吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 865-873.doi: 10.13229/j.cnki.jdxbgxb.20221060

• 车辆工程·机械工程 • 下一篇

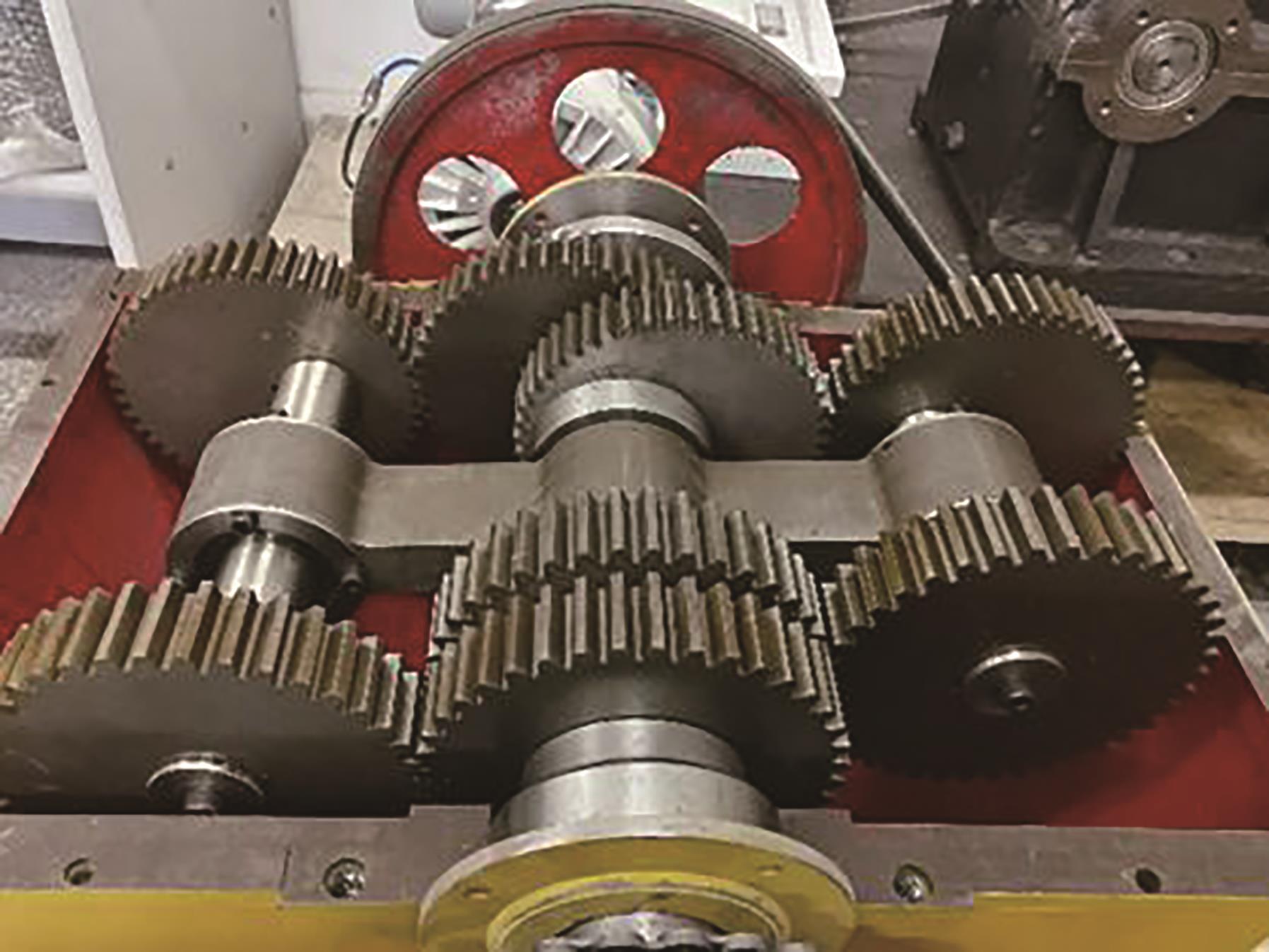

非圆齿轮传动误差及齿侧间隙的数值模拟与试验

- 兰州理工大学 机电工程学院,兰州 730050

Numerical simulation and experiment of non-circular gear transmission error and backlash

Chang-bin DONG( ),Long-kun LI,Yong-ping LIU,Wang-peng PEI

),Long-kun LI,Yong-ping LIU,Wang-peng PEI

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

摘要:

