吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (3): 757-765.doi: 10.13229/j.cnki.jdxbgxb20171082

基于路表分形摩擦理论的整车雨天制动性能模拟

- 1. 东南大学 交通学院,南京 210096

2. 武汉科技大学 汽车与交通工程学院,武汉430070

Simulation of vehicle braking performance on rainy daysbased on pavement surface fractal friction theory

Xiao⁃ming HUANG1( ),Qing⁃qing CAO1,Xiu⁃yu LIU1,Jia⁃ying CHEN1,Xing⁃lin ZHOU2

),Qing⁃qing CAO1,Xiu⁃yu LIU1,Jia⁃ying CHEN1,Xing⁃lin ZHOU2

- 1. School of Transportation, Southeast University, Nanjing 210096, China

2. School of Automobile and Traffic Engineering, Wuhan University of Science and Technology, Wuhan 430070, China

摘要:

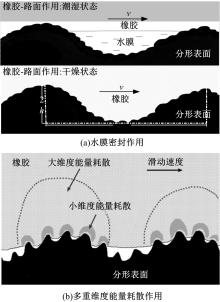

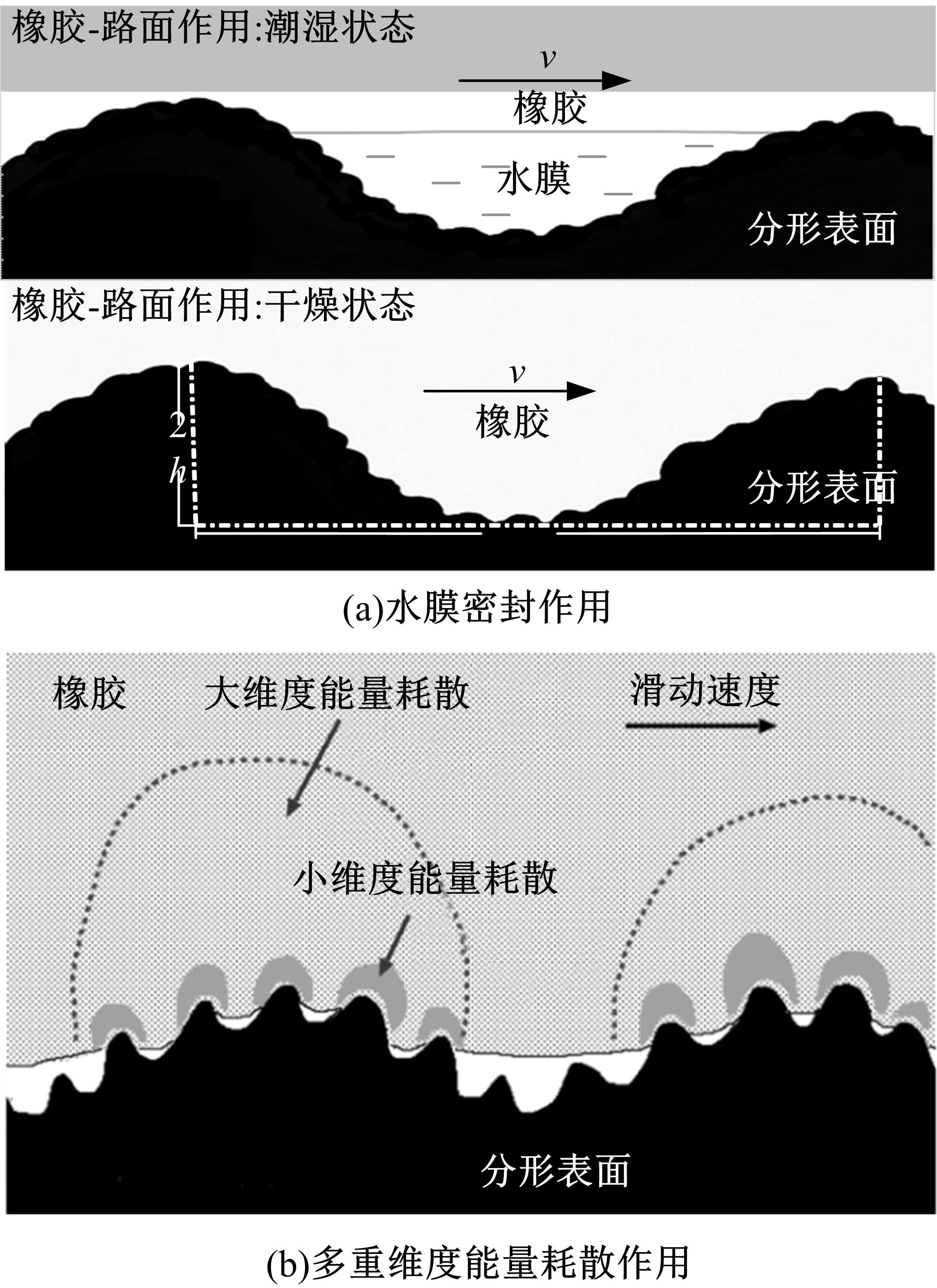

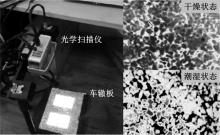

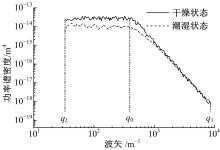

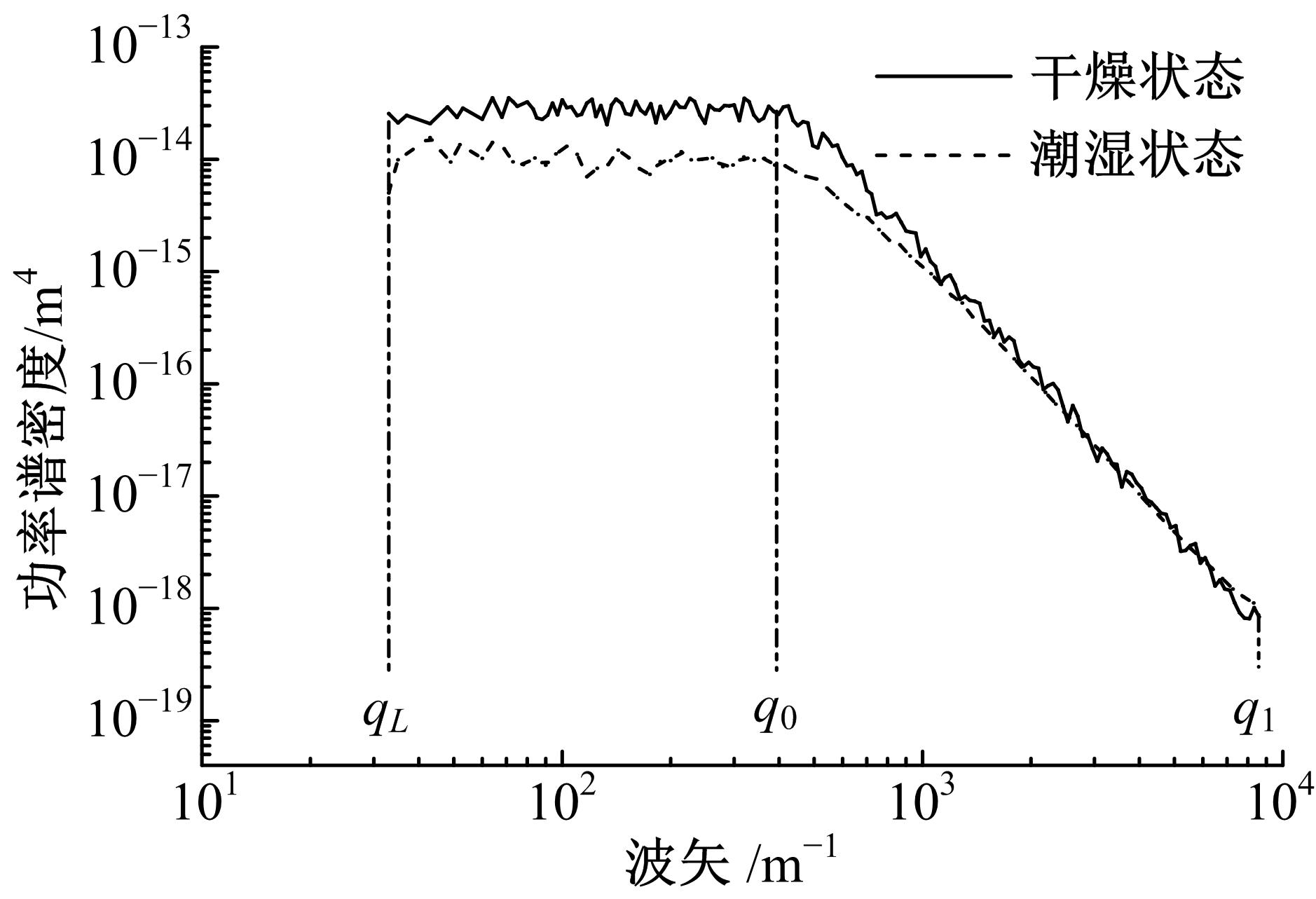

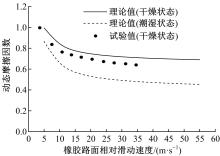

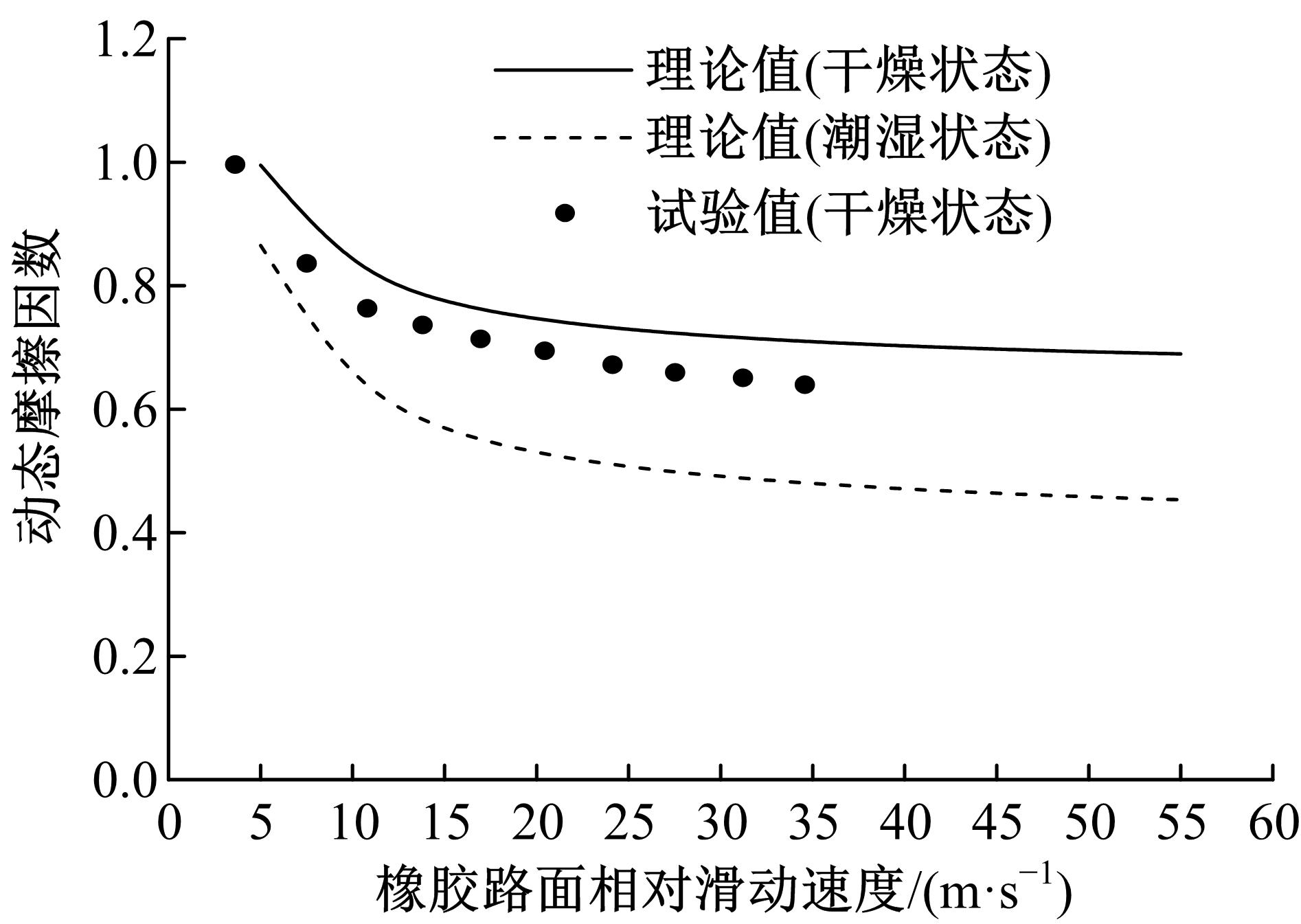

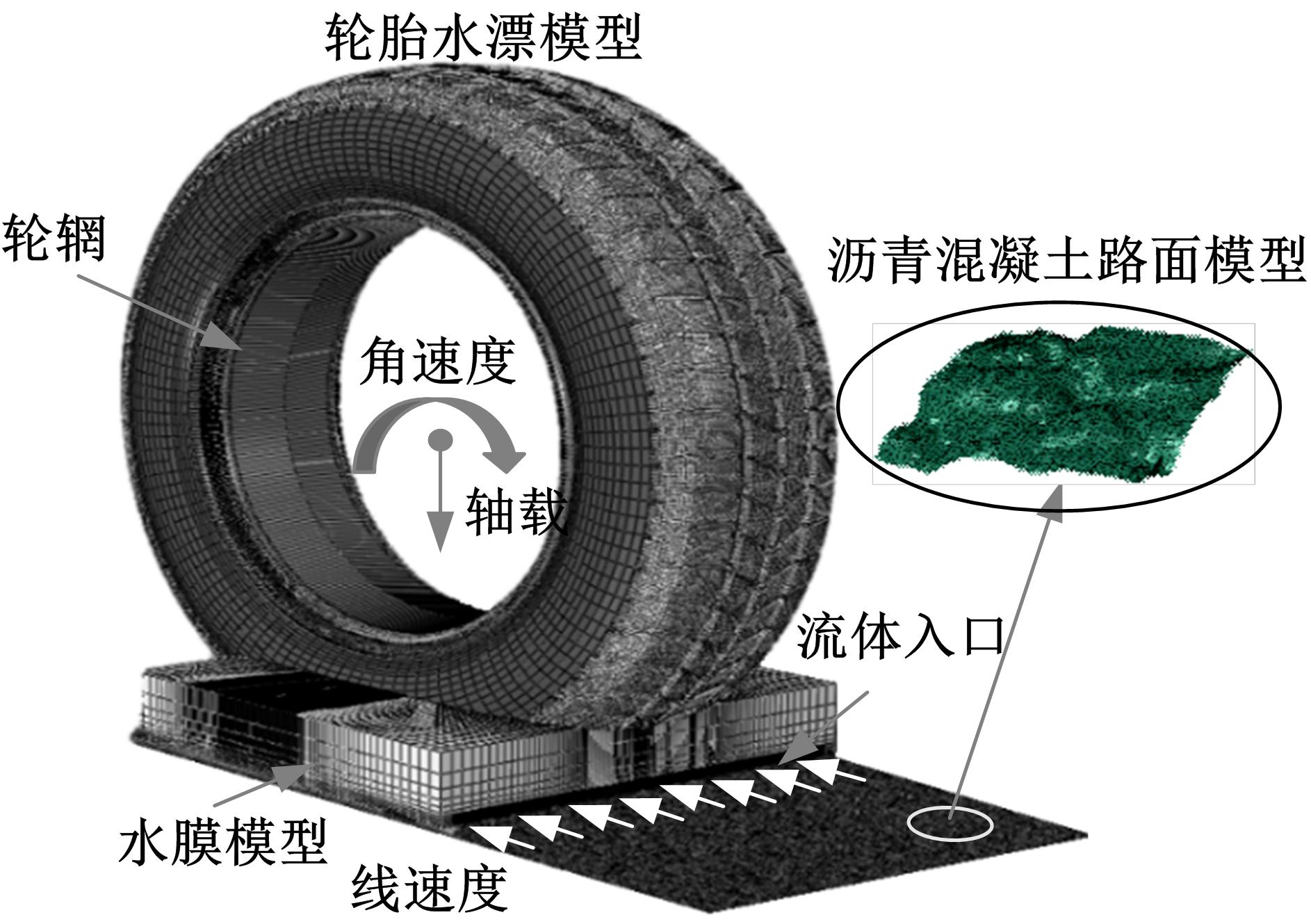

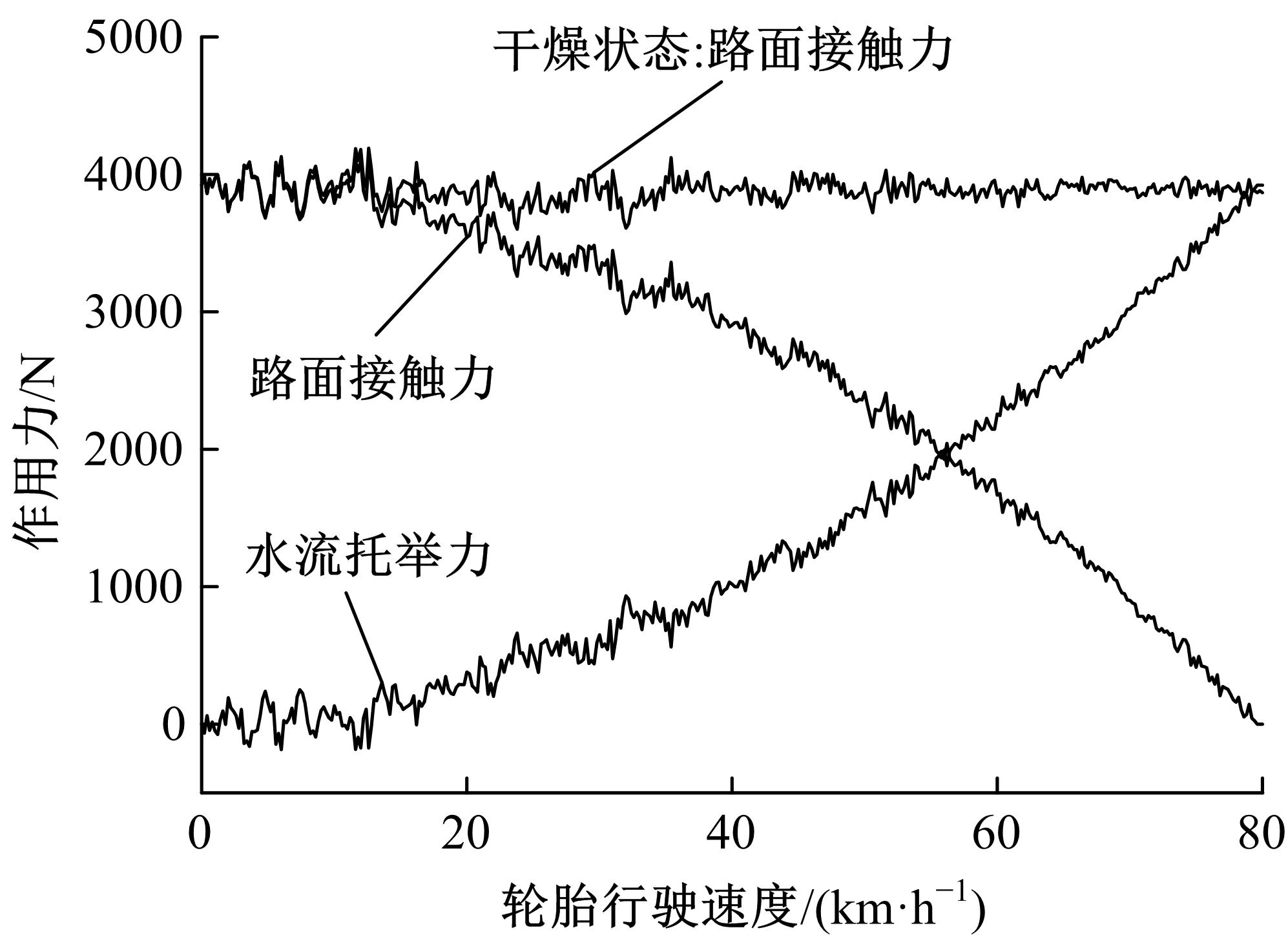

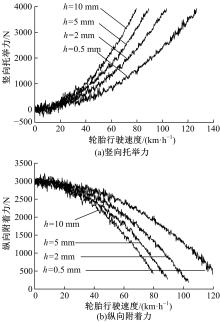

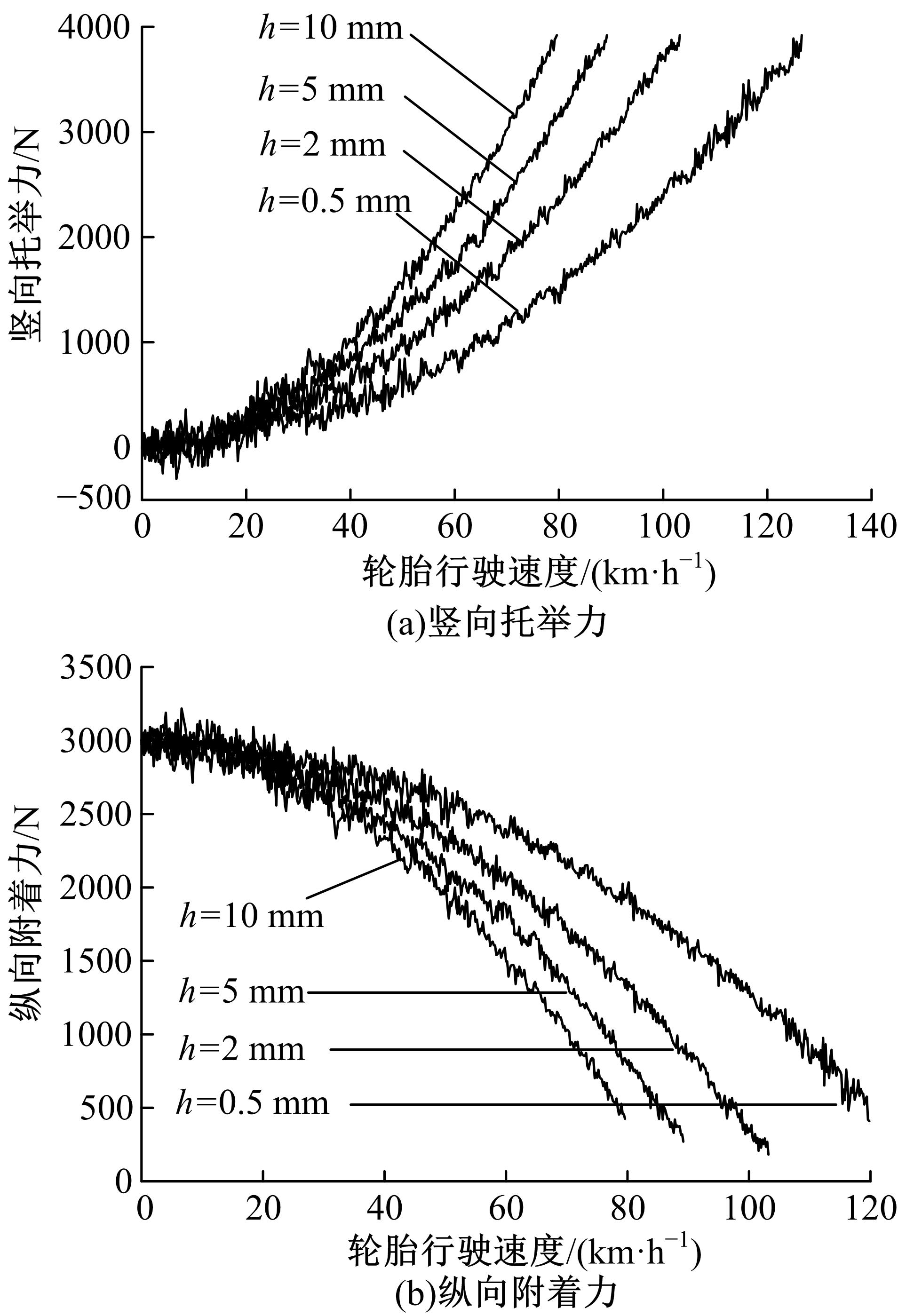

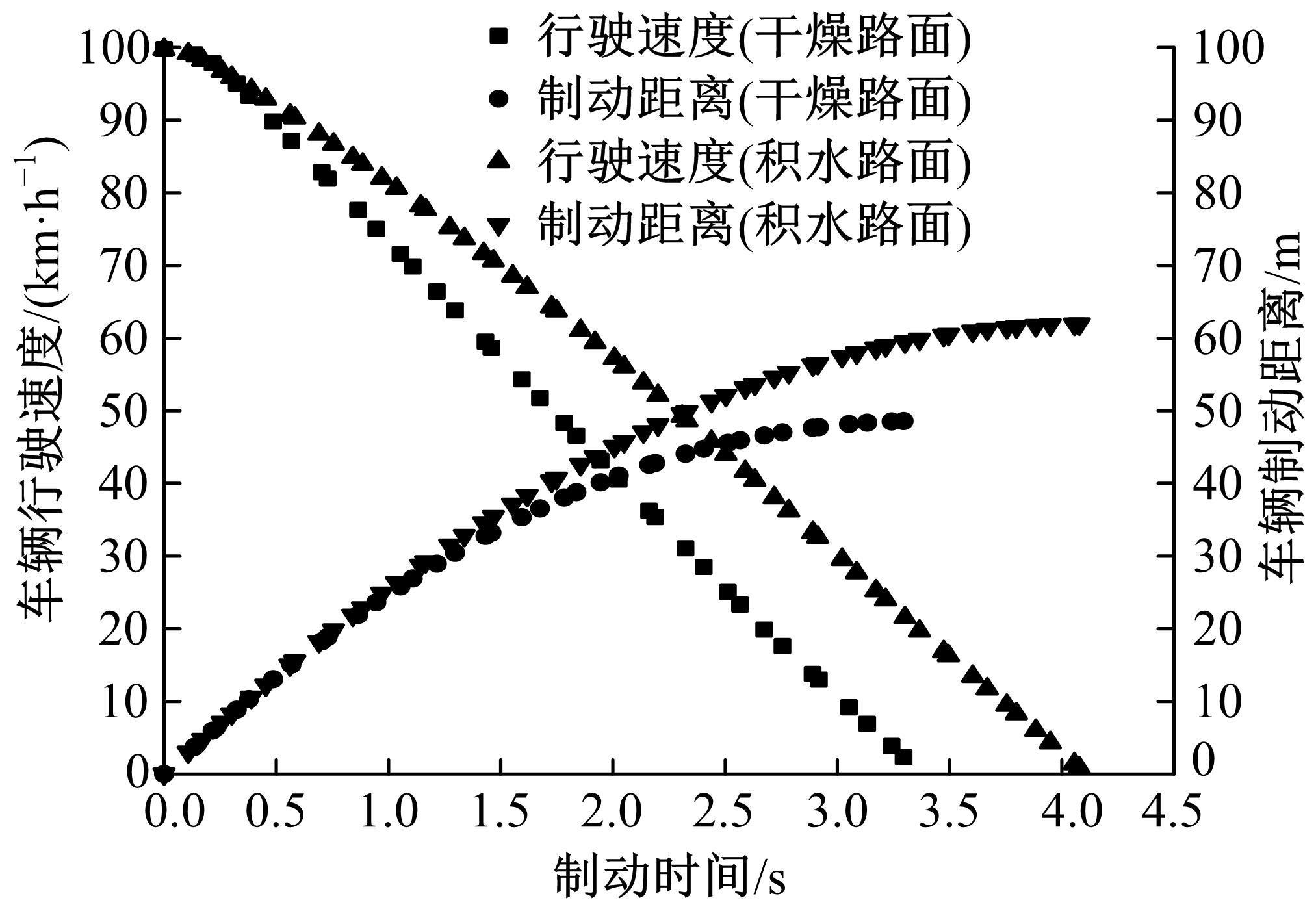

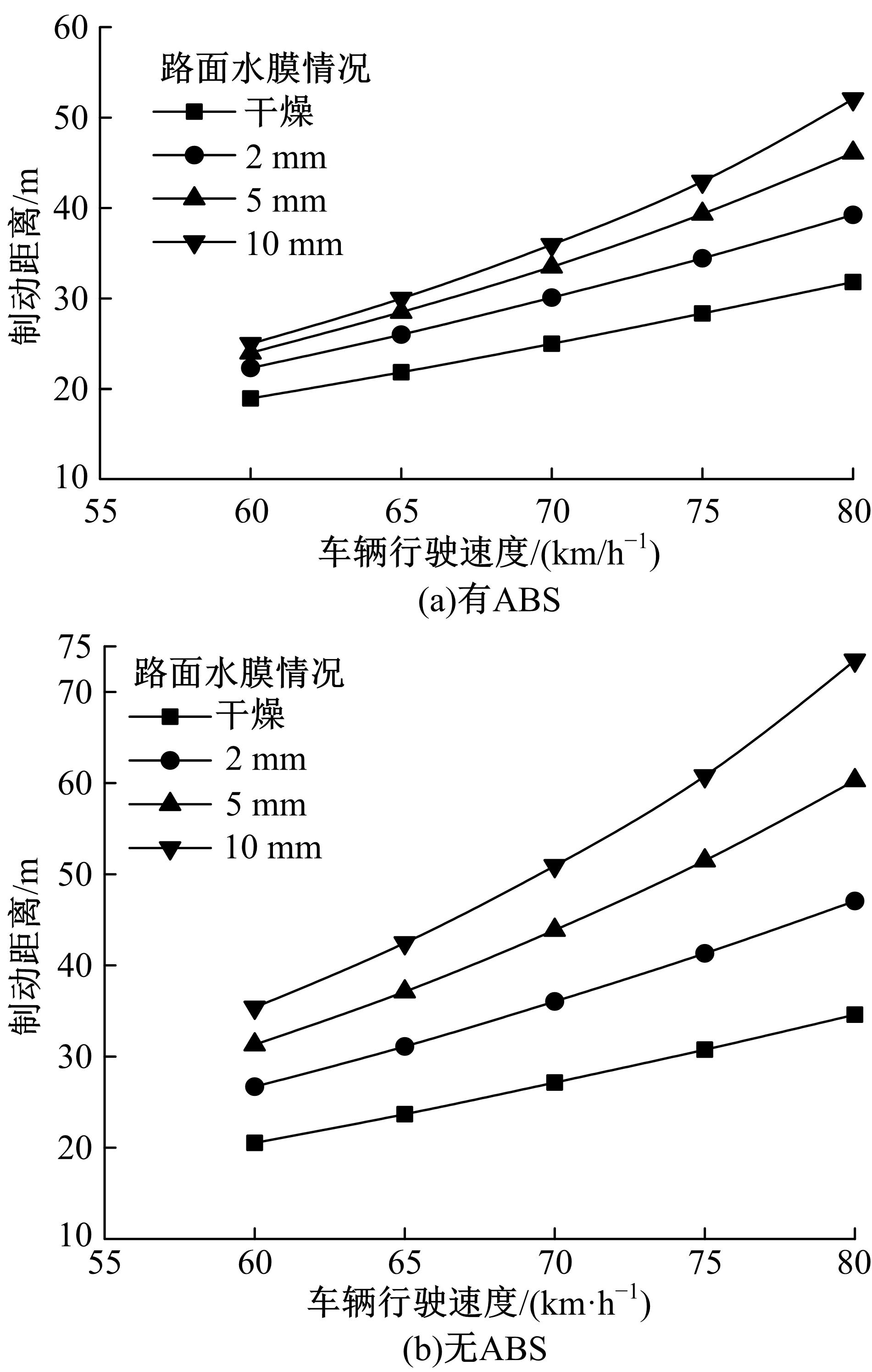

