吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2859-2869.doi: 10.13229/j.cnki.jdxbgxb.20221520

• 交通运输工程·土木工程 • 上一篇

路基智能压实的地统计分析与空间均匀性评价

- 1.同济大学 道路与交通工程教育部重点实验室,上海 201804

2.同济大学 民航飞行区设施耐久与运行安全重点实验室,上海 201804

Geostatistical analysis and evaluation of subgrade spatial uniformity based on intelligent compaction technology

Jin-song QIAN1,2( ),Yi-cheng YANG1,2,Jian-ming LING1,2

),Yi-cheng YANG1,2,Jian-ming LING1,2

- 1.Key Laboratoty of Road and Traffic Engineering of the Ministry of Education,Tongji University,Shanghai 201804,China

2.Key Laboratoty of Infrastructure Durability and Operation Safety in Airfield of CAAC,Tongji University,Shanghai 201804,China

摘要:

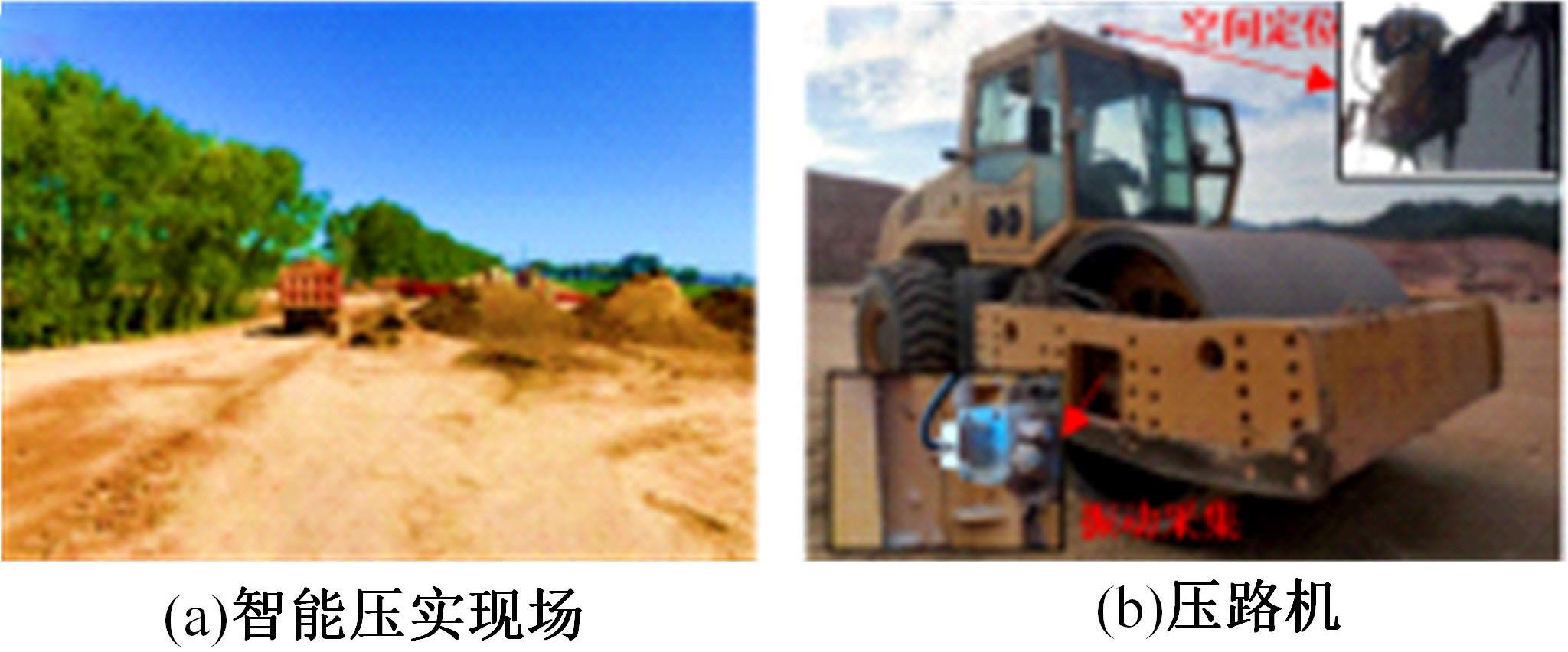

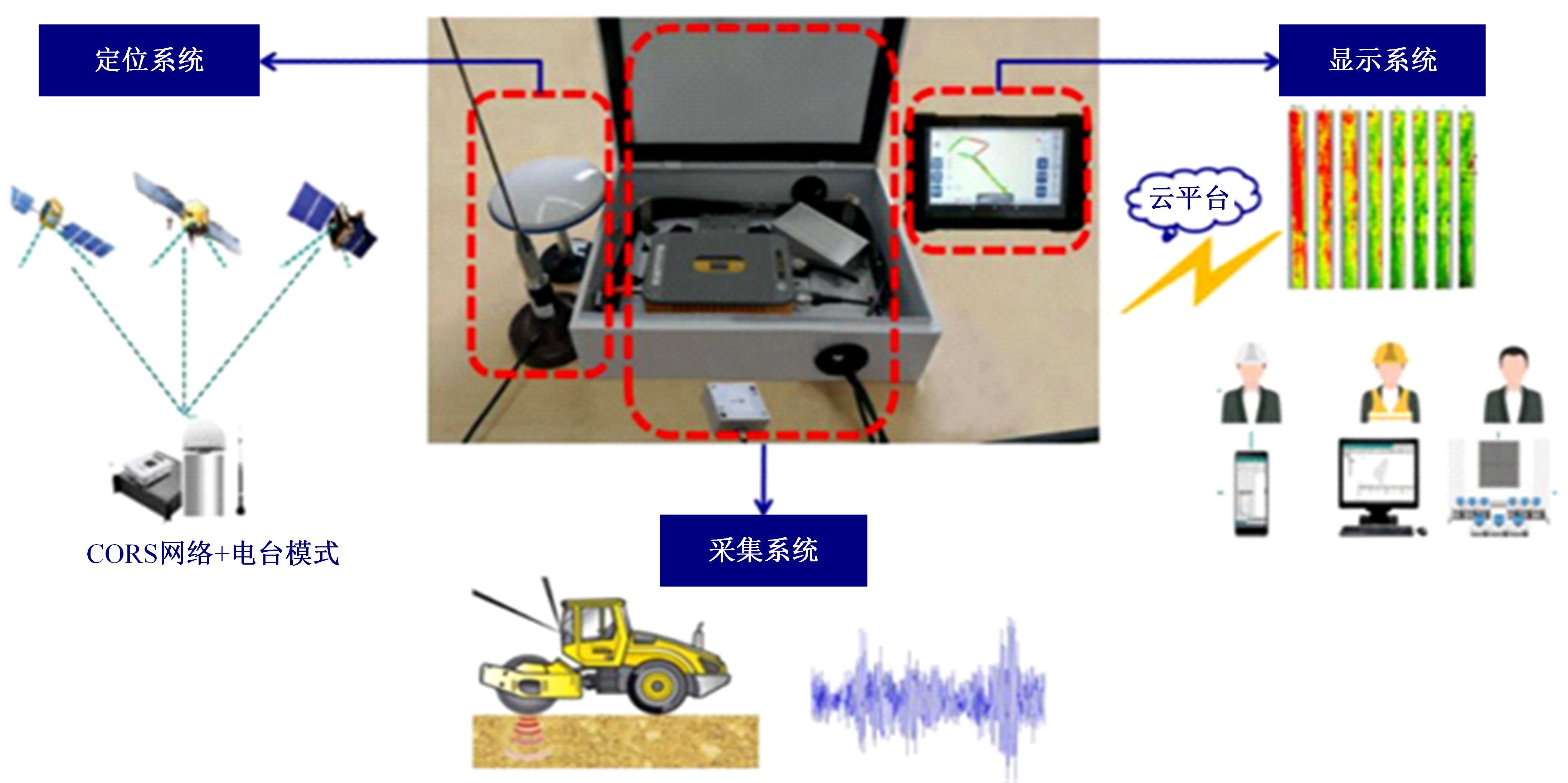

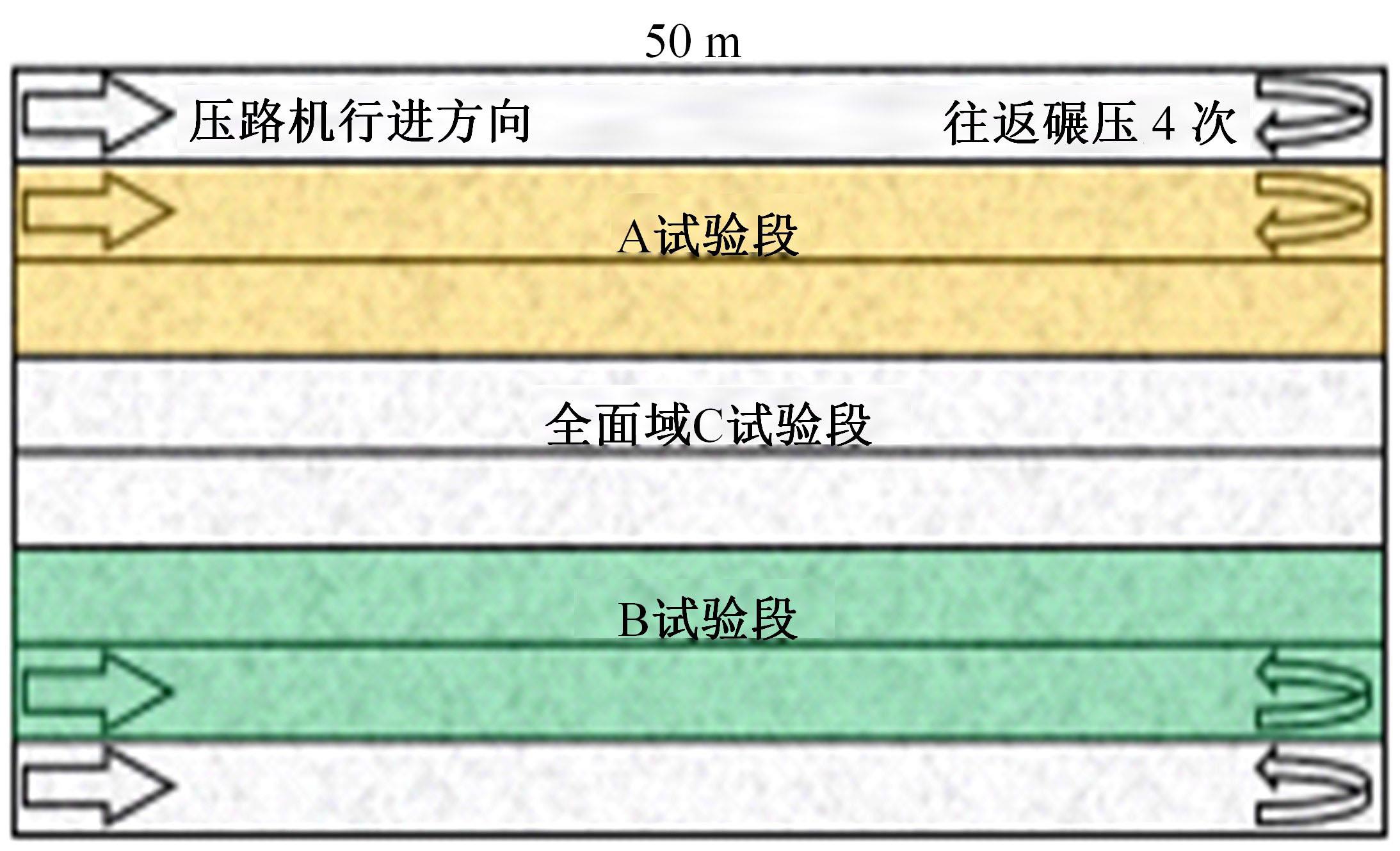

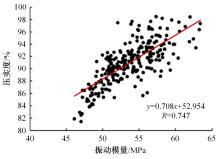

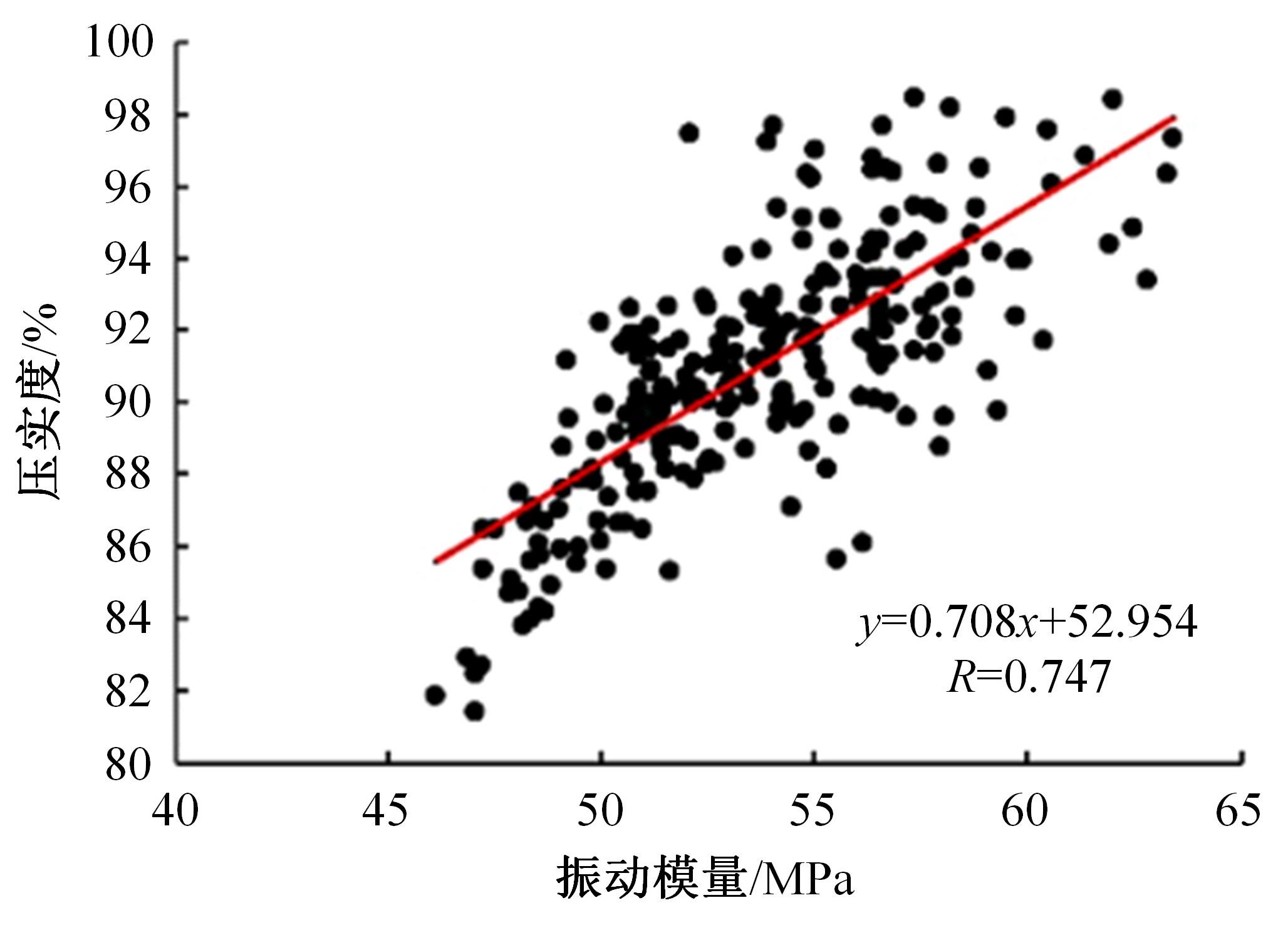

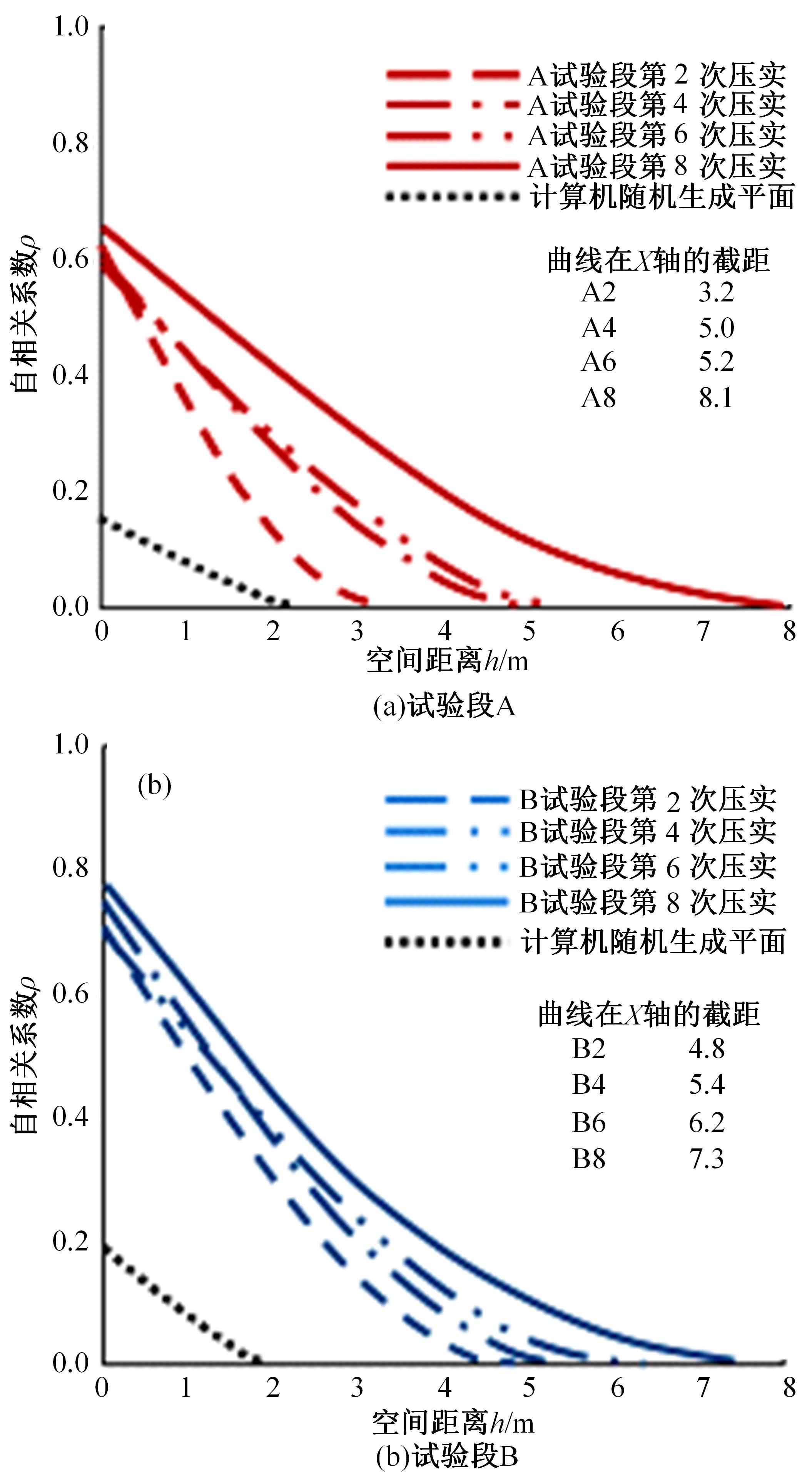

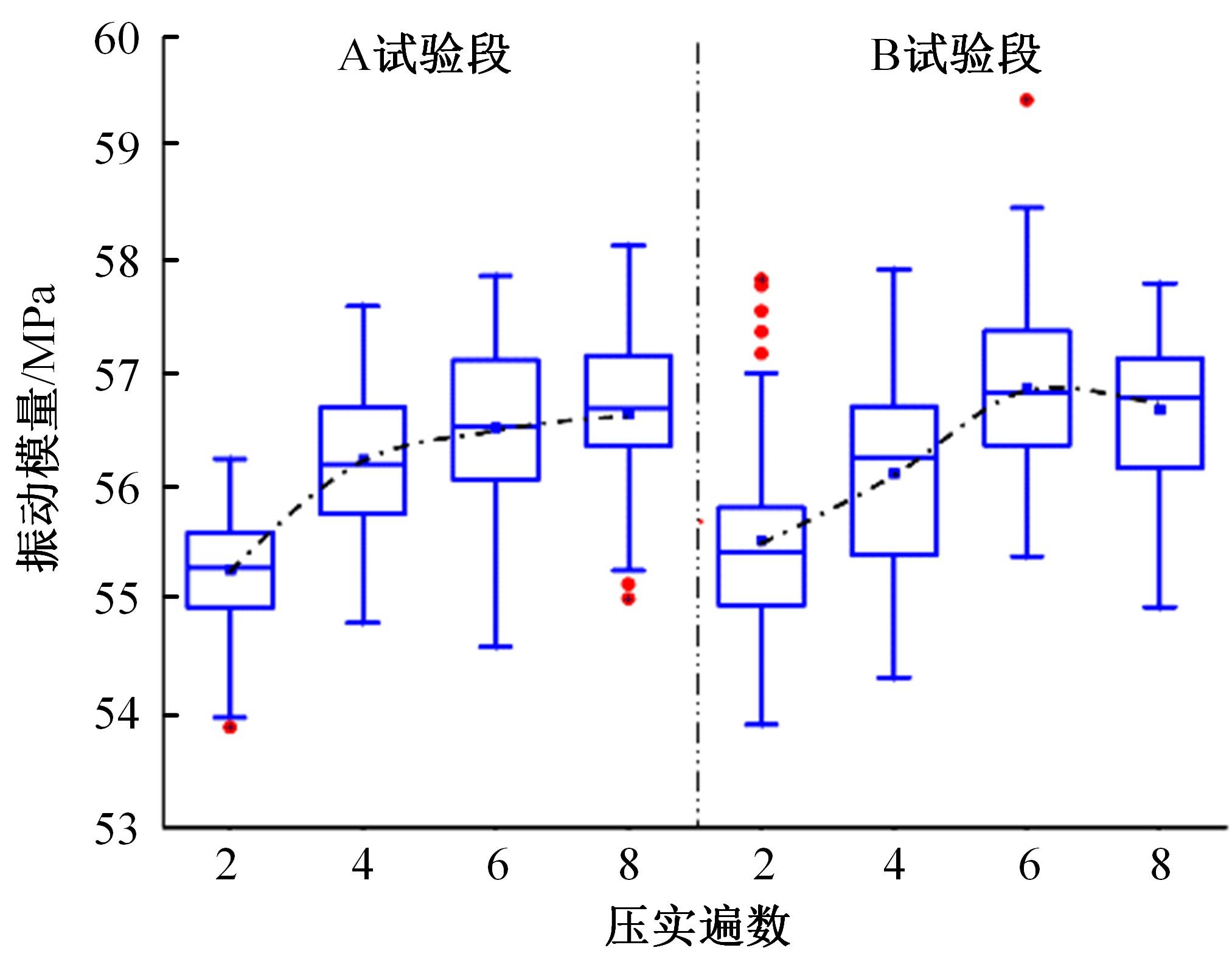

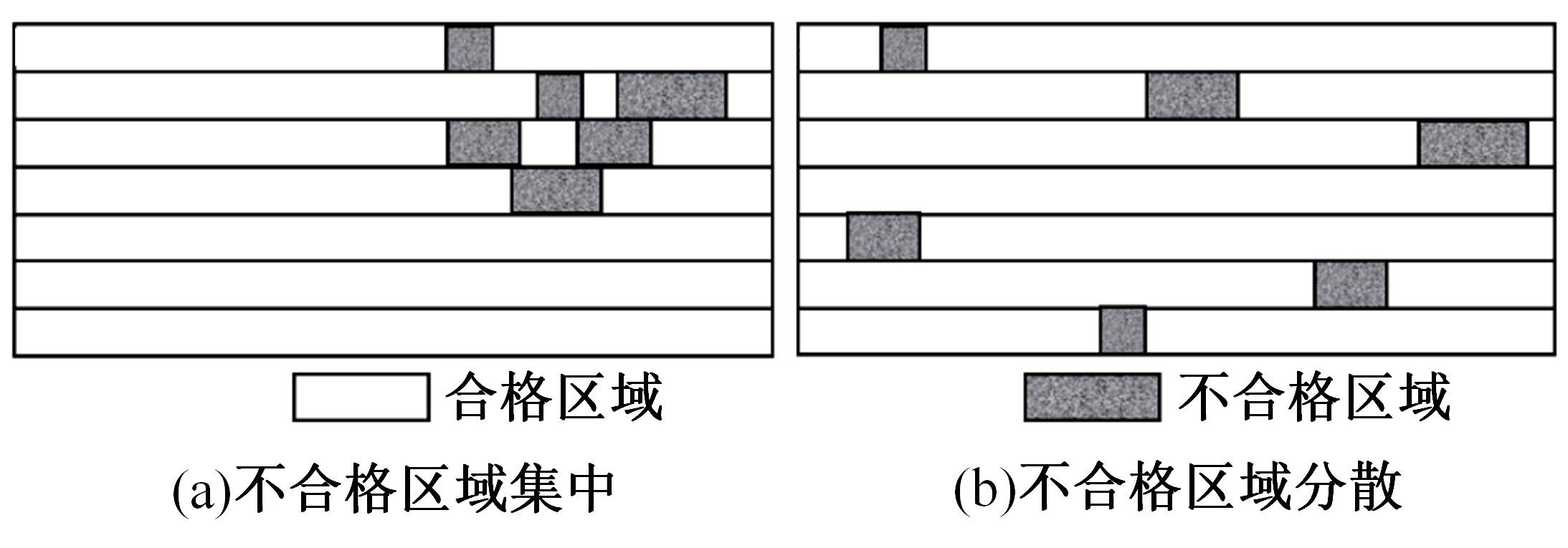

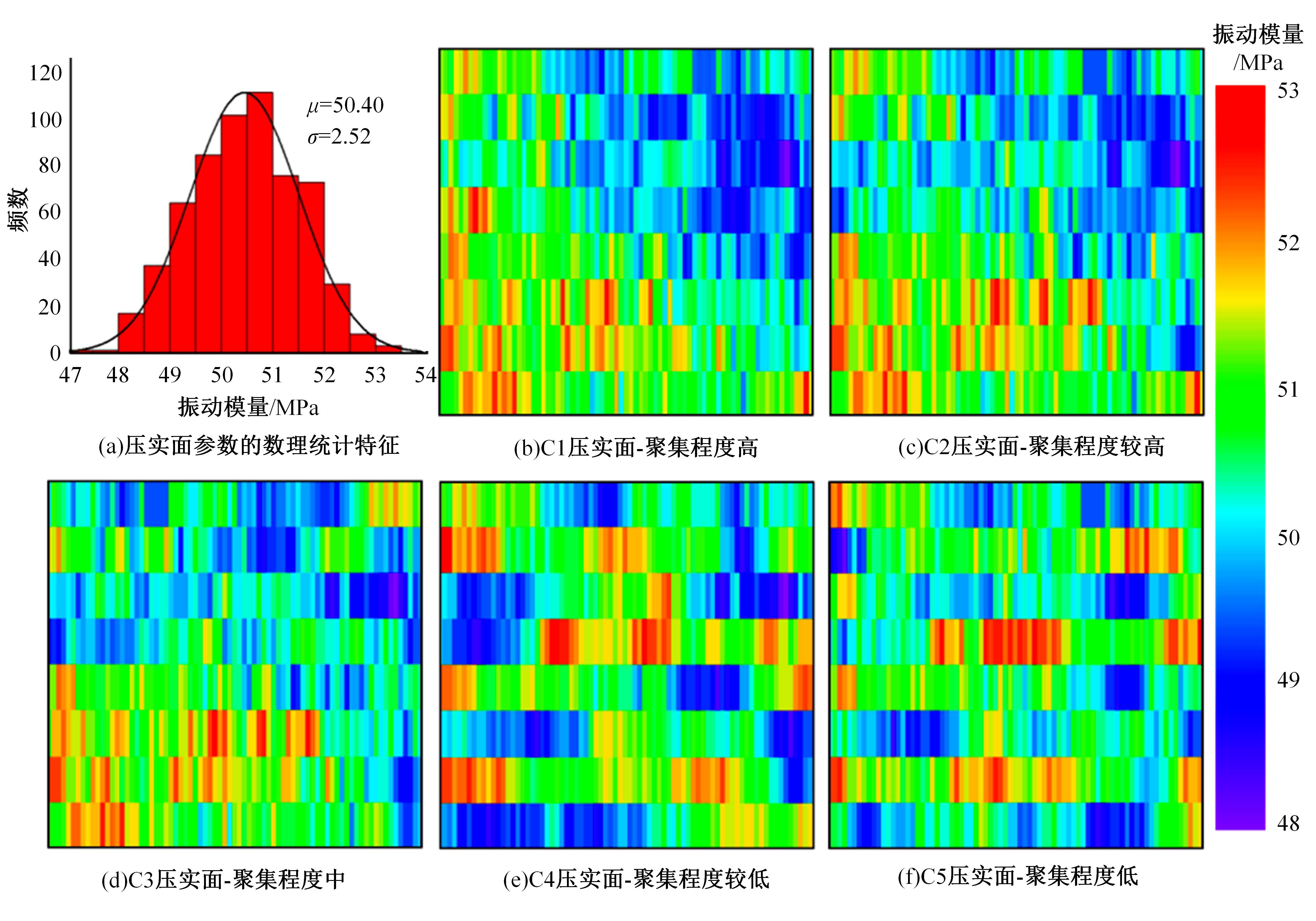

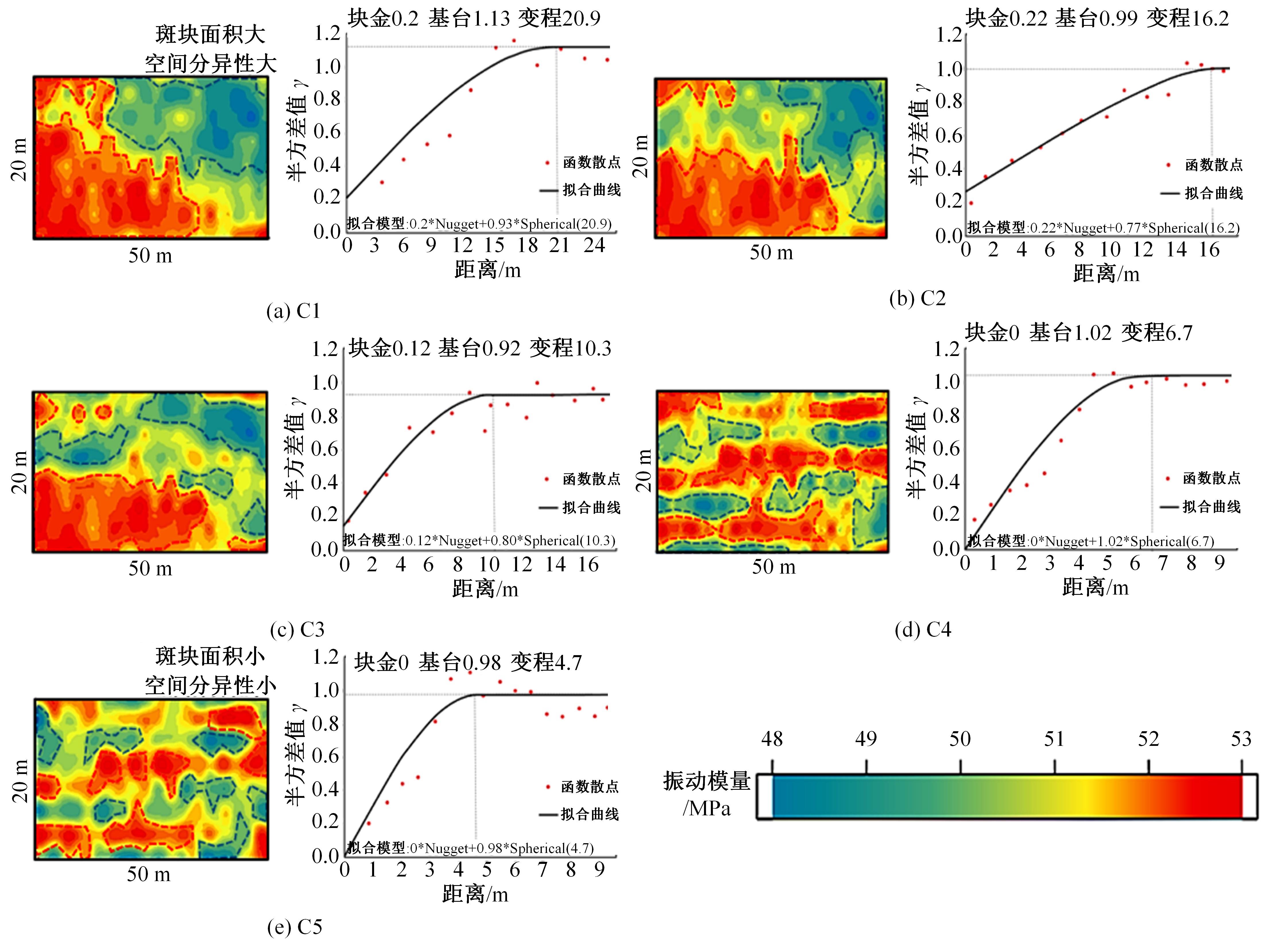

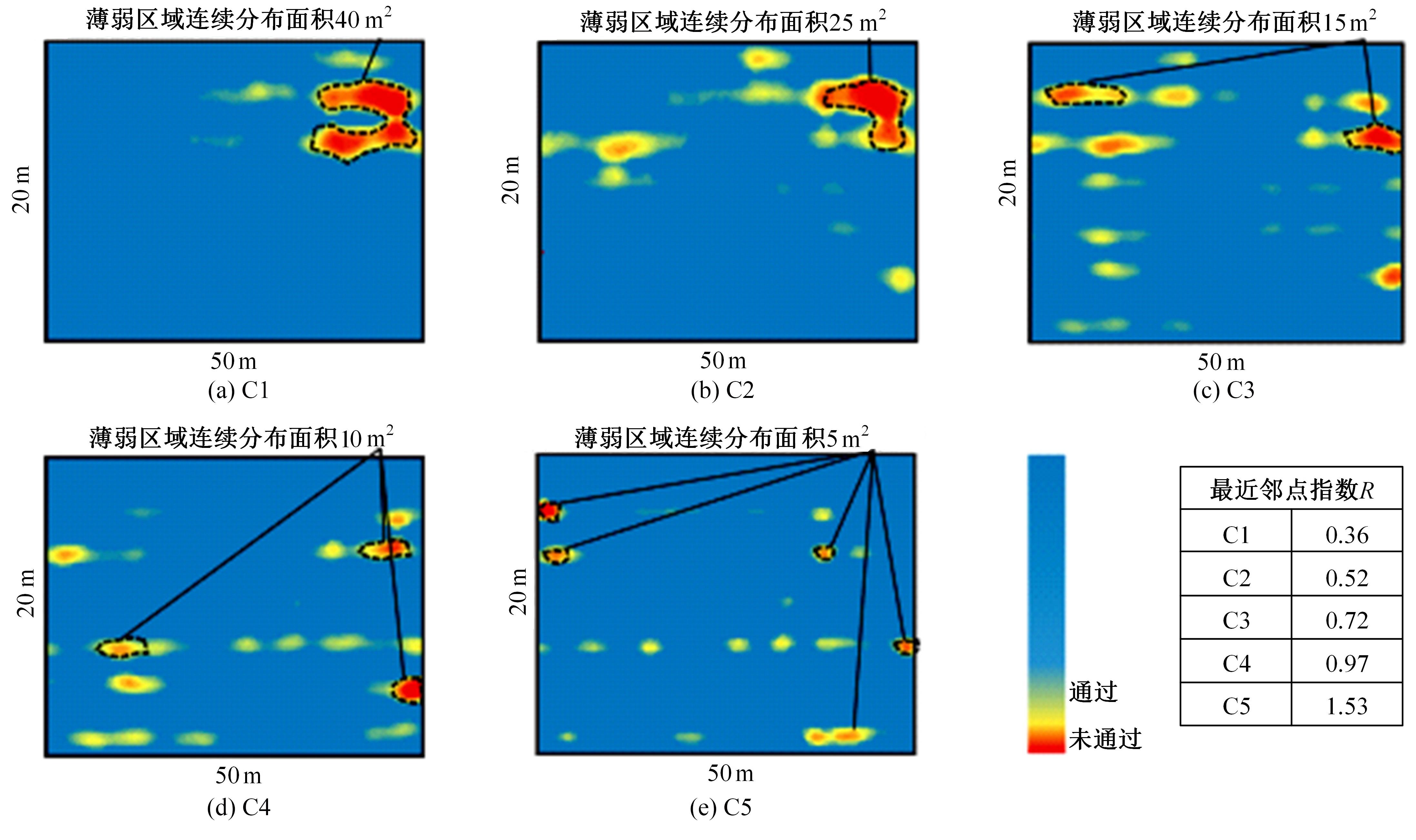

