吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 749-757.doi: 10.13229/j.cnki.jdxbgxb20181022

• 农业工程·仿生工程 • 上一篇

覆草冬种马铃薯收获机稻草分离机构设计与试验

陈学深1( ),陈涛1,武涛1,马旭1,2(

),陈涛1,武涛1,马旭1,2( ),曾令超1,陈林涛1

),曾令超1,陈林涛1

- 1.华南农业大学 工程学院,广州 510642

2.华南农业大学 南方农业机械与装备关键技术教育部重点实验室,广州 510642

Design and experiment on harvester for winter planting potato of straw coverage

Xue-shen CHEN1( ),Tao CHEN1,Tao WU1,Xu MA1,2(

),Tao CHEN1,Tao WU1,Xu MA1,2( ),Ling-chao ZENG1,Lin-tao CHEN1

),Ling-chao ZENG1,Lin-tao CHEN1

- 1.College of Engineering, South China Agricultural University, Guangzhou 510642, China

2.Key Laboratory of Key Technology on Agricultural Machine and Equipment(South China Agricultural University), Ministry of Education, Guangzhou 510642, China

摘要:

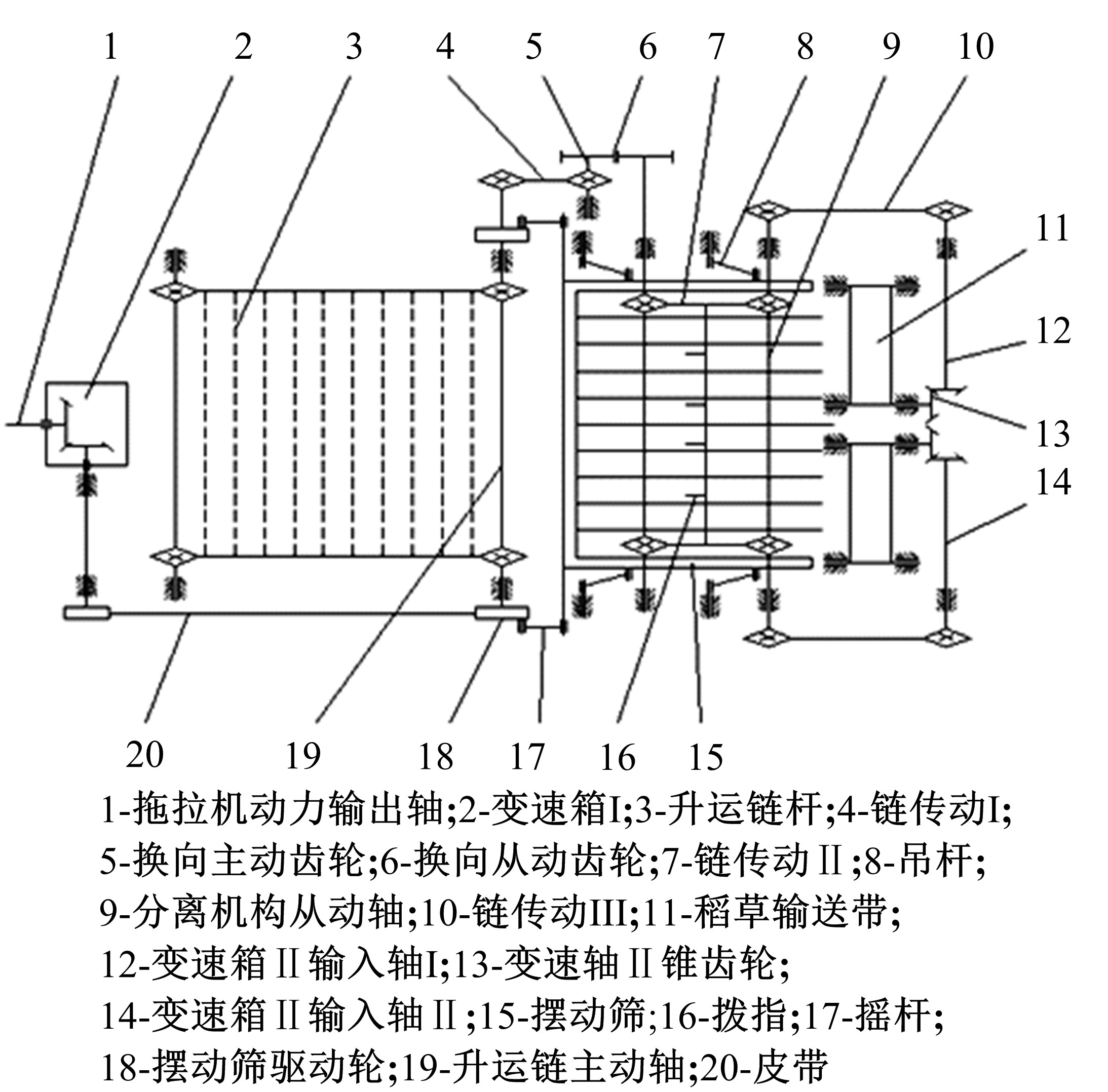

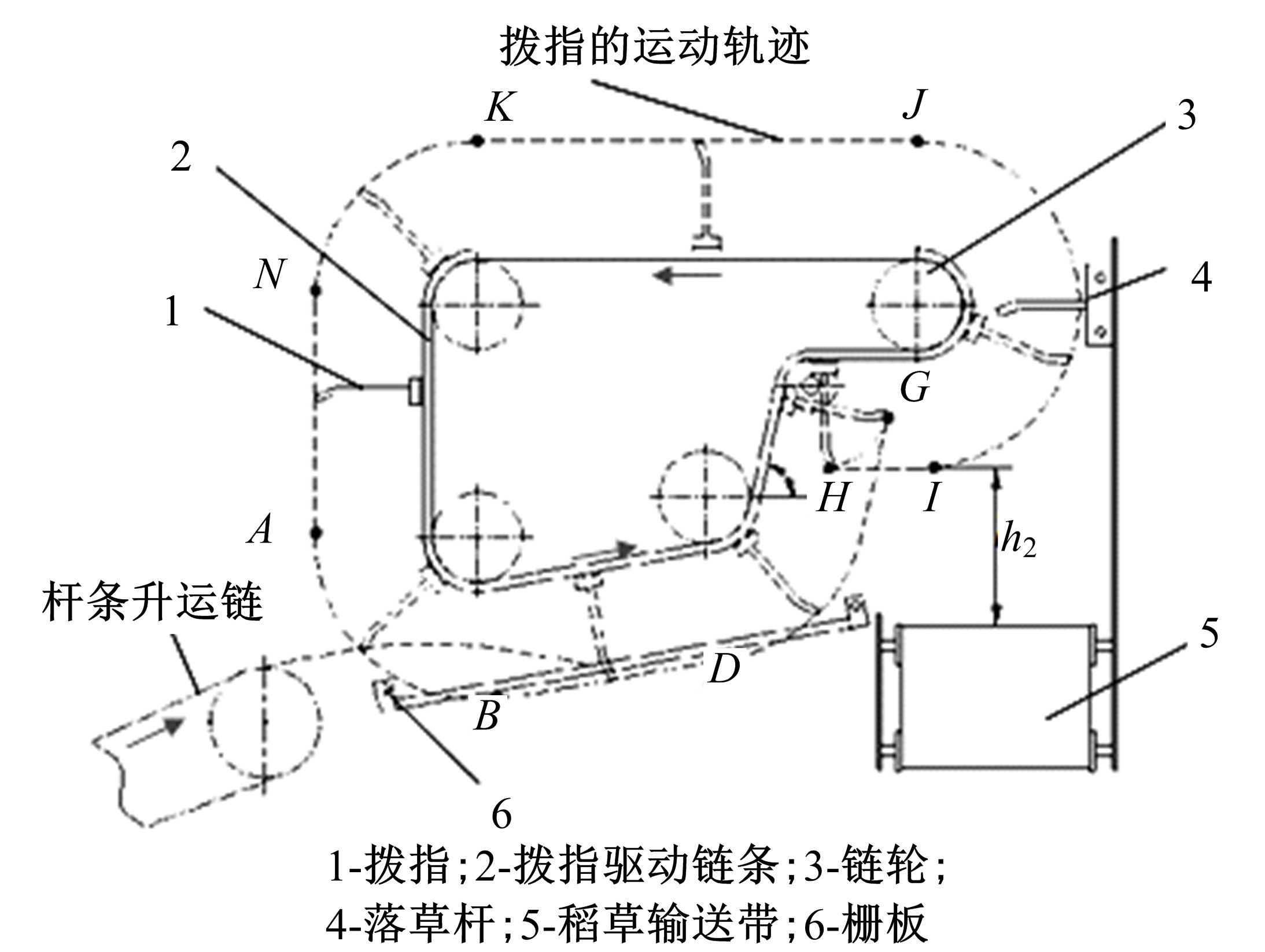

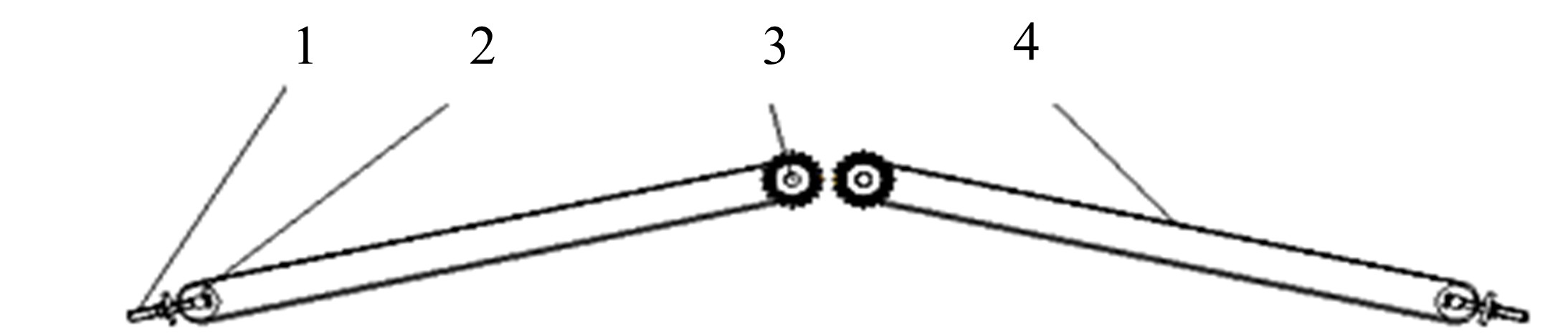

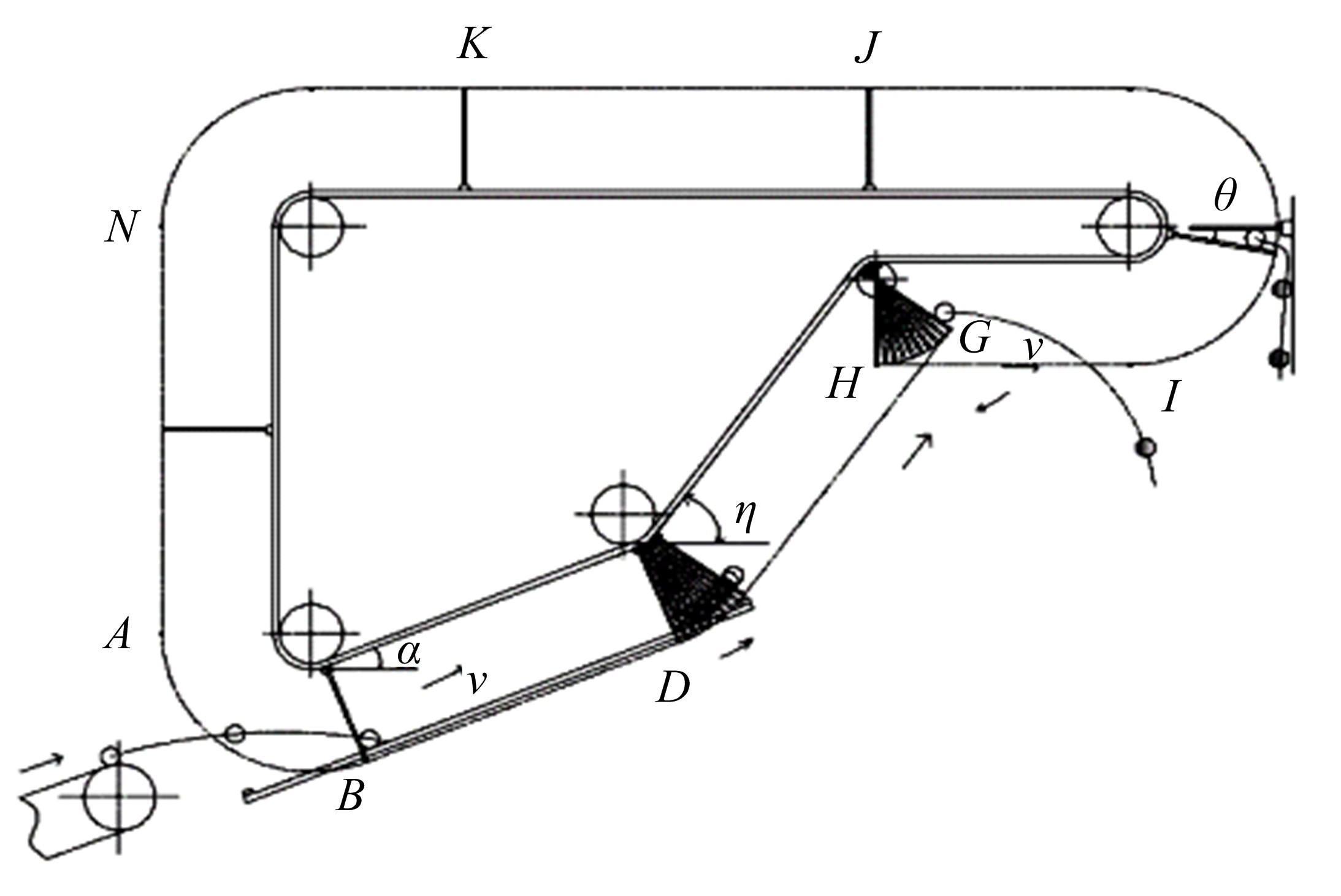

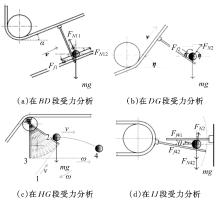

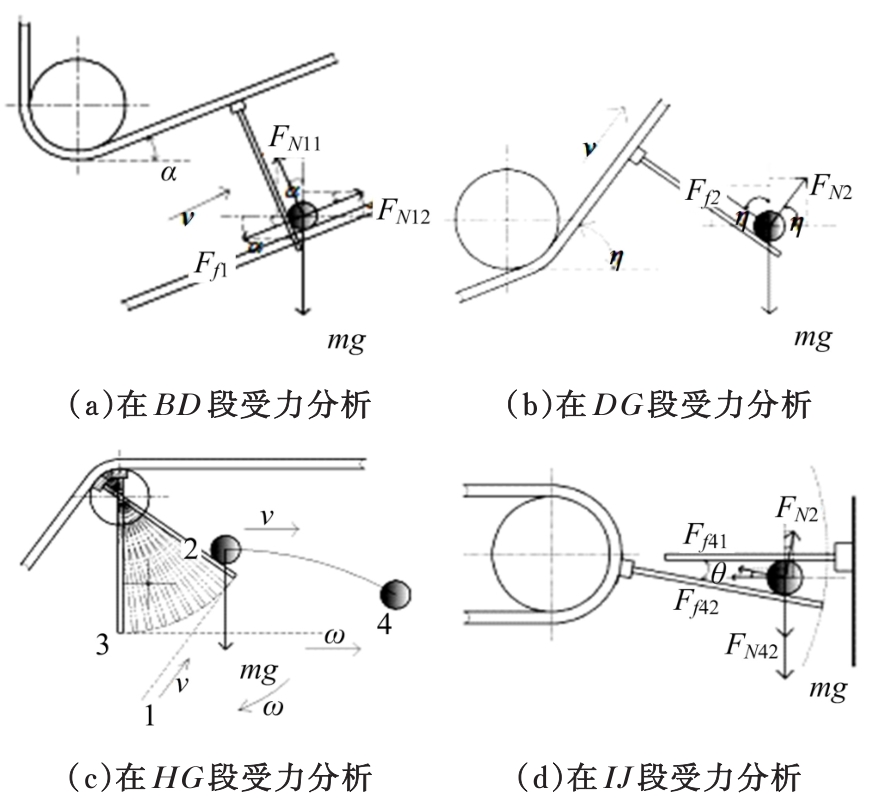