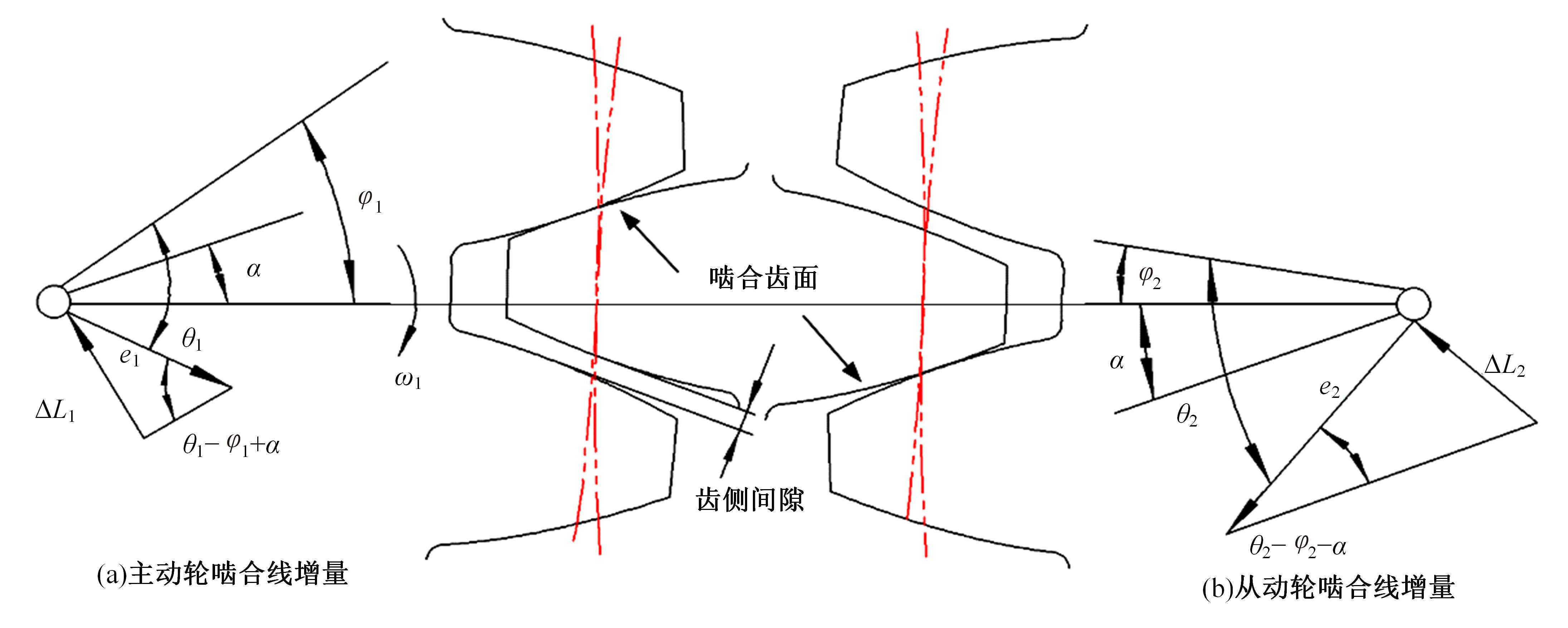

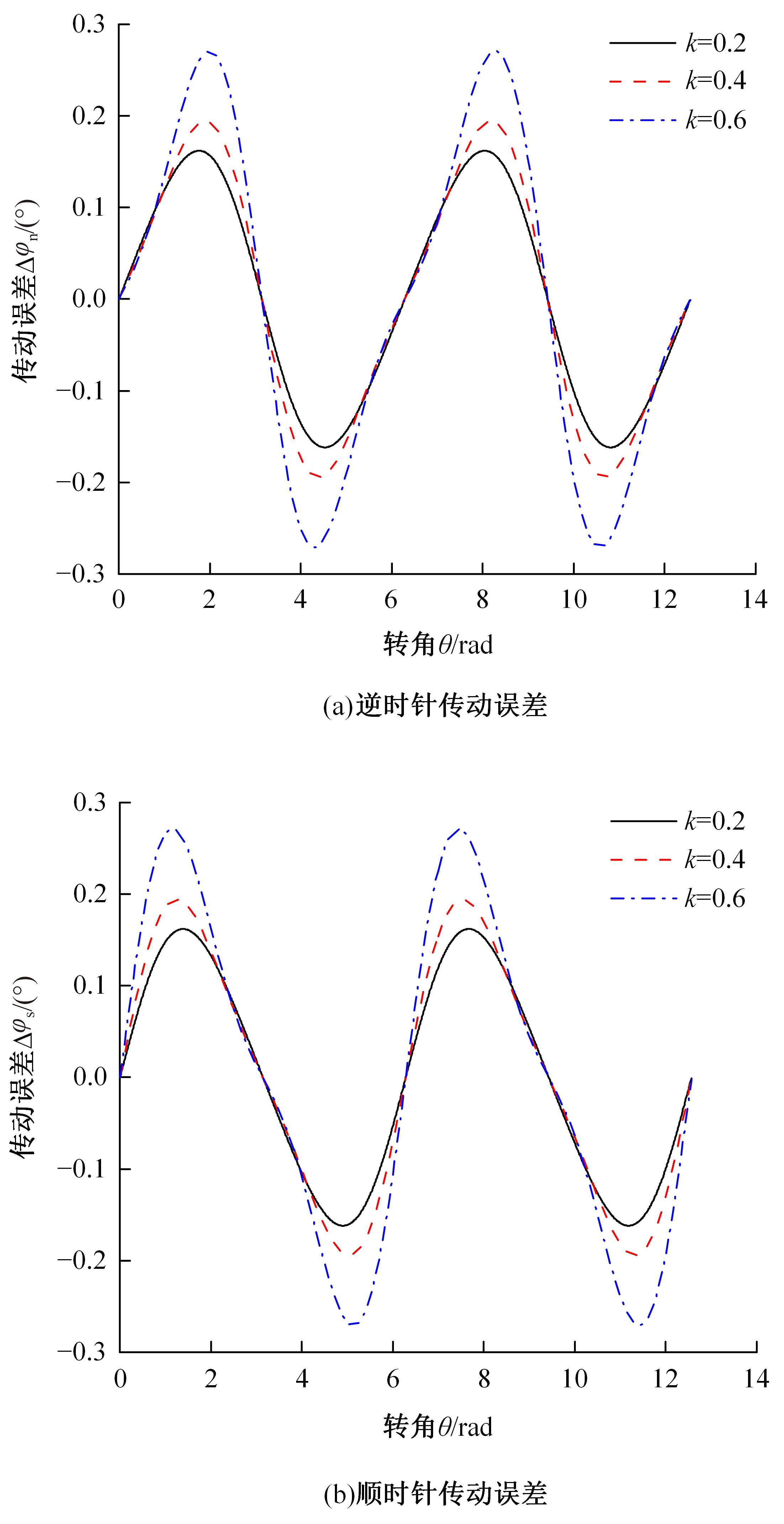

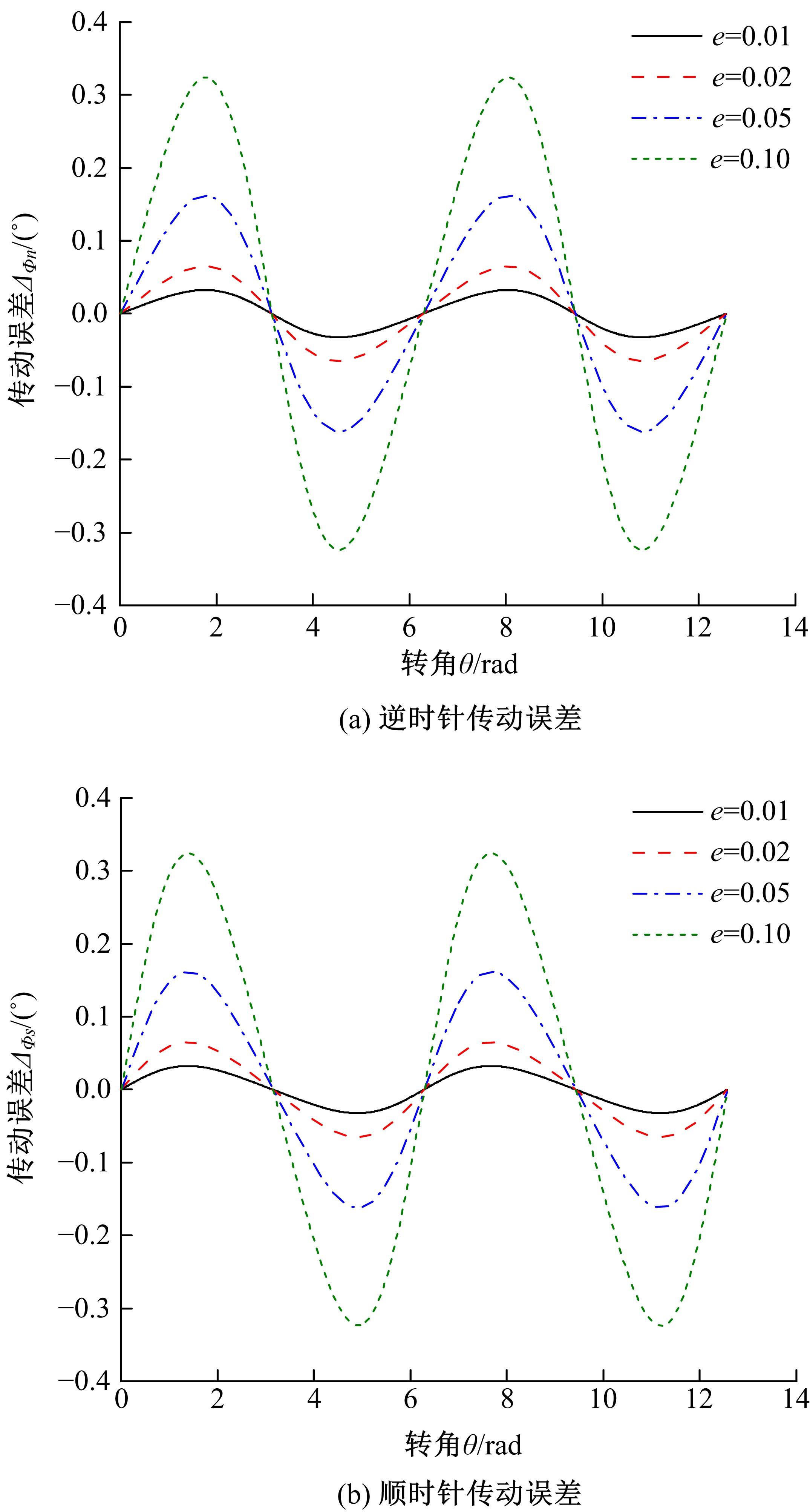