基于数据变异性的传统路基智能压实均匀性评价,难以量化压实数据的空间分布特性和反映路基压实的局部不均匀现象。为解决上述问题,本文在吉林省松原市松通高速进行路基智能压实试验,采集不同压实遍数下压实参数的空间信息,基于地统计学原理建立路基压实面的半方差函数模型,明晰压实参数的概率分布特征和空间自相关性,评价路基的空间分布特性和局部均匀性。结果表明:试验段压实参数振动模量服从正态分布,其空间自相关距离为5~8 m,最大自相关系数为0.6~0.8;地统计参数的块金和变程分别与压实面的空间分异性和斑块分布面积相关;最近邻指数可以量化工程中压实薄弱点的聚集程度,其大于1时薄弱点分散空间均匀性好。

中图分类号:

- U416.1

| 1 | 张家玲. 连续压实无砟轨道路基结构支承刚度均匀性研究[D]. 成都:西南交通大学土木工程学院,2014. |

| Zhang Jia-ling. Study on the uniformity of the bearing rigidity of continuously compacted subgrade structure of ballastless tracks[D]. Chengdu:School of Civil Engineering,Southwest Jiaotong University,2014. | |

| 2 | 《中国公路学报》编辑部. 中国路面工程学术研究综述 2020[J]. 中国公路学报, 2020, 33(10): 1-66. |