针对残留稻草导致的覆草冬种马铃薯收获机薯土分离效果差、明薯率低等问题,在马铃薯收获机上增设了一套稻草分离机构,通过稻草与分离拨指的运动分析,建立了拨指运动的速度模型,获得拨指拨离稻草速度的最小值为1.99 m/s,通过稻草与拨指在不同运动轨迹处的受力分析,建立了稻草不同分离阶段的状态方程,优化了拨指的运动轨迹。田间试验结果表明:在不清除残草条件下,改制的收获机可实现覆草冬种马铃薯的草、薯、土层次化分离,以及稻草的条铺作业。利用多目标优化设计方法对试验结果进行综合评价表明:当收获机作业速度为0.4 m/s、拨指速度为3 m/s、拨杆数量为6根时,综合作业性能较优,此时明薯率为99.5%,伤薯率为4.2%,薯草分离率为80.4%,均满足冬种马铃薯收获的技术要求。

中图分类号:

- S224.1

| 1 | 黄瑶珠, 高旭华, 陈明周, 等. 广东省冬种马铃薯全生物降解地膜覆盖高产栽培技术规程[J]. 现代农业科技, 2018( 1): 67- 68. |

| Huang Yao-zhu, Gao Xu-hua, Chen Ming-zhou, et al. High yield technical regulation of winter potato covered by truly