, 50(10): 88-95, 207. |

| Shi Lin-rong, Sun Bu-gong, Zhao Wu-yun, et al. Optimization and test of performance parameters of elastic air suction type corn roller seed-metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 88-95, 207. | |

| 23 | . 铺膜穴播机作业质量 [S]. |

| 24 | . 单粒(精密)播种机试验方法 [S]. |

| [1] | 史瑞杰,戴飞,赵武云,刘小龙,瞿江飞,张锋伟. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2746-2755. |

| [2] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

|