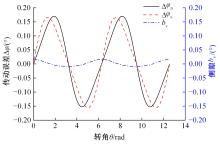

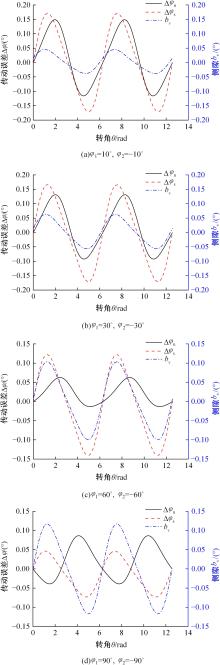

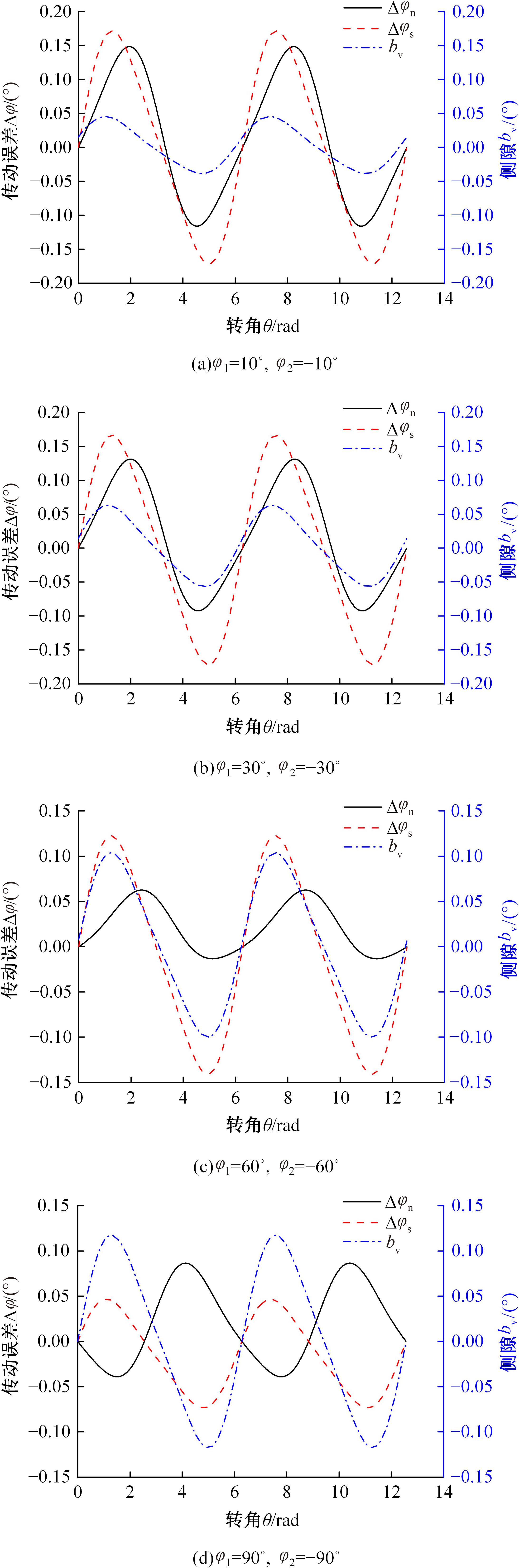