biodegradable herbicidal mulch filmin in guangdong province[J]. Modern Agricultural Science and Technology, 2018( 1): 67- 68. | |

| 2 | 李柱栋, 王小敏, 欧有量. 马铃薯稻草覆盖免耕栽培技术[J]. 广西农业科学, 2006( 1): 32- 33. |

| Li Zhu-dong, Wang Xiao-min, You-liang Ou, et al. No-tillage cultivation techniques for potato with straw covering[J]. Guangxi Agricultural Sciences, 2006( 1): 32- 33. | |

| 3 | 吕巨智, 姜建初, 裴铁雄, 等. 不同覆盖模式对稻田冬种马铃薯产量和品质的影响[J]. 湖北农业科学, 2010, 49( 3): 539- 541. |

| Lv Ju-zhi, Jiang Jian-chu, Pei Tie-xiong, et al. Effects of different mulch on yield and quality of winter potato in rice paddy[J]. Hubei Agricultural Sciences, 2010, 49( 3): 539- 541. | |

| 4 | 许巧玲, 曹先维, 高雅丽, 等. 覆土厚度对冬种马铃薯还田稻草腐解进程的影响[J]. 安徽农业科学, 2011, 39( 27): 16595- 16597. |

| Xu Qiao-ling, Cao Xian-wei, Gao Ya-li, et al. Effectsof soil-covered depth on decomposition of rice straw in winter potato field[J]. Journal of Anhui Agricultural Sciences, 2011, 39( 27): 16595- 16597. | |

| 5 | 张招娟, 翁定河, 谢向誉, 等. 不同栽培方式冬种马铃薯的生长发育特性及产量品质研究[J]. 农业现代化研究, 2009, 30( 5): 628- 632. |