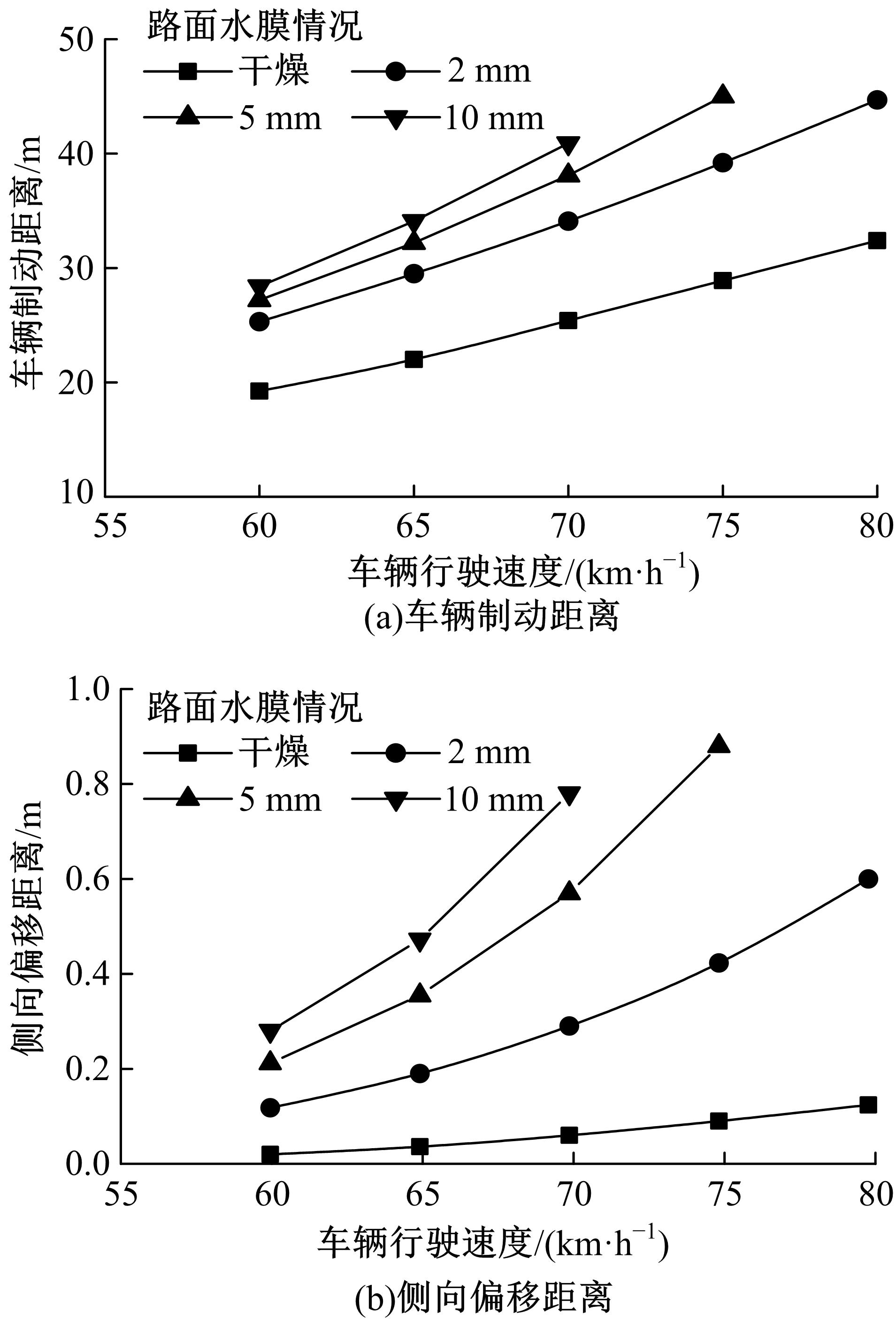

采用一种考虑橡胶?路面摩擦特性与水膜动水压力的雨天车辆制动模拟方法,研究了积水沥青路面上车辆的制动性能。首先运用路表分形摩擦理论,基于路面功率谱和橡胶的复模量计算出橡胶?路面的动摩擦因数。然后建立轮胎有限元滑水模型,分析了不同行驶速度及水膜厚度下轮胎?水膜?路面接触力变化规律。在此基础上,建立整车动力模型,基于车辆防抱死制动机理模拟评估了积水直线与弯道路面上整车制动性能。研究表明:与干燥状态相比,潮湿状态下橡胶?路面动摩擦因数下降了13%~34%;轮胎滑水过程中,随着轮胎行驶速度的增加,轮胎?路面接触力逐渐减小、水流竖向托举力逐渐增大,水膜厚度的增加也会产生相同的效果;较低的车辆行驶速度、较小的路表水膜厚度以及防抱死系统,都能有效降低车辆制动距离;相比于单个车轮的临界水漂速度,采用整车模型分析积水路面车辆行驶状况更切合实际状态。

中图分类号:

- U416.217

| 1 | HorneW B, JoynerU T. Pneumatic tire hydroplaning and some effects on vehicle performance[R]. Hampton, Virginia, USA: Langley Research Center, 1965: 1⁃28. |

