吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2718-2731.doi: 10.13229/j.cnki.jdxbgxb.20211267

滚筒式机收膜杂除土装置设计及试验

周鹏飞1( ),陈学庚1,2,蒙贺伟1,2,梁荣庆1,张炳成1,坎杂1,2(

),陈学庚1,2,蒙贺伟1,2,梁荣庆1,张炳成1,坎杂1,2( )

)

- 1.石河子大学 机械电气工程学院,新疆 石河子 832003

2.农业农村部西北农业装备重点实验室,新疆 石河子 832003

Design and experiment of trommel with function of separating soil from residual film mixture

Peng-fei ZHOU1( ),Xue-geng CHEN1,2,He-wei MENG1,2,Rong-qing LIANG1,Bing-cheng ZHANG1,Za KAN1,2(

),Xue-geng CHEN1,2,He-wei MENG1,2,Rong-qing LIANG1,Bing-cheng ZHANG1,Za KAN1,2( )

)

- 1.College of Mechanical and Electronic Engineering,Shihezi University,Shihezi 832003,China

2.Key Laboratory of Northwest Agricultural Equipment,Ministry of Agriculture and Rural Affairs,Shihezi 832003,China

摘要:

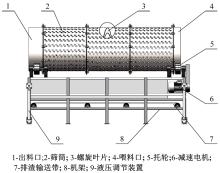

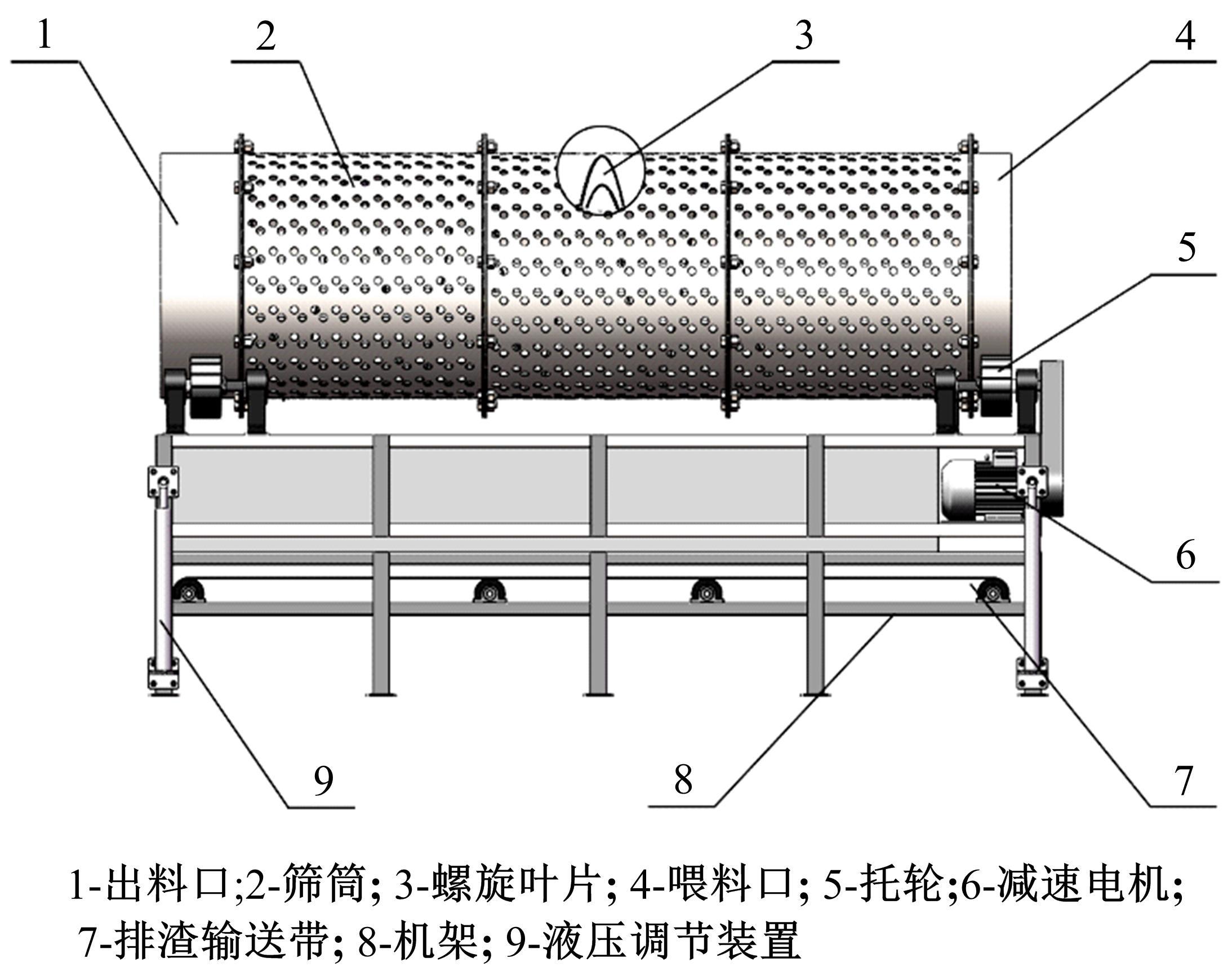

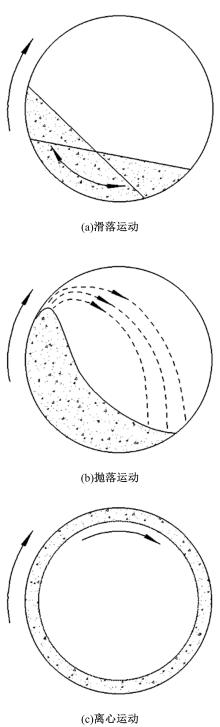

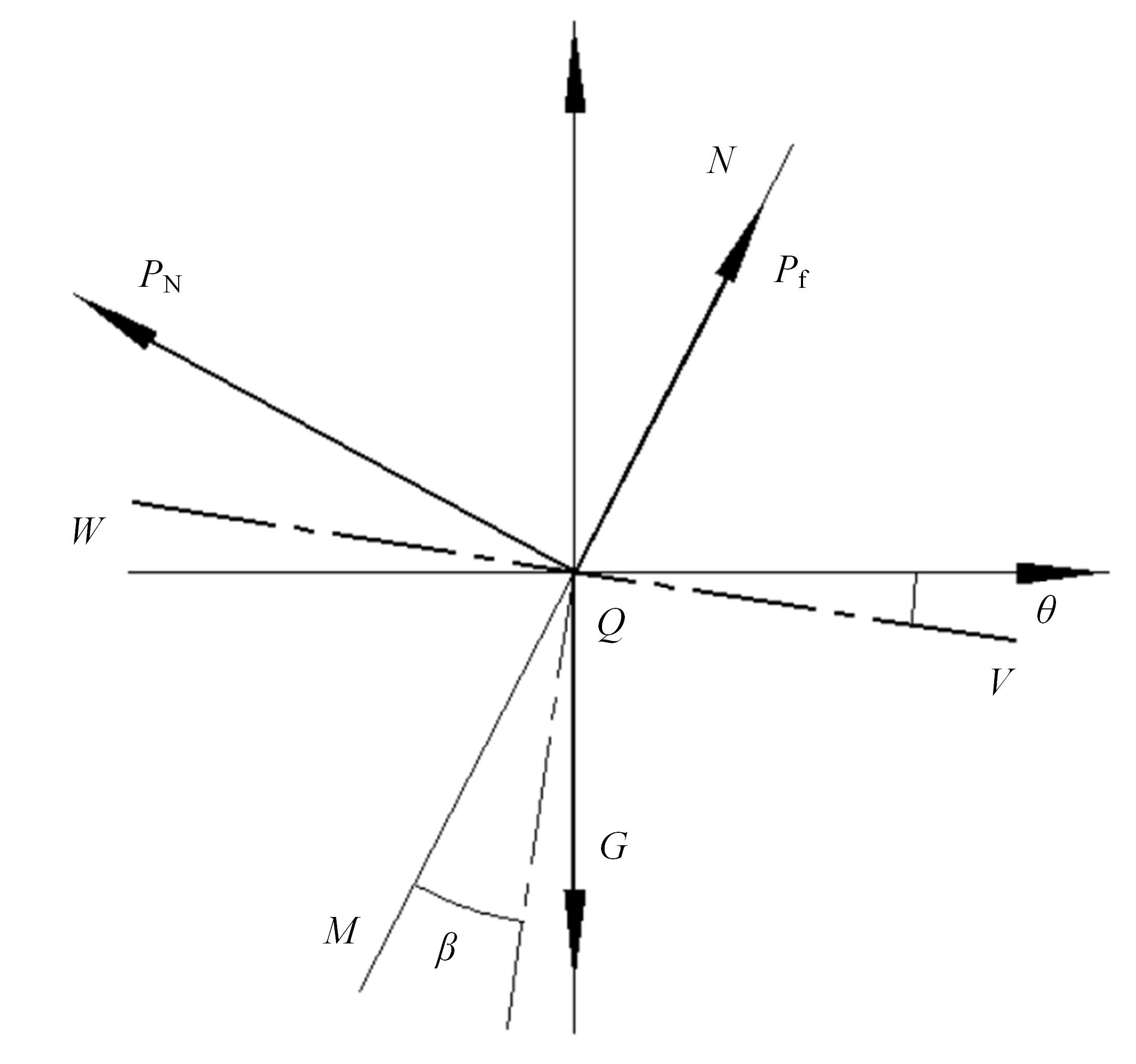

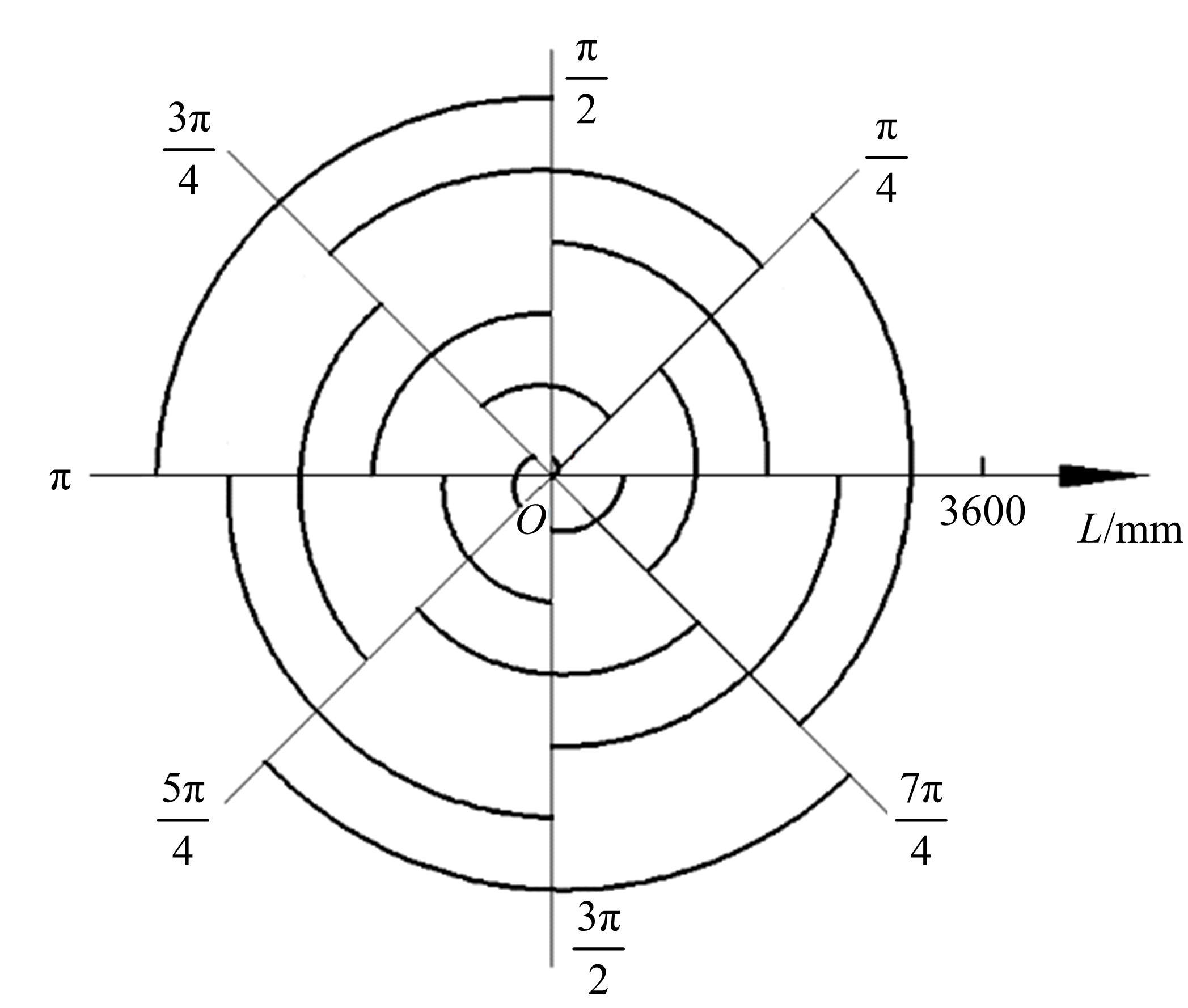

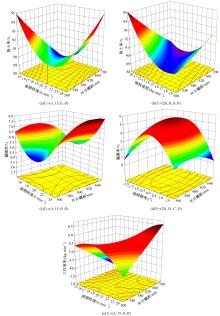