| Zhang Zhao-juan, Weng Ding-he, Xie Xiang-yu, et al. Characteristics of growth and development and performance of yield and quality for winter-planting potato in different cultivation models[J]. Research of Agricultural Modernization, 2009, 30( 5): 628- 632. | |

| 6 | 翁定河. 马铃薯稻草包芯高产栽培及其生理机制研究[D]. 福建: 福建农林大学农学院, 2011. |

| Weng Ding-he. Study on high yield of potato(solanum tuberosum L) by straw as mulch in a sandwich model and its physiological mechanism[D]. Fujian: College of Agriculture, Fujian Agriculture and Forestry University, 2011. | |

| 7 | 李一聪, 刘晓津, 李康活, 等. 广州地区冬种马铃薯覆盖栽培试验[J]. 广东农业科学, 2006( 10): 15- 16. |

| Li Yi-cong, Liu Xiao-jin, Li Kang-huo, et al. Winter cultivating experiment of potato by covering measures in Guangzhou[J]. Guangdong Agricultural Sciences, 2006( 10): 15- 16. | |

| 8 | 邓其明, 李宇苗. 粤北冬种马铃薯地膜覆盖高产栽培技术[J]. 广东农业科学, 2011, 38( 18): 8- 9. |

| Deng Qi-ming, Li Yu-miao. High yield cultivation techniques of winter potato with plastic film mulchinin Northern Guangdong[J]. Guangdong Agricultural Sciences, 2011, 38( 18): 8- 9. | |

| 9 | 林健康. 新型冬种马铃薯收获机的研制[J]. 农机化研究, 2009, 31( 6): 90- 93. |

| Lin Jian-kang. The development of the potato of harvesting machine[J]. Journal of Agricultural Mechanization Research, 2009, 31( 6): 90- 93. | |

| 10 | 熊平原, 王毅, 林弘觉, 等. 改进型南方马铃薯收获机具的设计[J]. 农机化研究, 2016, 38( 6): 159- 162. |

| Xiong Ping-yuan, Wang Yi, Lin Hong-jue, et al. Improved design of southern potato harvester[J]. Journal of Agricultural Mechanization Research, 2016, 38( 6): 159- 162. | |

| 11 | 中国农业机械化科学研究院编. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007. |

| 12 | 李彦晶, 魏宏安, 孙广辉, 等. 4U-1400FD型马铃薯联合收获机挖掘铲的参数优化[J]. 甘肃农业大学学报, 2011, 46( 5): 132- 136. |

| Li Yan-jing, Wei Hong-an, Sun Guang-hui, et al. Parameters optimization on digging blade of 4U-1400FD potato combine harvester[J]. Journal of Gansu Agricultural University, 2011, 46( 5): 132- 136. | |

| 13 | 杨然兵, 杨红光, 尚书旗, 等. 马铃薯联合收获机立式环形分离输送装置设计与试验[J]. 农业工程学报, 2018, 34( 3): 10- 18. |

| Yang Ran-bing, Yang Hong-guang, Shang Shu-qi, et al. Design and experiment of vertical circular separating and conveying devicefor potato combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34( 3): 10- 18. | |

| 14 | 辛丽丽, 梁继辉, 闻邦椿. 考虑物料结合系数的倾角振动输送机系统动力学分析[J]. 农业机械学报, 2009, 40( 2): 87- 90. |

| Xin Li-li, Liang Ji-hui, Wen Bang-chun. Dynamic analysis of a vibrating conveyer with inclination in consideration of material combination coefficient[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40( 2): 87- 90. | |

| 15 | 徐海玉. 基于草方格铺设机器人草与铁及橡胶摩擦实验的研究[D]. 哈尔滨: 东北林业大学机电工学学院, 2006. |

| Xu Hai-yu. Study of test method to determine straw-iron,straw-rubber friction[D]. Harbin: School of Mechanical and Electrical Engineering, Northeast Forestry University, 2006. | |

| 16 | 吕金庆, 孙贺, 兑瀚, 等. 粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J]. 农业机械学报, 2017, 48( 11): 146- 155. |