| 2 | GroggerH, WeissM. Calculation of the three⁃dimensional free surface flow around an automobile tire[J]. Tire Science and Technology, 1996, 24(1): 39⁃49. |

| 3 | OngG P, FwaT F. A mechanistic interpretation of braking distance specifications and pavement friction requirements[J]. Transportation Research Record:Journal of the Transportation Research Board, 2010, 2155: 145⁃157. |

| 4 | FwaT F, PasinduH R, OngG P. Critical rut depth for pavement maintenance based on vehicle skidding and hydroplaning consideration[J]. Journal of Transportation Engineering, 2012, 138(4): 423⁃429. |

| 5 | JuF, FwaT F, OngG P. Evaluating wet weather driving benefits of grooved pavements[J]. International Journal of Pavement Research & Technology, 2013, 6(4): 287⁃293. |

| 6 | PasinduH R, FwaT F. Improving wet⁃weather runway performance using trapezoidal grooving design[J]. Transportation in Developing Economies, 2015, 1(1): 1⁃10. |

| 7 | ZhouHai⁃chao, WangGuo⁃lin, DingYang⁃min, et al. Effect of friction model and tire maneuvering on tire⁃pavement contact stress[J]. Advances in Materials Science and Engineering, 2015, 2015: 632647. |

| 8 | ZhuS, LiuX, CaoQ, et al. Numerical study of tire hydroplaning based on power spectrum of asphalt pavement and kinetic friction coefficient[J/OL].[2017-10-28].http:∥downloads.hindawi.com/journals/amse/2017/5843061. |

| pdf. | |

| 9 | 刘修宇, 曹青青, 朱晟泽, 等. 沥青混凝土路面轮胎临界滑水速度数值模拟[J]. 东南大学学报: 自然科学版, 2017, 47(5): 1020⁃1025. |

| LiuXiu⁃yu, CaoQing⁃qing, ZhuSheng⁃ze, et al. Numerical simulation of tire critical hydroplaning speed on asphalt pavement [J]. Journal of Southeast University (Natural Science Edition), 2017,47(5): 1020⁃1025. | |

| 10 | 黄晓明,刘修宇,曹青青,等. 积水路面轮胎部分滑水数值模拟[J]. 湖南大学学报: 自然科学版, 2018, 45(9): 113⁃121. |

| HuangXiao⁃ming, LiuXiu⁃yu, CaoQing⁃qing, et al. Numerical simulation of tire partial hydroplaning on flooded pavement[J]. Journal of Hunan University (Natural Science Edition), 2018, 45(9): 113⁃121. | |

| 11 | PerssonB N J. Theory of rubber friction and contact mechanics[J]. Journal of Chemical Physics, 2001, 115(8): 3840⁃3861. |

| 12 | 张敏, 郭鑫鑫, 张驰. 积水条件下考虑行车安全的车辙长度仿真分析[J]. 系统仿真学报, 2015, 27(4): 747⁃754. |

| ZhangMin, GuoXin⁃xin, ZhangChi. Simulation analysis of rutting length based on driving safety under condition of road waterlogging[J]. Journal of System Simulation, 2015, 27(4): 747⁃754. | |