| Editorial Department of China Journal of Highway and Transport. Review on China's pavement engineering research·2020[J]. China Journal of Highway and Transport, 2020, 33(10): 1-66. | |

| 3 | 中国工程院全球工程前沿项目组. 全球工程前沿:2020[R]. 北京:中国工程院, 2020. |

| The Chinese Academy of Engineering. Report on global engineering frontiers: 2020[R]. Beijing: The Chinese Academy of Engineering,2020. | |

| 4 | White D J, Pavana V, Erol T, et al. Spatial verification of modulus for pavement foundation system[J]. Journal of the Transportation Research Board, 2018, 2672(52): 333-346. |

| 5 | Vennapusa P, White D J, Siekmeier J, et al. Real-time modulus mapping of pavement foundation layers at MnROAD[R]. Minneapolis: Amer Soc Civil Engineers, 2020: 559-571. |

| 6 | Fathi A, Tirado C, Mazari M, et al. Correlating continuous compaction control measurements to in situ modulus-based testing for quality assessment of compacted geomaterials[J]. Information Technology in Geo-Engineering, Springer Series in Geomechanics and Geoengineering, 2020: 585-595. |

| 7 | Xu Q, Chang G K, Gallivan V L. Development of a systematic method for intelligent compaction data analysis and management[J]. Construction and Building Materials,2012,37:470-480. |