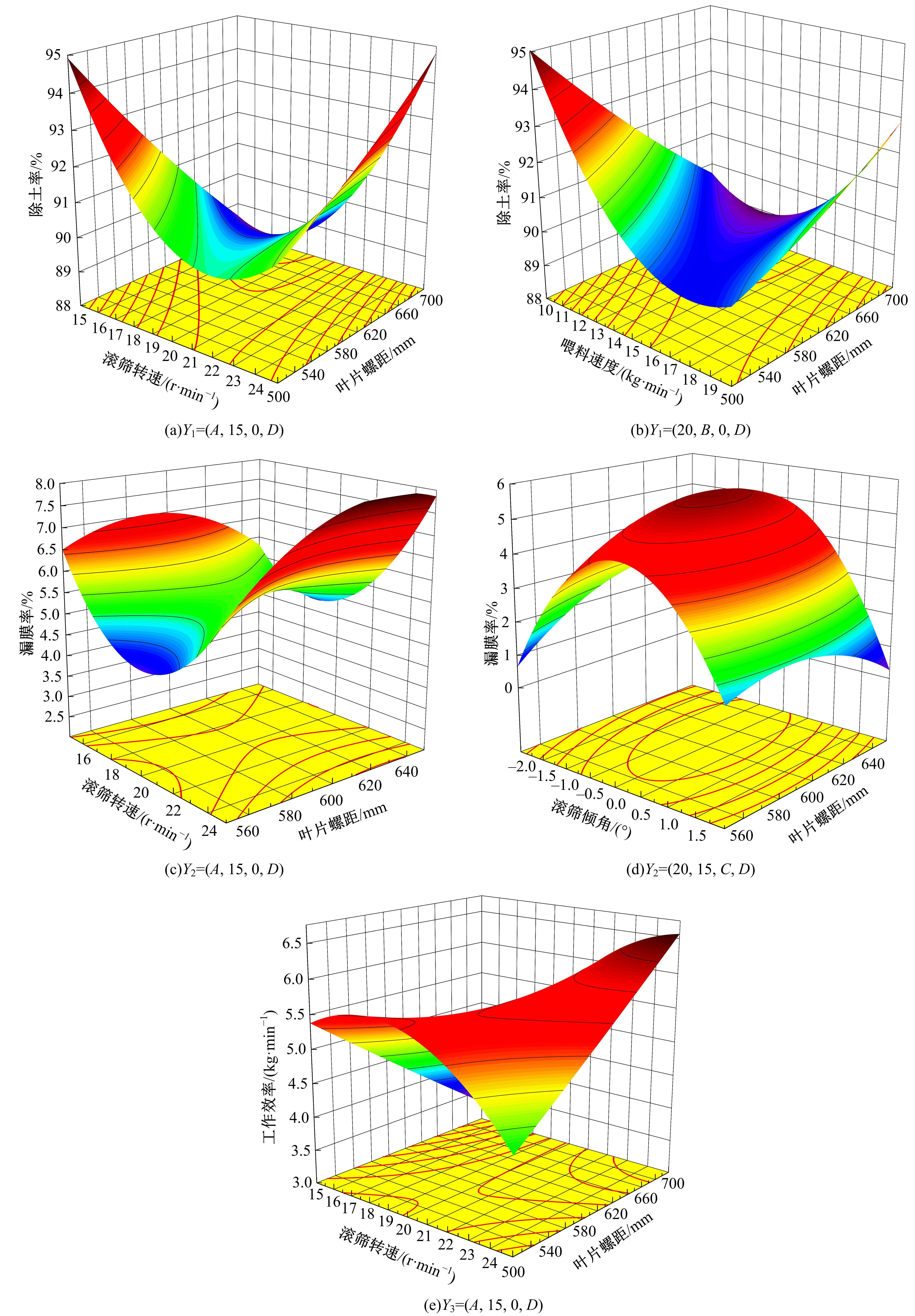

为解决机收膜杂含土率高的问题,设计了一种滚筒式机收膜杂除土装置,对装置内物料进行动力学分析,确定了该装置的基本参数。在此基础上,以滚筛转速、喂料速度、滚筛倾角和叶片螺距为试验因素,以除土率、漏膜率和工作效率为评价指标进行了四因素五水平的响应面试验,分析了各因素对膜土分离作业性能的影响规律,获得了最佳组合参数如下:滚筛转速为24.90 r/min、喂料速度为11.52 kg/min、滚筛倾角为-2°、叶片螺距为699.99 mm。在该条件下验证试验结果如下:除土率为92.48%、漏膜率为1.90‰、工作效率为7.61 kg/min,试验响应指标预测值与验证试验指标间误差分别为2.15%、5.79%、2.63%,表明所构建模型具有较好的预测可靠性,相关研究可为机收膜杂除土技术提供一定参考和理论支撑。

中图分类号:

- S223.5

| 1 | 胡灿, 王旭峰, 陈学庚, 等. 新疆农田残膜污染现状及防控策略[J]. 农业工程学报, 2019, 35(24): 213-224. |

| Hu Can, Wang Xu-feng, Chen Xue-geng, et al. Current situation and control strategies of residual film pollution in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(24): 213-224. | |

| 2 | 赵岩, 陈学庚, 温浩军, 等. 农田残膜污染治理技术研究现状与展望[J]. 农业机械学报, 2017, 48(6): 1-14. |

| Zhao Yan, Chen Xue-geng, Wen Hao-jun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. | |

| 3 | 梁荣庆, 陈学庚, 张炳成, 等. 新疆棉田残膜回收方式及资源化再利用现状问题与对策[J]. 农业工程学报, 2019, 35(16): 1-13. |

| Liang Rong-qing, Chen Xue-geng, Zhang Bing-cheng, et al. Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(16): 1-13. | |

| 4 | 蒋德莉, 陈学庚, 颜利民, 等. 农田残膜资源化利用技术与装备研究[J]. 中国农机化学报, 2020, 41(1): 179-190. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Research on technology and equipment for utilization of residual film in farmland[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(1): 179-190. | |

| 5 | Rose B L, Sr T R M, Gaude A, et al. System and method for removing soil from seed[P]. United States: 8590174, 2013-11-26. |