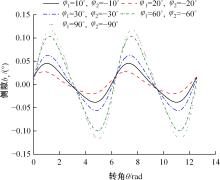

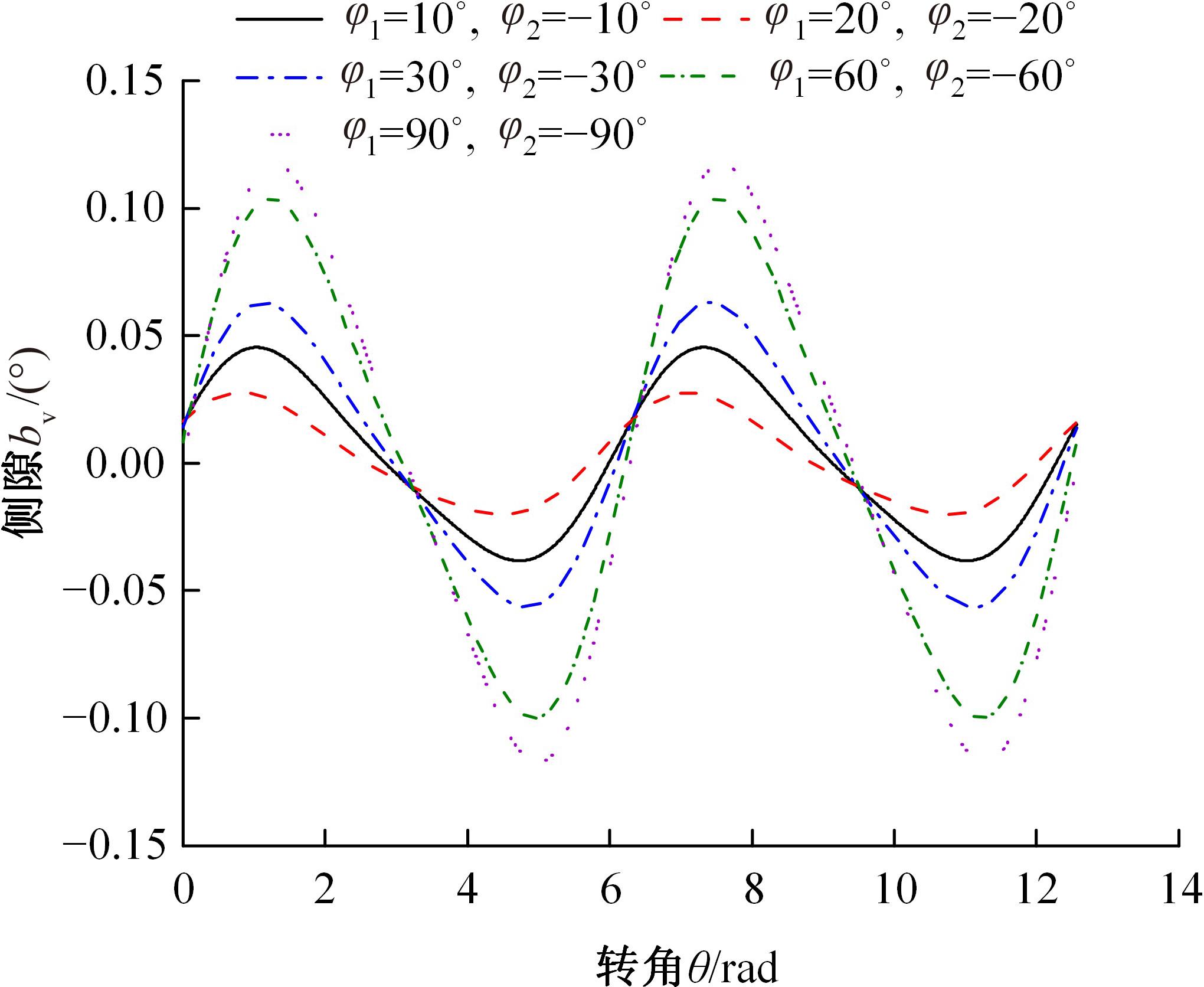

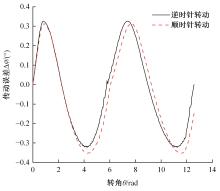