| Lu Jin-qing, Sun He, Dui Han, et al. Design and experiment on conveyor separation device of potato digger under heavy soil condition[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48( 11): 146- 155. | |

| 17 | 王俊发, 马浏轩, 邵东伟, 等. 玉米根茬收获机设计与试验[J]. 农业机械学报, 2012, 43( 6): 68- 72. |

| Wang Jun-fa, Ma Liu-xuan, Shao Dong-wei, et al. Design and experiment of maize root stubble harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43( 6): 68- 72. | |

| 18 | NY/T 648—2015. 马铃薯收获机作业质量评价技术规范[S]. |

| 19 | 董宁, 王宇平. 求解约束优化问题的引导多目标差分进化算法[J]. 吉林大学学报: 工学版, 2015, 45( 2): 569- 575. |

| Dong Ning, Wang Yu-ping. Guiding multi-objective differential evolution algorithm for constrained optimization[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45( 2): 569- 575. | |

| 20 | 宋康, 陈潇凯, 林逸. 汽车行驶动力学性能的多目标优化[J]. 吉林大学学报: 工学版, 2015, 45( 2): 352- 357. |

| Song Kang, Chen Xiao-kai, Lin Yi. Multi-objective optimization of vehicle ride dynamic behaviors[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45( 2): 352- 357. | |

| 21 | 贾晶霞, 张东兴. 马铃薯收获机摆动筛与块茎运动仿真分析[J]. 中国农业大学学报, 2006, 11( 3): 79- 82. |

| Jia Jing-xia, Zhang Dong-xing. Moving simulation analysis on swing sieve of potato harvester[J]. Journal of China Agricultural University, 2006, 11( 3): 79- 82. | |

| 22 | 顾丽霞. 4SW-170型马铃薯挖掘机摆动筛分离过程的仿真研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2012. |

| Gu Li-xia. Simulation on separation process of potato of the separation of 4SW-170 potato digger[D]. Hothot: School of Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, 2012. | |

| 23 | 贺仲熊. 模糊数学及其应用[M]. 天津: 天津科学技术出版社, 1983. |

| 24 | 辛有华, 陈举华, 王寿佑. 多目标模糊优化设计[J]. 模糊系统与数学, 1996, 10( 2): 76- 80. |

| Xin You-hua, Chen Ju-hua, Wang Shou-you. The fuzzy optimal design of the multi-objective function[J]. Fuzzy Systems and Mathematics, 1996, 10( 2): 76- 80. |

| [1] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [2] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [3] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [4] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [5] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [6] | 王家序,蒋倩倩,李俊阳,韩彦峰,张雷,唐挺. 双圆弧谐波传动柔轮齿形参数多目标优化设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1194-1202. |

| [7] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [8] | 夏利红, 邓兆祥. 电子机械制动执行器的整体最优匹配设计[J]. 吉林大学学报(工学版), 2018, 48(4): 998-1007. |

| [9] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [10] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [11] | 王登峰, 张帅, 汪勇, 陈辉. 基于疲劳和13°冲击性能的组装式车轮优化设计[J]. 吉林大学学报(工学版), 2018, 48(1): 44-56. |

| [12] | 于繁华, 刘仁云, 张义民, 张晓丽, 孙秋成. 机械零部件动态可靠性稳健优化设计的群智能算法[J]. 吉林大学学报(工学版), 2017, 47(6): 1903-1908. |

| [13] | 周放, 宋传学, 梁天唯, 肖峰. 采用NSGA-II算法的车载复合电源参数匹配[J]. 吉林大学学报(工学版), 2017, 47(5): 1336-1343. |

| [14] | 刘颖, 张凯, 于向军. 基于代理模型的中空轴式大型静压轴承多目标优化[J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

| [15] | 胡侃, 于野, 盈亮, 胡平, 侯文彬. 基于校车侧翻安全性的热冲压立柱结构优化设计[J]. 吉林大学学报(工学版), 2017, 47(3): 884-890. |

|

||