吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1162-1168.doi: 10.13229/j.cnki.jdxbgxb20171296

• • 上一篇

碳化作用下水泥浆内亚硝酸根离子的含量分布

- 宁波大学 建筑工程与环境学院, 浙江 宁波315211

Effect of carbonation on nitrite ion distribution in cement paste

Xiao⁃zhen LI( ),Jun⁃zhe LIU(

),Jun⁃zhe LIU( ),Yan⁃hua DAI,Zhi⁃min HE,Ming⁃fang BA,Yu⁃shun LI

),Yan⁃hua DAI,Zhi⁃min HE,Ming⁃fang BA,Yu⁃shun LI

- College of Architectural, Civil Engineering and Environment, Ningbo University, Ningbo 315211, China

摘要:

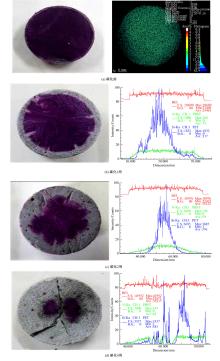

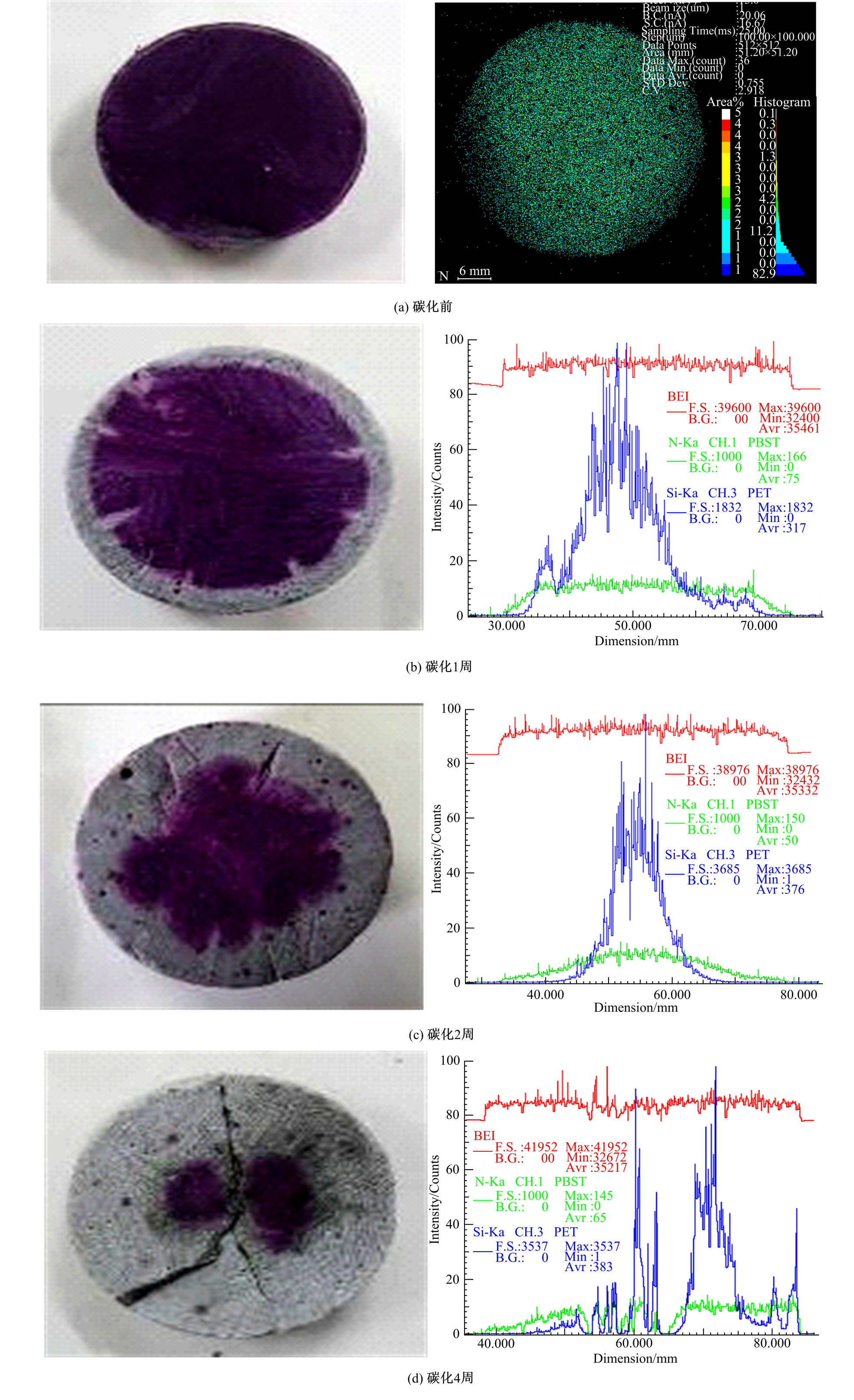

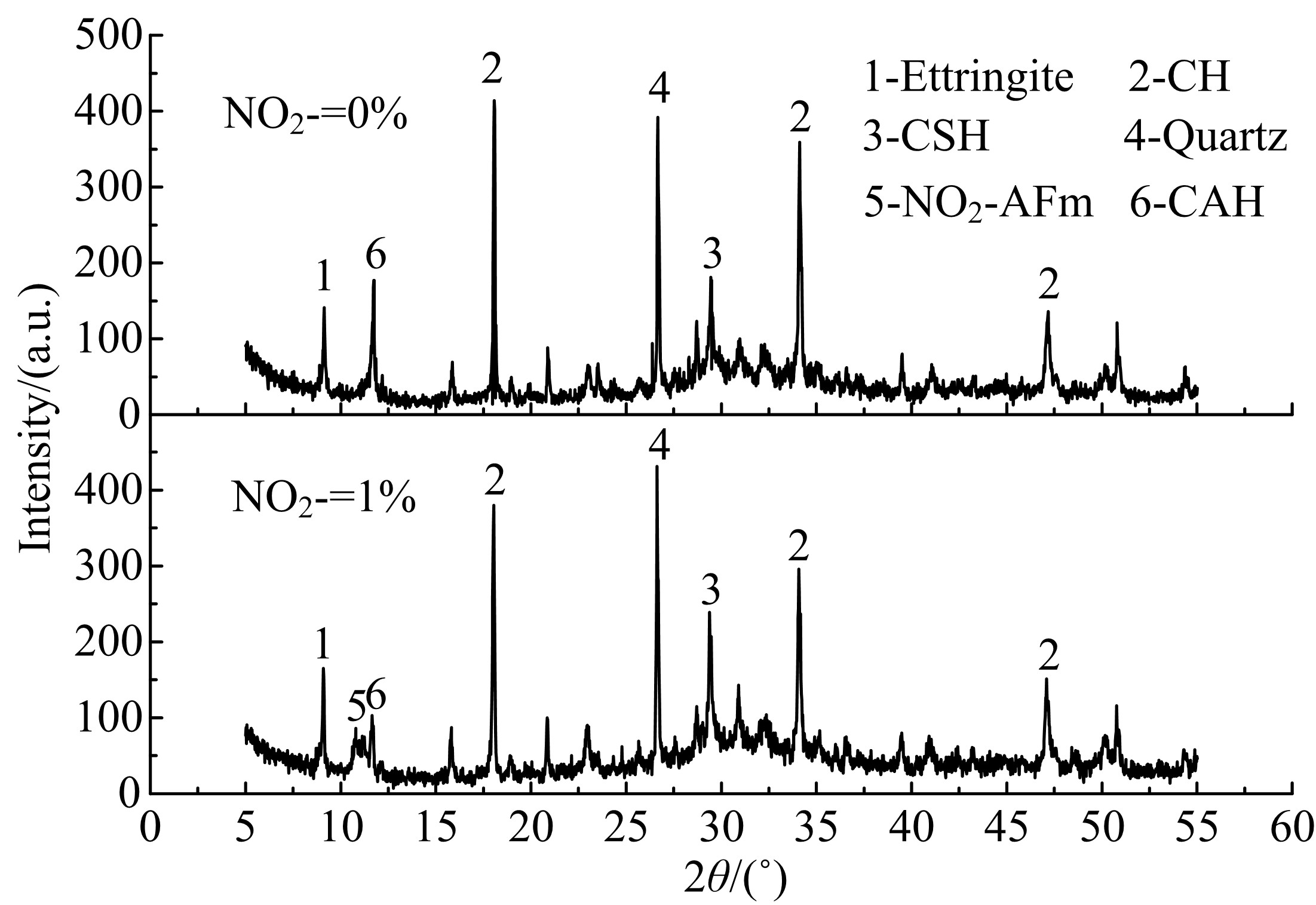

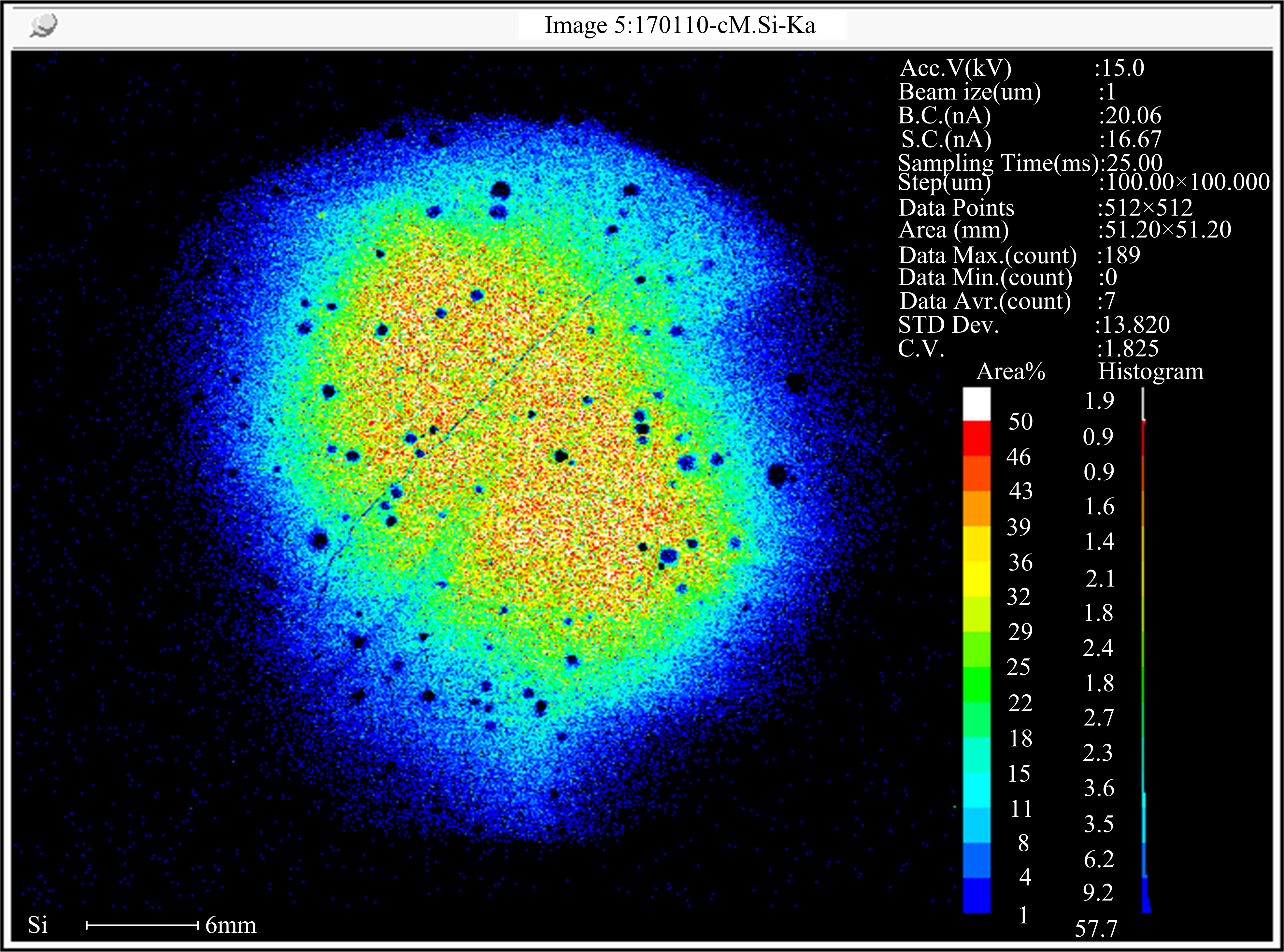

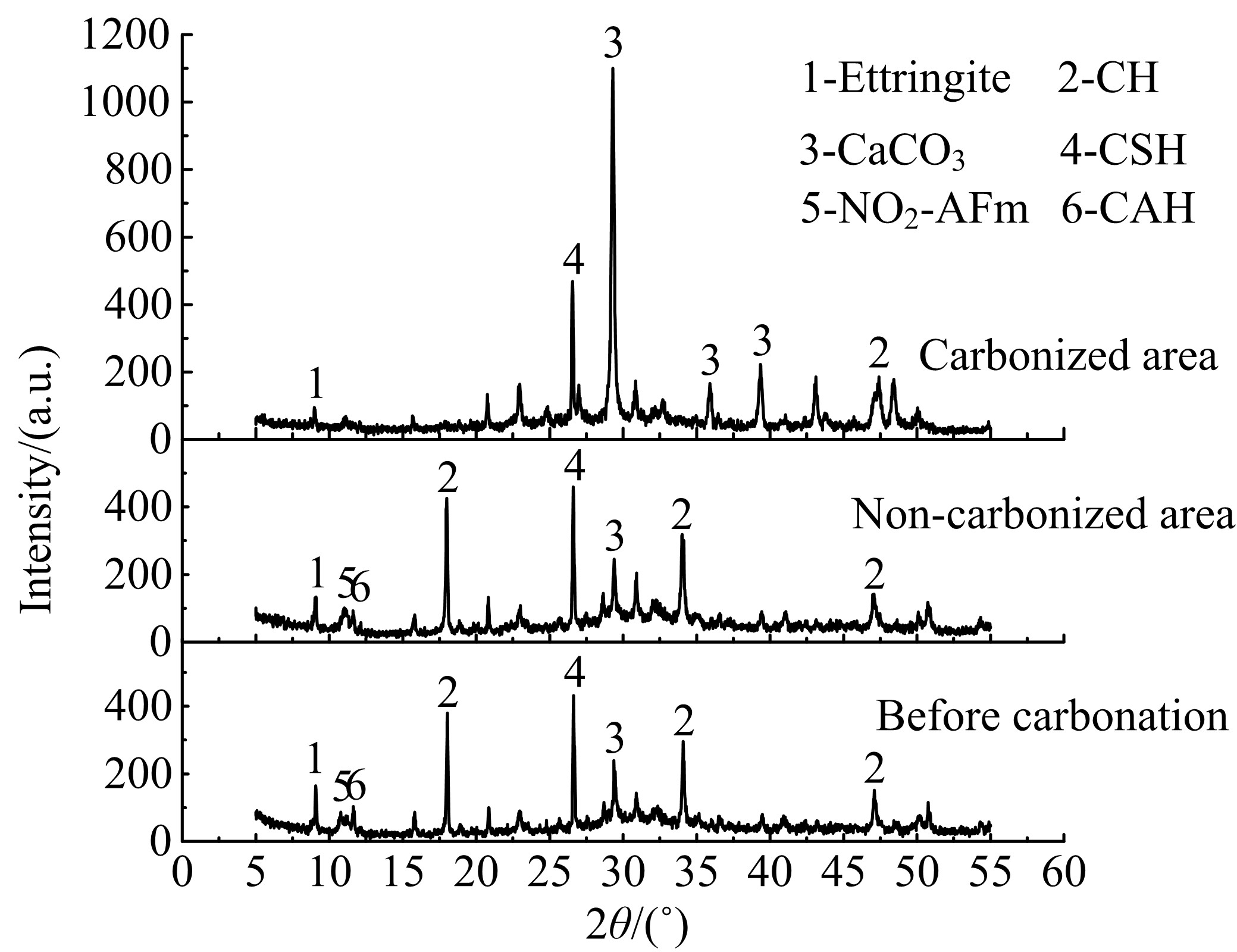

通过电子探针微区分析(EPMA)和X射线衍射分析(XRD)技术探明了碳化对硬化水泥浆内亚硝酸根离子分布的影响,阐明了游离亚硝酸根离子的迁移和吸附规律,有利于精确评价亚硝酸根离子在混凝土中的阻锈作用。结果表明:含亚硝酸盐的水泥浆体水化后生成新的水化产物结晶相NO2?AFm,并均匀分布于水泥浆内。NO2?AFm在碳化过程中重新分解生成亚硝酸根离子并向未碳化区扩散,致使碳化区NO2?含量减少,非碳化区NO2?含量增加。由于碳化过程中C?S?H凝胶分解,吸附于凝胶表面的游离亚硝酸根离子重新转变成游离态,碳化区游离态亚硝酸根离子含量增多,同时硅元素从碳化区向未碳化区迁移,未碳化区C?S?H凝胶非晶态含量增加,提高了游离态亚硝酸根离子的固化率,使碳化区游离态亚硝酸根离子含量高于未碳化区。

中图分类号:

- TQ172

| 1 | Marques P F , Chastre C , Nunes A . Carbonation service life modelling of RC structures for concrete with Portland and blended cements[J]. Cement and Concrete Composites, 2013, 37(6):171⁃184. |

| 2 | Kwon S J , Song H W . Analysis of carbonation behavior in concrete using neural network algorithm and carbonation modeling[J]. Cement and Concrete Research, 2010, 40(1): 119⁃127. |

| 3 | Liu Jun⁃zhe , Ba Ming⁃fang , Du Yin⁃gang , et al . Effects of chloride ions on carbonation rate of hardened cement paste by X⁃ray CT technic[J]. Construction and Building Materials, 2016, 122(7): 619⁃627. |

| 4 | Li Qin⁃fei , Ge Yong , Yang Wen⁃cui . Effect of sodium sulfate and sodium nitrite on air⁃void system in airentrained concrete[J]. Magazine of Concrete Research, 2016, 68(23): 1200⁃1209. |

| 5 | Fayala I , Dhouibi L , Nóvoa X R , et al . Effect of inhibitors on the corrosion of galvanized steel and on mortar properties[J]. Cement Concrete Comp, 2013, 35(1): 181⁃189. |

| 6 | Goulart C M , Esteves-Souza A , Martinez⁃Huitle C A , et al . Experimental and theoretical evaluation of semicarbazones and thiosemicarbazones as organic corrosion inhibitors[J]. Corrosion Science, 2013, 67:281⁃291. |

| 7 | Rakanta E , Zafeiropoulou T , Batis G . Corrosion protection of steel with DMEA⁃based organic inhibitor[J]. Construction and Building Materials, 2013, 44:507⁃513. |

| 8 | Verbruggen H , Terryn H , De Graeve I . Inhibitor evaluation in different simulated concrete pore solution for the protection of steel rebar[J]. Construction and Building Materials, 2016, 124: 887⁃896. |

| 9 | Mu G N , Li X H , Qu Q . Molybdate and tungstate as corrosion inhibitors for cold rolling steel in hydrochloric acid solution[J]. Corrosion Science, 2006, 48(2): 445⁃459. |

| 10 | Sanchez M , Alonso M C . Electrochemical chloride removal in reinforced concrete structures: improvement of effectiveness by simultaneous migration of calcium nitrite[J]. Construction and Building Materials, 2011, 25(2): 873⁃878. |

| 11 | Wong H S , Zhao Y X , Karimi A R , et al . On the penetration of corrosion products from reinforcing steel into concrete due to chloride⁃induced corrosion[J]. Corrosion Science, 2010, 52(7): 2469⁃2480. |

| 12 | Álvarez⁃Bustamante R , Negrón⁃Silva G , Abreu⁃Quijano M . Electrochemical study of 2⁃merca⁃ ptoimidazole as a novel corrosion inhibitor for steels[J]. Electrochimica Acta, 2009, 54(23): 5393⁃5399. |

| 13 | Valcarce M B , Vázquez M . Carbon steel passivity examined in solutions with a low degree of carbonation: the effect of chloride and nitrite ions[J]. Materials Chemistry and Physics, 2009, 115(1): 313⁃321. |

| 14 | El Haleem S M A , El Wanees S A , El Aal E E A , et al . Environmental factors affecting the corrosion behavior of reinforcing steel. IV. variation in the pitting corrosion current in relation to the concentration of the aggressive and the inhibitive anions[J]. Corrosion Science, 2010, 52(5): 1675⁃1683. |

| 15 | Yohai L , Schreiner W , Valcarce M B , et al . Inhibiting steel corrosion in simulated concrete with low phosphate to chloride ratios[J]. Journal of the Electrochemical Society, 2016, 163(13): 729⁃737. |

| 16 | Okeniyi J O , Omotosho O A , Ajayi O O . Effect of potassium⁃chromate and sodium⁃nitrite on concrete steel⁃rebar degradation in sulphate and saline media[J]. Construction and Building Materials, 2014, 50: 448⁃456. |

| 17 | 柳俊哲, 袁伟静, 贺智敏, 等 . 碳化对混凝土碱骨料反应的影响[J]. 吉林大学学报: 工学版, 2015, 45(3): 783⁃787. |

| Liu Jun⁃zhe , Yuan Wei⁃jing , He Zhi⁃min , et al . Influence of carbonation on alkali⁃aggregate reaction in concrete[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(3): 783⁃787. | |