| 8 | Zhu X, Bai S, Xue G, et al. Assessment of compaction quality of multi-layer pavement structure based on intelligent compaction technology[J]. Construction & Building Materials, 2018, 161:316-329. |

| 9 | 聂志红, 谢扬, 焦倓. 路基压实质量连续检测参数的空间分布特征分析[J]. 中国铁道科学, 2017, 38(2): 6-10. |

| Nie Zhi-hong, Xie Yang, Jiao Tan. Spatial distribution characteristic analysis of continuous detection parameters of subgrade compaction quality[J]. China Railway Science, 2017, 38(2): 6-10. | |

| 10 | Facas N W, Mooney M A. Characterizing the precision uncertainty in vibratory roller measurement values [J]. Journal of Testing and Evaluation,2012,40(1):43-51. |

| 11 | 徐光辉. 路基系统形成过程动态监控技术[D]. 成都:西南交通大学土木工程学院, 2005. |

| Xu Guang-hui. Technique of dynamic monitor on forming process of subgrade system[D]. Chengdu:School of Civil Engineering,Southwest Jiaotong University,2005. | |

| 12 | 中华人民共和国铁道部. 铁路路基填筑工程连续压实控制技术规程 ()[S]. 北京: 中国铁道出版社,2011. |

| 13 | 田利锋. 路基连续压实质量评价方法研究[D]. 成都:西南交通大学土木工程学院,2015. |

| Tian Lifeng. Study on evaluation method for compaction quality of continuous compaction control of railway subgrade[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University,2015. | |