| 13 | 徐进, 彭其渊, 邵毅明. 直线路段积水路面车辆事故产生机理分析[J]. 中国公路学报, 2009, 22(1): 97⁃103. |

| XuJin, PengQi⁃yuan, ShaoYi⁃ming. Mechanism analysis of vehicle accident on surface gathered water in straight sections[J]. China Journal of Highway and Transport, 2009, 22(1): 97⁃103. | |

| 14 | PerssonB N J, TartaglinoU, AlbohrO, et al. Rubber friction on wet and dry road surfaces: the sealing effect[J]. Physical Review B, 2005, 71(3): 035428. |

| 15 | PerssonB N. Rubber friction and tire dynamics[J]. Journal of Physics⁃Condensed Matter, 2011, 23(1): 015003. |

| 16 | LorenzB, PerssonB N, FortunatoG, et al. Rubber friction for tire tread compound on road surfaces[J]. Journal of Physics⁃Condensed Matter, 2013, 25(9): 095007. |

| 17 | LorenzB, OhY R, NamS K, et al. Rubber friction on road surfaces: experiment and theory for low sliding speeds[J]. The Journal of Chemical Physics. 2015, 142(19): 194701. |

| 18 | 赵战利. 基于分形方法的沥青路面抗滑技术研究[D]. 西安:长安大学公路学院, 2005. |

| ZhaoZhan⁃li. Research on pavement skid resistance technique based on fractal methods[D]. Xi′an: Highway College, Chang′an University, 2005. | |

| 19 | HouY, HuangY, SunF, et al. Fractal analysis on asphalt mixture using a two⁃dimensional imaging technique[J]. Advances in Materials Science and Engineering, 2016, 2016:8931295. |

| 20 | 冉茂平, 肖旺新, 周兴林, 等. 基于三维分形维数的沥青路面抗滑性能研究[J]. 公路交通科技, 2016(2): 28⁃32. |

| RanMao⁃ping, XiaoWang⁃xin, ZhouXing⁃lin, et al. Research of skid resistance of asphalt pavement based on 3D fractal dimension[J]. Journal of Highway and Transportation Research and Development, 2016(2): 28⁃32. | |

| 21 | 童申家, 谢祥兵, 赵大勇. 沥青路面纹理分布的分形描述及抗滑性能评价[J]. 中国公路学报, 2016, 29(2): 1⁃7. |

| TongShen⁃jia, XieXiang⁃bing, ZhaoDa⁃yong. Fractal description of texture distribution and evaluation of skid⁃resistance performance for asphalt pavement[J]. China Journal of Highway and Transport, 2016, 29(2): 1⁃7. | |

| 22 | PerssonB N J. On the fractal dimension of rough surfaces[J]. Tribology Letters, 2014, 54(1): 99⁃106. |

| 23 | JohannessonP, RychlikI. Laplace processes for describing road profiles[J]. Procedia Engineering, 2013, 66: 464⁃473. |

| 24 | JTJ—05995.公路路基路面现场测试规程[S]. |

| 25 | 郭孔辉. Unitire统一轮胎模型[J]. 机械工程学报, 2016, 52(12): 90⁃99. |

| GuoKong⁃hui. UniTire: unified tire model[J]. Journal of Mechanical Engineering, 2016, 52(12): 90⁃99. |

| [1] | 王静,吕翔,曲肖龙,钟春玲,张云龙. 路基土抗剪强度与化学及矿物成分的关系[J]. 吉林大学学报(工学版), 2019, 49(3): 766-772. |

| [2] | 李伊,刘黎萍,孙立军. 沥青面层不同深度车辙等效温度预估模型[J]. 吉林大学学报(工学版), 2018, 48(6): 1703-1711. |

| [3] | 臧国帅, 孙立军. 基于惰性弯沉点的刚性下卧层深度设置方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [4] | 念腾飞, 李萍, 林梅. 冻融循环下沥青特征官能团含量与流变参数灰熵分析及微观形貌[J]. 吉林大学学报(工学版), 2018, 48(4): 1045-1054. |

| [5] | 宫亚峰, 申杨凡, 谭国金, 韩春鹏, 何钰龙. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [6] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [7] | 季文玉, 李旺旺, 过民龙, 王珏. 预应力RPC-NC叠合梁挠度试验及计算方法[J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [8] | 张仰鹏, 魏海斌, 贾江坤, 陈昭. 季冻区组合冷阻层应用表现的数值评价[J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

| [9] | 马晔, 尼颖升, 徐栋, 刁波. 基于空间网格模型分析的体外预应力加固[J]. 吉林大学学报(工学版), 2018, 48(1): 137-147. |

| [10] | 罗蓉, 曾哲, 张德润, 冯光乐, 董华均. 基于插板法膜压力模型的沥青混合料水稳定性评价[J]. 吉林大学学报(工学版), 2017, 47(6): 1753-1759. |

| [11] | 尼颖升, 马晔, 徐栋, 李金凯. 波纹钢腹板斜拉桥剪力滞效应空间网格分析方法[J]. 吉林大学学报(工学版), 2017, 47(5): 1453-1464. |

| [12] | 郑传峰, 马壮, 郭学东, 张婷, 吕丹, 秦泳. 矿粉宏细观特征耦合对沥青胶浆低温性能的影响[J]. 吉林大学学报(工学版), 2017, 47(5): 1465-1471. |

| [13] | 于天来, 郑彬双, 李海生, 唐泽睿, 赵云鹏. 钢塑复合筋带挡土墙病害及成因[J]. 吉林大学学报(工学版), 2017, 47(4): 1082-1093. |

| [14] | 蔡氧, 付伟, 陶泽峰, 陈康为. 基于扩展有限元模型的土工布防荷载型反射裂缝影响分析[J]. 吉林大学学报(工学版), 2017, 47(3): 765-770. |

| [15] | 刘寒冰, 张互助, 王静. 失水干燥对路基压实黏质土抗剪强度特性的影响[J]. 吉林大学学报(工学版), 2017, 47(2): 446-451. |

|

||