| 18 | Al⁃Mehthel M , Al⁃Dulaijan S , Al⁃Idi S H , et al . Performance of generic and proprietary corrosion inhibitors in chloride⁃contaminated silica fume cement concrete[J]. Construction and Building Materials, 2009, 23(5): 1768⁃1774. |

| 19 | Tommaselli M A G , Mariano N A , Kuri S E . Effectiveness of corrosion inhibitors in saturated calcium hydroxide solutions acidified by acid rain components[J]. Construction and Building Materials, 2009, 23(1): 328⁃333. |

| 20 | Lee H , Ryu H , Park W , et al . Comparative study on corrosion protection of reinforcing steel by using amino alcohol and lithium nitrite inhibitors[J]. Materials, 2015, 8(1): 251⁃269. |

| 21 | Han Jian⁃de , Pan Gang⁃hua , Sun Wei . Investigation on carbonation induced meso⁃defects changes of cement mortar using 3D X⁃Ray computed tomography[J]. Journal of the Chinese Ceramic Society, 2011, 399(10):75⁃79. |

| 22 | Lu S , Landis E N , Keane D T . X⁃ray microtomographic studies of pore structure and permeability in portland cement concrete[J]. Materials and Structures, 2006, 39(6): 611⁃620. |

| 23 | Rougelot T , Burlion N , Bernard D D , et al . About microcracking due to leaching in cementitious composites: X⁃ray microtomography description and numerical approach[J]. Cement and Concrete Research, 2010, 40(2): 271⁃283. |

| 24 | Cao Yan⁃hui , Dong Shi⁃gang . Multifunctional inhibition based on layered double hydroxides to comprehensively control corrosion of carbon steel in concrete[J]. Corrosion Science, 2017, 126(9):166⁃179. |

| [1] | 于天来,李海生,黄巍,王思佳. 预应力钢丝绳加固钢筋混凝土梁桥抗剪性能[J]. 吉林大学学报(工学版), 2019, 49(4): 1134-1143. |

| [2] | 黄晓明,曹青青,刘修宇,陈嘉颖,周兴林. 基于路表分形摩擦理论的整车雨天制动性能模拟[J]. 吉林大学学报(工学版), 2019, 49(3): 757-765. |

| [3] | 王静,吕翔,曲肖龙,钟春玲,张云龙. 路基土抗剪强度与化学及矿物成分的关系[J]. 吉林大学学报(工学版), 2019, 49(3): 766-772. |

| [4] | 李伊,刘黎萍,孙立军. 沥青面层不同深度车辙等效温度预估模型[J]. 吉林大学学报(工学版), 2018, 48(6): 1703-1711. |

| [5] | 臧国帅, 孙立军. 基于惰性弯沉点的刚性下卧层深度设置方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [6] | 念腾飞, 李萍, 林梅. 冻融循环下沥青特征官能团含量与流变参数灰熵分析及微观形貌[J]. 吉林大学学报(工学版), 2018, 48(4): 1045-1054. |

| [7] | 宫亚峰, 申杨凡, 谭国金, 韩春鹏, 何钰龙. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [8] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [9] | 季文玉, 李旺旺, 过民龙, 王珏. 预应力RPC-NC叠合梁挠度试验及计算方法[J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [10] | 张仰鹏, 魏海斌, 贾江坤, 陈昭. 季冻区组合冷阻层应用表现的数值评价[J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

| [11] | 马晔, 尼颖升, 徐栋, 刁波. 基于空间网格模型分析的体外预应力加固[J]. 吉林大学学报(工学版), 2018, 48(1): 137-147. |

| [12] | 罗蓉, 曾哲, 张德润, 冯光乐, 董华均. 基于插板法膜压力模型的沥青混合料水稳定性评价[J]. 吉林大学学报(工学版), 2017, 47(6): 1753-1759. |

| [13] | 尼颖升, 马晔, 徐栋, 李金凯. 波纹钢腹板斜拉桥剪力滞效应空间网格分析方法[J]. 吉林大学学报(工学版), 2017, 47(5): 1453-1464. |

| [14] | 郑传峰, 马壮, 郭学东, 张婷, 吕丹, 秦泳. 矿粉宏细观特征耦合对沥青胶浆低温性能的影响[J]. 吉林大学学报(工学版), 2017, 47(5): 1465-1471. |

| [15] | 于天来, 郑彬双, 李海生, 唐泽睿, 赵云鹏. 钢塑复合筋带挡土墙病害及成因[J]. 吉林大学学报(工学版), 2017, 47(4): 1082-1093. |

|

||