| 6 | 张佳, 杨宛章, 韩长杰, 等. 驱动耙残膜回收联合作业机的残膜回收部件设计研究[J]. 中国农机化学报, 2013, 34(3): 143-146. |

| Zhang Jia, Yang Wan-zhang, Han Chang-jie, et al. Design and research on plastic film collecting component of the driving target and plastic film collecting combined operation machine[J]. Journal of Chinese Agricultural Mechanization, 2013, 34(3): 143-146. | |

| 7 | 张佳. 驱动耙残膜回收联合作业机的设计及试验研究[D]. 乌鲁木齐: 新疆农业大学机电工程学院, 2013. |

| Zhang Jia. Design and experimental study on driving target and plastic film collecting combined operation machine[D]. Urumqi: College of Mechanical and Electrical Engineering, Xinjiang Agricultural University, 2013. | |

| 8 | 游兆延, 吴惠昌, 陈有庆, 等. 双筛体驱振式膜土分离与输送装置设计与试验[J]. 中国农机化学报,2018, 39(11): 4-11. |

| You Zhao-yan, Wu Hui-chang, Chen You-qing, et al. Design and experiment on double-sieve-driving apparatus for film-soil separation and transportation[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(11): 4-11. | |

| 9 | 魏忠彩, 李洪文, 孙传祝, 等. 基于多段分离工艺的马铃薯联合收获机设计与试验[J]. 农业机械学报, 2019,50(1): 129-140, 112. |

| Wei Zhong-cai, Li Hong-wen, Sun Chuan-zhu, et al. Design and experiment of potato combined harvester based on multi-stage separation technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(1): 129-140, 112. | |

| 10 | 魏忠彩, 苏国粱, 李学强, 等. 基于离散元的马铃薯收获机波浪形筛面参数优化与试验[J]. 农业机械学报, 2020, 51(10): 109-122. |

| Wei Zhong-cai, Su Guo-liang, Li Xue-qiang, et al. Parameter optimization and test of potato harvester wavy sieve based on EDEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 109-122. | |

| 11 | 张学军, 刘家强, 史增录, 等. 残膜回收机逆向膜土分离装置的设计与参数优化[J]. 农业工程学报, 2019, 35(4): 46-55. |

| Zhang Xue-jun, Liu Jia-qiang, Shi Zeng-lu, et al. Design and parameter optimization of reverse membrane and soil separation device for residual film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(4): 46-55. | |

| 12 | 吕金庆, 杜长霖, 刘中原, 等. 马铃薯料斗机除杂装置设计与试验[J]. 农业机械学报, 2021, 52(1): 82-90, 61. |

| Lv Jin-qing, Du Chang-lin, Liu Zhong-yuan, et al. Design and test of impurity removal device of potato receiving hopper[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(1): 82-90, 61. | |

| 13 | 石鑫, 牛长河, 王学农, 等. 滚筒筛式废旧地膜与杂质风选装置设计[J]. 农业工程学报,2017,33(18): 19-26. |

| Shi Xin, Niu Chang-he, Wang Xue-nong, et al. Design of roller sieve waste plastic film and trash winnowing machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(18): 19-26. | |

| 14 | 牛长河, 石鑫, 蒋永新, 等. 废旧地膜杂质风选装置的设计及试验[J]. 新疆农机化,2018(5): 23-25. |

| Niu Chang-he, Shi Xin, Jiang Yong-xin, et al. Design and test on type of waste plastic mulch films and impurities winnowing machine[J]. Xinjiang Agricultural Mechanization, 2018(5): 23-25. | |

| 15 | 王冠, 霍丽丽, 赵立欣, 等. 秸秆类生物质原料筛分除杂试验及滚筒筛改进[J]. 农业工程学报,2016,32(13): 218-222. |

| Wang Guan, Huo Li-li, Zhao Li-xin, et al. Screening of biomass straw materials and improvement of feedstock equipment[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(13): 218-222. | |