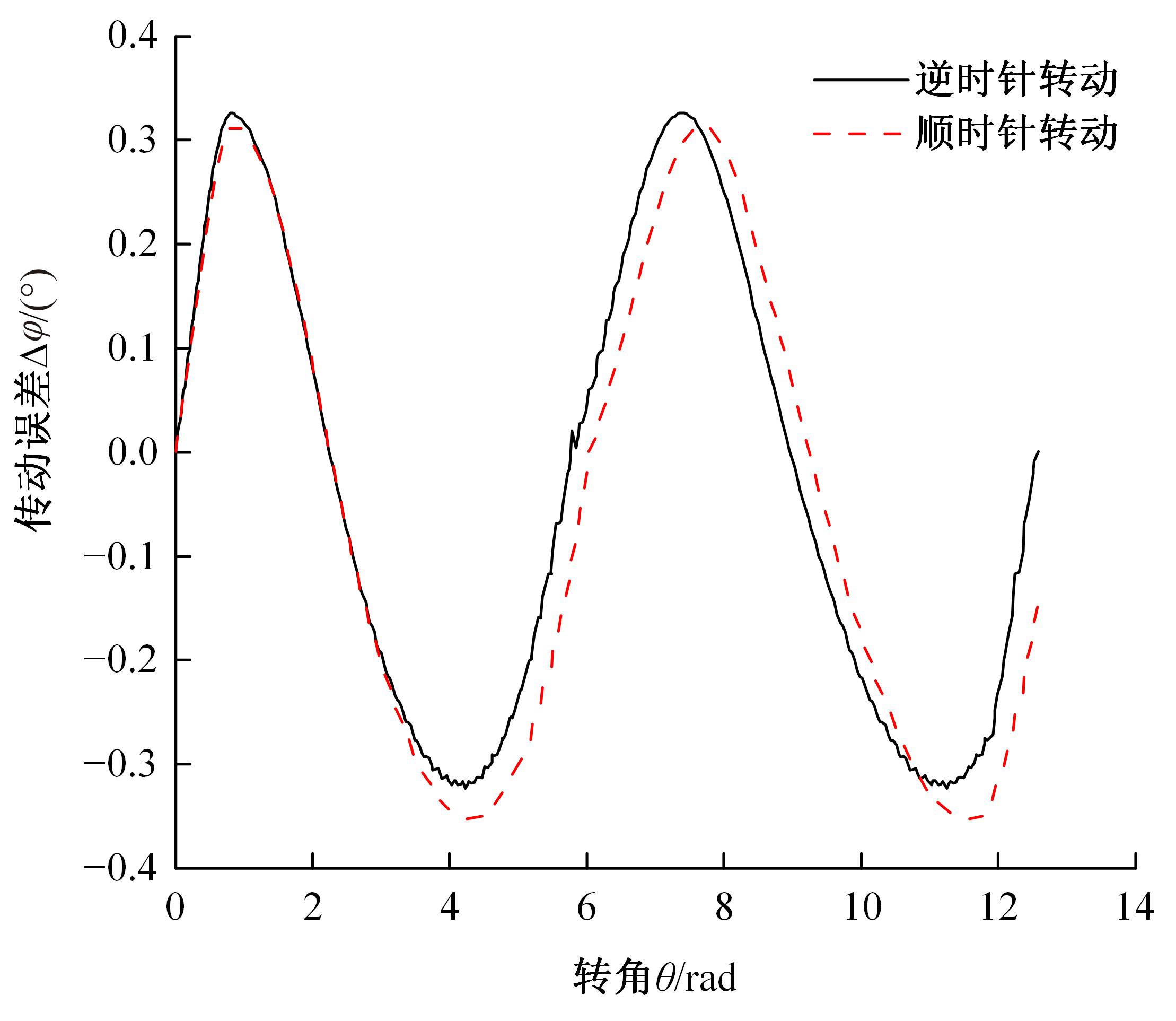

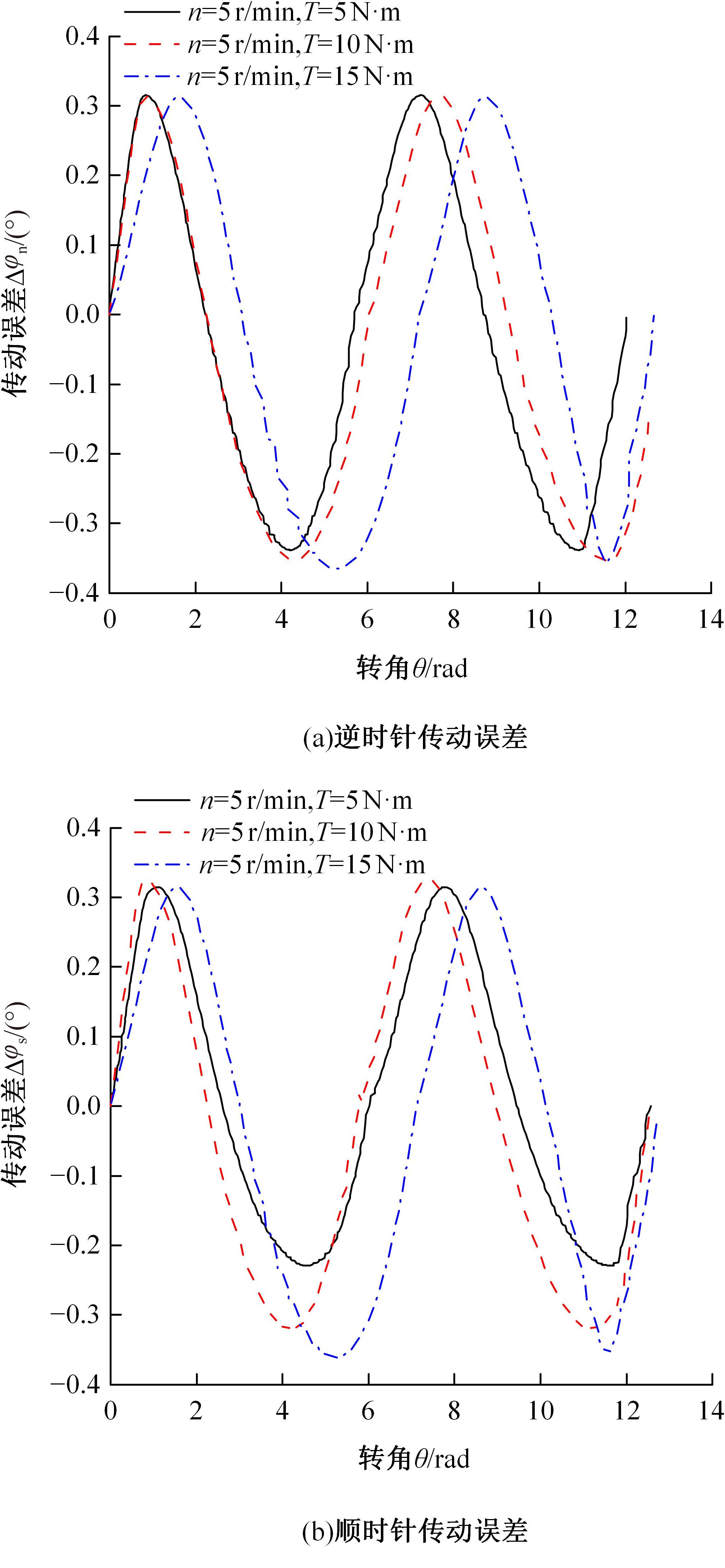

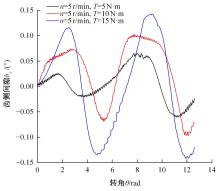

非圆齿轮的传动误差模型建立困难以及齿侧间隙难以获取等问题限制了它在精密场合的应用。为了提高非圆齿轮的传动精度,在考虑偏心误差的基础上,基于啮合线增量法建立了双向传动下的非圆齿轮传动误差模型及齿侧间隙模型,分析了偏心率及偏心误差对双向传动误差和齿侧间隙的影响,并通过传动试验验证了理论分析的正确性。分析表明:非圆齿轮的齿侧间隙可通过双向传动误差获得;随着偏心率和偏心误差的增大,双向传动误差均呈现递增趋势;优化初始相位在一定程度上可以降低传动误差和齿侧间隙;随着负载的增大,传动误差和齿侧间隙也呈现递增趋势,且由于轮齿变形的存在,齿侧间隙有一定累计值产生。

中图分类号:

- TH132.4

| 1 | 董长斌, 刘永平, 魏永峭. 不同载荷条件下椭圆柱齿轮动态接触特性分析[J]. 华中科技大学学报: 自然科学版, 2019, 47(8): 103-107. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao. Dynamic contact characteristics analysis of elliptic cylinder gear under different load conditions[J]. J Huazhong Univ of Sci & Tech(Natural Science Edition) 2019, 47(8): 103-107. | |

| 2 | 董长斌. 椭圆齿轮传动系统的啮合特性研究[D]. 兰州: 兰州理工大学机电工程学院, 2021. |

| Dong Chang-bin. Study on meshing characteristics of elliptic gear transmission system[D]. Lanzhou: School of Mechanical & Electronical Engineering,Lanzhou University of Technology, 2021. | |

| 3 | Kim S C, Moon S G. Macro geometry optimization of a helical gear pair for mass, efficiency, and transmission error[J]. Mechanism and Machine Theory, 2020, 144: No. 103634. |

| 4 | 刘国政, 史文库, 陈志勇. 考虑安装误差的准双曲面齿轮传动误差有限元分析[J]. 吉林大学学报: 工学版, 2018, 48(4): 984-989. |

| Liu Guo-zheng, Shi Wen-ku, Chen Zhi-yong. Finite element analysis of transmission error for hypoid gears considering installation error[J]. Journal of Jilin Univeraity (Engineering and Technology Edition), 2018, 48(4): 984-989. | |

| 5 | Rezaei M, Poursina M, Jazi S H. Multi crack detection in helical gear teeth using transmission error ratio[J]. Journal of Mechanical Science and Technology, 2019, 33(3): 1115-1121. |

| 6 | Hotait M A, Kahraman A. Experiments on the relationship between the dynamic transmission error and the dynamic stress factor of spur gear pairs[J]. Mechanism and Machine Theory, 2013, 70: 116-128. |

| 7 | Liu D W, Ba Y B, Ren T Z. Flow fluctuation abatement of high-order elliptic gear pump by external noncircular gear drive[J]. Mechanism and Machine Theory, 2019, 134: 338-348. |

| 8 | 刘大伟, 任廷志, 巴延博, 等. 基于弹性转角分离的非圆齿轮扭振模型及其动态特性[J]. 振动与冲击, 2016, 35(23): 228-233. |

| Liu Da-wei, Ren Ting-zhi, Ba Yan-bo, et al. Torsional vibration model and its dynamic characteristics for a noncircular gear based on separation of elastic rotating angle[J]. Journal of Vibration and Shock, 2016, 35(23): 228-233. | |

| 9 | Liu D W, Wang G H, Ren T Z. Transmission principle and geometrical model of eccentric face gear[J]. Mechanism and Machine Theory, 2017, 109: 51-64. |

| 10 | David B D, Domenico M. Unloaded transmission error and instantaneous gear ratio for non-circular gears with misalignments[J]. Mechanism and Machine Theory, 2022, 170: No.104728. |

| 11 | Dong C, Liu Y, Wei Y, et al. Analysis on meshing characteristics and transmission error of elliptic gears[J]. Mathematical Problems in Engineering, 2020(1): 1-10. |

| 12 | Margielewicz J, Gąska D, Litak G. Modelling of the gear backlash[J]. Nonlinear Dynamics, 2019, 97(1):355-368. |

| 13 | Wang G, Chen L, Li Y. Research on the dynamic transmission error of a spur gear pair with eccentricities by finite element method[J]. Mechanism and Machine Theory, 2017, 109:1-13. |

| 14 | 邹帅东, 王光建. 双齿轮偏心的传动误差计算与研究[J]. 电子科技大学学报, 2017, 46(6): 955-960. |

| Zou Shuai-dong, Wang Guang-jian. Research on transmission error of dual-eccentric gears[J]. Journal of University of Electronic Science and Technology of China, 2017, 46(6): 955-960. | |

| 15 | 邹帅东, 王光建, 蒋宇将, 等. 交变负载下变齿厚齿轮副侧隙控制试验研究[J]. 机械工程学报, 2020, 56(15): 152-160. |

| Zou Shuai-dong, Wang Guang-jian, Jiang Yu-jiang, et al. Experimental investigation on backlash control of variable tooth thickness gear pair under varying load excitation[J]. Journal of Mechanical Engineering, 2020, 56(15): 152-160. | |

| 16 | Han J, Li D, Tian X, et al. Meshing principle and transmission analysis of a beveloid non-circular gear[J]. Advances in Mechanical Engineering, 2020, 12(11):1-11. |

| [1] | 吴飞,农皓业,马晨浩. 基于粒子群优化算法⁃长短时记忆模型的刀具磨损预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 989-997. |

| [2] | 宋林,王立平,吴军,关立文,刘知贵. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 439-449. |

| [3] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [4] | 段春争,张方圆,寇文能,魏斌. 高速硬切削表面白层马氏体相变[J]. 吉林大学学报(工学版), 2019, 49(5): 1575-1583. |

| [5] | 刘国政, 史文库, 陈志勇. 考虑安装误差的准双曲面齿轮传动误差有限元分析[J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

|

||