| 14 | White D J, Vennapusa P R, Gieselman H H. Field assessment and specification review for roller-integrated compaction monitoring technologies[J]. Advances in Civil Engineering, 2011(2): No.783836. |

| 15 | Vennapusa P R, White D J, Morris M D. Geostatistical analysis or spatially referenced roller-integrated compaction measurements[J].Journal of Geotechnical and Geoenvironmental Engineering, 2009, 136(6): 813-822. |

| 16 | 王翔, 焦倓, 聂志红,等. 基于地统计学的路基连续压实均匀性评价[J]. 岩土力学, 2016, 37(12):3545-3552. |

| Wang Xiang, Jiao Tan, Nie Zhi-hong, et al. Evaluation of roller-integrated compaction uniformity based on geostatistics[J]. Rock and Soil Mechanics, 2016, 37(12): 3545-3552. | |

| 17 | 陈春宏, 王翔. 基于半变异函数的路基压实度均匀性评价方法[J]. 公路工程, 2017, 42(3):86-89. |

| Chen Chun-hong, Wang Xiang. Semivariogram-based evaluation of compaction uniformity for railway subgrade construction[J]. Highway Engineering, 2017, 42(3): 86-89. | |

| 18 | Hu W, Jia X, Zhu X, et al. Investigating key factors of intelligent compaction for asphalt paving:comparative case study[J].Construction and Building Materials, 2019,229: No. 116876. |

| 19 | Hu W, Shu X, Jia X, et al. Geostatistical analysis of intelligent compaction measurements for asphalt pavement compaction[J]. Automation in Construction, 2018, 89(3): 162-169. |

| 20 | Xu Q, Chang G K, Gallivan V L. Development of a systematic method for intelligent compaction data analysis and management[J]. Construction and Building Materials, 2012, 37:470-480. |

| 21 | 马源,方周,韩涛,等.路基智能压实关键控制参数动态仿真及演变规律[J]. 中南大学学报:自然科学版,2021,52(7):2246-2257. |

| Ma Yuan, Fang Zhou, Han Tao, et al. Dynamic simulation and evolution of key control parameters for intelligent compaction of subgrade[J]. Journal of Central South University(Science and Technology), 2021,52(7):2246-2257. | |

| 22 | 刘媚. 基于振动反应的路基压实控制原理及指标[D]. 上海:同济大学土木工程学院, 2016. |

| Liu Mei. Subgrade Compaction Control Principle and Index Based on Vibration Response[D].Shanghai: School of Civil Engineering, Tongji University,2016. | |

| 23 | 焦倓,聂志红,王翔.基于连续压实质量检测的压实薄弱区域评价指标研究[J].铁道学报,2015,37(8):66-71. |

| Jiao Tan, Nie Zhi-hong, Wang Xiang.Evaluation of compaction weak areas based on continuous compaction quality detection[J]. Journal of the China Railway Society, 2015,37(8):66-71. | |

| 24 | 曹丽萍,周杰,李涛,等.基于连续压实控制技术的路基压实均匀性评价[J].中南大学学报:自然科学版,2021,52(7):2200-2210. |

| Cao Li-ping, Zhou Jie, Li Tao, et al. Evaluation of subgrade compaction uniformity based on continuous compaction control technology[J]. Journal of Central South University(Science and Technology), 2021,52(7):2200-2210. | |

| 25 | Liu D H, Wang Y, Chen J, et al. Intelligent compaction practice and development: a bibliometric analysis[J]. Engineering Construction & Architectural Management, 2020, 27(5):1213-1232. |

| 26 | Xu Q, Chang G K. Experimental and numerical study of asphalt material geospatial heterogeneity with intelligent compaction technology on roads[J]. Construction & Building Materials, 2014, 72:189-198. |

| 27 | Pyrcz M J, Deutsch C V. The whole story on the hole effect[R]. Alberta: Centre for Computational Geostatistics Department of Civil and Environmental Engineering, University of Alberta Edmonton,2003. |

| 28 | 吴龙梁,江辉煌,唐建伟,等.基于多元回归分析的连续压实监控技术[J].岩土力学,2020,41(6):2081-2090. |

| Wu Long-liang, Jiang Hui-huang, Tang Jian-wei, et al. Continuous compaction monitoring technology based on multiple regression analysis[J]. Rock and Soil Mechanics, 2020,41(6):2081-2090. | |

| 29 | 黄芳. 空间统计学及其在空间模式分析中的应用[D]. 武汉:华中师范大学城市与环境科学学院,2005. |

| Huang Fang. Spatial statistics and its application in the analysis of spatial pattern[D]. Wuhan:College of Urban and Enviornmental Sciences,Central China Normal University,2005. |

| [1] | 李崛,张安顺,张军辉,钱俊峰. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1782-1789. |

| [2] | 文畅平,任睆遐. 基于Lade模型的生物酶改良膨胀土双屈服面本构关系[J]. 吉林大学学报(工学版), 2021, 51(5): 1716-1723. |

| [3] | 张云龙,周刘光,王静,吴春利,吕翔. 冻融对粉砂土力学特性及路堤边坡稳定性的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1531-1538. |

| [4] | 王静,吕翔,曲肖龙,钟春玲,张云龙. 路基土抗剪强度与化学及矿物成分的关系[J]. 吉林大学学报(工学版), 2019, 49(3): 766-772. |

| [5] | 张仰鹏, 魏海斌, 贾江坤, 陈昭. 季冻区组合冷阻层应用表现的数值评价[J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

| [6] | 朱福,佴磊,战高峰,王静. 软土地基路堤临界填筑高度改进计算方法[J]. 吉林大学学报(工学版), 2015, 45(2): 389-393. |

| [7] | 刘寒冰, 李国恒, 谭国金, 孙晏一. 基于时间序列的边坡位移实时预测方法[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 193-197. |

| [8] | 戴文亭,魏海斌,刘寒冰,高一平. 冻融循环下粉质黏土的动力损失模型[J]. 吉林大学学报(工学版), 2007, 37(04): 790-793. |

|

||