| 16 | Mellmann J. The transverse motion of solids in rotating cylinders—forms of motion and transition behavior[J]. Powder Technology, 2001, 118(3): 251-270. |

| 17 | Forsyth A J, Hutton S R, Rhodes M J, et al. Effect of applied interparticle force on the static and dynamic angles of repose of spherical granular material[J]. Physical Review E Statistical Nonlinear & Soft Matter Physics, 2001, 63(3): 293-305. |

| 18 | 张禄文. 城市生活垃圾破碎筛分设备工艺研究[D]. 昆明: 昆明理工大学环境科学与工程学院, 2004. |

| Zhang Lu-wen. Research on technology of municipal solid waste crushing and screening equipment[D]. Kunming: Faculty of Environmental Science and Engineering, Kunming University of Science and Technology, 2004. | |

| 19 | 张林海, 薛党勤, 马世榜, 等. 农作物秸秆物料杂质及滚筒筛分研究[J]. 太阳能学报,2014,35(3): 433-438. |

| Zhang Lin-hai, Xue Dang-qin, Ma Shi-bang, et al. Reserch on impurities of the cropstraw and trommel sieve[J]. Acta Energiae Solaris Sinica, 2014, 35(3): 433-438. | |

| 20 | 蒋德莉. 随动式残膜回收机清杂系统研究与试验[D]. 石河子: 石河子大学机械电气工程学院, 2020. |

| Jiang De-li. Research and experiment on cleaning system of profile modeling residual film recovery machine[D]. Shihezi: College of Mechanical and Electrical Engineering, Shihezi University, 2020. | |

| 21 | 蒋德莉, 陈学庚, 颜利民, 等. 随动式残膜回收机清杂系统作业参数优化[J]. 农业工程学报, 2019, 35(19): 1-10. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Optimization of working parameters of cleaning system for master-slave residual plastic film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(19): 1-10. | |

| 22 | 罗凯, 袁盼盼, 靳伟, 等. 链筛式耕层残膜回收机设计与工作参数优化试验[J]. 农业工程学报,2018, 34(19): 19-27. |

| Luo Kai, Yuan Pan-pan, Jin Wei, et al. Design of chain-sieve type residual film recovery machine in plough layer and optimization of its working parameters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(19): 19-27. | |

| 23 | 张征. Φ3 m×10 m垃圾滚筒筛设计与应用[J]. 水泥工程, 2012(5): 53-55, 67. |

| Zhang Zheng. Design of Φ3 m×10 m garbage trommel screen and the application[J]. Cement Engineering, 2012(5): 53-55, 67. | |

| 24 | 李伟平, 张新昌. 田间残膜压缩打包装置及其关键技术[J]. 轻工机械,2017,35(5): 70-75. |

| Li Wei-ping, Zhang Xin-chang. Research on residual film compression and packaging device and key technology[J]. Light Industry Machinery, 2017, 35(5): 70-75. | |

| 25 | 刘廷发. 堆肥滚筒筛分机开发研究[D]. 北京: 中国农业机械化科学研究院, 2017. |

| Liu Ting-fa. Research and design of compost trommel screen[D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2017. | |

| 26 | 郭祯祥. 小麦加工技术[M]. 北京:化学工业出版社, 2003. |

| 27 | 万星宇, 舒彩霞, 徐阳, 等. 油菜联合收获机分离清选差速圆筒筛设计与试验[J]. 农业工程学报, 2018, 34(14): 27-35. |

| Wan Xing-yu, Shu Cai-xia, Xu Yang, et al. Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(14): 27-35. | |

| 28 | 王升升, 陈盼, 卢梦晴, 等. 大白菜种子收获分离清选装置设计与试验[J]. 农业机械学报,2020, 51(): 181-190. |

| Wang Sheng-sheng, Chen Pan, Lu Meng-qing, et al. Design and experiment of separation and cleaning device for chinese cabbage seeds harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 181-190. | |

| 29 | 张世军, 蒋恩臣, 王明峰, 等. 生物质热解柔性输送装置性能研究[J]. 农机化研究, 2017, 39(6): 250-254. |

| Zhang Shi-jun, Jiang En-chen, Wang Ming-feng, et al. Study on flexible delivery device performance of biomass pyrolysis[J]. Journal of Agricultural Mechanization Research, 2017, 39(6): 250-254. | |

| 30 | 张炎, 芮延年, 周宏伟, 等. 基于粒子群算法的高黏度大比重物料无轴螺旋输送机构优化设计[J]. 工程设计学报, 2014(2): 161-165. |

| Zhang Yan, Rui Yan-nian, Zhou Hong-wei, et al. Optimization design of shaft-less screw conveyor mechanism for high viscosity and large specific gravity materials based on PSO[J]. Journal of Engineering Design, 2014(2): 161-165. | |

| 31 | 徐强. 螺旋滚筒式生物质连续热解装置送料器设计及仿真[D]. 广州: 华南农业大学材料与能源学院, 2017. |

| Xu Qiang. Design and simulation of screw drum biomass continuous pyrolysis device feeder[D]. Guangzhou: College of Materials and Energy, South China Agricultural University, 2017. | |

| 32 | 付双成, 张亚磊, 姜毓圣, 等. 卧螺离心机不同螺旋结构流场的数值模拟研究[J]. 常州大学学报: 自然科学版, 2020, 32(1): 56-61. |

| Fu Shuang-cheng, Zhang Ya-lei, Jiang Yu-sheng, et al. Numerical simulating study on flow field of decanter centrifuges with different spiral structure[J]. Journal of Changzhou University (Natural Science Edition), 2020, 32(1): 56-61. | |

| 33 | 武军, 范德顺. 间断式螺旋挤压过滤机[J]. 过滤与分离, 2008, 18(1): 36-37. |

| Wu Jun, Fan De-shun. Interrupted screw filter[J]. Journal of Filtration & Separation, 2008, 18(1): 36-37. | |

| 34 | 陈学深, 陈涛, 武涛, 等. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 749-757. |

| Chen Xue-shen, Chen Tao, Wu Tao, et al. Design and experiment on harvester for winter planting potato of straw coverage[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 749-757. | |

| 35 | 黄继承, 沈成, 纪爱敏, 等. 工业大麻收割机切割-输送关键部件作业参数优化[J]. 吉林大学学报: 工学版, 2021, 51(2): 772-780. |

| Huang Ji-cheng, Shen Cheng, Ji Ai-min, et al. Optimization of cutting-conveying key working parameters of hemp harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. | |

| 36 | 成科扬, 朱雪森, 裴运申, 等. 农业自动化机械障碍物检测研究进展[J]. 江苏大学学报: 自然科学版, 2023, 44(4): 415-425. |

| Cheng ke-yang, Zhu Xue-sen, Pei Yun-shen, et al.Research progress of agricultural automatic machinery obstacle detection[J]. Journal of Jiangsu University(Natural Science Edition), 2023, 44(4): 415-425. | |

| 37 | 李妍颖, 刘孟楠, 徐立友,等. 基于非线性规划遗传算法的混合动力拖拉机控制策略[J]. 江苏大学学报:自然科学版, 2023, 44(2): 166-172, 185. |

| Li Yan-ying, Liu Meng-nan, Xu Li-you, et al. Control strategy of series hybrid tractor based on nonlinear program genetic algorithm[J]. Journal of Jiangsu University(Natural Science Edition), 2023, 44(2): 166-172, 185. | |

| 38 | 孙岳, 简建明, 田玉泰, 等. 残膜回收机旋转式起膜装置起膜机理分析与试验[J]. 农业机械学报, 2018, 49(): 304-310. |

| Sun Yue, Jiang Jian-ming, Tian Yu-tai, et al. Analysis and experiment of filming mechanism of rotary film-lifting device of residual film recycling machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1): 304-310. |

| [1] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [2] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [3] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [4] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [5] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [6] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [7] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [8] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [9] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [10] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [11] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [12] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [13] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [14] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [15] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

|